Struers AbraPlan-10 User manual

Manual No.: 15497001

Date of Release 16.03.2005

AbraPlan-10

Instruction Manual

AbraPlan-10

Instruction Manual

AbraPlan-10

Instruction Manual

Table of Contents Page

User’s Guide ..............................................................1

Reference Guide ......................................................25

Quick Reference Guide............................................36

A

lways state Serial No and Voltage/frequency if you have technical questions or when ordering spare parts.

You will find the Serial No. and Voltage on the type plate of the machine itself. We may also need the Date

and Article No of the manual. This information is found on the front cover.

The following restrictions should be observed, as violation of the restrictions may cause cancellation of

Struers legal obligations:

Instruction Manuals: Struers Instruction Manual may only be used in connection with Struers equipment

covered by the Instruction Manual.

Service Manuals: Struers Service Manual may only be used by a trained technician authorised by Struers.

The Service Manual may only be used in connection with Struers equipment covered by the Service Manual.

Struers assumes no responsibility for errors in the manual text/illustrations. The information in this manual is

subject to change without notice. The manual may mention accessories or parts not included in the present

version of the equipment.

The contents of this manual are the property of Struers. Reproduction of any part of this manual without the

written permission of Struers is not allowed.

A

ll rights reserved. © Struers 2005.

Struers A/S

Pederstrupvej 84

DK-2750 Ballerup

Denmark

Telephone +45 44 600 800

Fax +45 44 600 801

AbraPlan-10

Instruction Manual

AbraPlan-10

Safety Precaution Sheet

To be read carefully before use

1. The operator should be fully aware of the use of the machine according

to the Instruction Manual.

2. The machine must be installed in compliance with local safety

regulations.

3. Be aware that the machine’s centre of gravity is located in the upper

half of the machine.

4. Before lifting the machine, ensure that the supplied lifting boom is

securely bolted to the machine.

5. When lifting the machine using a forklift, lift from front or rear - never lift

the machine from the side.

6. When lifting the machine using lifting straps, ensure that the straps are

crossed and do not press on the sides of the machine.

7. The machine must be placed on a safe and stable support, which is

capable of bearing the weight of this machine. Before using the

machine, it must be levelled using the adjustable legs.

8. Be sure that the actual voltage corresponds to the voltage stated on the

side of the machine and that the connections comply with local

regulations. The machine must be earthed.

9. Be aware that when the machine is connected to a compressed air

supply the specimen holder arm moves upwards.

10. Make sure that the specimens in the specimen holder are securely

fixed, and ensure that the securing screws are not sticking out.

11. Keep clear of the grinding stone when operating.

AbraPlan-10

Instruction Manual

12. Always use Safety Goggles when operating the machine.

13. If you observe malfunctions or hear unusual noises - stop the machine

and call technical service.

14. The machine must be disconnected from the mains supply prior to any

service and before connecting or disconnecting the recirculation pump.

15. To achieve maximum safety and lifetime of the machine, use only

original Struers consumables.

The equipment is designed for use with consumables supplied by Struers. If subjected to misuse, improper

installation, alteration, neglect, accident or improper repair, Struers will accept no responsibility for

damage(s) to the user or the equipment.

Dismantling of any part of the equipment, during service or repair, should always be performed by a qualified

technician (electromechanical, electronic, mechanical, pneumatic, etc.)

AbraPlan-10

Instruction Manual

1

User’s Guide

Table of Contents Page

1. Getting Started

Checking the Contents of the Packing Box ..................................... 2

AbraPlan-10............................................................................. 2

Recirculation Cooling Unit (optional)..................................... 2

Placing AbraPlan-10......................................................................... 2

Getting Acquainted with AbraPlan-10............................................ 3

Noise Level........................................................................................ 3

Supplying Power............................................................................... 4

Direction of Rotation ............................................................... 4

Supplying Compressed Air............................................................... 4

Connecting the Recirculation Cooling Unit (accessory).................. 5

Mounting the Grinding Stone/ Diamond Grinding Disc................. 6

Flushing Unit Head.......................................................................... 8

Mounting Stock Removal Sensor (accessory) .................................. 9

Mounting the Water Level Indicator (accessory)............................ 9

2. Basic Operations

Front Panel ..................................................................................... 10

Front Panel Controls ...................................................................... 10

Software Settings............................................................................ 11

Setting the Language ............................................................ 12

Reading the Display ....................................................................... 14

Sleep Mode............................................................................. 15

Changing/Editing Values ...............................................................15

Numeric Values ..................................................................... 15

Text Values ............................................................................ 16

Setting up the Software.................................................................. 17

Dressing Arm Movement ...................................................... 18

Inserting/Removing the Specimen Holder .................................... 18

Inserting the Specimen Holder............................................. 18

Removing the Specimen Holder............................................ 19

Grinding Setup ...............................................................................19

Setting the Process Time ......................................................20

Setting Stock Removal (accessory) ....................................... 20

Setting the Force ................................................................... 21

Cooling Water ........................................................................ 21

Starting the Preparation Process .................................................. 22

