STULZ Ultra-Series Humidifier Controller

(April 2013) i

Table of Contents

1.0

GENERAL INFORMATION........................1

1.1

Forward ......................................................1

1.2

Safety Summary.........................................1

1.3

Warnings & Cautions .................................1

1.4

Product Warranty .......................................2

2.0

DESCRIPTION........................................... 3

2.1

General.......................................................3

2.2

Features .....................................................3

BMS Interface............................................. 3

2.2.1

Field Configurable ......................................3

2.2.2

Password Protection ..................................3

2.2.3

Timed Drain Cycle...................................... 4

2.2.4

Restorable Set Points ................................4

2.2.5

2.3

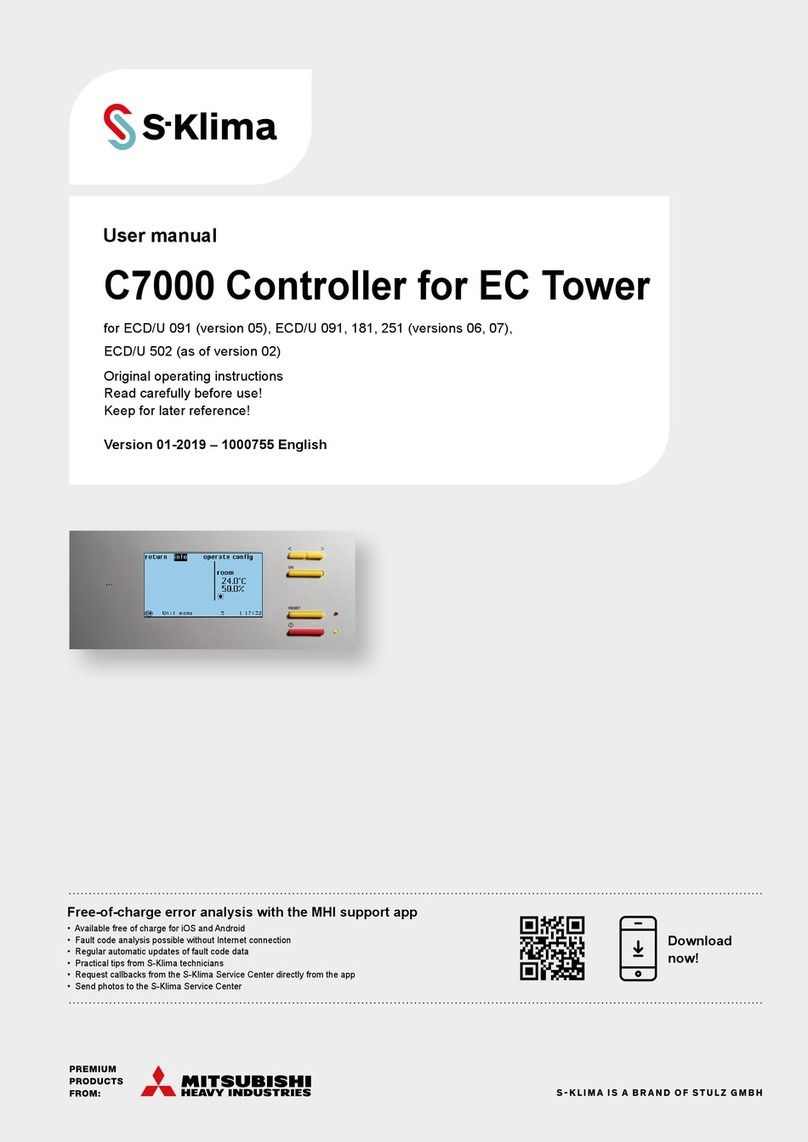

User Interface Display Panel......................4

Function Keys............................................. 4

2.3.1

Alarms ........................................................4

2.3.2

2.4

Controller Nomenclature ............................5

2.5

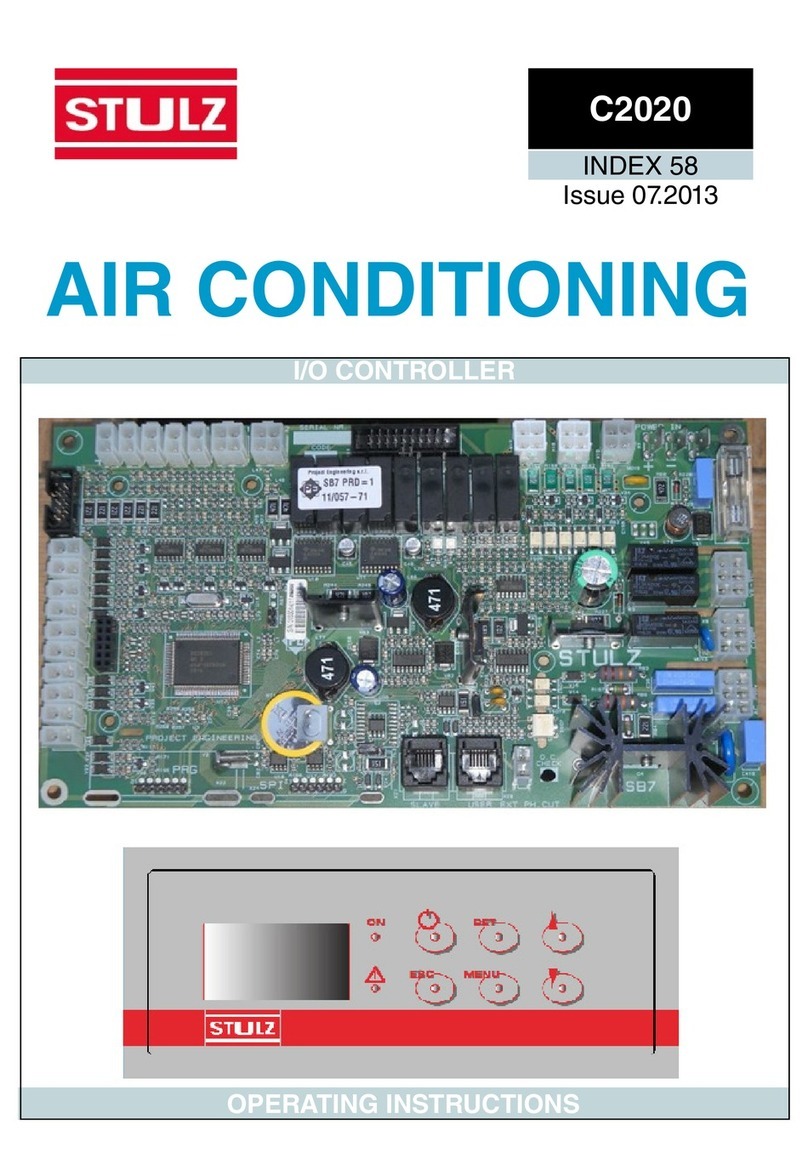

Controller I/O Module .................................6

Controller I/O Module Layout .....................6

2.5.1

2.6

Auxiliary Terminals.....................................6

Control Sensors..........................................6

2.6.1

Alarm Contacts........................................... 6

2.6.2

Water Conductivity Probe .......................... 7

2.6.3

Air Velocity Sensor..................................... 7

2.6.4

Air Proving Switch ...................................... 7

2.6.5

Water Leak Detector .................................. 7

2.6.6

Remote On/Off ...........................................7

2.6.7

Multiple Humidifier Grouping...................... 7

2.6.8

BMS Operation........................................... 8

2.6.9

3.0

INSTALLATION.......................................... 9

3.1

Uncrating and Inspection ...........................9

3.2

Mounting.....................................................9

3.3

Wiring Connections ....................................9

AC Input .....................................................9

3.3.1

DC Output to Humidifier(s)......................... 9

3.3.2

Control Wiring to Humidifiers .....................9

3.3.3

Sensors .................................................... 10

3.3.4

Water Conductivity Probe ........................ 10

3.3.5

Remote On/Off .........................................11

3.3.6

Remote Alarm Signal Contacts ................ 11

3.3.7

Water Leak Detector ................................ 11

