1

WARNING: If not followed, death or serious injury may result.

Caution: If not followed injury or damage may result.

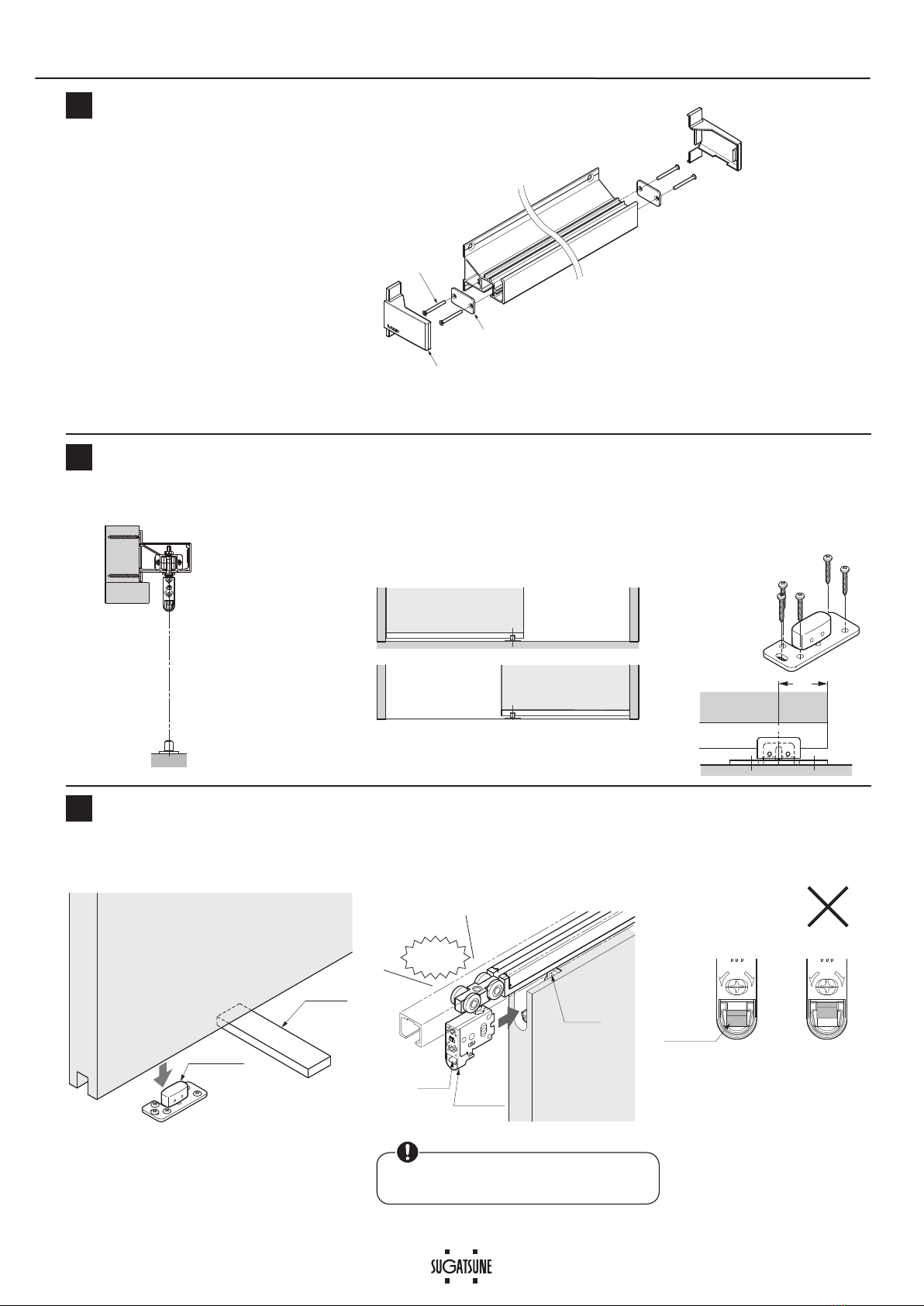

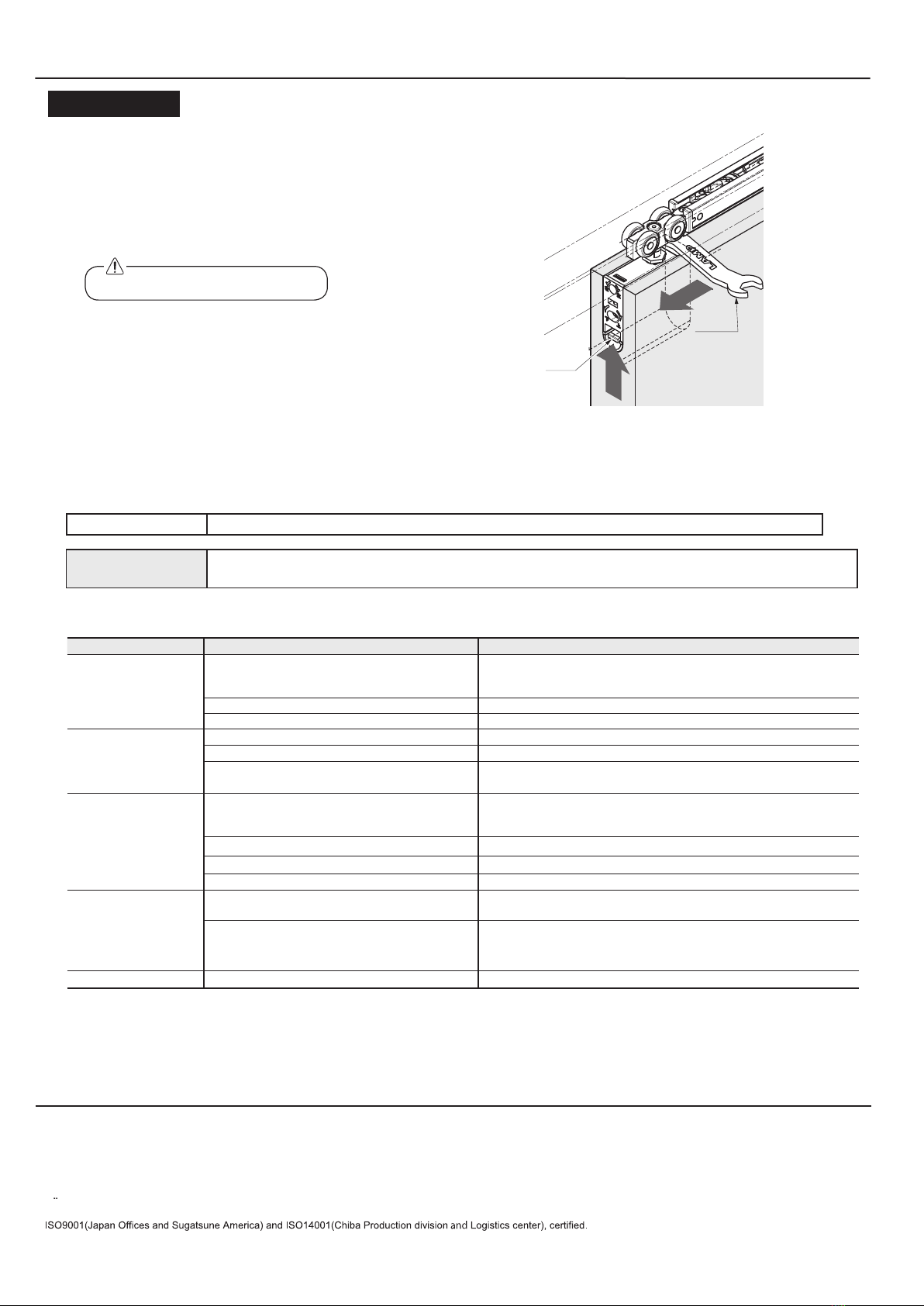

This (sliding door system) should be installed by a qualified person. If the system is not installed correctly, the door will not

operate smoothly, and may cause injury.

