STUCCHI ST1-C Instruction manual

MANUAL OF USE

ST1-C

Manualofuse

2

ST1-C

Manualofuse 3

ST1-C

CONFORMITY

DECLARATION FOR MACHINE

THEMANUFACTURER:

Stucchi Italia s.a.s.

Via Figino, 115

20016 PERO (Mi)

IT DECLARES THAT THE MACHINE OF NEW DESCRIBED CONSTRUCTION OF

CONTINUATION:

Type:.............................................................................

Model: ...........................................................................

Matriculation: ................................................................

Year of costruction: ......................................................

it is in compliance with essential requirement of:

DIRECTIVE MACHINE 98/37 CE, ATTACHED II, PART A, OF 98/06/22

he is consistent moreover to requirement previewed from:

LOW DIRECTIVE TENSION 73/23 OF 19/02/73

DIRECTIVE ELECTROMAGNETIC COMPATIBILITY 89/336 CE OF 89/05/03

The technical responsible

Stucchi Marino

The legal represented

Stucchi Sara

Manualofuse

4

ST1-C

Manualofuse 5

ST1-C

Index

DECLARATION OF CONFORMITY FOR MACHINE.......................... 3

1 PREMISED............................................................................................... 7

1.1 GeneralWarning................................................................................ 7

1.2 General Warning of Emergency ........................................................ 8

1.3 Conditions of emergency electrical worker....................................... 9

2 INFORMATION GENERAL ................................................................. 10

2.1 Applied Norm ................................................................................... 10

2.2 Identification Data ............................................................................. 10

2.3 Guarantee .......................................................................................... 11

2.4 Terms and symbols........................................................................... 11

3 PRELIMINARY INFORMATION OF THE MACHINE ................... 13

3.1 General Description .......................................................................... 13

3.2 Technical Data................................................................................... 15

3.3 Previewed use ................................................................................... 15

4 TRANSPORT AND INSTALLATION .................................................. 16

4.1 Transport ..........................................................................................

4.2 GeneralWarning................................................................................ 16

4.3 Environmentalconditions.................................................................. 16

4.4 Installation ......................................................................................... 17

4.5 Spaces operated................................................................................ 17

4.6 Connections and control................................................................... 17

4.7 Equipments ....................................................................................... 17

5 PREPARATION TO USE OF THE MACHINE.................................. 18

5.1 GeneralWarning................................................................................ 18

5.2 Description operation........................................................................ 18

5.3 Use of the tool .................................................................................. 19

Manualofuse

6

ST1-C

6 DIAGNOSTIC .......................................................................................... 20

6.1 Diagnostic and problems solution..................................................... 20

6.2 Substitution card electronic .............................................................. 21

6.4 Emptying container powder .............................................................. 21

6.5 Electric motor ................................................................................... 22

7 PUTTING OUTSIDE SERVICE AND DISMANTLING ................... 23

7.1 Indication for the putting otside service............................................ 23

7.2 Modifications .................................................................................... 23

Manualofuse 7

ST1-C

1. Premised

1.1 General Warning

To carefully read the instructions of use before using the machine in object.

This handbook must be considered integrating part of the machine and/or the system supplied

from Stucchi Italia s.a.s.

In case the same one does not come united delivered to the machine to/or system or goes lost, is

recommended to ask of a copy Stucchi Italia s.a.s. that will be activated in such sense in the short

possible time.

This handbook contains the norms of operation, ordinary maintenance, out of order extraordinary

maintenance/search and the directory of the replacement parts for the machine produced from

Stucchi Italia s.a.s.

In case difficulties of interpretation of the witnesses or the tables are met, or the designs/outlines

do not turn out enough clear, maintenance is prayed to contact Stucchi Italia s.a.s. company for

having all the clarifications through the experts of operation/or through the attache’s to the

compilation of the handbook.

Stucchi Italia s.a.s. is however to complete disposition of the operating, of the responsibles trades

them to of every other unit interested for one effective collaboration turns to improve the

understanding of the entire handbook.

Stucchi Italia s.a.s. will not think responsible of disadvantages, breaches, incidents whom had to

the lacked respect and/or application the indications brought back in the manual present.

The machine comes supplied wired and tested near our plant

To verify scrupulously before executing whichever working, than not are parts damaged of the

machine.

