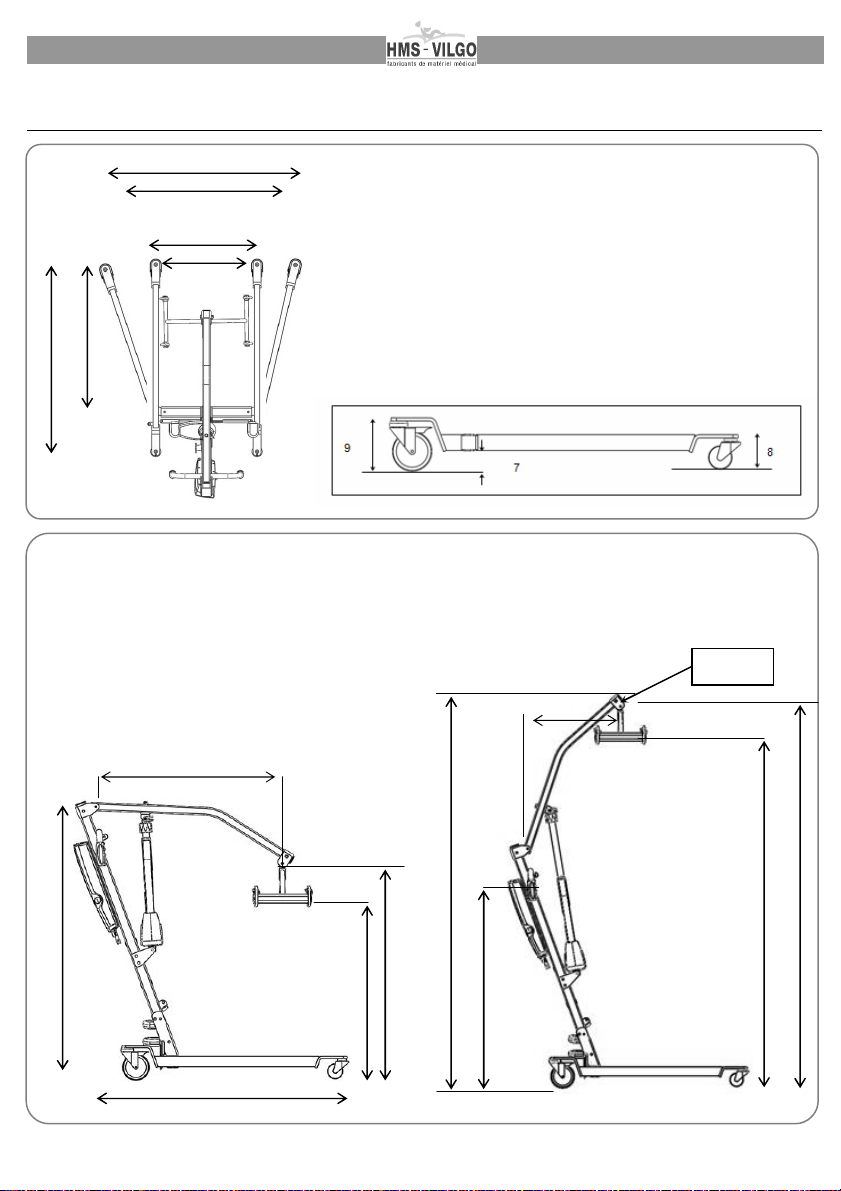

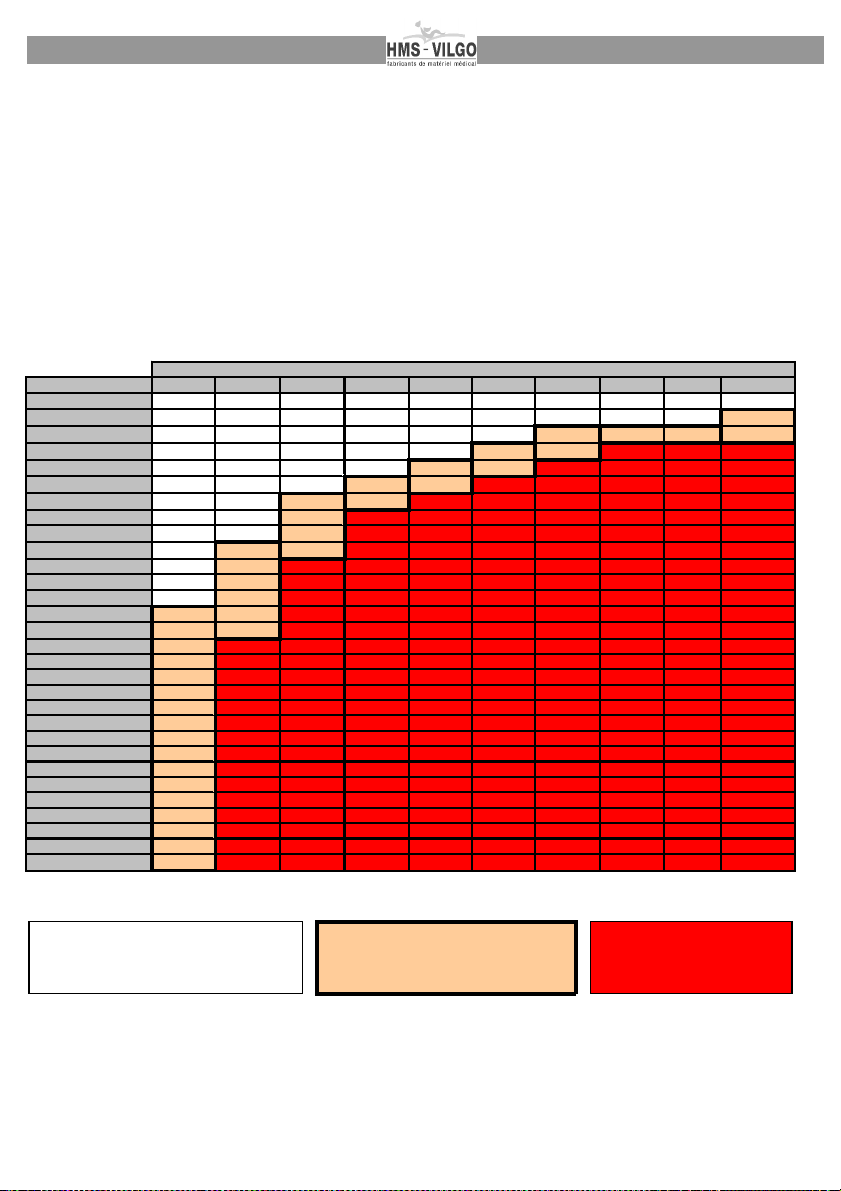

HMS-VILGO LIFTY 4 User manual

Table of contents

Other HMS-VILGO Lifting System manuals

Popular Lifting System manuals by other brands

Nussbaum

Nussbaum SPL 3200 Operating Instruction and Documentation

Vestil

Vestil EHLT Series instruction manual

Sinoboom

Sinoboom TB18E Plus Operation manual

Future Automation

Future Automation TSLM-MO-3 Technical sheet

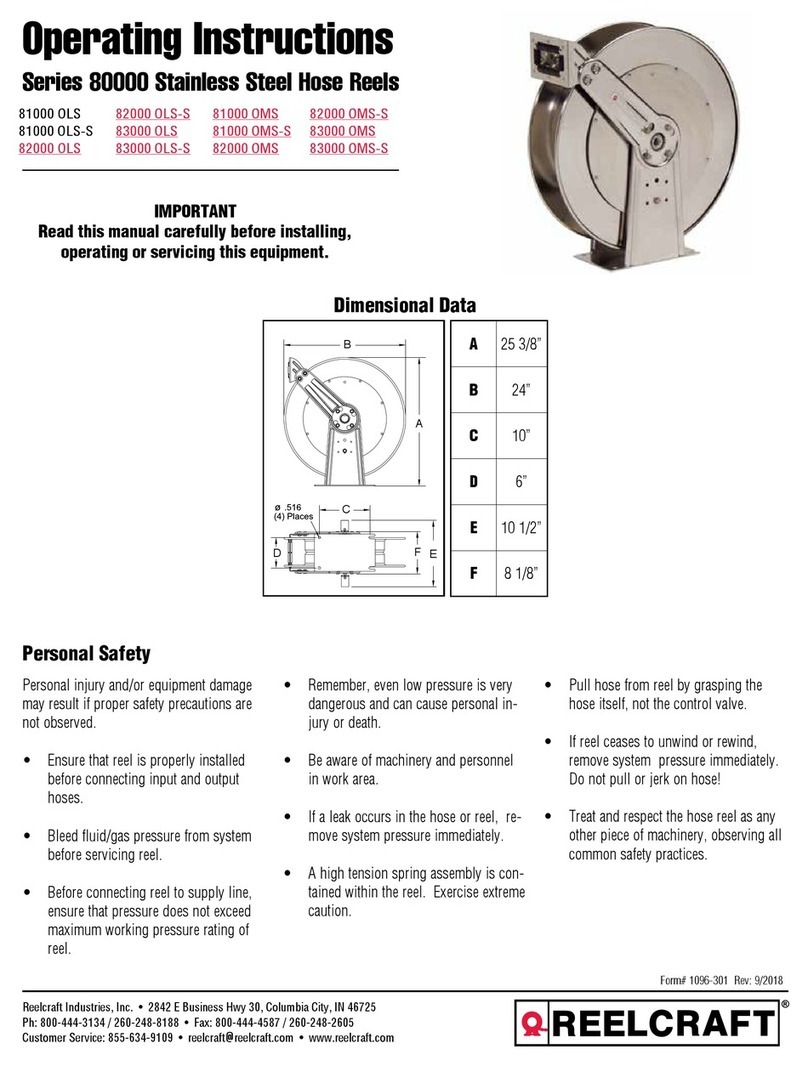

