Strongarm BRK4T User manual

4 & 10 Ton

Body Repair Kit

Owner’s Manual

WARNING:

Read all instructions and safety warnings before

operating this equipment. Failure to follow the

instructions and safety warnings may result in

personal injury or property damage.

!

PROD NO. 030202 / 030207

MOD NO. BRK4T / BRK10T

www.strongarminc.com

MSA-030202-7

2

The use of shop equipment is subject to certain hazards that cannot be prevented by mechanical means,

but only by exercise of intelligence, care, and common sense. It is therefore essential to have personnel

involved in the use and operation of equipment who are careful, competent, trained, and qualified in the

safe operation of this equipment and its proper use. Examples of hazards are dropping, tipping, or slipping

of parts/components caused primarily by improperly securing loads, overloading, off-centered loads, use

on other than hard level surfaces, and using equipment for a purpose for which it was not designed.

The owner and / or operator shall study and understand the product and safety instructions before operat-

ing this equipment. Safety information shall be emphasized and understood. If the operator is not fluent in

English, the product and safety instructions shall be read to and discussed with the operator in the oper-

ator’s native language by the purchaser / owner or his designee, making sure that the operator compre-

hends their contents. A copy of these instructions / warnings shall be retained for future reference.

• ItistheresponsibilityoftheownerofthiskittoensureitisbeingusedinaccordancewithallOSHA,

provincial, and local safety regulations. Always wear protective eye wear when working with this

piece of equipment.

• Do Notusebeyondratedcapacity.IMPORTANT:Theratedcapacityofthisrepairkitisaffectedand

can be reduced depending on the attachments used. Wedge rams are rated at 1/2 ton capacity. When

using extension tubes, each tube used reduces the capacity by 50%. For example if one extension tube

isusedthecapacityis50%.WhenusingtheRamToeandPlungerToecapacityisreducedto50%of

ramcapacity.MaximumRubberHeadcapacityis0.5Tonforthe0302024Tonunitand1.0Tonforthe

030207 - 10 Ton unit. (see chart below) Use only adapters / extensions provided with the unit.

• Alwayspositiontheshortestextensiontubefarthestawayfromtheraminamultipletubesetup.

• Do Not use this equipment as a vehicle lifting device or as a vehicle support

• Do Not subject the hose to extreme cold, heat sharp surfaces, abrasion, or impact.

• Ensurethehoseisfreeofobstructions,andisinastraightlineorarc,donotoperatethepumpwiththe

hose bent sharply.

• Do not operate the pump when the ram reaches full extension, operating the pump with the ram

at full extension could cause damage to the ram and/or personal injury.

• Never operate the pump with release valve closed and hose disconnected from ram, this will pressurize

the hose and connections, possibly causing a burst condition and damage to the pump, hose and / or

personal injury.

• Checkthehoseandconnectionsoftenforleaksordamage.Preventthehosefrombeingpinched,cut

or having heavy objects fall onto the hose. If a leak occurs, the ram will retract, if the hose is cut, the

setup will immediately lose pressure.

• Noalterationsormodificationsshallbemadetothisproduct.

• Do Not carry the pump / ram assembly by the hose.

• STOP and Checktoensurethesetupisstablepriortostartinganywork,aswellasCHECKOFTEN

thatthesetupremainsstableduringanyworkbeingperformed.Operatethepumpslowly,whileatthe

same time watching the ram and points of contact to ensure the operation is safe and secure.

• Failuretoheedthesewarningsmayresultinpersonalinjury,propertydamageorboth.

!WARNING!

3

!SETUP

!INSPECTION

The hydraulic hose is shipped attached to the pump, with a threaded male connector at the

opposite end to the pump. Attach the male connector to the female connector on the ram and

screw the threaded collar all the way onto the male threads and hand tighten. Ensure ram is fully

retracted before detaching hose from ram.

AIR PURGE

From time to time, air may enter the hydraulic system and will need to be purged. Evidence of air

in the system is a “spongy” feel when pumping or an incomplete stroke on the pump.

Turn the release valve counterclockwise by 1-1/2 turns. With ram fully retracted and release valve

open, pump the handle 10-20 times

It is recommended to use a pressure gauge to monitor the pressure when using components that

reduce the capacity of the unit.