Stopping the Preparation Process.................................................. 22

Dressing the Grinding Stone.......................................................... 23

Adjusting the Position of the Dressing Arm ........................ 23

Dressing the Diamond Grinding Disc............................................ 24

AbraPlan-10

Instruction Manual

2

1. Getting Started

In the packing box you should find the following parts:

1 AbraPlan-10

1 Outlet hose (factory mounted)

1 Inlet hose (factory mounted)

2 Hose clamps, 17 mm

1 Drain angle, 900

1 Hose clamp, 35-60 mm

1 Hose for compressed air

2 Hose clamps, 12 mm

1 Hose connection for compressed air

1 Rubber disc 350 mm

1 Flange

1 Bolt M12

1 Allen key 8 mm

1 Set of Instruction Manuals

1 Recirculation Cooling Unit

1 Drain angle, 450

1 Funnel

2 Plastic inserts

AbraPlan-10 should be placed directly on a plane and horizontal

floor, capable of bearing the weight of this machine, please refer

to the Technical Data section.

Checking the Contents of the

Packing Box

A

braPlan-10

Recirculation Cooling Unit

(optional)

Placing AbraPlan-10

AbraPlan-10

Instruction Manual

3

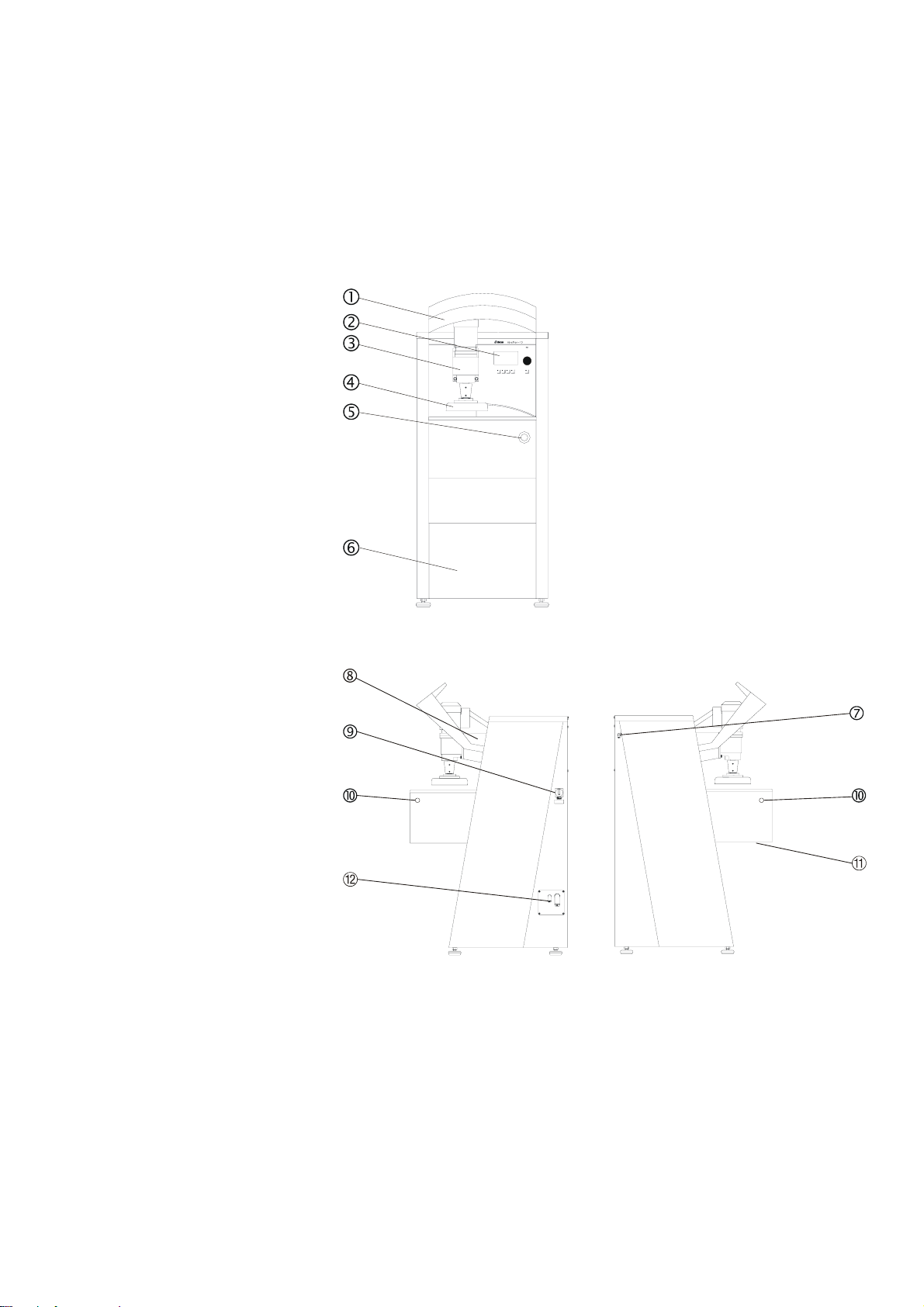

Take a moment to familiarise yourself with the location and

names of the AbraPlan-10 components.

