―2 ―

4. PRECAUTIONS FOR INSTALLATION

3. TOOLS REQUIRED

PHILLIPS SCREWDRIVER

FLAT BLADE SCREWDRIVER

10mm,14mm SOCKET WRENCH

PLIERS

φ24mm (15/16") HOLE SAW

φ3.5mm (1/8") DRILL

VOLT METER (or CIRCUIT TESTER)

SIDE CUTTERS

SCISSORS

UTILITY KNIFE

CENTER PUNCH

CHALK

MASKING TAPE

ELECTRICAL TAPE

TRIM REMOVAL TOOL

ISOPROPYL ALCOHOL

CLEANING TOWEL

CAUTION

Please follow the Instructions for your safety.

If these Instructions are not followed. Personal injury.

Vehicle damage or degraded performance of the 110V Outlet may result.

CAUTION

Always perform installation in a building or a room.

Venlilate air to avoid exhaust gas-filled almosphere

when checking aclivalion.

Make sure to fully ungage and connect all wire plugs &

receptacles and connectors to their individual mating

parts. Use screws or other similar fasteners to secure all

lead wire terminals in order to prevent connection failure

and/or looseness caused by vibration or oscillation.

To prevent potential damage to your vehicle during

installation, use reasonable protective covers to cover

the passenger compartment and body surface around

the engine.

Use a proper tool of correct size to tighten bolts and nuts.

Fully tighten bolts and nuts with specified tightening

torque as required. Inobservance of this instruction will

cause a potential risk of damage to bolts and nuts or.

Remove the negative battery terminal before start of

wiring work. With the battery kept connected, wiring

work will lead to a potential risk of failure or of electric

shock or inlury due to short circuit.

Do not apply an excessive force to pull off a vehicle

wire harness, to prevent loose connectors,

disconnection and/or damage.

Check that all electrical systems of your vehicle are

properly operative. Back up all memories of a radio and

other electrical systems, to avoid any possible loss

during recovery checks after installation.

When installing parts and/or removed finishers, avoid

dragging or pinching wires in order to prevent

a potential risk of accident, electric shock or fire due to

disconnection and/or short circuit.

Use appropriate cleaner or mild detergent to remove

all dirt and old grease before attaching one-sided and/or

double-sided tapes during installation. Tapes applied

onto an unclean area cannot demonstrato desirable.

If the vehicle body needs to be drilled for installation,

check the positions of pipings, tanks and electrical

wirings before drilling and avoid any interference or

contact with them.

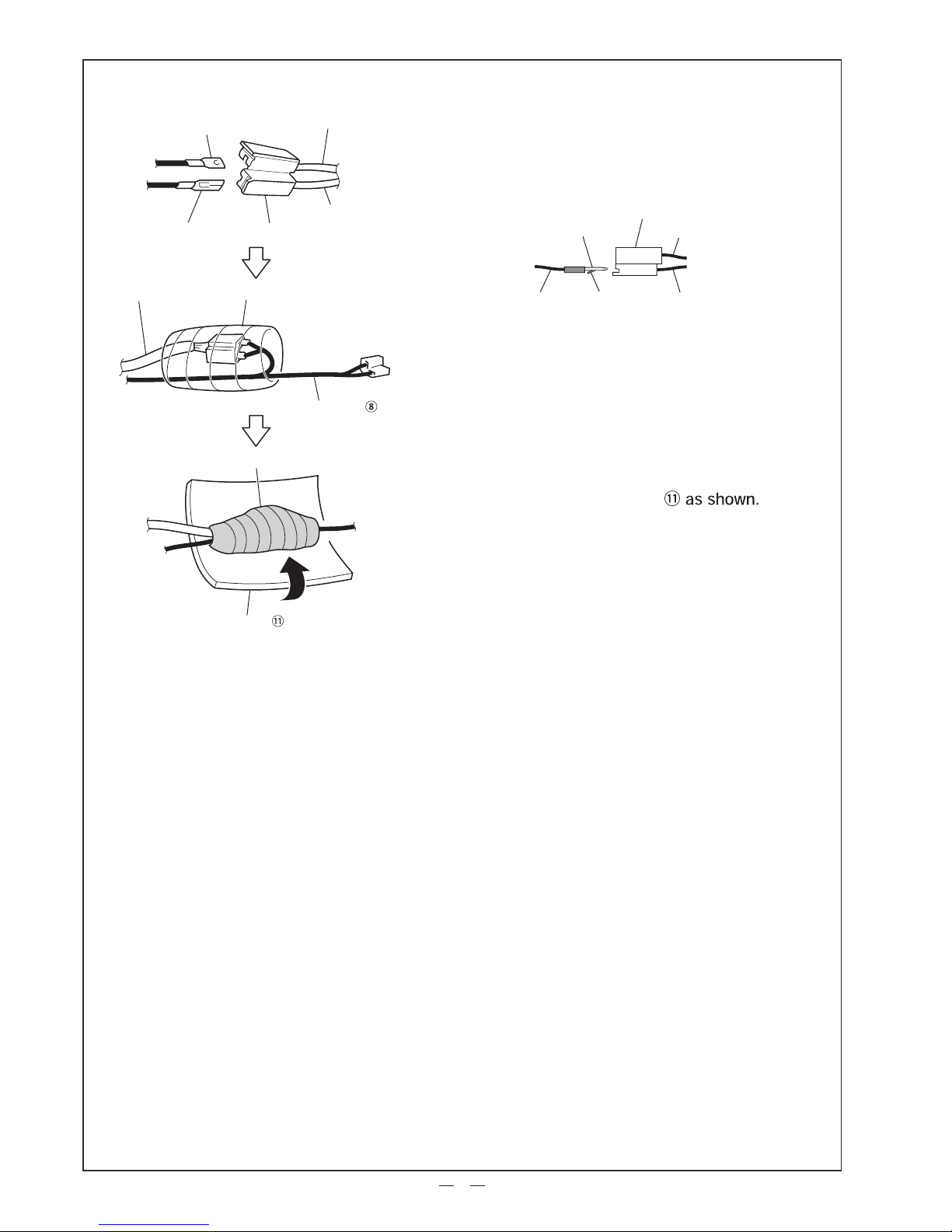

When harnessing,follow all instructions provided in the

Installation Instruction. Use reasonable bands or other

similar materials to tack and secure wiring to prevent

entrapment into the steering, shift lever and/or brake

pedal.