3.3.8

4.0

OPERATION ............................................12

4.1

General Theory of Operation ...................12

Humidification Control .............................. 12

4.1.1

Operating Modes......................................12

4.1.2

P/I- Proportional/Integral Control.............. 13

4.1.3

4.2

Navigating Controller Screens .................14

Menu Selection......................................... 14

4.2.1

Menu Loops..............................................14

4.2.2

4.3

Password Authorization ...........................16

Password Protected Screens...................16

4.3.1

Wrong Password ......................................16

4.3.2

Setting the Passwords..............................16

4.3.3

4.4

Start-up / Commissioning.........................17

Main Info Screen ......................................18

4.4.1

Saving & Restoring Set points .................18

4.4.2

4.5

Controller Features...................................18

Alarms ......................................................18

4.5.1

Remote On/Off .........................................19

4.5.2

Automatic Drain Cycle..............................19

4.5.3

Manual Drain ............................................19

4.5.4

Communication with the Controller ..........20

4.5.5

Loading New Software .............................20

4.5.6

5.0

MENU SCREENS ....................................21

5.1

Main Menu................................................21

5.2

Information Menu .....................................21

Main Info Screen ......................................21

5.2.1

Control Sensor .........................................22

5.2.2

Limit Sensor ............................................. 22

5.2.3

Conductivity..............................................22

5.2.4

Control Points...........................................22

5.2.5

Cabinet Temperature ...............................22

5.2.6

NTC Temperature Sensors ......................22

5.2.7

Air Speed (optional)..................................23

5.2.8

Humidifier Information (Loop)...................23

5.2.9

About Screen............................................23

5.2.10

5.3

Alarm Log .................................................23

Alarms ......................................................24

5.3.1

Non-Critical Alarms ..................................24

5.3.2

Critical Alarms ..........................................24

5.3.3

Alarm Screen Messages ..........................25

5.3.4

5.4

Control Menu............................................26

Set Point Screens..................................... 26

5.4.1

Alarm Set Point Screens ..........................27

5.4.2

(August, 2013)