Torc HYFLOW 230-2 Setup guide

Hydraulic unit

HYFLOW 230-2

English translation of the original german

Maintenance and repair instructions

for qualified and authorized personnel at the TORC LLC branch

Version 7/2015

Always store these maintenance and repair instructions together with the hydraulic unit. Ensure that the

maintenance and repair instructions are available to the qualified and authorized personnel at the TORC LLC

branch. Read and observe the maintenance and repair instructions.

Failure to comply can result in injuries or even death. The operating instructions contain information for using

the unit.

Table of contents

Notes concerning this manual and the manufacturer............................................ 5

Referenced documents...................................................................................................5

Design features of this manual.......................................................................................6

Manufacturer's address ..................................................................................................6

Safety ....................................................................................................................... 7

Responsibilities of the operating company.....................................................................7

Persons at particular risk................................................................................................7

Ambient conditions .........................................................................................................7

Qualification of personnel...............................................................................................8

Carrying out electrical work..................................................................................8

Carrying out mechanical and hydraulic tasks.......................................................9

Ban of unauthorized conversions ...................................................................................9

Personal protective equipment.......................................................................................9

Basic safety information................................................................................................10

Preventing serious injury or death......................................................................10

Preventing explosion hazards ............................................................................10

Preventing electric shock ...................................................................................10

Preventing burns from fire..................................................................................10

Preventing burns from oil and hot surfaces........................................................10

Preventing poisoning..........................................................................................11

Preventing bone fractures and crushing.............................................................11

Preventing eye damage .....................................................................................11

Preventing skin irritation.....................................................................................12

Preventing material damage ..............................................................................12

Intended use.................................................................................................................12

Design characteristics of warning information..............................................................12

Design of information about property damage .............................................................13

Warning and information signs.....................................................................................13

Carrying and setting down.................................................................................... 14

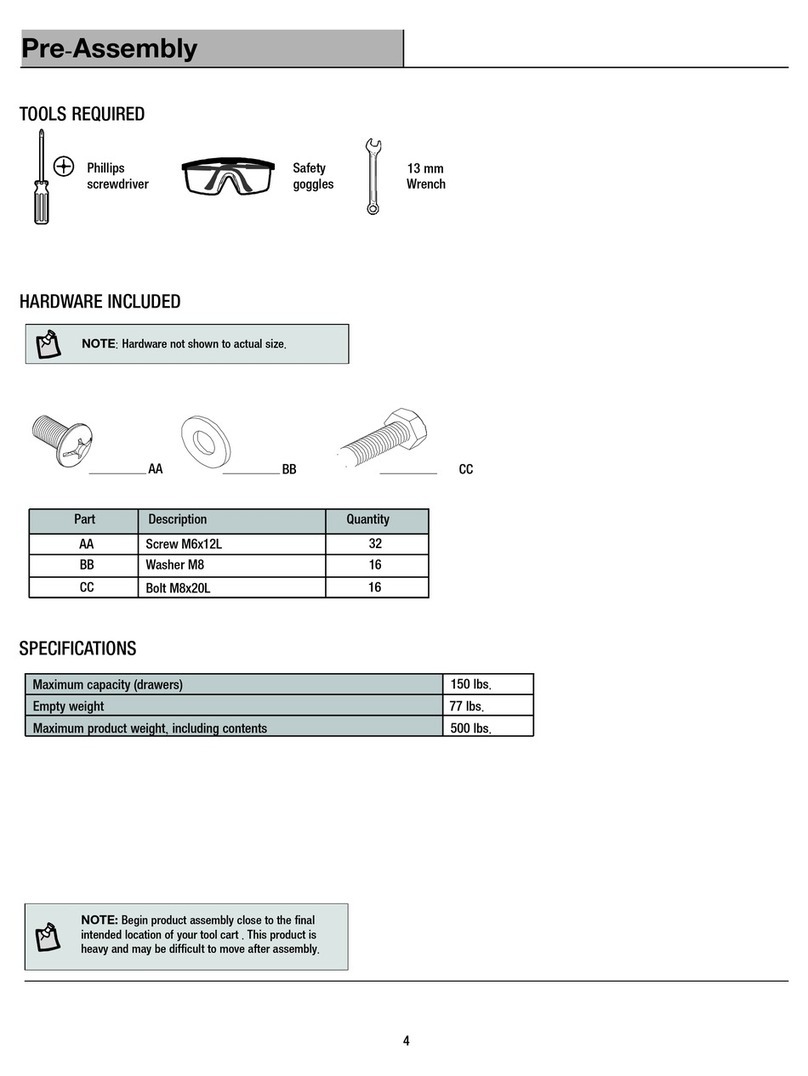

Required tools........................................................................................................ 15

