Strongarm TW4000 User manual

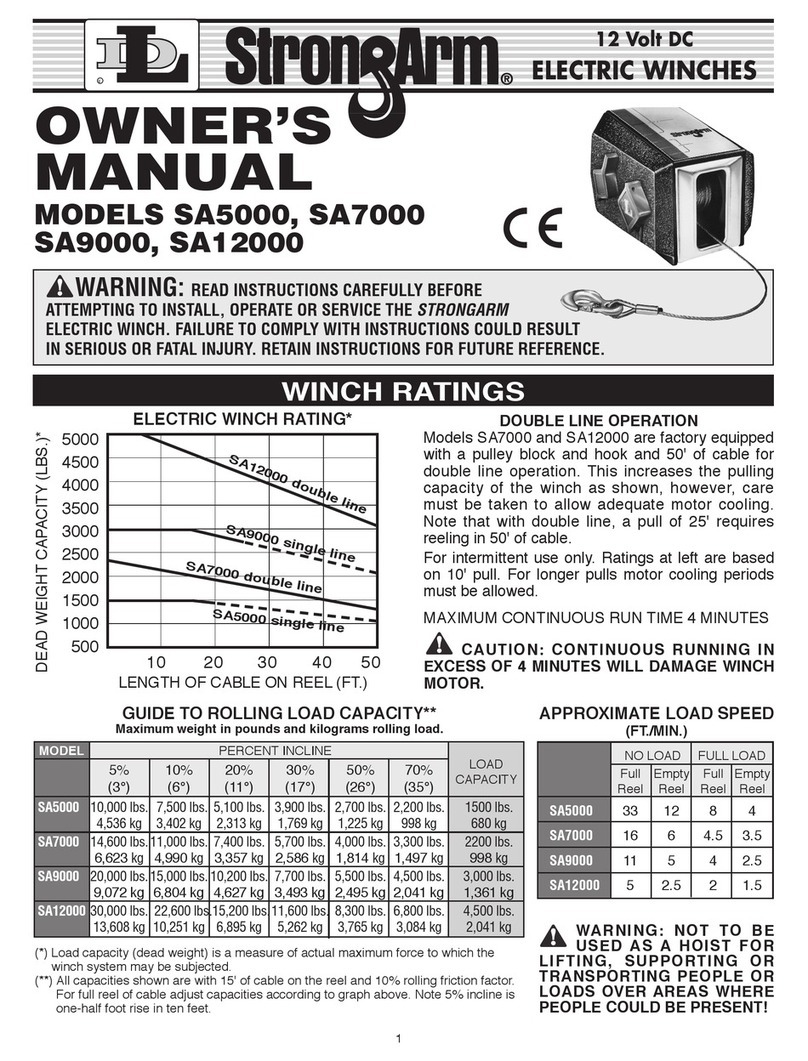

5% 10% 20% 30% 50% 70%

(3°) (6°) (11°) (17°) (26°) (35°)

TW4000 10,000 lbs. 7,500 lbs. 5,100 lbs. 3,900 lbs. 2,700 lbs. 2,200 lbs. 1500 lbs.

4,536 kg 3,402 kg 2,313 kg 1,769 kg 1,225 kg 998 kg 681 kg

TW9000 20,000 lbs.15,000 lbs.10,200 lbs. 7,700 lbs. 5,500 lbs. 4,500 lbs. 3,000 lbs.

9,072 kg 6,804 kg 4,627 kg 3,493 kg 2,495 kg 2,041 kg 1,362 kg

12 Volt DC

ELECTRIC

TRAILER

WINCHES

WARNING: READ INSTR CTIONS CAREF LLY

BEFORE ATTEMPTING TO INSTALL, OPERATE OR SERVICE

THE STRONGARM ELECTRIC WINCH. FAIL RE TO COMPLY

WITH INSTR CTIONS CO LD RES LT IN SERIO S OR FATAL

INJ RY. RETAIN INSTR CTIONS FOR F T RE REFERENCE.

!