Visual inspection shall be made before each use of this equipment, checking for abnormal conditions,

such as cracked welds, leaks, damaged, loose or missing parts. This equipment shall be removed

immediately from service if it is believed to have been subjected to an abnormal or shock load, the

equipmentshallbeinspectedbyaqualifiedrepairfacility.Ownersand/oroperatorsshouldbeaware

that repair of this equipment may require specialized knowledge and facilities. It is recommended

that this equipment be inspected annually by a qualified repair facility. Defective parts, decals, safety

labels or signs should be replaced with Strongarm specified parts.

Pressure Gauge

030285 – Pressure Gauge c/w adapter Block

NOTE:Whenaddingthreadedcomponentsto

this hydraulic system be sure to use a good

quality hydraulic thread sealant.

TheCapacitychartontheleftindicates

reduction in overall capacity based on various

extension and adapter configurations.

4

!OPERATING INSTRUCTIONS

A. This kit is designed for the following applications, spreading, bending, stretching, pulling,

clamping, pushing, lifting, pressing and straightening.

B. Inspect all components prior to using, if any damage, leaking or excessive wear is found, repair

orreplacepriortousing.Hosesshouldbefreefromcutsorcrimps,allconnectionstopump

andramshouldbetight.Keepprotectiveringonramwhennotusingthreadsontheram.

C. The pump can be used flat, or vertical provided the hose is pointing down.

D. The ram can be used in any position, provided the setup is safe and stable.

1) Openthebreathervalve(valveshouldbeclosedwhentransportingtheunit).

2) Closethereleasevalvebyrotatingitclockwiseuntilfingertight.

2) Position and secure the ram and extensions / adapters to be used in such a manner that

the setup is stable and will operate in a safe manner.

3) Slowly operate the pump handle until the setup meets the load, double check that the

setup is secure.

4) Operatethepump,observingthepressuregaugetoensurenottoexceedmaximum

operating pressure for specific load and setup. If the setup becomes unstable, stop

pumping and slowly release the pressure by rotating the release valve counterclockwise.

Re-positionramandextensions/adapterstoasafersetup.

5) When releasing pressure, SLOWLY rotate the release valve counterclockwise, (never

more than one turn) while observing the setup for instability.

1) Store ram in retracted state to protect from damage and corrosion.

2) Protect components from corrosive chemicals, dirt, or damage by storing in a clean

protected area.

3) Use plastic threaded coupler protectors on ram and hose connectors when not in use.

4) ReplaceHydraulicOilannuallywithaHighGradeHydraulicOil,neverusealcohol,brake

fluid or transmission oil.

030202-4Ton-OilCapacity=350ml

030207-10Ton-OilCapacity=500ml

5) Periodically check the ram and pump piston for signs of rust, clean exposed areas with a

clean oiled cloth. Always ensure setup contact points are free of oil and debris.

6) Repairsshouldonlybeperformedbyaqualifiedhydraulicrepairtechnician.