Maintenance schedule........................................................................................... 16

Carrying out maintenance tasks ........................................................................... 17

Changing the hydraulic oil ............................................................................................17

Replacing hydraulic hoses............................................................................................18

Replacing the pressure gage........................................................................................19

Malfunctions...........................................................................................................20

Checks and repairs on electrical components......................................................23

Preparing checks and repairs on electrical components..............................................23

Moving the unit into the repair position for the electric control...........................24

Carrying out checks and repairs on electrical components..........................................25

Checking the circuit board..................................................................................25

Replacing the circuit board.................................................................................26

Checking the energy supply...............................................................................27

Replacing the power cord...................................................................................29

Checking the remote control ..............................................................................31

Replacing the remote control .............................................................................35

Checking a motor temperature problem.............................................................36

Replacing the capacitor......................................................................................42

Checking the solenoid valve electrically.............................................................43

Replacing the solenoid valve..............................................................................47

Checks and repairs on hydraulic components .....................................................49

Preparing checks and repairs on hydraulic components..............................................49

Removing the carrying handle............................................................................50

Moving the unit into the repair position for the upper structures ........................51

Moving the unit into the repair position for the lower structures.........................52

Carrying out checks and repairs on hydraulic components..........................................55

Checking the torque valve hydraulically.............................................................55

Checking the solenoid valve hydraulically..........................................................58

Checking the pump flange..................................................................................61

Checking and cleaning the screen filter .............................................................64

Checking the maximum pressure valve .............................................................65

Replacing the maximum pressure valve ............................................................67

Checking and replacing the pump element........................................................69

Checking the low-pressure cut off valve.............................................................72

Replacing the low-pressure cut off valve............................................................74

Checking the back pressure valve .....................................................................76

Replacing the back pressure valve ....................................................................79

Checking the pipe work......................................................................................80

Replacing the pipe work.....................................................................................83

Checks and repairs on mechanical components..................................................84

Preparing checks and repairs on mechanical components..........................................84

Carrying out checks and repairs on mechanical components......................................84

Checking the torque valve mechanically............................................................84

Replacing the torque valve.................................................................................86

Completing repair work......................................................................................... 87

Mounting the unit on the oil tank...................................................................................87

Cleaning unit.......................................................................................................... 90

Carry out a test run................................................................................................ 91

Disposal ................................................................................................................. 92

In Europe ......................................................................................................................92

In the USA ....................................................................................................................93

Notes concerning this manual and the manufacturer

5

Notes concerning this manual and the

manufacturer

The HYFLOW 230-2 hydraulic unit is referred to as the “unit” in the following.

Referenced documents

WARNING

Risk of injury through failure to observe the referenced

documents.

Read and observe all referenced documents before

carrying out any maintenance or repair work.

These can be found in the documentation folder of the unit.

More information, instructions and details about the unit components can be

found in the documentation from the respective manufacturers. These

documents are regarded as a part of these instructions. Store these

documents together with this manual. Hand over these documents when

selling the unit or passing it on in other ways.

Referenced documents are the following document types in particular:

operating instructions

assembly instructions

maintenance or repair instructions

wiring diagrams

terminal diagrams

hydraulic diagrams

safety data sheets

drawings

Observe and follow the information from the referenced documents.

These can be found in the documentation folder of the unit.

Notes concerning this manual and the manufacturer

6

Design features of this manual

Various elements of these maintenance and repair instructions have fixed

design characteristics. These allow you to easily distinguish the following

elements:

Normal text

Lists

Action steps

References to headers are set in quotation marks.

‘Labels’ of switches or other elements are set in inverted commas.

Table titles are set in bold.

Tips. Contains additional information.