To use dispositive you of protection characterizes appropriates them to you in order to avoid

damages to the hearing in case the acoustic level exceeded the 85 dBA.

Themachine mustwork inatmospheresdidnotexplodetoyouandnot tofire danger;the verification

of these conditions remains to cargo of the customer.

The integrating handbook is part of the machine and must be read carefully before

completing whichever operation.

Manualofuse

8

ST1-C

During the job lend attention to the aim to avoid damages to persons or things.

The norms of emergency of the manual present integrate and they do not replace those enforced

ones.

On the handbook it comes indicated the date of press and the number of review.

It is recommended to record the manual present and its it encloses to you in place and way adapts

to you in order to guarantee integrity and the reperibilità for the staff assigned to the installation,

maintenance or repair.

For whichever repair of the machine, to address exclusively to the centers of technical

attendance authorizes to you.

The manual present must be conserved for all the duration of the machine.

The contained information in the manual present are subject to modification without

warning.

1.2 General warning of emergency

Whichever manipulation of the machine from part of the customer raises Stucchi Italia s.a.s from

every responsibility and renders the customer same only responsible towards the competent

organs for the prevention of the accidents.

Thedeepenedacquaintanceof the machine and itsoperation,frompart of the operating ones,are

guarantee of prevention of possible accidents.

Inorderto guarantee the respectofthe emergency conditionsitis necessary to followthefollowing

indications:

¾to control periodically all the accident-prevention devices and to assess themselves to you

that they are mount to you perfectly and working

¾the operating zone must be always maintained clears and cleaned up

¾before beginning the job, the operator must perfectly be to acquaintance of the position of the

push-buttons of start and arrest of the machine

¾the connections electrical workers must be carry out to you from qualified and authorized staff

¾to assess itself before the beginning of the job that not is situations of danger for persons and

things

¾not to never touch the emergency devices you

¾not to eliminate or to modify the emergency protections

¾it is prohibited to bring every type of modification to the machine

¾not to use the machine in presence and/or vicinity of children

¾not to allow that persons strangers (not assigned to the jobs), use the machine

¾one recommends the operator I use of dressed adapts it you to the atmosphere and to the

type of job to carry out

Manualofuse 9

ST1-C

¾it is prohibited the operator to wear chains, bracelets, clocks or any other object that has

tendency to entangle itself

¾during the working to use glances at them protected to you

¾not to inhale ignited cigarettes or matches

¾not to use the machine in order to inhale inflammable liquids

¾to maintain the free openings from powder, rags, hats or whichever thing can reduce the

aspiration flow

¾during the workings to always maintain to a good equilibrium avoiding positions malsicure

¾to always block the piece to work using adequate pliers or vices.

The use of accessories and/or not consistent tools to a corrected use of the machine and

however for various scopes from those recommends to you in the manual present can involve

the risk of accidents. To always use the tool adapted to the workings that agree to execute. To

always maintain the tool in efficiency conditions

1.3 Conditions of emergency electrical worker

During the use of the machine to follow ALWAYS the following basic precautions:

¾to carefully read the instructions before using the machine

¾lend attention to the aim to reduce risks of folgorazione or damages to the persons

¾not to inhale liquids

¾not to use the machine if the cable or the taken electrical worker is damages to you

¾to always detach the feeding thorn electrical worker before the maintenance operation

¾to detach the feeding thorn when the machine is not in use

¾to extinguish the general switch before detaching the feeding thorn

¾not to put hand the system electrical worker

¾to assess that the voltage of the line tension corresponds to that one of the machine

¾toremovefeeding electricalworkerand todetach thefeedingthorn beforewhicheveroperation

of maintenance on the machine.

Manualofuse

10

ST1-C

2. General information

2.1 Applied norm

Themachinehasbeen planned and constructedincompliancewith the Directive Machine89/392/

CE, like modified and to the national legislation that transposes it.

Theparts/clausesof harmonized normsobservedforthe planning andconstructionof the machine

in listed object are of continuation.

EN 292-1 Emergency of the machinery - fundamental Concepts; part 1ª.

EN 292-2 Emergency of the machinery - fundamental Concepts; part 2ª.

EN 60204-1 Emergency of the machinery - Equipment electrical worker of blots some.

89/392/CEE Directive blots some.

