Stucki HS-7-100 User manual

A. Stucki Company

2600 Neville Road, Pittsburgh, PA 15225

Phone 412.770.7300, Fax 412.771.7308

08072 www.stucki.com Revision 001, 6/12/2007

INSTALLATION INSTRUCTIONS FOR STUCKI®HS-7-100 HYDRAULIC

STABILIZERS

I. INTRODUCTION

The Stuck HS-7-100 stabilizer is a single-acting hydraulic damper that

fits into the freight car spring nest and operates as the truck springs

are compressed. One unit is installed in each spring group in the

space normally occupied by the center position truck spring when

applied with a typical D-5 spring group. This stabilizer is designed to

function only under a loaded car condition, no damping occurs when

the car is empty.

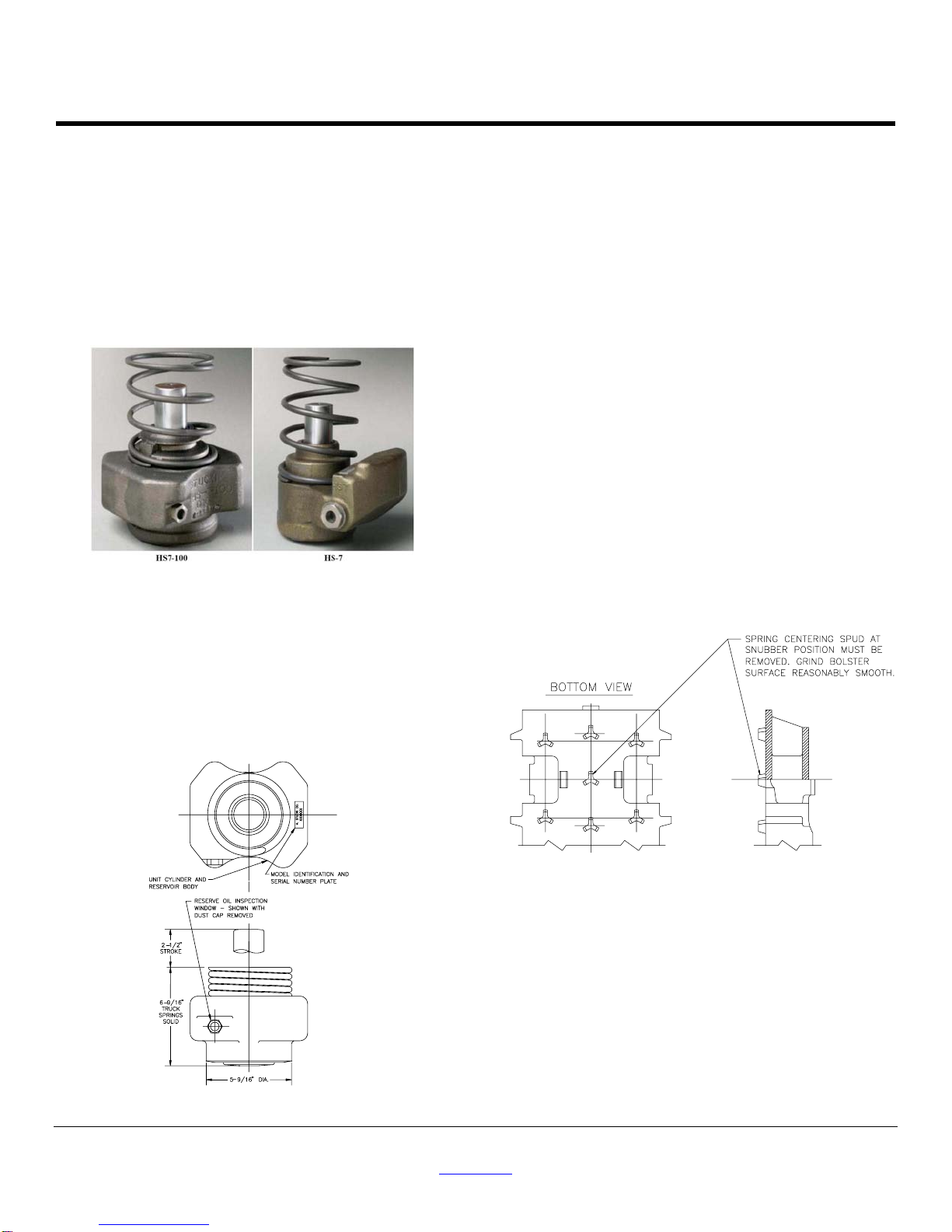

The Stucki HS-7-100 center position unit should not be confused with

the Stucki HS-7, which is designed to fit in an outboard spring position

only. Figure 1 clearly illustrates the distinctive features of each unit.

Note particularly that the body springs are not interchangeable

between the two models.

Figure 1. Comparison of HS-7-100 (left) & HS-7 (right)

Standard HS-7-100's are designed for use on 100-ton freight cars.