Manufacturer's address

TORC LLC

218 Island Road

N.J. 07430 Mahwah

USA

Phone: 1 888-444-TORC (8672)

Web: www.torc.com

Safety

7

Safety

WARNING

Danger to life from disregarding the information in the safety

chapter.

Disregarding the information in the safety chapter can lead to

accidents with serious injuries.

Read and observe all information in the safety chapter

before carrying out any maintenance or repair work.

In addition to the information in these maintenance and repair instructions,

always observe any statutory and other regulations which apply at the place of

installation, e.g.:

accident prevention regulations

regulations for safe and professional working

regulations on explosion protection and fire protection which apply at the

place of installation

Responsibilities of the operating company

The operating company has to ensure that all accident prevention

regulations are observed.

The responsibility lies with the head of the TORC LLC branch.

The head of the TORC LLC branch has to ensure that the maintenance and

repair work is only carried out by qualified and authorized personnel.

Persons at particular risk

The following groups of persons must not be granted access to the unit as

they might sustain serious or lethal injuries:

children

persons with physical or mental limitations

persons under the influence of drugs and medication

persons under the influence of alcohol

unauthorized persons, e. g. pedestrians

Ambient conditions

Information about ambient conditions and technical data can be found in the

operating instructions for the unit.

Safety

8

Qualification of personnel

These maintenance and repair instructions are intended for the qualified and

authorized personnel from the TORC LLC branch.

Carrying out electrical work

The following knowledge and experience are required for the qualified

personnel:

trained for the task

aware that improper maintenance and repairs can cause accidents

able to assess hazards which may arise from voltage and current

able to assess hazards which may arise from noise and heat

able to apply information from wiring and terminal diagrams

able to install electrical connections

able to measure voltage, current and resistance

able to create a measuring path for measuring currents

able to identify defective electronic components due to visual changes

able to localize defective electronic components using a multimeter

able to replace defective electronic components in a professional manner

knows the recognized safety rules and applies them

Safety

9

Carrying out mechanical and hydraulic tasks

The following knowledge and experience are required for the qualified

personnel:

trained for the task

aware that improper maintenance and repairs can cause accidents

knows the recognized safety rules and applies them

able to release and fasten screw connections with the permitted torque

able to assess hazards and environmental impact caused by hydraulic oil

able to assess hazards which arise from noise and heat

able to identify leaks

able to carry out work with hot or pressurized media in a professional

manner

able to replace hydraulic components such as hydraulic hoses, seals,

valves, etc.

Ban of unauthorized conversions

Unauthorized conversions or changes on the unit may lead to serious or even

lethal injuries. This applies in particular to changing and altering safety

devices.

Never bypass or shunt any safety devices.

Personal protective equipment

Risk of crushing feet when lifting and carrying the unit! Wear safety shoes

with steel toes.

Risk of slipping and therefore bone fractures during hydraulic work! Wear

safety shoes with non-slip soles.

Risk of skin irritation from contact with hydraulic oil and hydraulic

components! Always wear oil-resistant nitrile gloves.

Risk of burns from contact with hot media and components! Wear protective

gloves against thermal hazards.

Risk of skin cuts and grazes on sharp-edged components! Wear protective

gloves against mechanical hazards.

Risk of eye injuries when checking for leaks on open oil tanks and when

changing the hydraulic oil! Wear chemical-resistant protective goggles.

Risk of ear damage when the unit is running! Wear ear protection while the

unit is running.

Risk of poisoning in poorly ventilated rooms! The unit may overheat. This

may lead to the formation of oil mist and oil vapor. Wear respiratory

protection in this case.

Safety

10

Basic safety information

Preventing serious injury or death

Using untested replacement parts poses a risk of serious or lethal injuries as

these parts may fail.

Only use the original spare parts specified in the spare parts list which is

available as a separate document.

Preventing explosion hazards

Operation, maintenance and repair of the unit in explosive atmospheres may

lead to serious injuries or death.

Only operate, maintain and repair the unit in areas with no explosive

atmosphere (measure safe levels first).

Preventing electric shock

Electric shock can cause serious or even lethal injuries!

Check the electric supply cable for damage.

Only use the unit if the cable is in perfect condition.

Disconnect the mains plug before carrying out electrical work on the unit or

before cleaning the unit.

Use tools which are insulated up to at least 370 V.