2.2 Identification Data

Costructor ...................................................................................................... Stucchi Italia s.a.s

Adress:....................................................................................................................Via Figino 115

20016 PERO - Milano - ITALIA

Tel. ++ 39 02 38204162 Fax ++39 02 38205347

E-mail: [email protected]

Machine :............................................................IT ARRANGES of POLISHING andASPIRATION

Model: ..................................................................................................................................ST1-C

MatriculationNr.:.............................................................................................................................

Construction year :..........................................................................................................................

Manualofuse 11

ST1-C

2.3 Guarantee

To verify, to the action of the delivery, than the machine and eventual melted accessories, they

have not endured damages which had to the transport or the manipulation.

Eventual claims will have to be forward to you for enrolled to Stucchi Italia s.a.s within 8 (eight)

days from the reception date, enclosing copy of signed documents of delivery from the attache’ to

the transport.

The machine is guaranteed for a period of 24 (twenty four) months.

To exception of the parts subject to usury.

2.4 Terms and symbols

In the manual present they are uses running terms you in the industrial within which the machine

is turned; for greater clarity we give of continuation a list of terms whose wrong meant it could

induce in confusion the persons who could come to direct or indirect contact with the machine.

OPERATOR: person/and people in charge to install, to use, to regulate, to clean up, to execute

maintenance or repairs on the machine.

QUALIFIED STAFF: person/and that “they have understood” the machine and the operations of

use, maintenance and repair; they must be moreover to acquaintance of the tasks and the rules to

which adhering itself.

In the handbook to rerun to the use of the word DANGER,ATTENTION, WARNING in order to

mean the gravity of the consequences of one eventual inosservanza of the prescribed norms.

! DANGER

Thissymbolwillcome used in the handbookwhensituationsare signaled of upgrade themdanger

that, if not avoided, CAUSE to the DEAD Or SERIOUS ACCIDENTS FOR the OPERATOR,

OPERATING Or the OTHER PERSONS

! ATTENTION

This symbol will come used in the handbook when situations are signaled of upgrade them

danger that, if not avoided, CAN CAUSE to LIGHT LESIONS Or MATERIALDAMAGES FOR the

OPERATOR, OPERATING Or the OTHER PERSONS

!

Manualofuse

12

ST1-C

! Avvertimento

WARNING

This symbol will come used in the handbook when situations are signaled of upgrade them

danger that, if not avoided, CAN CAUSEACCIDENTS FOR the OPERATOR, OPERATING Or

the OTHER PERSONS.

In order to draw the attention on some important points of the handbook that, if does not observe

to you, they can carry damages to the machine, the dicitura will be used: “IMPORTANT”.

Manualofuse 13

ST1-C

3. Preliminary information of

the machine

3.1 General description

ST1-C is a complete on wheels system for roughing, finish and polishing with aspiration, of

manufactured article industrial.

It can be used also like professional exhaust fan with cleaning automatic of the filters.

Support

Powder

container

Suction

opening

Automatic socket

220V 50/60Hz

Regolatoraspiration

Pushbutton

AutomaticManual

Additionalpush-button

filterscleaning

Lubricatedair automatic

Manualofuse

14

ST1-C

UNDERCARRIAGE

Constructed in sturdy structure of it outlines you of steel has the function to support all the parts

that constitute the machine.

A series of revolving wheels, opportunely determine the proportions, allows the movement of all

the system.

LEAKING GROUP

It finds itself to the inside of the structure of the machine, has the function to filter the air previously

inhaled through the tool; a system automatic of cleaning allows to obtain one constant and high

aspiration.

The aspiration power is adjustable through a grip handle on the forehead of the machine.

The machine is equipped of a air tank that allows the operation of the pneumatic system of

pulizia filters without that the same one is connected to the net of the air, with an autonomy

of approximately 20 hours of operation of the aspiration.

The loading of the tank happens through attack place in proximity of the current taken one.

POWDER CONTAINER

It collects powders from the leaking group; a system closing express allows to an express taking

apart of the same one for the emptying.

ELETTRONIC CARD

It commands to all the functions of the machine.

Easy accessibility and substitution render the maintenance operations extremely simple and fast.