StrongArm

TW electric trailer winches are manufac-

tured for loading and unloading of boats, personal

watercraft, vehicles, etc. The TW4000 winch fea-

tures power-in, free wheel out and 20' of 2" wide

strap. The TW9000 features power-in, power-out,

free wheel and 20' of 2" wide strap.

Note that as strap builds up on the reel, the pulling

capacity of the winch decreases (see graph at left).

or intermittent use only. Ratings at left are based

on 6' pull. or longer pulls adequate motor cooling

periods must be allowed.

TW4000-MAXIMUM CONTINUOUS RUN TIME

3 MINUTES

TW9000-MAXIMUM CONTINUOUS RUN TIME

4 MINUTES

CAUTION: CONTINUOUS RUNNING IN

EXCESS OF 3 INUTES (TW4000) AND 4 IN-

UTES (TW9000) WILL DA AGE WINCH OTOR.

GUIDE TO ROLLING LOAD CAPACITY**

aximum weight in pounds and kilograms rolling load.

APPROXI ATE LOAD SPEED

(FT./ IN.)

ODEL PERCENT INCLINE

LOAD

CAPACITY

(**) All capacities shown are with 2' of strap on the reel and 10% rolling friction factor.

or full reel of line adjust capacities according to graph above. Note 5% incline is

one-half foot rise in ten feet.

!

WINCH RATINGS

TW series electric winches are built for trailer loading and other horizontal pulling applications. They are not to

be used for lifting, supporting or transporting people or loads over areas where people could be present or for

any vertical lifting or lowering applications.

NO LOAD ULL LOAD

ull Empty ull Empty

Reel Reel Reel Reel

TW4000 22 11 8.2 4.4

TW9000 15 9 6.3 4.3

500

1000

1500

2000

2500

3000

3500

0

10 20 30 40

TW 9000

TW 4000

DEAD WEIGHT CAPACITY (LBS.)

LENGTH O STRAP ON REEL ( T.)

ELECTRIC WINCH RATING

E

N

G

L

I

S

H

R

TW4000 & TW9000 OWNER’S MANUAL

TW4000

This electric winch should be respected as power

equipment. High forces are created when using a

winch, creating potential safety hazards. Never

allow children or anyone who is not familiar with

the operation of the winch to use it.

Never exceed rated winch load. Dangerously high

forces can be created if the load being moved is

too large or is allowed to get in a bind, etc. Pay

attention to the sound of the winch and stop

pulling immediately if the winch begins to stall.

Note that installing longer than normal line results

in increased load on the winch.

Winch is equipped with high-quality strap capable

of handling the rated winch load. Never exceed

the rated capacity. Do not use vehicle pulling

power to increase the pulling capacity of your

winch.

Keep the winching area free of all unnecessary

personnel. Never stand between load and winch

or directly in line with load and winch.

This winch operates from a low voltage 12 volt

D.C. power source (e.g., a car or truck battery).

DO NOT connect winch to 120V A.C. power.

When winching operation has been completed,

do not depend on the winch to support the load.

Always secure the load properly. Use tie down

straps or chains.

The auxiliary handle is for emergency use only.

Never use the auxiliary handle as an assist to the

motor when the motor is running. Always remove

the auxiliary handle when it is not in use. Do not

operate the winch motor or allow the winch to free

wheel with the handle installed.

Keep hands and fingers clear of the drum and

line area of the winch when operating. Do not

attempt to guide the line by hand as it rewinds on

the drum.

The winch must be securely attached to a struc-

tural member or frame that is capable of sustain-

ing loads in excess of the winch capacity. When

attaching the winch to a vehicle, make sure the

mounting pad area is rigidly supported by the

vehicle frame. Always block the wheels to prevent

vehicle from rolling when pulling a load with the

winch.

When releasing a load with the clutch, maintain

control of the speed. Excess speed could result in

winch damage and serious personal injury.

Keep the pull of the strap onto the reel as straight

as possible to avoid strap damage.

Inspect strap and hook on each use and replace

at the first sign of wear or abnormal appearance.

I PORTANT SAFETY INFOR ATION

!

!

!

!

!

!