Compressed air inlet

Cast iron beam

Mains power switch

Two-handed start buttons

1 Bottom cover

2Electrical connections

Approx. 68 dB (A) measured during idle running, at the operator's

position in front of the machine.

Getting Acquainted with

AbraPlan-10

Noise Level

Front view

Side views

Shield

Control panel,

(see 2. Basic Operations)

Specimen holder motor

Specimen quick coupling

Emergency Stop

Cover plate for

Recirculation Cooling Unit

AbraPlan-10

Instruction Manual

4

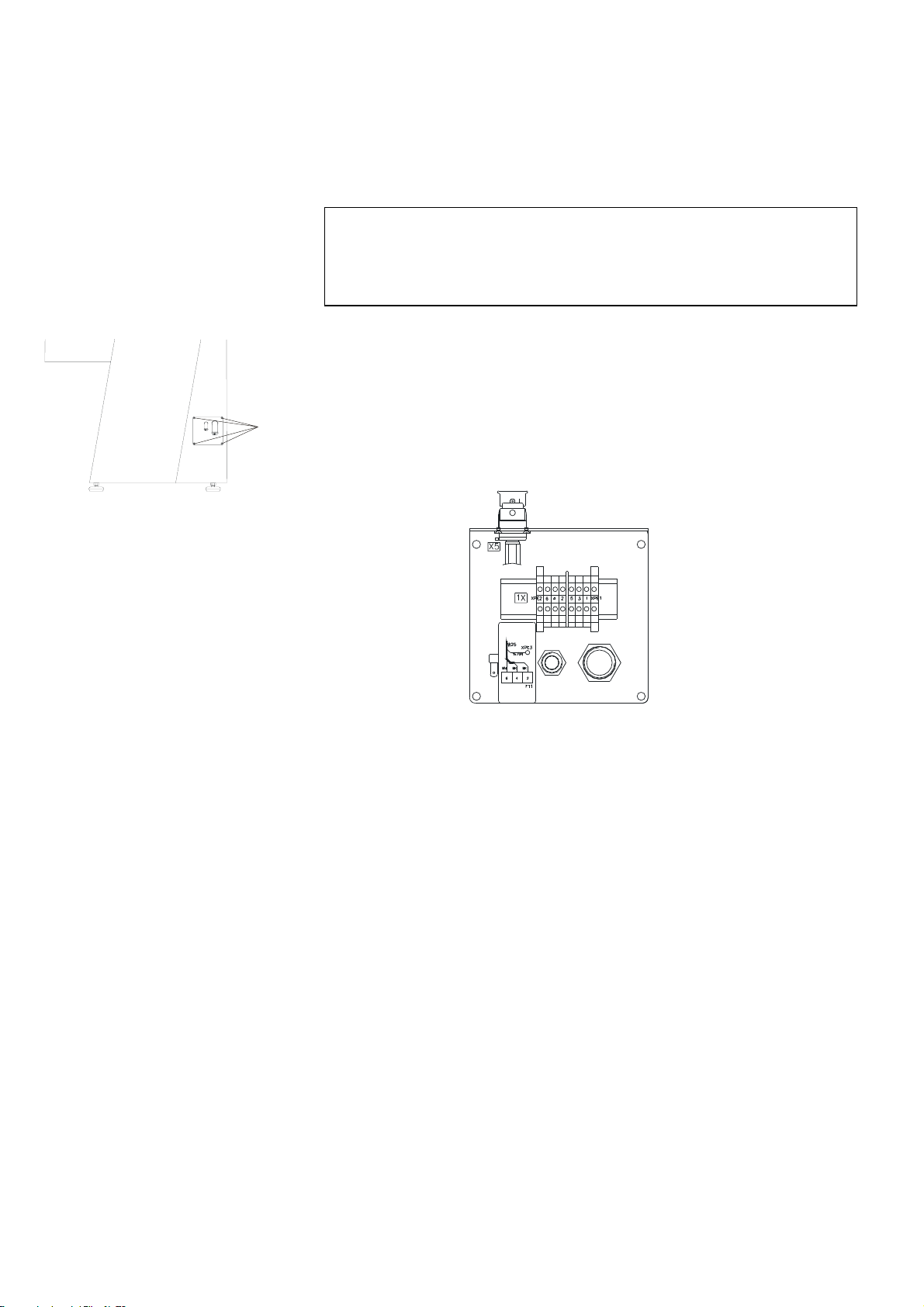

Remove the 4 Allen screws, on the right hand side of the

machine, securing the electrical panel, and let the electrical

panel rest on the tabs.

Lead the cable through the conduit in the panel and connect

the 3 phases and earth according to local regulations.

Where an external recirculation unit is used, connect the

electrical cable from the pump, according to the diagram

located inside the panel.

Check that when the power is turned on the grinding stone/

diamond grinding disc rotates counter-clockwise.