If you detect a broken cable with a continuity tester, replace the defective

cable.

Only clean the unit dry. Do not clean the unit with a high-pressure cleaner,

cold cleaners or water.

Preventing burns from fire

Short circuits can cause fires and result in serious burns.

Disconnect the mains plug before starting any maintenance and repair work.

Remove all highly flammable materials which are not required from your

work area.

Ensure that a fire extinguisher with powder and foam extinguishing agents is

available.

Preventing burns from oil and hot surfaces

Risk of burns from metal surfaces and hydraulic oil if the unit was previously in

operation.

Wear protective gloves against thermal hazards.

Safety

11

Preventing poisoning

The unit may overheat. This may lead to the formation of oil mist and oil vapor.

Ensure sufficient ventilation.

Wear respiratory protection in poorly ventilated rooms and if oil mist and oil

vapors are present.

Switch off of the unit if it overheats.

Leave the unit to cool down.

Use a contactless infrared thermometer to ensure that the unit has cooled

down to 25 °C (77 °F).

Check the unit for any damage.

If the unit is damaged, repair it before using it again.

Soak up any escaped liquid with a cloth immediately.

Dispose of the cloth in an environmentally friendly manner.

Preventing bone fractures and crushing

Bone fractures and crushing may occur. The unit can fall if it is set up, lifted or

carried in an unsafe manner. Risk of slipping and therefore bone fractures

during hydraulic work!

Always place the unit on a level, solid and strong surface.

Secure the unit and tools against falling.

Wear safety shoes with steel toes when lifting and carrying the unit.

Wear safety shoes with non-slip soles for hydraulic work.

Preventing eye damage

For pressure levels over 700 bar (10,000 psi) and operation of the unit outside

the tool and hose specification, hydraulic hoses may burst, causing hydraulic

oil to be ejected. Hydraulic oil may also escape during leak testing while the oil

tank is open.

Ensure that the permitted pressure levels are not exceeded.

Comply with the tool and hose specifications.

Consult the operating instructions for the tools and the hose specification.

Wear chemical-resistant protective goggles.

Safety

12

Preventing skin irritation

Contact with hydraulic oil during maintenance and repair work on hydraulic

components may lead to skin irritation.

Always create a permanent, tight connection between the unit and the

hydraulic tool.

Wear nitrile gloves when carrying out maintenance and repair work on

hydraulic components.

Ensure that the permitted pressure levels are not exceeded.

Comply with the tool and hose specifications.

Consult the operating instructions for the hydraulic tool.

Request the hose specifications from the manufacturer.

Preventing material damage

Avoid soiling the couplings by installing the protective caps and protective

plugs when the couplings are not in use.

Always set the hydraulic tool down safely.

Intended use

Information about intended use can be found in the operating instructions for

the unit.

Design characteristics of warning information

DANGER

Sections with the word DANGER warn of imminent

dangerous situations that lead to death or serious injury.

WARNING

Sections with the word WARNING warn of imminent

dangerous situations that may lead to death or serious injury.

CAUTION

Sections with the word CAUTION warn of dangerous

situations that may lead to minor or moderate injuries.

Safety

13

Explanation of symbols

Hazard from electric shock

Slipping hazard from leaked media

Burning hazard, scalding hazard

Design of information about property damage

ATTENTION!

These notes warn of situations that can lead to property

damage and limited functionality.

Warning and information signs

Ensure that all warning and information signs attached to the unit remain

well visible and legible at all times.

Replace any damaged or lost warning and information signs immediately.

Information about the warning and information signs attached to the unit can

be found in the operating instructions.

Carrying and setting down

14

Carrying and setting down

Only carry the unit by its carrying handle.

Place the unit on a dry, level, solid and strong surface.

Secure the unit and the associated tools against falling.