After removing clips and screws from your vehicle,

sort them by individual components for subsequent

reinstallation work to prevent use of wrong clips and

screws.Use of wrong clips and screws will cause

looseness and coming-off.

After harnessing, check activations of all parts installed

before recovery, to prevent wrong wiring.

When disconnecting vehicle connectors, hold

connectors (do not hold lead wires) to unlock them,

to prevent disconnection in lead wires.

To secure an optional GND terminal together with a

vehicle GND terminal, fasten them in a correct order

(bolt → vehicle GND → optional GND → body panel).

Option

Vehicle

Do not coat the surfaces of the sensor units to avoid degrading designed performance.

Note

Check

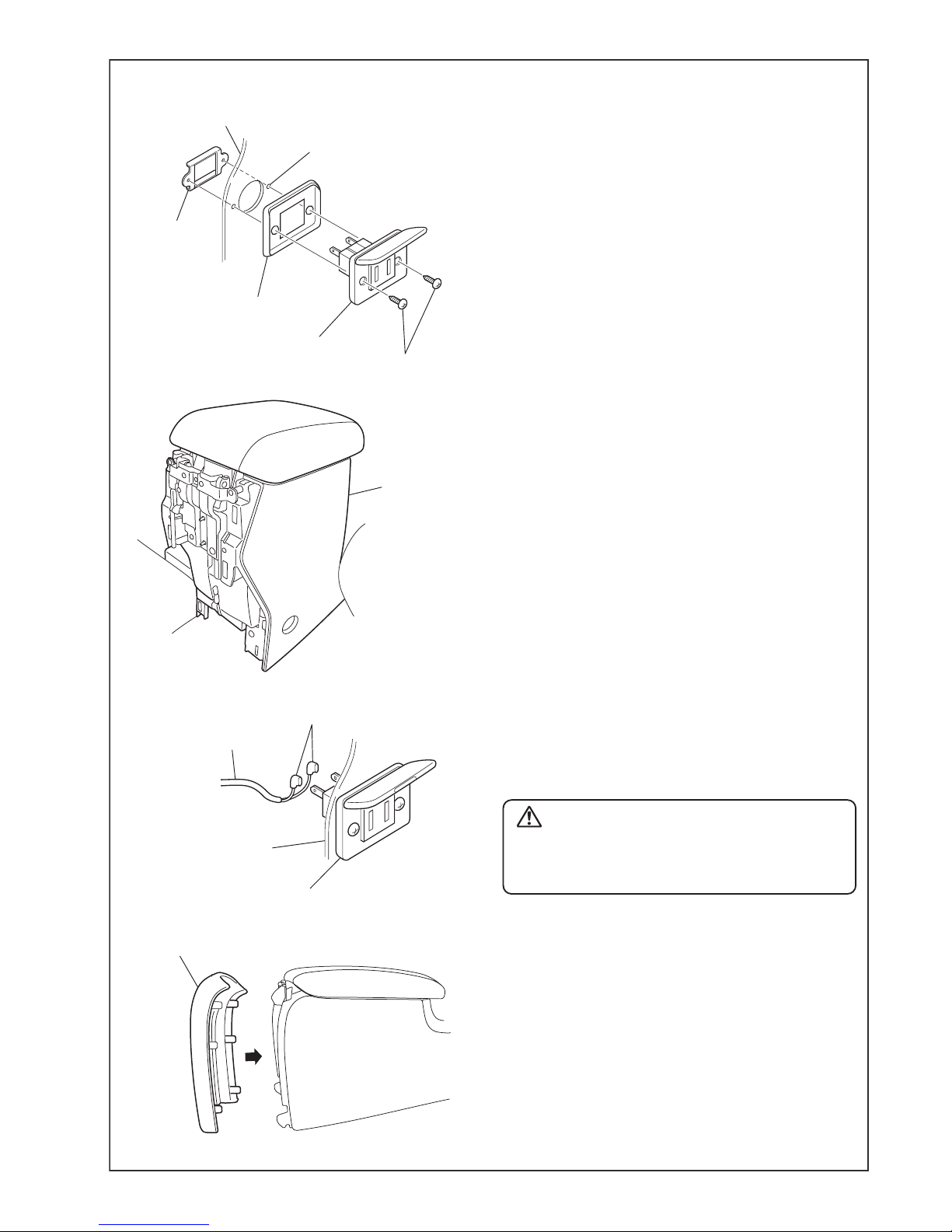

DOOR

CONSOLE

Fully ungaged

CAUTION

This product requires removal of the passenger 's seat. As a result of the removal of the passenger 's

seat it will be necessary to re-calibrate the Occupant Detection System. If not properly calibrated the

Occupant Detection System may not operate as designed which may result in injuries to the front

seat passenger. Therefore, it is strongly recommended that the product be installed at an authorized

Subaru dealer.