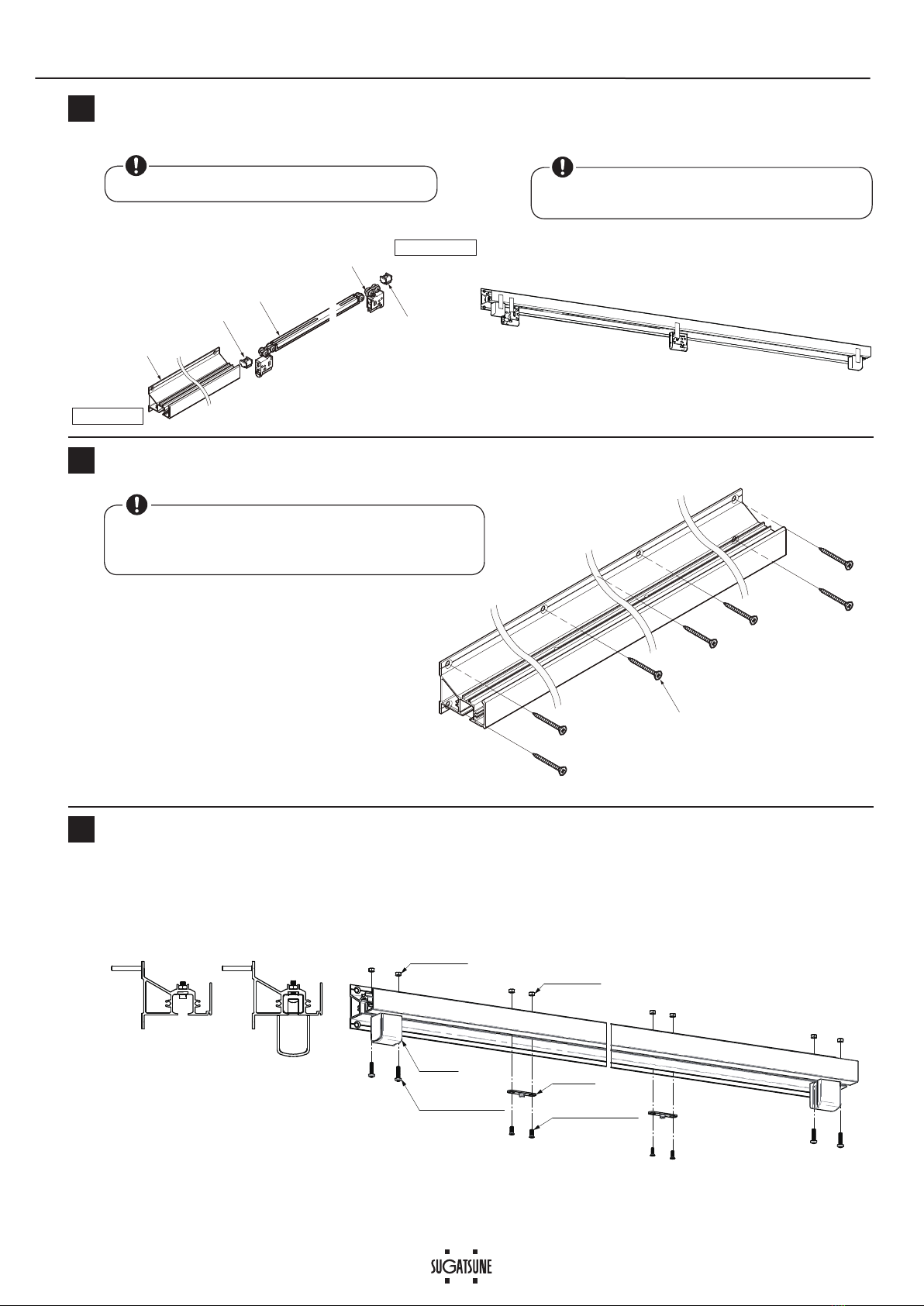

It is necessary to manufacture the frame with sufficient strength so that it endures the weight of the door and any impact

upon opening/closing the door. Only use designated screws and ensure that they are fastened firmly. A frame with poor

strength or loose screws might result in the door falling and causing injury.

Do not try to use this product for anything other than its original purpose. Do not use any part for applications outside of its

specification.