If this is not the case, switch off AbraPlan-10 and unplug the

machine.

Change two of the phases.

Repeat the rotation check.

Connect the compressed air supply to the inlet, located at the

rear of the left-hand side of the machine, using the air hose

and the hose connection delivered with the machine.

Fasten the air hose with a hose clamp.

The pressure supply should be 6-10 bar and can be supplied

either from a central compressor, a portable compressor with a

compressed air reservoir, or a compressed-air bottle. A capacity of

20 l/min at atmospheric pressure is sufficient.

Supplying Power IMPORTANT

Check that the mains supply voltage corresponds to the voltage stated on

the Type Plate (located under the mains switch on the side of the machine).

If the machine is already connected to a mains supply, disconnect this

supply before removing the Allen screws securing the electrical panel.

Direction of Rotation

Supplying Compressed Air

Allen screw

s

AbraPlan-10

Instruction Manual

5

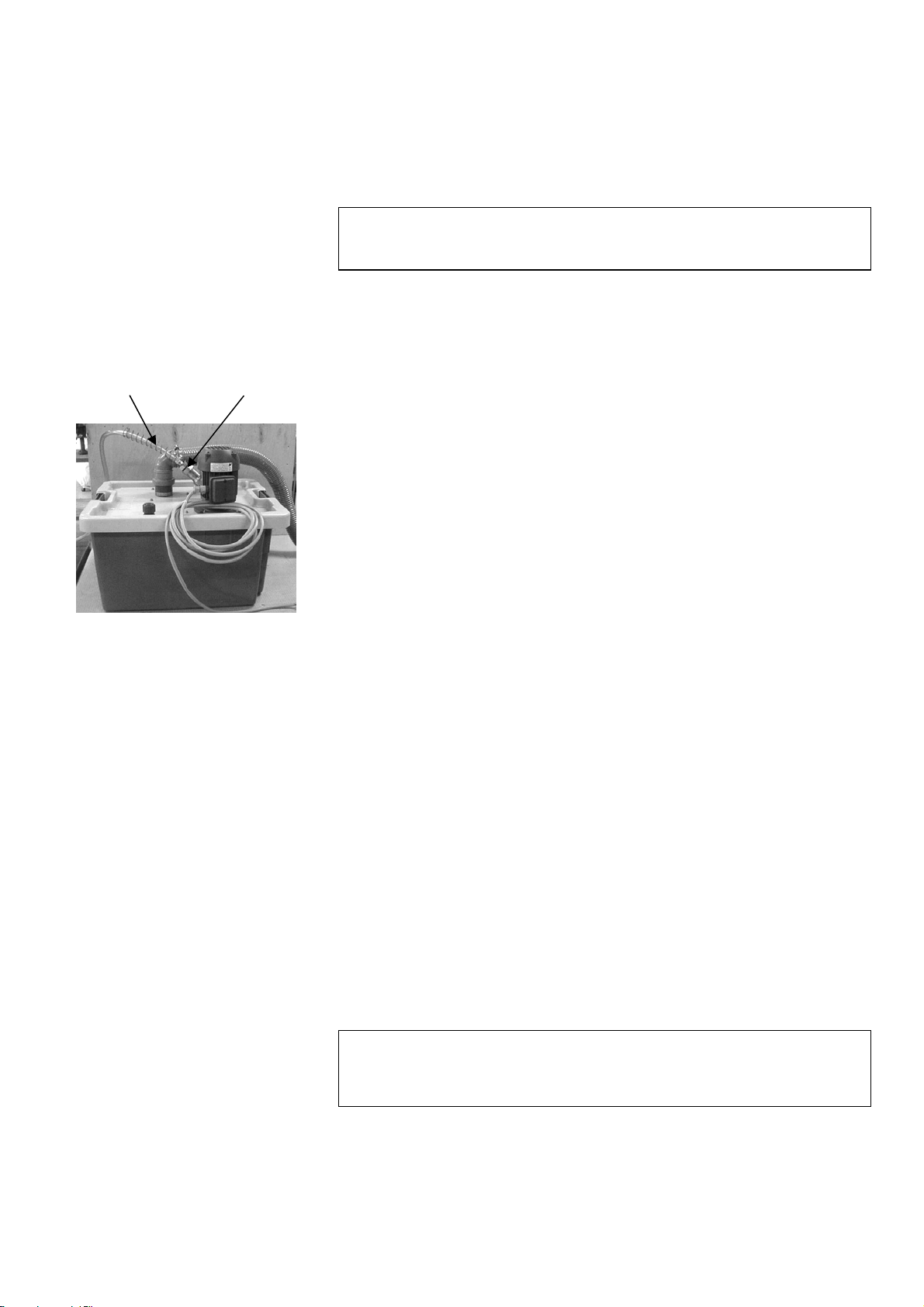

Place the unit where you find it convenient, either inside the

machine or outside, on the left.

Slide the metal spring over the inlet hose (this will prevent

kinks in the hose that could obstruct the flow of water).