!MAINTENANCE

www.strongarminc.com

PRODUCT NUMBERS 030202, 030207

MODEL NUMBERS BRK4T 4 TON BODY REPAIR KIT, BRK10T 10 TON BODY REPAIR KIT

PART NUMBER DESCRIPTION

PCN-BRK4T-01 CASE4TONPLASTIC

PCN-BRK4T-02.1 EXTENSIONTUBEI

PCN-BRK4T-02.2 EXTENSIONTUBEII

PCN-BRK4T-02.3 EXTENSIONTUBEIII

PCN-BRK4T-02.4 EXTENSIONTUBEIV

PCN-BRK4T-02.5 EXTENSIONTUBEV

PCN-BRK4T-03 FLATBASE

PCN-BRK4T-04 RAMTOE

PCN-BRK4T-05 PLUNGERTOE

PCN-BRK4T-06 WEDGEHEAD

PCN-BRK4T-07 V-BASE

PCN-BRK4T-08 MALECONNECT

PCN-BRK4T-09 SERRATEDSADDLE

PCN-BRK4T-10 RUBBERHEAD

PCN-BRK10T-01 CASE10TONPLASTIC

PCN-BRK10T-02.1 EXTENSIONTUBEI

PCN-BRK10T-02.2 EXTENSIONTUBEII

PCN-BRK10T-02.3 EXTENSIONTUBEIII

PCN-BRK10T-02.4 EXTENSIONTUBEIV

PCN-BRK10T-03 FLATBASE

PCN-BRK10T-04 RAMTOE

PCN-BRK10T-05 PLUNGERTOE

PCN-BRK10T-06 WEDGEHEAD

PCN-BRK10T-07 V-BASE

PCN-BRK10T-08 MALECONNECT

PCN-BRK10T-09 SERRATEDSADDLE

PCN-BRK10T-10 RUBBERHEAD

BRK4PHPUMP/HOSE#030283

BRK4RAM4TONRAM#030241

BRKSPRAM1/2TONSPREADER#030230

BRK10PHPUMP/HOSE#030284

BRK10RAM10TONRAM#030242

BRKH-HOSE#030292

www.strongarminc.com

PRODUCT NUMBERS 030202, 030207

MODEL NUMBERS BRK4T 4 TON BODY REPAIR KIT, BRK10T 10 TON BODY REPAIR KIT

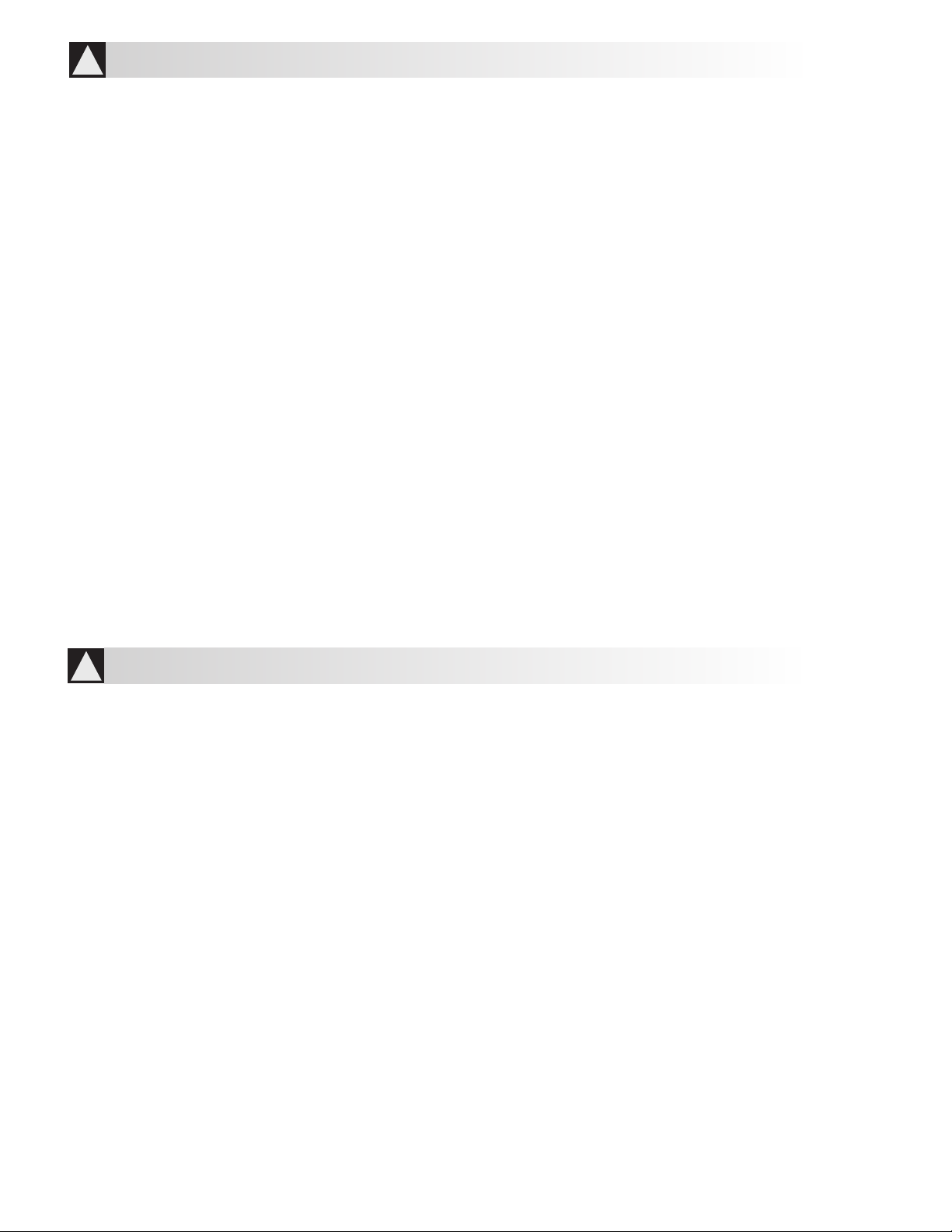

4 TON PCN-BRK4T-PRK

10 TON PCN-BRK10T-PRK

INCLUDES

1 Each: P02,P06,P07,P08,P09,P11,P14,P19,P20,P21,P22,P24,

P 2 5 , P 2 6 , P 2 7 , P 2 8 , P 2 9 , P 3 0 , P 3 1 , P 3 2 , P 3 3 , P 3 4 , P 3 5 , P 4 3 , P 4 4 , P 4 5

2 Each: P03, P13, P23

PUMP REPAIR KIT

4TONKIT

PCN-BRK4T-RRK

10TONKIT

PCN-BRK10T-RRK

RAM REPAIR KIT INCLUDES:

R02,R04,R05,R06,R07,R08

PCN-BRK4T-FHC FEMALE HYDRAULIC COUPLER

INCLUDES: S10, S11, P11, S12, S13

www.strongarminc.com

PRODUCT NUMBERS 030202, 030207

MODEL NUMBERS BRK4T 4 TON BODY REPAIR KIT, BRK10T 10 TON BODY REPAIR KIT

PART NUMBER DESCRIPTION

HYDRAM

PCN-BRK4T-R01 COVER

PCN-BRK4T-R12 PROTECTIONCAP

SPREADER/PUMP

PCN-BRK4T-P17 COUPLER

PCN-BRK4T-P18 DUSTCOVER

PCN-BRK4T-P15 RELEASEVALVE

PCN-BRK4T-P41 HANDLEWITHGRIP

PCN-BRK4T-S4 SPRING

PCN-BRK4T-S9 ENDCAP

PCN-BRK4T-S8 O-RING

PCN-BRK4T-S7 CUPSEAL

PCN-BRK4T-S6 PISTON

PCN-BRK4T-S5 FIXED JAW

PCN-BRK4T-S3 MOVEABLEJAW

PCN-BRK4T-S1 PIN

PCN-BRK4T-S2 CIRCLIP

HYDRAULICRAM

PCN-BRK10T-R01 COVER

PCN-BRK10T-R12 PROTECTIONCAP

SPREADER/PUMP

PCN-BRK10T-P17 COUPLER

PCN-BRK10T-P18 DUSTCOVER