!

!

!

!

!

!

!

OUNTING INSTRUCTIONS

1. Be sure that the mounting surface is of sufficient

strength to support a load well in excess of the rated

winch capacity.

2. asten the winch to the trailer winch stand (or other

mounting surface) with three 1/2" bolts, nuts, washers

and lock washers. Be sure that the winch is positioned

so that the strap winds onto the reel as straight as

possible.

3. On boat trailer installations the winch stand should be

adjusted so that the loading ring on the bow of the

boat is at the same height or slightly higher than the

winch drum when the boat is fully loaded on the trailer.

Be sure that the trailer-bow stop is located far enough

back of the winch drum so that the strap hook is not

drawn into the drum when the boat is fully loaded on

the trailer.

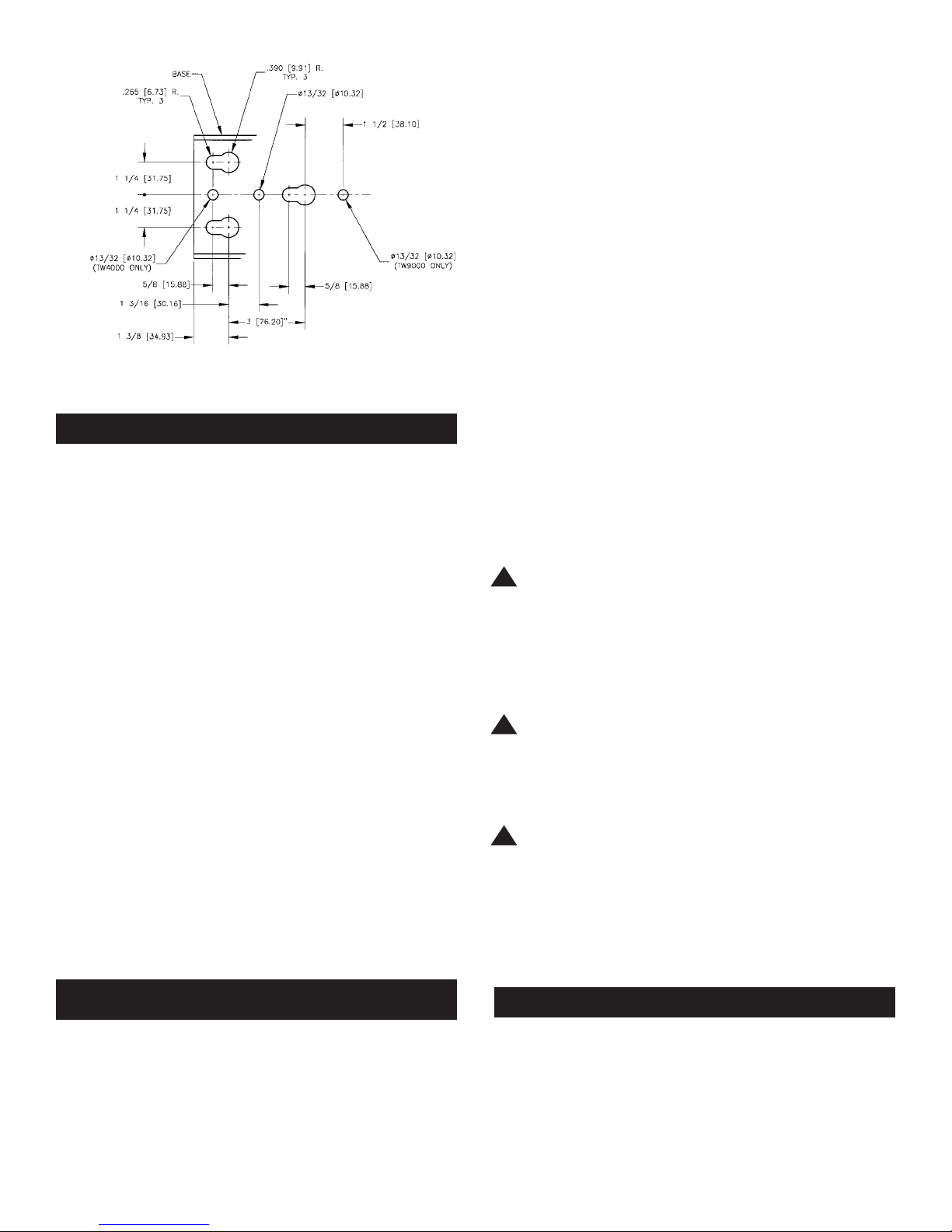

4. Your winch is equipped with keyhole slots in the base

for use with quick mounting shoulder studs, if desir-

able. (See IG. 1) If you wish to use quick mount

studs, (DL Accessory No. 6365) they should be

mounted securely into the winch stand. After position-

ing the winch on the studs, a 3/8" bolt should be

placed in one of the other holes available to keep the

winch securely in position.

WARNING: FAILURE TO READ AND FOLLOW INSTRUCTIONS BELOW COULD RESULT IN

SERIOUS OR FATAL INJURY.

!

WARNING: This winch is built for trailer loading and other horizontal pulling applications. NOT TO BE

USED FOR LIFTING, SUPPORTING OR TRANSPORTING PEOPLE OR LOADS OVER AREAS

WHERE PEOPLE COULD BE PRESENT OR FOR ANY VERTICAL LIFTING OR LOWERING

APPLICATIONS.

The wiring harness is designed to remain in the trunk of

the car when not in use. This prevents tampering, accident

or misuse since the harness is needed to operate the

winch electrically.

These installation instructions provide ready access for

use, yet allow the complete harness to be quickly removed

if desired.

1. eed positive lead (long) wire only through any con-

venient access hole inside the car trunk. It may be nec-

essary to remove a knockout plug or rubber grommet

from the trunk floor. It may also be necessary to

remove the circuit breaker assembly from the positive

wire in order to feed the wire under the car.

2. Pull the positive lead wire along the underside of the

car into the engine compartment and up to the battery.