! Attention

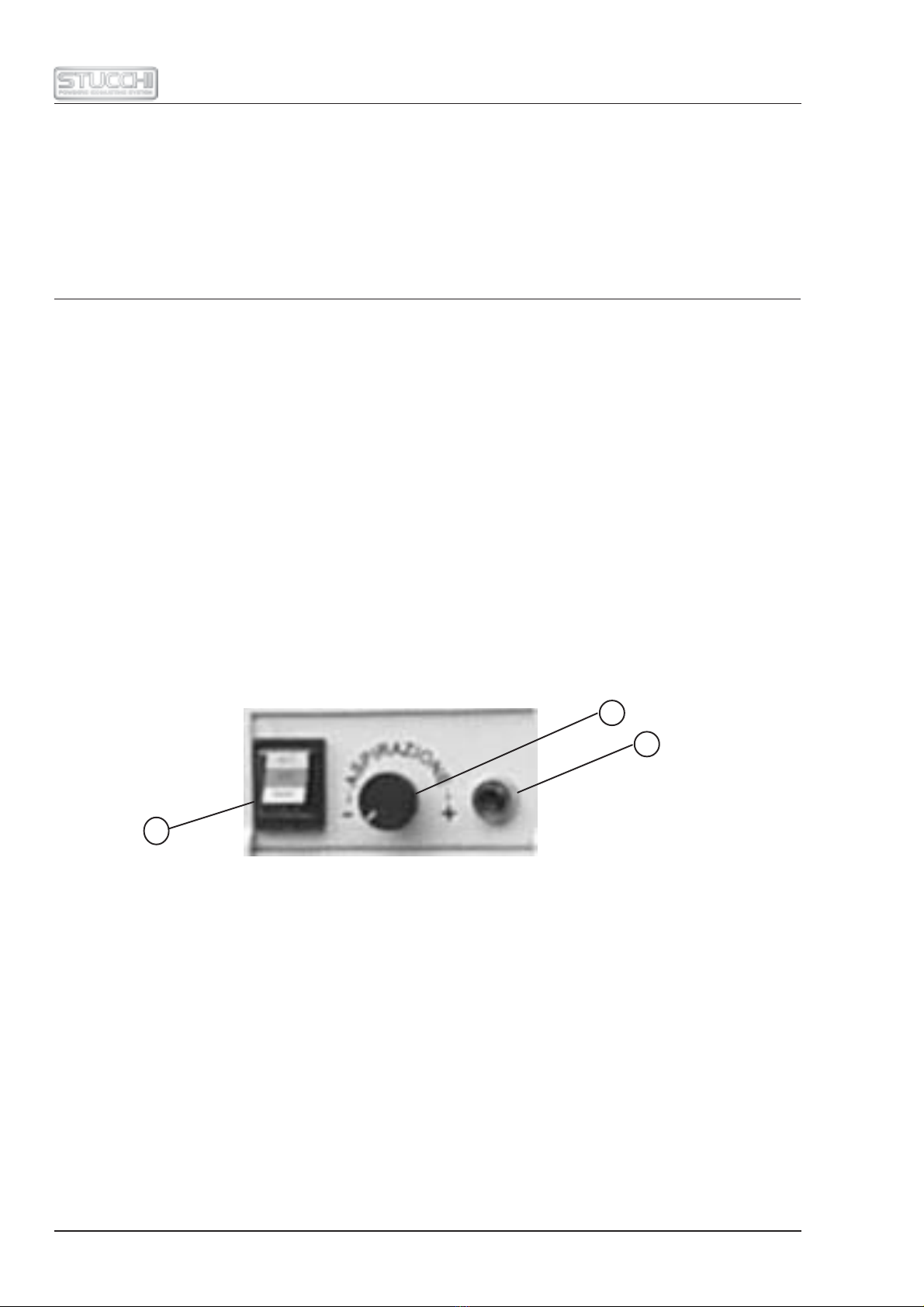

To verify that the pression is always between 2 and 8 bar.

