1

16/08/2017, STS Instruments Ltd, Testing & Commissioning Manual

TABLE OF CONTENTS

1.0 Manual Guide ..................................................................................................... 2

1.1

Document Version ....................................................................................... 2

1.2

Symbols Used ............................................................................................. 2

1.3

Safety Information ....................................................................................... 3

1.4

Environmental parameters ............................................................................. 4

1.5

Instrumentation Safety Symbols ...................................................................... 4

2.0

Overview ...................................................................................................... 5

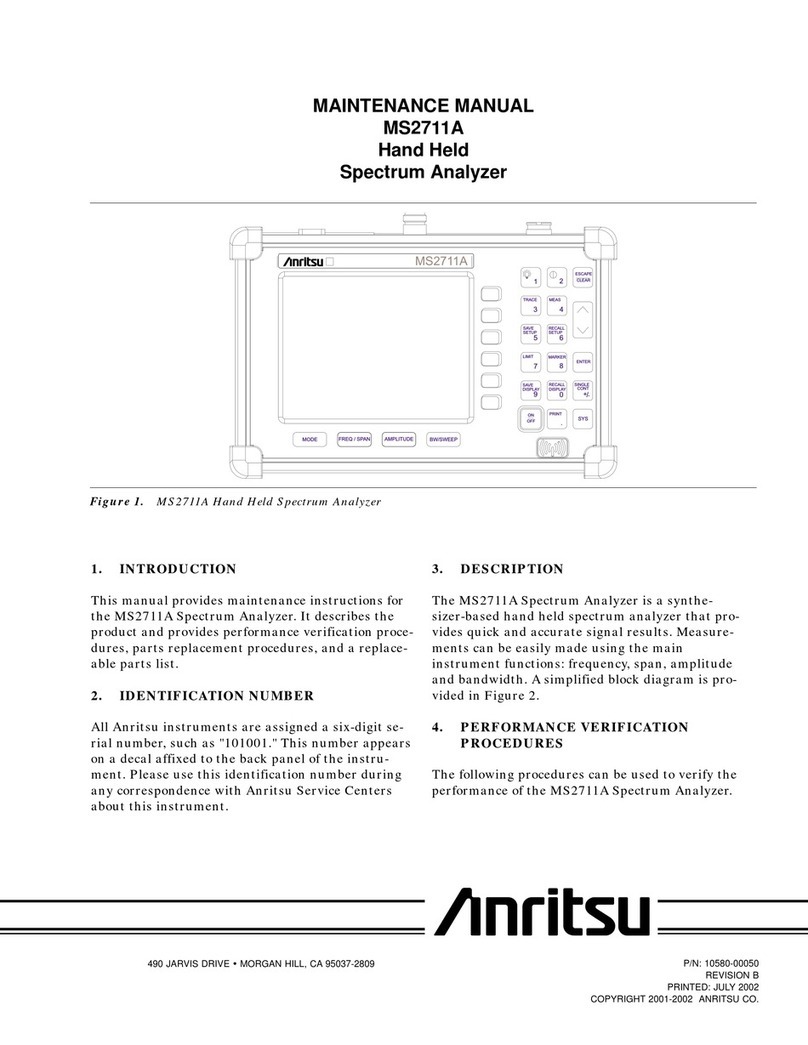

2.1

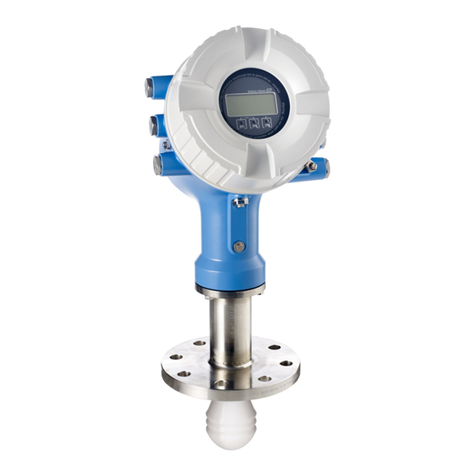

Instrument schematic .................................................................................. 5

2.2

Samplings schematic ..................................................................................... 6

3.0

Sampling system gas testing ............................................................................... 7

3.1

Features.................................................................................................... 7