Connect the inlet hose from the flushing unit to the pump of

the recirculation unit.

Secure the metal spring in place by turning two coils around

the connector (see illustration).

Cut the drain hose to the correct length, remove

approximately 20 mm of the spring inside the drain hose and

fit the hose over the 900drain angle.

Slide the drain angle over the pipe in the top of the reservoir

lid. (Note: The 450elbow pipe delivered with the Recirculation

Cooling Unit is not used with this machine).

Check that there is a steady fall on the whole course of the

outlet hose.

Open the electrical connections cover

−If mounting inside the machine, lead the cable into the

electrical panel from inside the machine through the rear.

−If mounting outside the machine, lead the cable through

the conduit in the panel.

Now connect the cable to the AbraPlan-10 using the terminal

connectors in the electrical panel.

Check that when the power is turned on, the pump rotates in

the direction indicated by the arrow on the top of the pump. If

this is not the case, change 2 of the electrical phases.

Replace the cover to the electrical connections.

If mounting inside the machine, remove the front cover and

place the tank on the trolley.

Place a disposable plastic insert in the tank and fold it over

the rim.

Fill the tank with 29.1 l water and 900 ml Struers Additive

for Cooling Fluid.

The water level should be 8-10 cm below the upper rim of the

tank.

Connecting the Recirculation

Cooling Unit (accessory)

Warning

Disconnect the machine from the mains power supply

before connecting or disconnecting the recirculation pump.

IMPORTANT

Too high a level of coolant in the tank might damage the pump. To avoid

this, place the disposable insert so that the pre-punched hole is in front of

the overflow aperture in the tank.

Metal Spring Connector

AbraPlan-10

Instruction Manual

6

Fit the tank lid and sieve.

Move the unit into place and lead the outlet and overflow

drain hoses into the cooling water tank. Adjust the lengths if

necessary.

If mounting inside, replace the front cover.

Flushing unit head

Securing finger screws

Stone guard

Dressing arm

Ensure that the sample motor is fully raised, and lift the

shield to gain access to the grinding area.

Make sure that the dressing arm is located in its storage

position (on the left-hand side).

Lift the flushing unit head and, using its built-in magnet,

attach it to the sample motor mounting arm.

Move the sliding cover on the stone guard across until it is

free at both ends.

Unscrew the 2 finger screws (located on the right-hand side)

Use both the handle and the flushing unit connection to lift

the stone guard up and away to the right.

IMPORTANT

Always maintain the correct concentration of Struers Additive in the cooling

water (percentage stated on the Additive container).

Remember to top up with Struers Additive each time you refill with water.

Mounting the Grinding Stone/

Diamond Grinding Disc IMPORTANT

Make sure that the grinding stone/diamond grinding disc is intact.

The stone/disc must be dry when mounted and the flange should be

clean and smooth.

AbraPlan-10

Instruction Manual

7

Assemble the grinding stone/ diamond grinding disc on the

flange as illustrated:

Motor Flange

Rubber disk

Grinding stone/ diamond grinding disc

Securing flange and cardboard washer

Securing bolt

Mount the bolt and fasten firmly.

Replace the stone guard and secure it with the 2 finger

screws.

IMPORTANT

Do not over tighten the securing bolt as this may damage the

grinding stone/disc.

IMPORTANT

Remember to re-attach the flushing unit head.

Remember to raise the dressing arm to the top of its travel.

AbraPlan-10

Instruction Manual

8

When attached to its mounting (as illustrated), the flushing unit

supplies water/coolant to the grinding stone/ diamond grinding

disc during the grinding and dressing processes. However, the

flushing unit can be removed from the mounting and used to hose

down the grinding area and samples etc. To do this:

Squeeze in and hold the clamp buttons (illustrated by arrows)

to cut-off the water/coolant flow.

Press F1 to start the pump.

Lift the flushing unit free of its mounting.

Direct the flushing unit in the desired direction and release

the clamp buttons.

Press F1 to stop the pump.

Reinsert the flushing unit in its mounting.

If the grinding/dressing process is not active, a water/coolant flow

can be achieved by pressing F1 when the GRINDING or

DRESSING Menus are displayed.