Required tools

15

Required tools

The following tools and equipment are required for maintenance and repair of

the unit:

one set of box and open-end wrenches

one set of hexagon socket wrenches

one set of crosshead screwdrivers

one set of slotted screwdrivers

one torque wrench (10–30 N m) with suitable attachments (e. g. open-end

keys, ratchet)

a vise

an infrared thermometer

a multimeter

a current clamp

a circuit continuity tester

a wooden wedge

Maintenance schedule

16

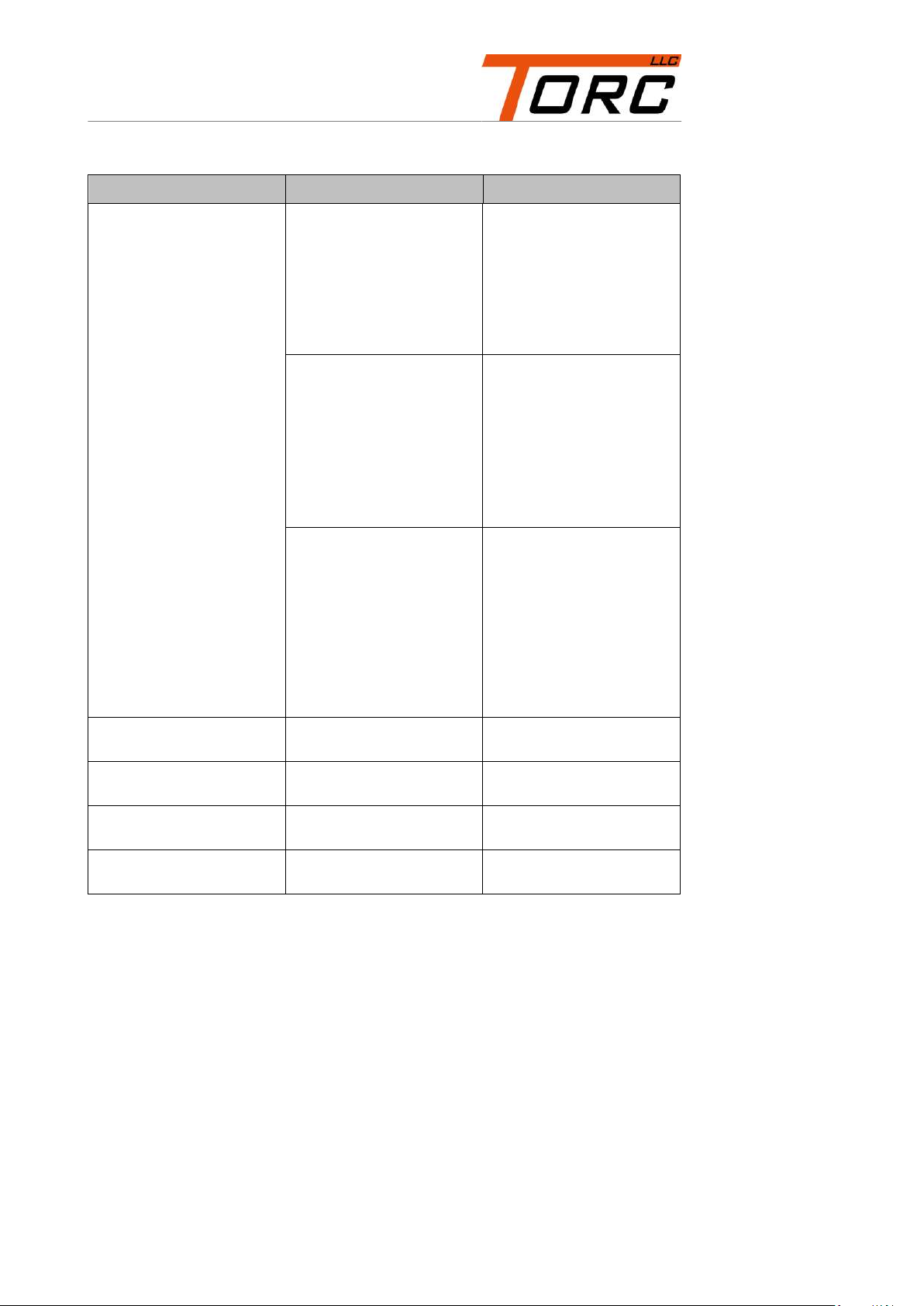

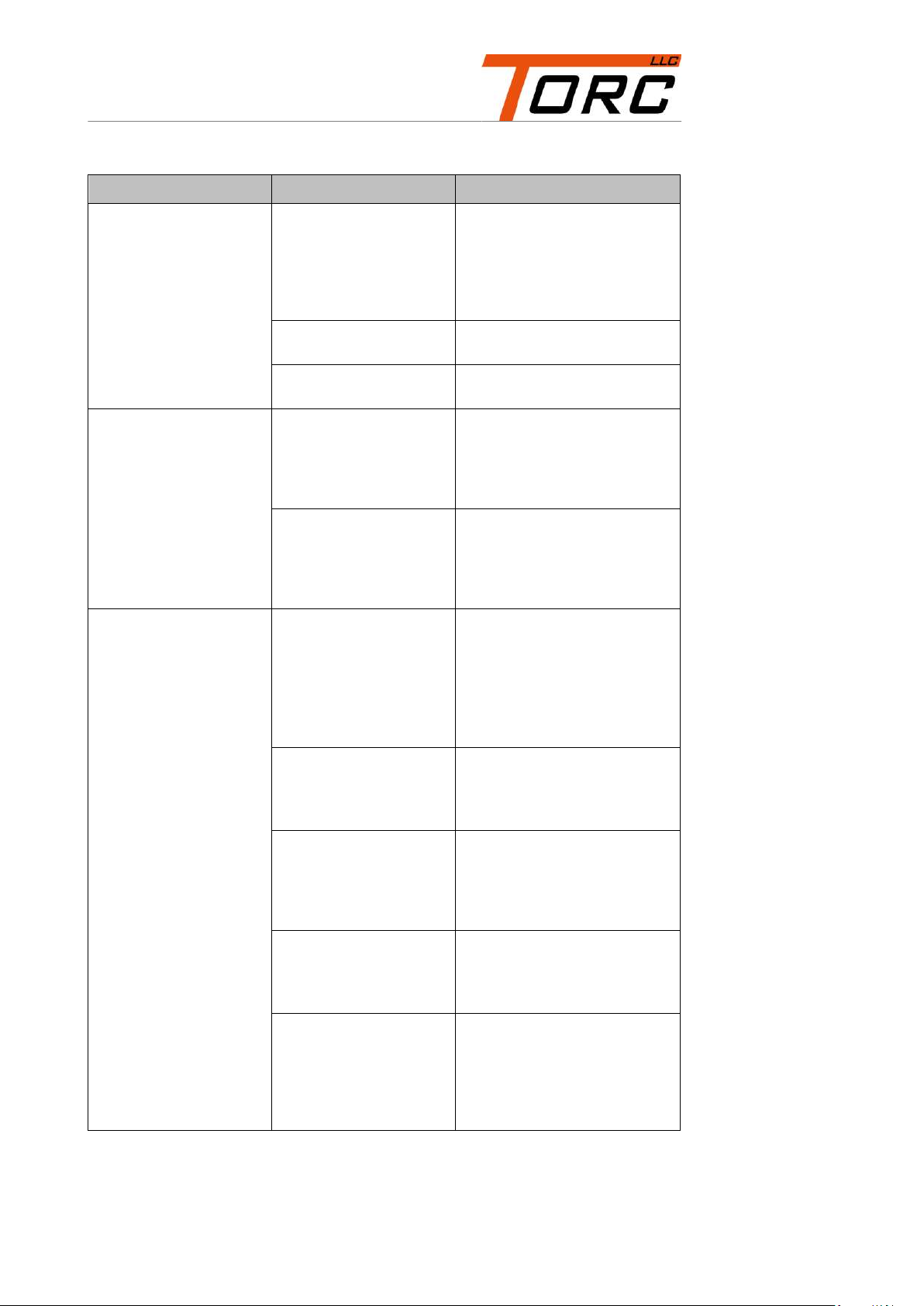

Maintenance schedule

Interval

Component

Action

Before each operation

Pressure gage

Check whether the

display of the pressure

gage reacts after

switching on the unit.

Have the defective

pressure gage replaced

by qualified personnel,

see page 19.

Hydraulic hoses

Check hydraulic hoses

for visible damage,

twisting and kinks.

Remove the twists.

Have defective or bent

hydraulic hoses

replaced by qualified

personnel, see

page 18.

Electric supply lines

Check electric supply

lines for visible

damage, twisting and

kinks.

Remove the twists.

Have defective or bent

electric supply lines

replaced by qualified

personnel, see

page 29.

Before each coupling

Couplings

Clean the couplings

with a dry cloth.

