3

Contents

1. Information on this document ............................................................................................... 4

1.1 Scope ................................................................................................................................................4

1.2 Other applicable documents ..............................................................................................................4

2. Presentation of the control system ....................................................................................... 5

3. Hardware components ........................................................................................................... 6

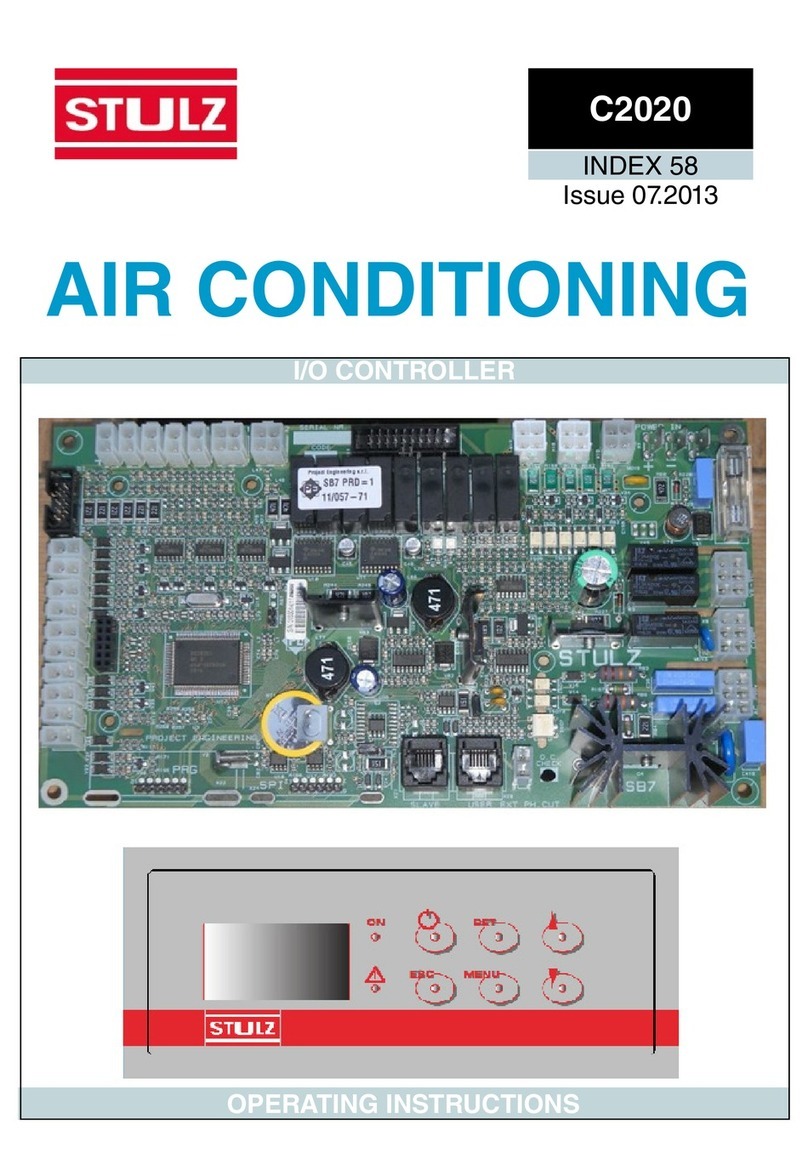

3.1 I/O controller (C7000 IOC) ................................................................................................................6

3.1.1 PIN assignment - I/O controller .................................................................................................................. 7

3.2 EDIO -Expansion card for digital inputs and outputs .........................................................................8

3.3 EBUS expansion board for RS485 bus ...........................................................................................10

3.4 C7000 Advanced - Terminal (C7000AT) ..........................................................................................11

3.5 Driver module ..................................................................................................................................12

4. C7000 Advanced user interface .......................................................................................... 13

4.1 Operational controls ........................................................................................................................13

5. Controller start ...................................................................................................................... 14

6. Info menus ............................................................................................................................. 18

6.1. Info and Operate menus of the operation interface C7000AT .........................................................18

7. Configuration ........................................................................................................................ 23

7.1 Values ..............................................................................................................................................23

7.2 Components ....................................................................................................................................29

7.2.1 Refrigerant circuit, standard ..................................................................................................................... 29

7.2.2 Air circuit, internal standard components ................................................................................................. 34

7.2.3 Air circuit, internal components ................................................................................................................ 39

7.2.4 Air circuit, external optional components ................................................................................................. 42

7.2.5 Sensors .................................................................................................................................................... 42

7.2.6 Contacts ................................................................................................................................................... 44

7.3 Statistics ..........................................................................................................................................45

8. Special operating modes ..................................................................................................... 47

8.1 Week program .................................................................................................................................47

8.2 Zone control ....................................................................................................................................48

8.2.1 Sequencing .............................................................................................................................................. 51

8.3 Manual mode ...................................................................................................................................55

8.4 UPS operation .................................................................................................................................55

9. Bus communication on the EC tower ................................................................................. 56

9.1 System examples with the C7000 Advanced ..................................................................................56

9.2 Bus set-up .......................................................................................................................................57

9.2.1 General .................................................................................................................................................... 57

9.2.2 Setting up an IO bus ................................................................................................................................ 57

9.2.3 Manual preparations ................................................................................................................................ 58

9.2.4 Adjusting the bus addresses .................................................................................................................... 58

9.2.5 Bus overview ............................................................................................................................................ 59

9.2.6 Special cases ........................................................................................................................................... 60

10. Basic settings ..................................................................................................................... 62

10.1 Load basic settings for the EC tower .............................................................................................69

10.1.1 Basic settings of size 1 and 2 ................................................................................................................. 69

10.1.2 Basic settings of size 3 ........................................................................................................................... 69

11. Alarm treatment .................................................................................................................. 70

11.1 Event log ........................................................................................................................................70

11.2 Alarm configuration .......................................................................................................................70

11.3 Alarm reset ....................................................................................................................................70

11.4 Alarm texts ....................................................................................................................................72

12. Menu structure of the main menu for operating the EC tower ....................................... 74

12.1 Menu structure of the Info main menu ...........................................................................................74

12.2 Menu structure of the Operate main menu ....................................................................................76

12.3 Menu structure of the Config main menu ......................................................................................78

BA C7000 for EC Tower | EN | 01-2019 | 1000755