Flushing Unit Head

AbraPlan-10

Instruction Manual

9

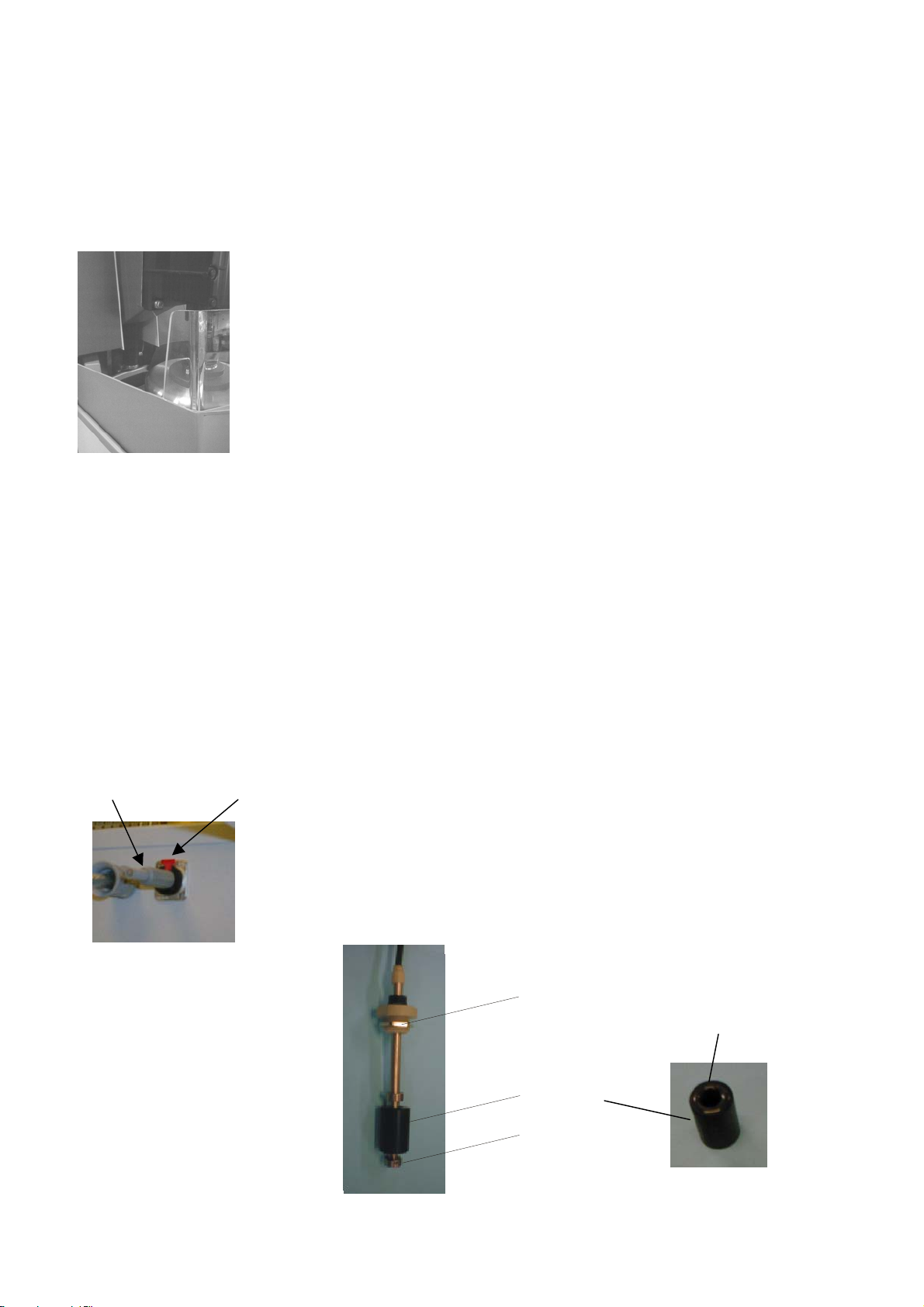

Disconnect main power.

Connect the plug on the removal sensor with the plug located

on the inside of the control panel.

Take the removal sensor and gently slide it up in the hole

located in the bottom of the cast iron beam.

Let the bracket slide over the factory installed bracket.

From the left, slide the two screws through the brackets, and

tighten them with a 10 mm spanner.

Reconnect the main power and follow the instructions on the

display, using the tools supplied and the calibrating sticks.

Switch the machine off.

Pull out the recirculation unit.

Remove the pump, drain hose and the top cover.

Remove the red cover from the hole for the sensor or remove

the existing Water Level Indicator.

Remove the locking nut on the bottom of the sensor and slide

off the black float.

Mount the new Water Level Sensor on the recirculation unit

cover and secure using the nut supplied (flat side of nut up).

Replace the float (with the clear surface up) and secure the

locking nut in place.

On the right hand side of the machine, remove the 4 Allen

screws securing the electrical panel, and let the electrical

panel hang on the two tabs (as illustrated in Supplying

Power).

Remove the dummy jack plug located on the electrical panel

by pressing down the red tab.

Plug in the jack plug from the sensor.

Reassemble the recirculation unit and slide it back into

position.

Replace the front cover.

Switch the machine on.

Nut

Black float

Locking nut

Mounting the Stock Removal

Sensor (accessory)

Mounting the Water Level

Sensor (accessory)

Clear surface

Dummy jack Red tab

AbraPlan-10

Instruction Manual

10

2. Basic Operations

AbraPlan-10

Power

F3

F1 Esc

F4

F2

Name Key Function Name Key Function

FUNCTION

KEY

F1 Controls for various purposes.

See the bottom line of the

individual screens.

Push/Turn

Knob Used for entering and changing

parameters.

Combined cursor and enter key.

FUNCTION

KEY

F2 Controls for various purposes.

See the bottom line of the

individual screens.

Esc Esc Leaves the present menu or

aborts functions/changes.

FUNCTION

KEY

F3 Controls for various purposes.