ReelCraft

ReelCraft 81000 OLS operating instructions

SKYLOTEC

SKYLOTEC Ergogrip SK12 BFD Instructions for use

Terex

Terex Genie SX-105 XC Operator's manual

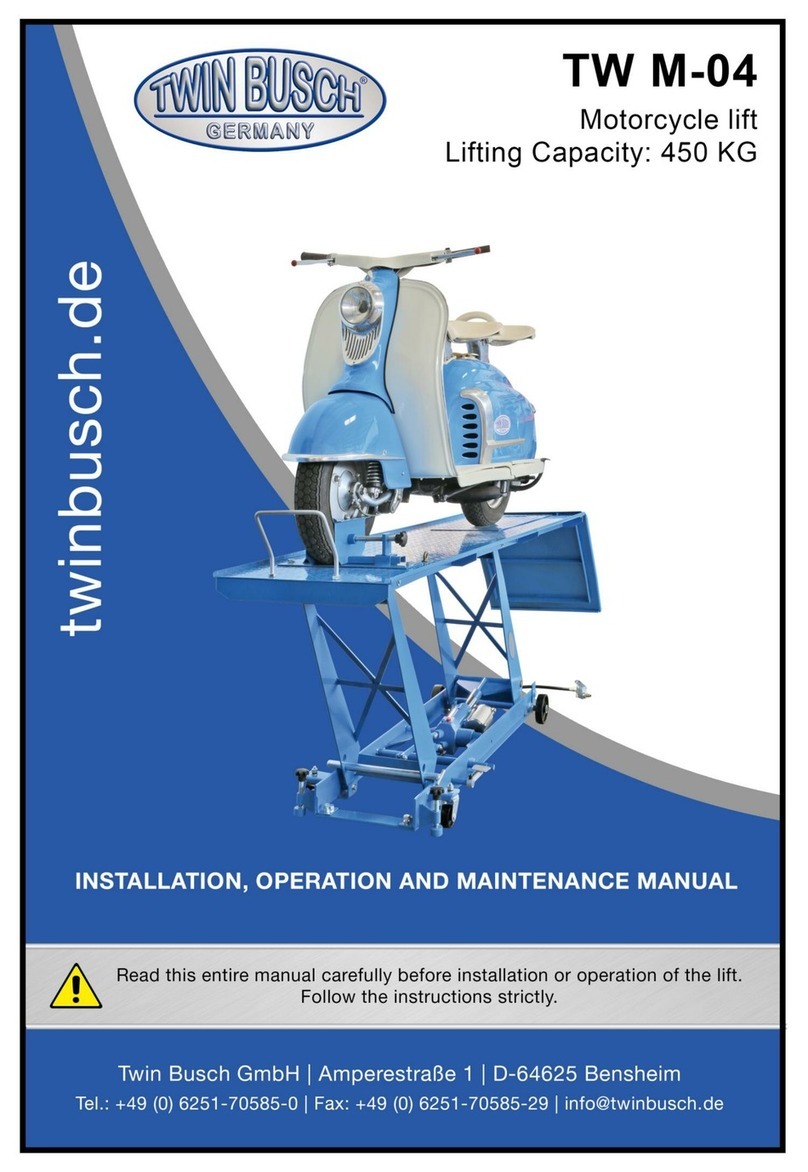

twin busch

twin busch TW M-04 Installation, operation and maintenance manual

OHAUS

OHAUS DEFENDER SERIES instruction manual

KSF

KSF CM-340H1 Instruction book

Pride Mobility

Pride Mobility SILVER BOOM 250 owner's manual

HOLZMANN MASCHINEN