asten the wire to the car undercarriage with existing

wiring clamps and brackets, making sure wire is not

located near the exhaust system, or any hot or moving

parts. Wire should be fastened securely and without

slack. Excess wire should remain in the trunk.

3. asten the circuit breaker to the positive (+) battery

terminal (if nut and bolt type) or to the battery side of

the starter solenoid.

4. Attach negative wire to vehicle frame using a 1/4" bolt

and locknut. Make sure you have a clean, tight con-

nection.

NOTE: If winch is to be mounted in front of vehicle, cut

harness to the length needed making sure, if spliced,

the splice is tight and well insulated. Attach ground as

described in 4 above.

ODEL TW4000

1. Attach the plug end of the power supply (wiring har-

ness) into the connector located at the back of the

winch. This pushes and snaps into place easily and

will only fit in one direction. With the clutch knob in the

“Engaged” position, activation of the toggle switch on

the side of the winch will power a load in. The switch is

spring loaded and will stop the winch and lock the

load in position when toggle is released. Leave your

car engine running on fast idle as a precaution in case

the battery is not in top condition.

2. Always disconnect the power when winching opera-

tion is complete. To disconnect power supply, simply

pinch the top and bottom locking device on the plug

end with fingers and pull out.

3. or remote switching, place looped spring on toggle

switch and attach lanyard.

ODEL TW9000

1. Attach the plug end of the power supply (wiring har-

ness) into the connector located at the back of the

winch. This pushes and snaps into place easily and

will only fit in one direction. With the clutch lever in the

“Engaged” position, you may power the winch in either

the load or unload direction. The switch is spring

loaded and will stop the winch and lock the load in

position when switch lever is released. Leave your car

engine running on fast idle as a precaution in case the

battery is not in top condition.

2. Always disconnect the power when the winching

operation is complete. To disconnect power supply

simply pull the plug end of power supply from the

winch.

NOTE: It is normal for smoke to be produced during

the initial power down use.

3. or remote switching, attach lanyard to hole in switch

lever.