See the bottom line of the

individual screens.

STOP o Stops the preparation process.

FUNCTION

KEY

F4 Controls for various purposes.

See the bottom line of the

individual screens.

EMERGENCY

STOP

The EMERGENCY STOP is

located on the front of the

machine.

- Push the red button to stop.

- Pull the red button to release.

MAIN

SWITCH

The main switch is located on

the right side of the machine.

Front Panel

Front Panel Controls

↵

AbraPlan-10

Instruction Manual

11

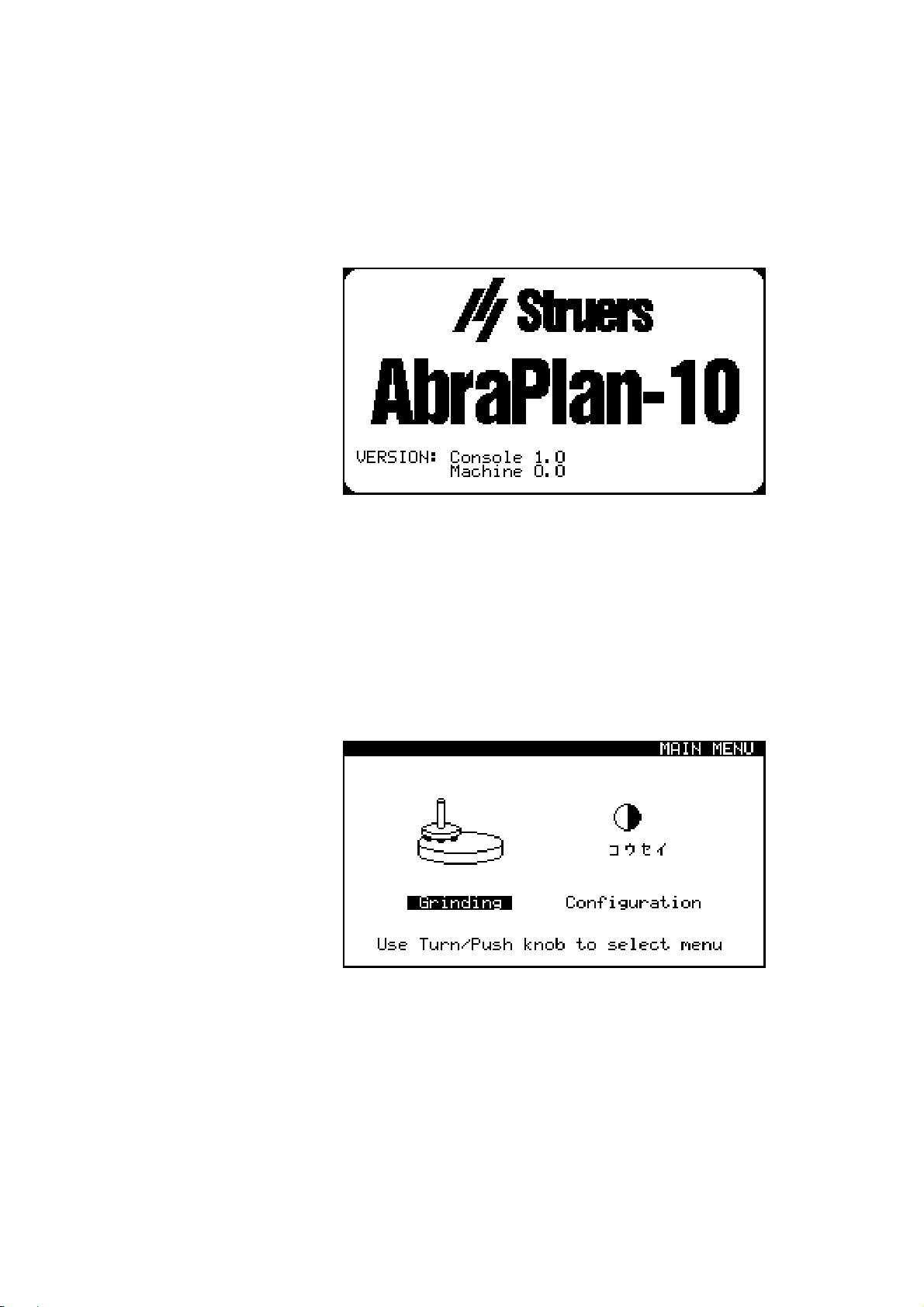

Switch on the power at the main switch located at the right hand

side of the machine. The following display will appear briefly:

The display will then change to the last screen shown before

AbraPlan-10 was switched off. When switching on AbraPlan-10

for the first time, the MAIN MENU display will appear. If the

heading in the display is different, press Esc, until the MAIN

MENU appears.

The MAIN MENU is the highest level in the menu structure.

From this menu, you can enter the configuration menu and

grinding process menu.

Software Settings

AbraPlan-10

Instruction Manual

12

Before continuing, we recommend that you select the language

that best suits you.