HOLZMANN MASCHINEN SHT310 user manual

aidapt

aidapt VA144B Fitting and Maintenance Instructions

Nubbaum Hebetechnik

Nubbaum Hebetechnik 2.50 SE Operating Instruction and Documentation

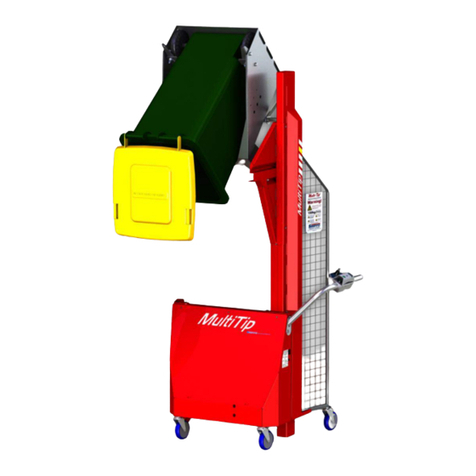

Simpro

Simpro Multi-Tip 1600 Service manual

Power Towers

Power Towers pecolift Operating and maintenance manual

HOLZMANN MASCHINEN

HOLZMANN MASCHINEN SHT310 user manual

Nussbaum

Nussbaum HL 2.30 NT Operating Manual and Inspection Book