PCN-BRK10T-P15 RELEASEVALVE

PCN-BRK10T-P41 HANDLEWITHGRIP

PCN-BRK10T-S4 SPRING

PCN-BRK10T-S9 ENDCAP

PCN-BRK10T-S8 O-RING

PCN-BRK10T-S7 CUPSEAL

PCN-BRK10T-S6 PISTON

PCN-BRK10T-S5 FIXED JAW

PCN-BRK10T-S3 MOVEABLE JAW

PCN-BRK10T-S1 PIN

PCN-BRK10T-S2 CIRCLIP

This manual suits for next models

3

Table of contents

Popular Service Equipment manuals by other brands

CAS

CAS LAUNCHER LCH-AC944 manual

KE2 Therm Solutions

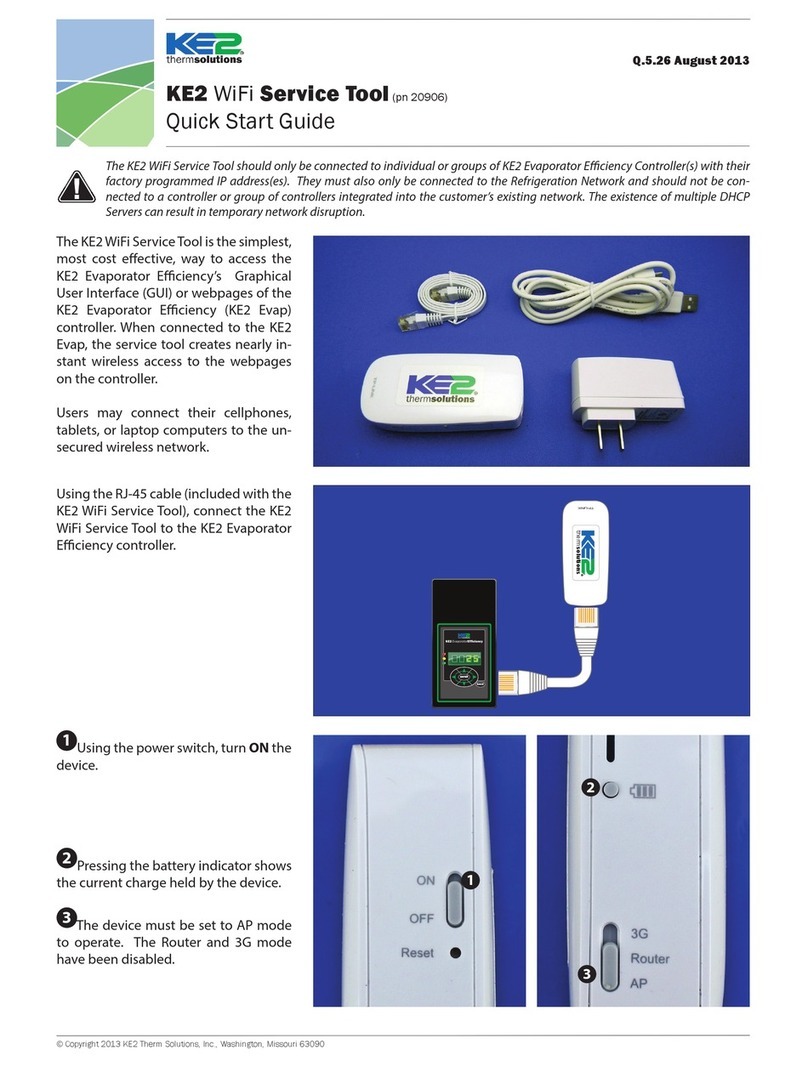

KE2 Therm Solutions 20906 quick start guide

DeVilbiss

DeVilbiss KK-4456 Service instruction

Heavy Equipment Repair

Heavy Equipment Repair TRACBUSTER 2000 Operation manual

Craftsman

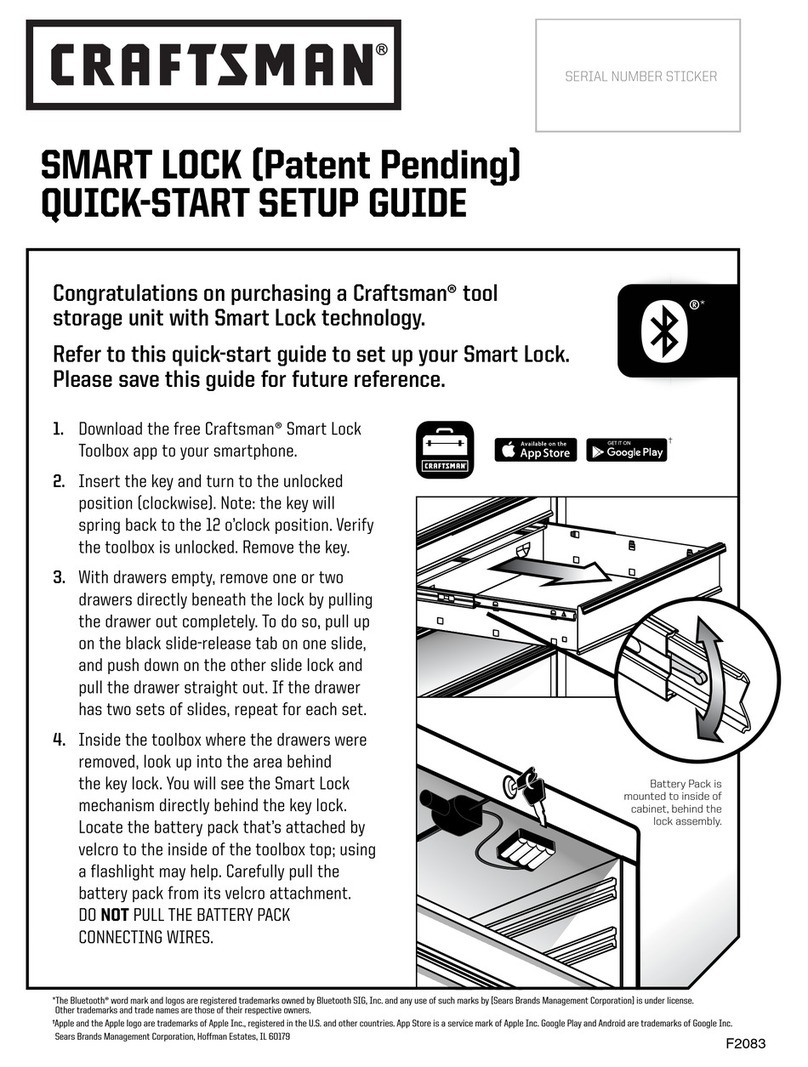

Craftsman Smart Lock Quick start setup guide

Maddox

Maddox MC21-1 owner's manual