D

Turn knob to select CONFIGURATION

D

Push knob to activate the

CONFIGURATION Menu

D

D

Turn knob to select Language.

D

Push knob to activate the Language pop-up

menu.

D

D

Turn knob to select the language you

prefer.

D

Setting the Language

AbraPlan-10

Instruction Manual

13

Push knob to accept the language.

The CONFIGURATION Menu now appears in the

language you have chosen.

Esc Press Esc to return to the MAIN MENU.

AbraPlan-10

Instruction Manual

14

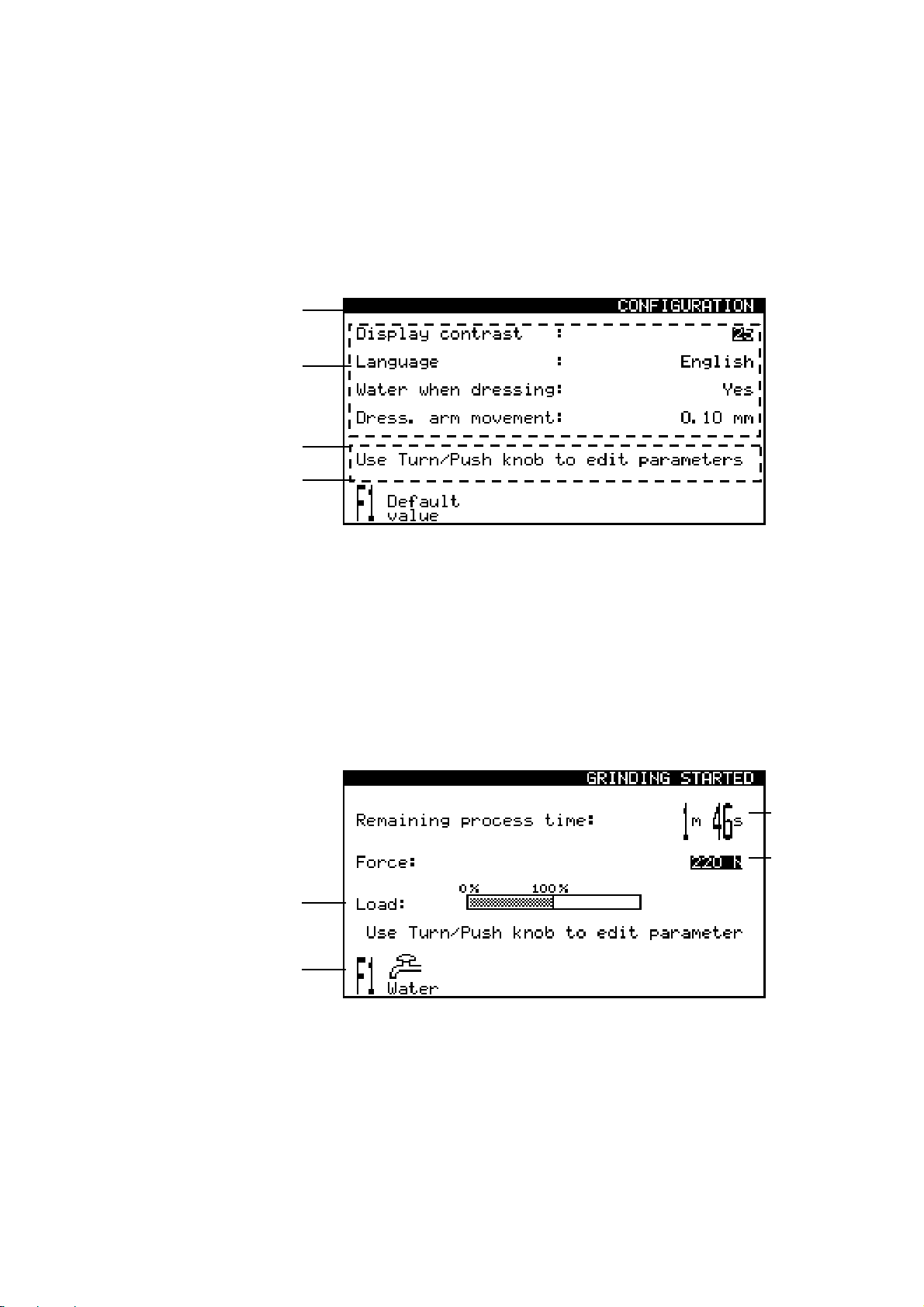

The display is primarily divided into 4 areas. The position of these

areas and the information they contain are explained in the

illustration below, which uses the CONFIGURATION Menu as an

example:

A Heading: this tells you where you are in the software.

B Information fields: these will either be numerical values or

text fields providing information associated with the process

shown in the heading. The inverted text shows the cursor

position.

C Help text: helpful hints to allow you to continue.

DFunction key options: the functions of these change with the

window displayed.

During the grinding process the screen could look as follows:

A Grinding time remaining

B Force applied on specimen holder

C Load on main motor

D Function(s) selectable during process

Reading the Display

B

A

A

B

D

C

C

D

Table of contents

Languages:

Other Struers Grinder manuals