KAHUNA

Users Manual

1

TABLE OF CONTENTS

WARRANTY.........................................................................................................2

GENERAL SAFETY INSTRUCTIONS .................................................................3

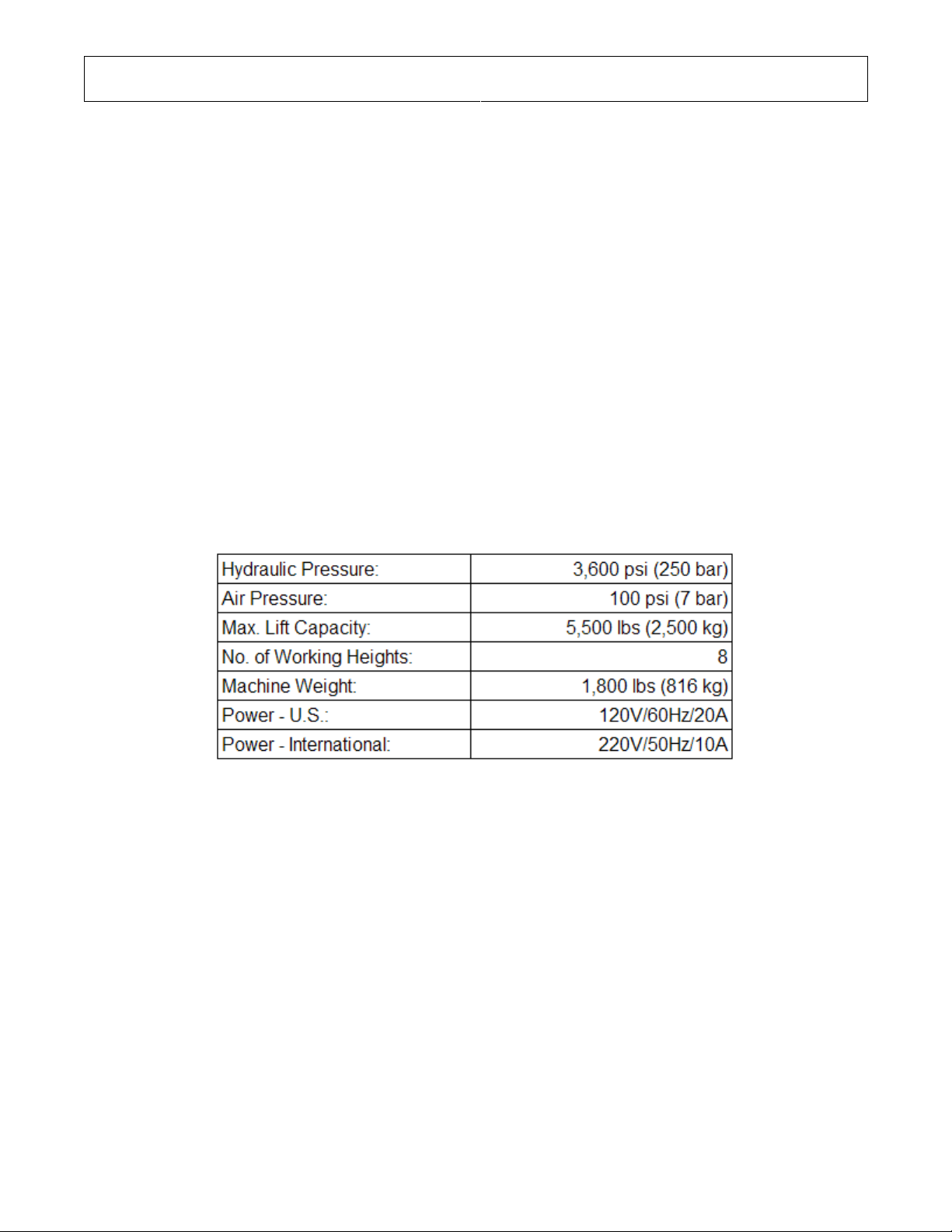

GENERAL SPECIFICATIONS .............................................................................4

INSTALLATION....................................................................................................5

General Information ........................................................................................5

Machine Anchoring .........................................................................................5

Installation Test ...............................................................................................6

OPERATING INSTRUCTIONS.............................................................................7

Safety Procedures...........................................................................................7

Daily Pre-Operation Check .............................................................................8

Controls ...........................................................................................................9

Operation .......................................................................................................10

Owner/Employer Responsibilities: ..............................................................12

Lift Lockout/Tagout Procedure ....................................................................13

Raising Vehicle..............................................................................................15

Lowering Vehicle...........................................................................................16

Anchoring Vehicle (Short Stands) ...............................................................17

Anchoring Vehicle (Optional Tall Stands & Wheel Stands).......................18

Vector Pulling ................................................................................................20

Attaching the Vector Pulling Arm to the Deck ........................................20

Basic Pulling Setup ...................................................................................20

Pulling Setup Examples ............................................................................22

Foot Pump Assembly ................................................................................23

MAINTENANCE .................................................................................................24

Periodic Maintenance Schedule...................................................................24

Daily Pre-Operation Check ...........................................................................24

Monthly Maintenance....................................................................................24

Chain Maintenance........................................................................................25

Refilling Hydraulic Fluid Reservoirs............................................................25

Priming the Foot Pump.................................................................................26

TROUBLESHOOTING .......................................................................................27