TW4000 AND TW9000

WARNING: EVEN THOUGH THE WINCH IS

EQUIPPED WITH CIRCUIT BREAKER OVERLOAD

PROTECTION, PARTICULAR CARE SHOULD BE

TAKEN NOT TO CREATE AN OVERLOAD. PAY

ATTENTION TO THE SOUND OF THE WINCH AND

THE LOAD BEING PULLED. AKE CERTAIN THAT

THE STRAP TENSION DOES NOT RISE SUDDENLY

BECAUSE OF A BIND IN THE LOAD.

CAUTION: The electric motor is designed for inter-

mittent service only. Extended use without cooling

off periods will cause overheating resulting in

motor damage. aximum recommended continu-

ous run time is three minutes (TW4000) and four

minutes (TW9000).

CAUTION: These winches are built for trailering

boats, PWCʼs, vehicles, etc. Secure the load onto

the trailer with appropriate bow and transom tie

down straps or chains. With the load fully secured

on the trailer, it is advisable to relieve the tension

on the winch strap to avoid damage to the winch

and trailer due to high shock loads encountered

when traveling.

1. The knob (TW4000) or clutch lever (TW9000) pro-

vides a means for releasing a load without power

while maintaining control of the speed and provides

for freewheeling so that strap can be removed from

the winch by hand. The clutch lever on the TW9000 is

spring loaded so that it returns to the engaged posi-

tion when released. The lever will, however, remain in

the freewheeling position if rotated completely forward

to freewheel.

LOADING AND UNLOADING

UNDER POWER

WIRING HARNESS INSTALLATION

IG. 1

!

!

!

CLUTCH OPERATION

2. In order to release a load without power, rotate the

knob or clutch lever slowly and carefully forward

toward “ reewheel.” When the load begins to move, it

can be controlled by the knob or clutch lever. Careful,

slow movement of the knob or lever will provide

smooth control of the load.

WARNING: ALWAYS AINTAIN CONTROL OF THE

LOAD. ALLOWING EXCESS SPEED COULD

RESULT IN WINCH DA AGE AND SEVERE PER-

SONAL INJURY.

3. Remember that the gear train and brake mechanism

are completely disengaged in the “ ree Wheel” posi-

tion and in order to power the winch or hold a load in

position, the knob or lever must be returned to the

“Engaged” position.

NOTE: On the TW9000 it is not necessary to turn the

clutch lever completely to the “Engaged” position man-

ually. The spring tension built into the winch provides

adequate force on the clutch lever.

CAUTION: Never force knob or clutch lever in

either direction.

An emergency crank handle is provided for the model

TW9000 for use in the event of a power failure. The model

TW4000 requires the use of a ratchet wrench and 5/8"

deep well socket or a standard 5/8" socket with an exten-

sion.

1. Disconnect the electrical power from the winch and

remove the plastic plug from the side of the winch

housing.

WARNING: NEVER OPERATE THE WINCH ELEC-

TRICALLY WITH THE E ERGENCY HANDLE OR

RATCHET WRENCH IN POSITION.

TW4000

2. Insert the 5/8" socket and

ratchet handle so that it com-

pletely engages with the

drive shaft. Turn the drive

shaft in the counterclock-

wise direction only. (See

ig. 2)

WARNING: KEEP THE

CLUTCH KNOB IN THE

“ENGAGED” POSITION

WHILE CRANKING WINCH.

DO NOT PUT CLUTCH IN

“FREE WHEEL.”

TW9000

2. Insert the emergency handle so it completely engages

with the drive shaft. Pull in strap by turning the handle

in the clockwise direction (See ig. 2A). To make

cranking easier, the clutch handle can be placed in the

“free wheel” position while holding onto the emer-

gency crank handle.

WARNING: IF THE CLUTCH IS PLACED IN FREE

WHEEL FOR HAND CRANKING, BE SURE TO

AINTAIN A FIR GRIP ON THE HANDLE AT ALL

TI ES.

Because the TW9000 emergency crank handle

attaches to the clutch side of

the winch, it is equipped with

a spring-operated clip which

will be depressed by the

clutch handle in the free

wheel position when crank-

ing in a clockwise direction to

retrieve strap. This clip is a

safety feature and will re-

enage the clutch mechanism

in the event the operator

loses control of the handle

with a load on the winch.