They can be used with either D-5 or D-7 truck spring groups. Units

having damping characteristics suitable for 70-ton cars are designated

as HS-7-100-B's.

The model is identified on the unit serial number tag as shown in

Figure 2. Whenever a Stucki stabilizer is to be replaced, it is important

that it be replaced by a unit of equal capacity rating. Factory rebuilt

units will have the letters “RB” and the date they were rebuilt stamped

on the model identification tag.

Figure 2. HS-7-100 Identification

II. STORAGE PRECAUTIONS

Each HS-7-100 stabilizer is packaged in a manner that under normal

circumstances will prevent corrosion of the piston rod while in storage.

Units should not be stored outdoors any longer than necessary.

Incoming stock should be rotated, and units held in long-term storage

should be protected from moisture. Units which have been stored for

long periods should be inspected for any signs of rust on the chrome

surface of the piston rods before using.

III. SPRING GROUPS

For optimum performance the HS-7-100 must be applied with the

proper combination of truck springs. A. Stucki company's general

HS-7-100 truck arrangement drawings list recommended groups for

conventional applications. In special cases where cars are to be used

in assigned service for loads which will consistently be significantly

greater or less than their rated capacity, Stucki Company should be

contacted for a compatible spring group recommendation.

When stabilizers are applied on a retrofit basis to older cars the

existing truck springs if re-used, should be load or height checked

according to AAR Specifications.

IV.INSTALLATION OF THE HS-7-100 INTO TRUCK

Figure 4 shows an HS-7-100 in a conventional combination type

7-position spring nest. Note how the stabilizer reservoir utilizes the

free space between the center spring position and the side coil

positions. With some rare exceptions (which should be approved by A.

Stucki Company), this is the only spring arrangement that permits the

use of the HS-7-100.

In most cases installation of the HS-7-100 requires no modification of

the truck bolster or side frame. However, some Barber or S-2 type

bolsters will have a spring centering boss at the center position which

must be removed as indicated in Figure 3.

Figure 3. Removal of Spring Centering Spud

Once the installer has checked that there are no projections on the

side frame or bolster that will interfere with the flush seating of the

stabilizer, the unit can be placed into position as follows:

1. Install all but outboard row of truck springs in their respective

positions (see "spring groups").

2. Remove HS-7-100 from shipping bag and remove cardboard

sleeve from the piston rod (in all cases where unit exchange is

being made, sleeve should be installed over piston rod of unit

being removed from car, to protect it during shipping).

3. Place body spring on unit as illustrated in Figure 1.

4. Position unit, piston rod up, in truck as illustrated in Figure 4.

Make certain sight window is facing outward (toward installer).

5. Install remaining truck springs

A. Stucki Company

2600 Neville Road, Pittsburgh, PA 15225

Phone 412.770.7300, Fax 412.771.7308

08072 www.stucki.com Revision 001, 6/12/2007

V. REMOVAL / REPLACEMENT OF HS-7-100

If it becomes necessary to remove and replace an HS-7-100 see

Section VI: Field Inspection of the HS-7-100. The unit can be easily

removed after removing the two outboard truck springs, and the

replacement unit installed in its place. Please note that units removed

due to a low reserve oil level condition can be returned to A. Stucki

Company to be rebuilt. It is advisable to mark on the returned unit the

car number and date removed if warranty credit is applicable. It is also

important that the cardboard sleeve taken from the piston rod of the

new unit be placed on the rod of the used unit to protect it from

damage during shipping.

If units are being removed and returned to A. Stucki Company as part

of a normal rebuild cycle, the body springs may be re-used but should

be checked for wear or damage.

*Note that the damping characteristics of the Stucki HS-7-100 are

identical to those of the HS-7 and its predecessor, the Stucki HS-6,

within a given capacity rating. Thus, on the basis of performance they

are interchangeable. However, the installer must insure that the

retention requirements specified in the installation instructions for the

particular design are fulfilled. Also, to alleviate future logistics

problems, it is advisable not to mix various models on a given car.

VI.FIELD INSPECTION OF THE HS-7-100

The HS-7-100 incorporates a low pressure seal on the piston rod

which characteristically will pass slight amounts of oil under normal

operating conditions. This oil will gradually accumulate on the body of

the unit and on the side frame spring seat, and will attract considerable

dirt. A dirty, oily appearance does not in itself constitute a defective

unit. Lost fluid is compensated for by reserve oil in the unit which

comprises about 45 percent of the total oil volume of 1350ml (46

ounces). The availability of reserve oil can be checked by visual

inspection of the oil level sight glass on the reservoir (see Figure 2).

The gage consists of a plug with a glass window, located such that the

presence of oil in the window is an indication of a functioning unit.