Pressure

gauge

Loads

compressed

air

Feeding

compressed

air

Manualofuse 15

ST1-C

3.2 Technical data

TECHNICAL CHARACTERISTICS

Width (mm) ............................................................................................................. 450

Length(mm) ............................................................................................................. 450

Height (mm)............................................................................................................. 800

Discharge (m3/h)...................................................................................................... 150

Noise (dBA) ............................................................................................................. 70

Volume of aspiration (m3/h)...................................................................................... 120

Depression of aspiration (Mbar).............................................................................. 210

Pressure air feeding (bar)........................................................................................ 8

Turbine of aspiration with starter autometic (W) ...................................................... 1200

Weight (Kg. ca.)...................................................................................................... 30

ELECTRICAL FEED

Feed voltage (V) ...................................................................................................... 220

Pulsantingvoltage(V) .............................................................................................. 12

Frequency (Hz) ........................................................................................................ 50/60

Aspiration motor (Watt) ............................................................................................ 1200

Degree of protection (IP).......................................................................................... 54

3.3 Previewed use

The called machine “ST1-C”, object of this handbook, is planned for:

- To inhale mixed air to powders produced from tools I abraded to you during the working on

superficial painted or puttied.

- To filter inhaled air separating the heavy parts.

- To give back to the ambient filtered air.

- Ignition and extinction with manual push-button

- To be activated/ not activated automatically from the activation/not activation of the tool.

- It concurs a simple elimination of filtered powders.

800

450 450

Manualofuse

16

ST1-C

4. Transport and Installation

4.1 Transport

The machines come dispatch packed.

The transport must be carried out with suitable means, fixing adequately the machine.

The movement must be carried out with transpallet.

Being the endowed machine of wheels, the final positioning is carried out manually.

In the storage case, to put the machine in a repaired place and to avoid to overlap cargos that

could damage in not repairable way the same machine.

4.2 General warning

The spaces operated must rigorously be respect to you in order not to cause to danger to persons

or things to you.

The connections must be are followed from staff qualified and authorized scrupulously following

the indications of the specific paragraph.

4.3 Environmental conditions

The machine is destined to operate in industrial atmospheres.

The environmental conditions advised, are the following:

Temperature:................................................. 5÷45 °C.

Relative humidity:......................................... 0¸90 %.

Manualofuse 17

ST1-C

4.4 Installation

The machine does not need of installation.

4.5 Spaces operated

The emplacement of job and the spaces operated to you necessary to the workings to carry out

with the machine, are identifiable from the following outline.

In any case the flexible tree must be used with a minimal beam of the curving of 300 milimeter.

4.6 Connections and controls

The connections must be are followed from staff qualified and authorized following the

indications of the table.

1 - It connect to the net

4.7 Equipments

The machine comes delivered completes of the tools necessary to carry out the operations like

demands.

Presa 220 V

Manualofuse

18

ST1-C

5. Preparation to use of the

machine

5.1 General warning

Before to use the machine for the first time, to read the instructions.

5.2 Description operation

All the controls are positioning on the front of the machine.

1) switch to three positions AUT-OFF MAN

POSITION OFF - The machine is OFF

POSITION AUT - The aspirator works with the automatic’s system

POSITION MAN - The aspirator works with the manual’s system

2) SUCTION REGULATOR

If you rotate the grip handle in hour sense, the aspiration increases, while in the inverse

sense it diminishes.

3) push button for additional filter cleaning

to press the push-button you make another filter cleaning beyond that automatic one.

2

1

3

Manualofuse 19

ST1-C

5.3 Use of the tool

The machine is planned for the simultaneous operation of the system of aspiration and electric

and pneumatic tool’s.

For to put the march you must do to insert the thorn in the socket, if you work whit an electric

tool you must do to insert the tool’s thorn in the provided socket gived on the machinery’s face,

you must do to put the button on the “AUT” so the aspiration is automaticly actives when you

start up the tool.

If you work whit pneumatic tool you must to connect the tablet air in the entrance behind of the

machinery.

For to arrest the machinery is simple,you must to switch off the tool.

Advice for tool’s utilize:

You must start up the tool and you must to controle that the tool hasn’t contact whit the surface.

Manualofuse

20

ST1-C

6. Diagnostic

6.1 Diagnostic and problems solutions

The more recurrent defects and their elimination are evidence to you from the following table

DEFECTS POSSIBLECAUSE POSSIBLE SOLUTION

The machine does not go net not connected to connect to net to the terminal

controlpanel

lack line tension toverifygeneral panel and

eventualexisting protections

tension of line not corrected to connect correctly

Insufficient aspiration accumulate powders in the cont.emptythe container

Table of contents