WARNING: EVEN WITH

THIS SAFETY FEATURE, THE HANDLE WILL SPIN

VIOLENTLY ONE OR TWO TURNS BEFORE RE-

ENGAGING THE CLUTCH TO STOP THE WINCH.

DO NOT LOSE CONTROL.

3. Always remove the handle from the winch after use

and replace the plastic plug.

or long life and trouble-free operation your winch

should periodically be inspected for any required mainte-

nance. This should be done at least once annually and

more frequently in adverse conditions such as salt water

areas or areas of extreme dust and dirt.

WARNING: BEFORE PERFOR ING ANY AINTE-

NANCE BE SURE THERE IS NO LOAD ON THE

WINCH AND THAT THE POWER HAS BEEN

DISCONNECTED.

1. Carefully inspect the winch strap and replace at the

first sign of damage. In order to replace the winch

strap, it is necessary to remove the winch cover. On

the TW4000, remove the slotted nut in the end of the

knob with a screwdriver and unscrew the knob from

clutch stud. Remove the nut holding the toggle switch

into the cover and push the switch inside the winch.

Remove the six cover screws and lift the cover from

the winch while gently stretching it open to clear the

clutch stud. On the TW9000, remove the clutch handle

by removing the two clutch handle screws and then

remove the six cover screws. Lift the cover from the

winch while gently stretching it open to clear the clutch

stud.

Rotate the winch reel to gain access to the strap bolt.

Remove the old strap and replace it with a new strap

of the same size. If the strap bolt is bent, replace it

with a bolt of the same size and length. Note that nut

on the strap bolt must be on gear side of winch reel

and locknut must be used. Do not substitute free run-

ning nut. Slide bolt to bottom of slot and tighten nut

until snug. Do not over tighten, strap will hold bolt in

bottom of slot.

NOTE: STRAP IS WOUND OVER THE TOP O THE

DRUM ON MODEL TW4000 AND UNDER THE

DRUM ON MODEL TW9000.

2. With the cover removed as described above, inspect

the entire gear train and all drive shafts for any signifi-

cant wear or loose bearing fits. Also, check all nuts,

bolts, retaining rings, etc., to be sure that they are tight

and secure. Grease all of the gears on the inside of

the winch base and apply a drop of oil on all of the

bearings in the base. Also, very sparingly oil all of the

WINCH AINTENANCE

AUXILIARY HANDLE

!

!

!

!

!

!

!

Socket & Ratchet

Handle Illustration

(TW4000)

IG. 2

Emergency Handle

Illustration (TW9000)

IG. 2A

SY PTO POSSIBLE CAUSE(S) CORRECTIVE ACTION

Safety hook spreads 1. Point loading of hook. 1. Replace hook.

2. Load exceeds rated capacity of unit. 2. Lighten load, reduce % of incline or reduce load friction.

Strap breaks 1. Improperly maintained strap. 1. See “Maintenance.”

2. Overloading. 2. Reduce load.

Strap folds over (binds up) Pulling load at too severe of Make straighter pulls.

an angle.

Load creeps when power is O 1. Clutch out of adjustment. 1. TW4000 - tighten knob. TW9000 - adjust (see

Maintenance)

2. Roller clutch, not engaging. 2. Replace.

3. Overloading. 3. Reduce load.

Winch does not hold load Strap wound on drum incorrectly. Strap must be wound over top of drum on TW4000 & under

the drum on model TW9000.

Winch motor runs hot In operation too long. Let motor cool for at least 20 minutes. (See Winch Rating

Section.)

Winch motor fails to run Electrical. Check the following: power supply, wiring, control

switch, male/female connections, motor and circuit

breakers.

Winch motor runs but fails 1. Clutch is slipping. 1. Check clutch lining for grease or oil. See “Maintenance”

to wind strap for clutch adjustment procedure.