3.1.1

4-20mA data line ...................................................................................... 7

3.1.2

emote Data access .................................................................................. 8

3.1.3

Solenoid Switching valves............................................................................ 8

3.1.4 Kiosk enclosure fan control ............................................................................ 8

3.1.5 Heated line ............................................................................................... 8

3.1.6 Automated Water Trap ................................................................................. 8

3.1.7 Coalescing Filter ......................................................................................... 8

3.1.8

Ancillary Control Box ................................................................................. 9

3.1.9 Nitrogen connection..................................................................................... 9

4.0

Cabinet Layout .............................................................................................. 10

4.1

Ventilation ................................................................................................ 12

4.2

Kiosk Images ............................................................................................. 13

4.3

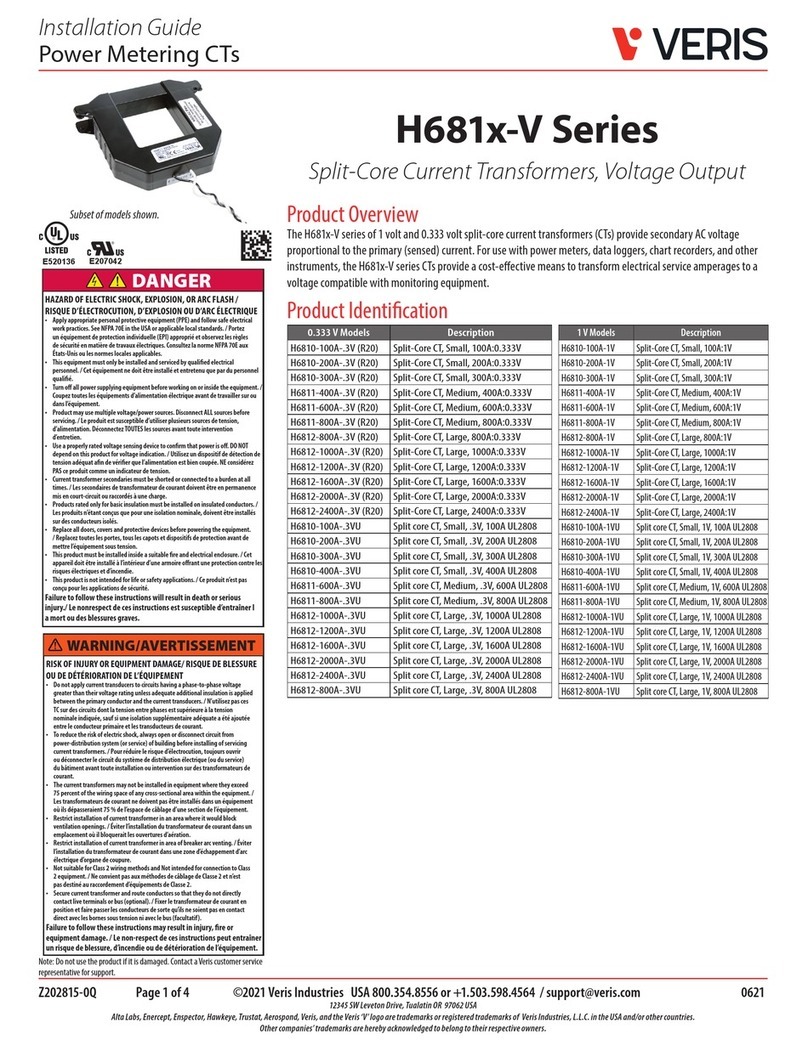

Instrument Connections ................................................................................ 14

4.3.1

Biogas Connection ................................................................................... 14

4.3.2

Nitrogen Connection ................................................................................ 14

4.3.3

Instrument Air Intake ................................................................................ 14

4.3.4

Instument air Exhaust ............................................................................... 14

4.3.5

Vent .................................................................................................... 14

4.3.6

Power ................................................................................................... 14

4.3.7

DataComms ............................................................................................ 15

4.3.8

Ancillary Box .......................................................................................... 16

4.4

Circuit Board Connector information ............................................................... 17

4.4.1 Main Silox PCB Layout ................................................................................. 17

4.4.2 MCU PCB .................................................................................................. 19

5.0 Operation ........................................................................................................ 20