As required

Unit

Clean the unit with a

dry cloth.

Every 500 operating

hours

Oil tank

Change the hydraulic

oil, see page 17.

Every 7 years

Hydraulic hoses

Replace the hydraulic

hoses, see page 18.

Carrying out maintenance tasks

17

Carrying out maintenance tasks

Changing the hydraulic oil

WARNING

Slipping hazard from leaked oil.

Bruising and bone fractures possible.

Clean up any leaked oil with a cloth or suitable binding

agents.

Wear safety shoes with non-slip soles.

CAUTION

Health hazard from contact with hydraulic oil.

Wear nitrile gloves and chemical-resistant protective

goggles during work that may include contact with

hydraulic oil.

To change the hydraulic oil, proceed as follows:

Switch off the unit.

Disconnect the mains plug.

Leave the hydraulic oil to cool until it is tepid.

Place a container under the oil drain plug which can hold the oil volume in

the unit, 8 l (2.1 gal).

Open the oil drain plug.

The hydraulic oil will flow into the container.

Check the seal of the drain plug for damage.

Replace the damaged seal if required.

After completely draining the hydraulic oil from the oil tank, seal the oil drain

opening with the oil drain plug.

Tighten the oil drain plug with a torque of 20 N m.

Open the filler opening of the unit.

Fill in fresh hydraulic oil (manufacturer's recommendation: Castrol Hyspin

HVI 32) until the oil level fills half of the upper sight glass.

Close the filler opening with the corresponding cap.

Dispose of the drained hydraulic oil in line with the environmental

regulations at the place of installation.

Carrying out maintenance tasks

18

Replacing hydraulic hoses

WARNING

Slipping hazard from leaked oil.

Bruising and bone fractures possible.

Clean up any leaked oil with a cloth or suitable binding

agents.

Wear safety shoes with non-slip soles.

CAUTION

Health hazard from contact with hydraulic oil.

Wear nitrile gloves and chemical-resistant protective

goggles during work that may include contact with

hydraulic oil.

The hydraulic hoses have to be replaced with new hoses of the same type if

any visible damage is found, but after seven years at the latest.

To replace a hydraulic hose, proceed as follows:

Switch off the unit.

To depressurize the unit, press the Stop button on the remote control

several times until the display of the pressure gage shows 0 bar (0 psi).

Disconnect the mains plug.

Release the screw connection of the couplings.

Remove one end of the hydraulic hose from the coupling on the unit.

Remove the other end of the hydraulic hose from the coupling on the tool.

Place one end of the new hydraulic hose on the coupling of the tool.

Place the other end of the new hydraulic hose on the coupling of the unit.

Tighten the screw connection of the coupling.