2. Gear train is damaged. 2. Check entire gear train and replace any damaged parts.

Strap will not pull out (freewheel) Sticking clutch. a. “Jog” power switch with clutch in freewheel (No load only).

b. Remove cover (see Maintenance) and separate clutch

gear from mating gear.

Smokes (TW9000 only) Normal on initial power down use. None.

TROUBLESHOOTING CHART

bearings in the clutch mechanism and place a drop of

oil on the roller clutch. Do not over lubricate these

areas and do not use grease in the roller clutch. The

clutch mechanism and the brake pads and brake disc

on the TW9000 must be kept clean and oil free.

ADDITIONAL AINTENANCE TW9000

3. Check the operation of the roller clutch in the brake

disc assembly (A ). Carefully rotate the brake disc

and observe the motor shaft. When the disc is turned

clockwise the motor shaft should turn with it. When the

disc is turned counterclockwise the motor shaft should

not turn.

4. If the clutch has been slipping and requires adjust-

ment the following procedures should be used. The

clutch is adjustable in ten degree increments. With a

screwdriver and pliers, remove the end of the clutch

spring from the hole in the winch base. The spring

tension is quite high so be careful to maintain a firm

grip on the spring. The O-ring should be rotated so

that the cut out portions align with the lugs on the

spring keeper. (See IG. 3)

The ring can then be expanded with a pencil or similar

object and the spring keeper can be lifted free from

the clutch nut. Rotate the keeper clockwise 10

degrees and install on the next serration in the clutch

nut. Reinstall O-ring and rotate slightly so that the cut

outs are not in line with the lugs on the spring keeper

and reinstall the clutch spring into the hole in the

base. Adjustment of the clutch more than 10 degrees

to 20 degrees should normally not be necessary. With

only spring pressure (do not forcibly tighten the clutch

mechanism) the spring lug on the spring keeper

should come to rest at approximately the 2:30 o’clock

position. (See IG. 4)

IG. 3 IG. 4

O-Ring Illustration (TW9000) Clutch Spring Illustration (TW9000)

Spring Lug

Horizontal

Adjust to this posi-

tion (2:30 oʼclock)

Clutch Spring

Keeper

Clutch Spring

TW4000 PARTS LIST

Ref. Part Number

A Retaining Ring 204468

B Bushing 204006

C Drive Shaft Ass’y 304967

D 56T Gear 204703

E Retaining Ring 205191

F Base Shroud - Left 404834

G Base Shroud - Right 404833

H Screw (6) 205337

Base 404940

K Hex Nut 406002

L Locknut 10-32 (3) 205193

M Stop 404829

N Washer 205109

P Washer 203813

Q ‘E’-Ring 205135

R Motor Pinion 206228

S Roller Clutch Ass’y 304698

T Reel Shaft 404559

U Base Spacer 404557

V Spacer (4) 404822

X Reel Ass’y 304858

Z Motor 304695

Ref. Part Number

AA Cover Plug 204713

BB Cover Ass’y 304684

CC Mounting Screw (6) 205086

EE Screw (4) 205338

FF Strap 2" x 20' 5242607

GG Locknut 7/16-20 205192

HH Washer (2) 204360

Thrust Bearing Replacement Kit 5703194

KK 120 Tooth Gear Ass’y 304409

LL Clutch Stud 404826

MM Clutch Gear Ass’y 304305

NN Finger Spring Washer 205200

PP Bushing 204012

QQ Front Plate 404825

RR Knob 206243

SS Slotted Nut 404614

TT Wiring Harness 5240411

UU Connector 206240

VV Toggle Switch 206249

WW Toggle Switch Guard 404831

WIRING DIAGRAM

To order replacement parts contact:

Dutton-Lainson Company

www:dlco.com

Tel: 800-569-6577

ax: 402-460-4612

e-mail: [email protected]

In Europe Contact:

Aqua- arine International Ltd.