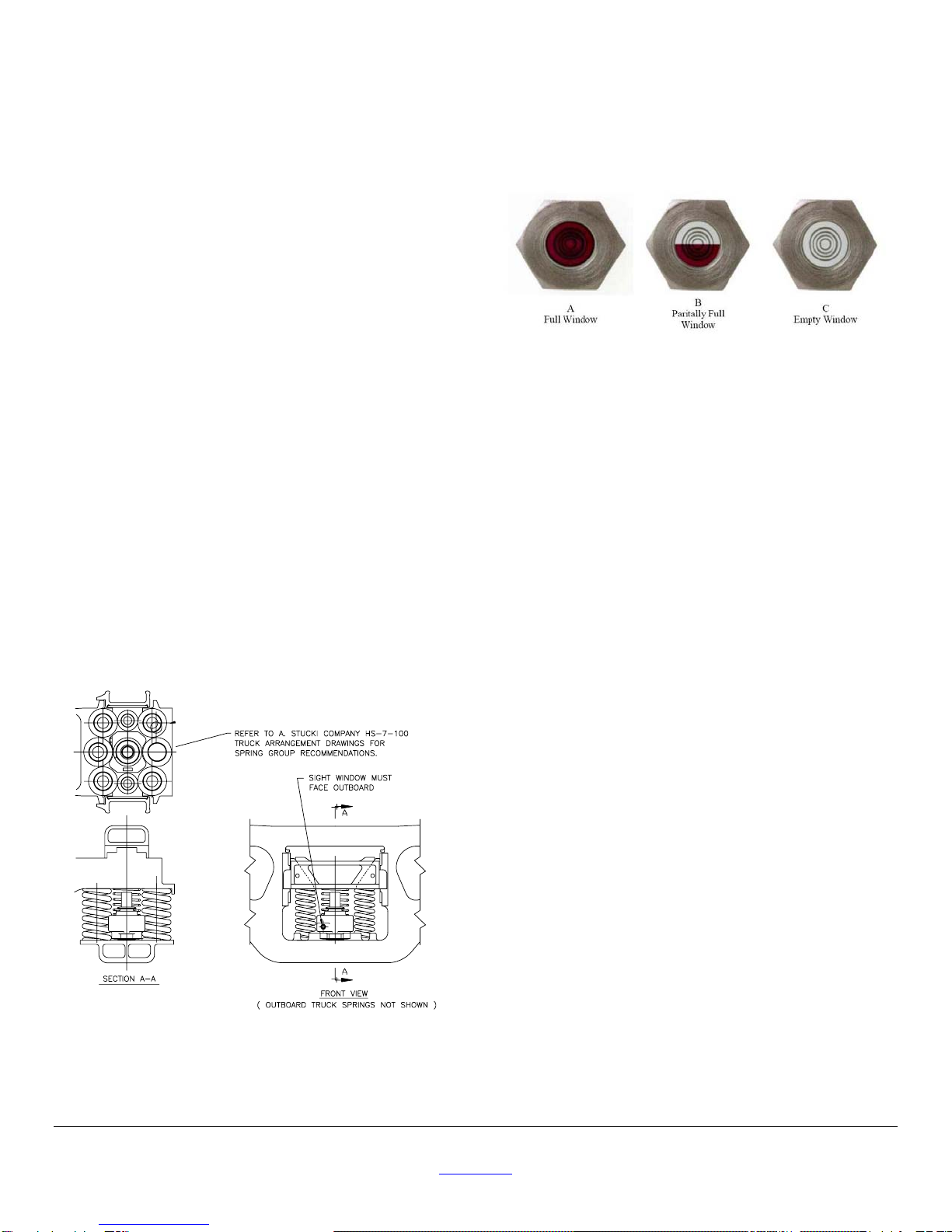

Figure 5 illustrates the conditions that can be encountered on visual

inspection of the sight glass. When the oil level is above the window,

the entire glass area will appear dark, as in illustration "A". Once the

oil level has dropped into the window area as in "B", the portion of two

rings on the inside of the glass above the oil level will reflect light back

to the viewer and appear shiny as shown. When the oil level recedes

below the window, these "shiny" rings will be totally visible as complete

circles as in "B".

Figure 4. Arrangement of HS-7-100

in Conventional Freight Car Truck

When inspecting the sight glass, the unit must be sitting in its normal

operating, upright position.

If the inspection of the oil level sight glass reveals condition "C" the unit

should be scheduled for replacement as soon as practical and returned

to A. Stucki Company to be rebuild. When the oil level is in the window

area, as in "B", the unit should be scheduled for replacement when the

car is next shopped. As long as the window shows full, as in "A", the

unit should be left in service, regardless of any external oil sludge

accumulation.

We strongly recommend units not be opened for refilling in the field.

This can lead to dirt contamination or overfilling with excess oil. Either

condition will result in damage to the seal and so will void the warranty.

Figure 5. Oil Level Sight Glass Conditions