Carrying out maintenance tasks

19

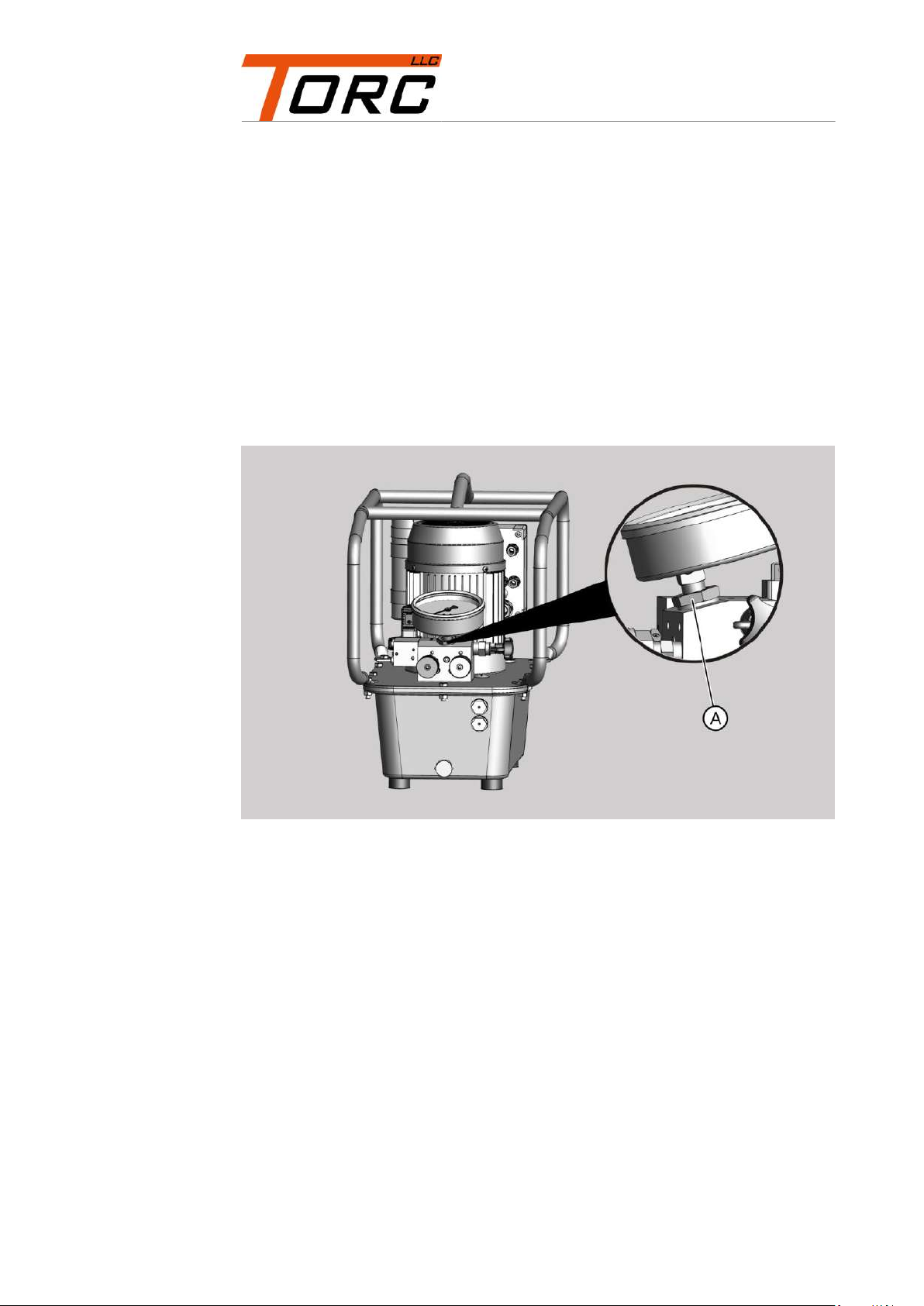

Replacing the pressure gage

To replace the pressure gage, proceed as follows:

Switch off the unit.

To depressurize the unit, press the stop button on the remote control

several times.

Disconnect the mains plug.

Release the screw connection (A) below the pressure gage.

Lift the pressure gage upwards to remove it.

Ensure that an intact O-ring is installed on the underside of the part to be

screwed in.

Place a new pressure gage of the same type on the screw fitting.

Fix the pressure gage with the screw fitting.

Malfunctions

20

Malfunctions

Malfunction

Possible cause

Corrective action

The pump is not

working.

Electrical components

are damaged.

Check the electrical

components, see page 25.

Replace damaged

electrical components or

have these replaced by the

manufacturer.

The power supply is

interrupted.

Check the power supply,

see page 27.

The remote control is

defective.

Check the remote control,

see page 31.

The motor only hums.

The stator is defective.

Check the motor windings,

see page 36.

Have the defective motor

windings repaired by the

manufacturer.

The capacitor is

defective.

Check the current of the

capacitor, see from

page 36.

Replace a defective

capacitor, see page 42.

No pressure or

pressure below 70 bar.

The solenoid valve is

defective.

Check the solenoid valve

electrically, see page 43.

Check the solenoid valve

hydraulically, see page 58.

Replace the defective

solenoid valve, see

page 47.

The torque valve is

defective.

Check the torque valve

hydraulically, see page 55

Replace the defective

torque valve, see page 86.

Leak on the pump

flange.

Check the pump flange,

see page 61.

Have the defective pump

flange repaired by the

manufacturer.

The screen filter is

blocked.

Check the screen filter, see

page 64.

Clean the blocked screen

filter, see page 64.

The maximum pressure

valve is leaking.

Check the maximum

pressure valve, see

page 65.

Replace the defective

maximum pressure valve,

see page 67.

Table of contents