8 landers Park

Hedge End, Southampton

Hants, England SO30 2 Z

Tel: +44 (0) 1489-776050

ax: +44 (0) 1489-776055

e-mail: [email protected]

TW9000 PARTS LIST

Ref. Part Number

A Bearing Housing Assy. 304314

B Primary Drive Shaft Assy. 304304

C Retaining Ring (2) 205191

D Bushing (2) 204012

E 56T Gear 204703

F Aux. Handle Assy. 5703079

G Drive Shaft Bushing 304313

Housing Assy.

Interm. Drive Shaft Assy. 304814

K “E” Ring 205116

L Base 404932

M Nut, 7/16-20 Locknut 205192

N Clutch Stud 404517

P Clutch Handle Replacement Kit 5703178

(Includes Items V, W, AX & AY)

Q Thrust Bearing Replacement Kit 5703194

(Includes Item W, O-Ring)

R Clutch Gear Assy. 304305

S Washer (2) 204360

T 84T Gear Assy. 304311

U Clutch Handle Nut 404518

V Clutch Spring Keeper 204721

W “O”-Ring 204770

X Brake Spring Replacement Kit 5703160

Ref. Part Number

Y Screw, 1/4-20x7/8" (3) 205242

Z Clutch Spring 204711

AA Spacer (3) 404513

AB Front Plate 404495

AE Nut, 10-32 Locknut (2) 205193

AF Brake Disc Assy. 304422

AG Screw, 1/4-20x3/8" (4) 205337

AH 12T Pinion Gear 404522

A “E” Ring 205135

AK Base Spacer 404510

AL Reel Shaft 404514

AM Retaining Ring 204468

AN Screw, 1/4x20x1/2" (2) 205189

AP Washer (2) 205109

AR Reel Assy. 304815

AV Cover Assy. 304748

AW Cover Plug 204713

AX Clutch Handle 204712

AY Screw – #4x1/2 205196

AZ Strap (2" x 20') 5242516

BA Base Shroud – LF 404866

BB Base Shroud – RT 404865

BC Screw (6) 205086

BD Finger Spring Washer 205200

MOTOR PARTS

CA Motor Assy 304742

CB Connector Ass’y 5241518

CC Screw – 1/4x20x3/8 205018

CD Switch 404888

CE Connector 206055

CF Nut – 1/4-20 206225

CG Circuit Breaker Assy 304025

CH Screw, 6-32x7/8" (2) 204959

WIRING DIAGRAM

NEG.

NEG.

POS.

POS.

To order replacement parts contact:

Dutton-Lainson Company

www:dlco.com

Tel: 800-569-6577

ax: 402-460-4612

e-mail: [email protected]

In Europe Contact:

Aqua- arine International Ltd.

8 landers Park

Hedge End, Southampton

Hants, England SO30 2 Z

Tel: +44 (0) 1489-776050

ax: +44 (0) 1489-776055

e-mail: [email protected]

FLORIDA

Hagood Brothers Marine

1121 West Church St.

Orlando, L 32805

Tel: 407-843-4220

INDIANA

RG Shamory Enterprises

55625 Currant Road

Mishawaka, IN 46545

Tel: 219-255-5050

NEBRASKA

Dutton-Lainson Company

1601 West 2nd

Hastings, NE 68902

Tel: 402-462-4141

OKLAHO A

Tow Dolly Enterprises

1520 S. Memorial Drive

Tulsa, OK 74112

Tel: 918-627-4777

R

ELECTRIC WINCH SERVICE CENTERS

These authorized centers will be able to supply parts and technical service on all StrongArm®Electric Winches

or warranty claims follow instruction given in “Limited One Year Warranty.”

EC DECLARATION OF CONFOR ITY

Dutton-Lainson Company, Hastings, NE 68902-0729 U.S.A. manufactures and declares that this winch is in conformity with the

essential health and safety requirements specified in The Supply of Machinery (Safety) Regulations 1992 and the provisions of the

Machinery Directive (89/392/EEC). This declaration does not apply to other machinery using this winch.

WINCH DATE CODE:

(LOCATED INSIDE FRA E AT REAR)

WINCH ODEL NU BER:

DATE PURCHASED:

NOTES

This manual suits for next models

1

Table of contents

Other Strongarm Batteries Charger manuals