Do not disassemble nor modify any parts other than those described in this document.

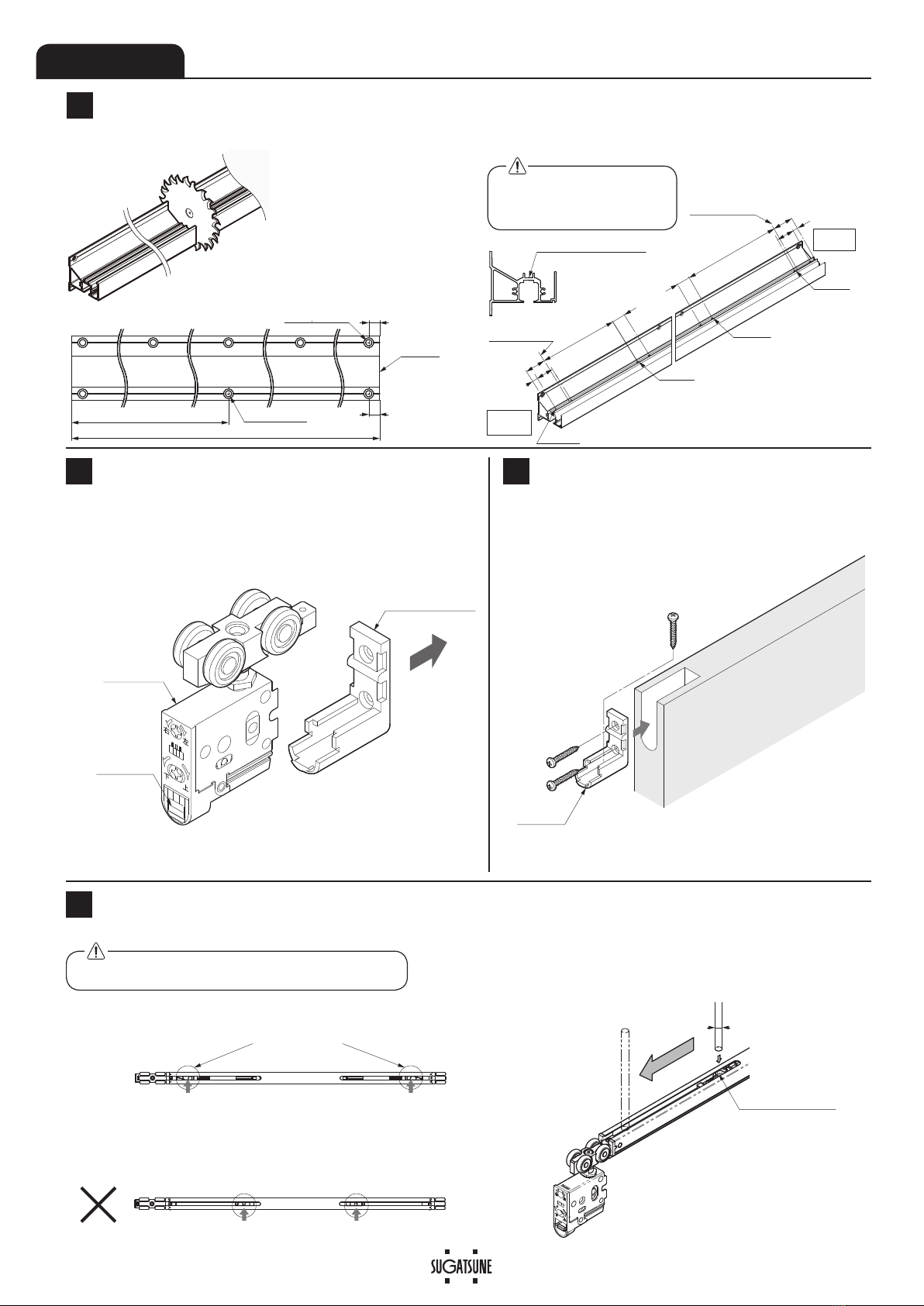

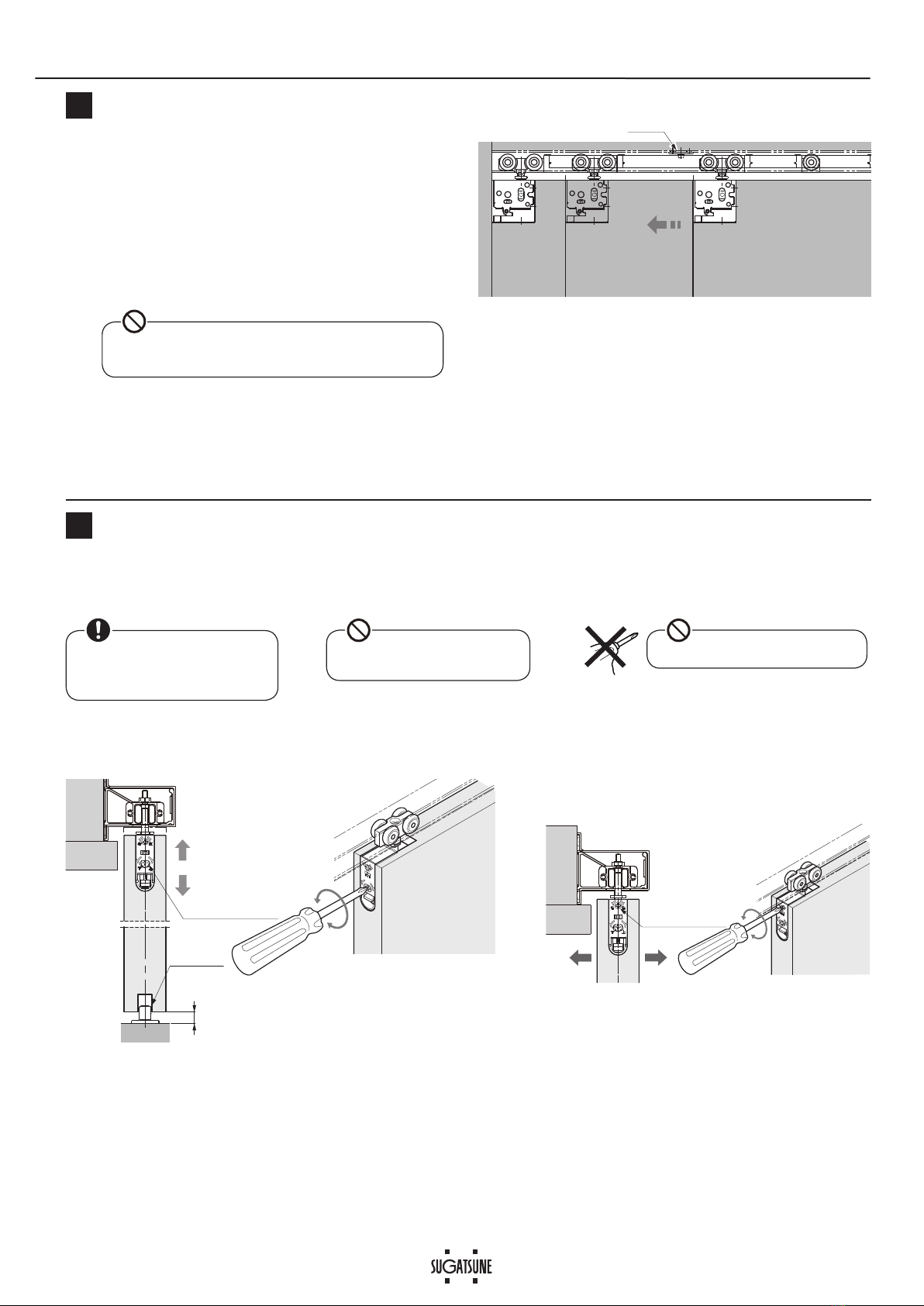

Make sure to follow the designated dimensions, specifications, and horizontal/vertical angles. Make sure that the frame is

not warped, since it may affect the movement of the door.

If cutting any parts, make sure to remove any burrs before installation. Also check the upper track for any left-over burrs or

scraps and remove these.

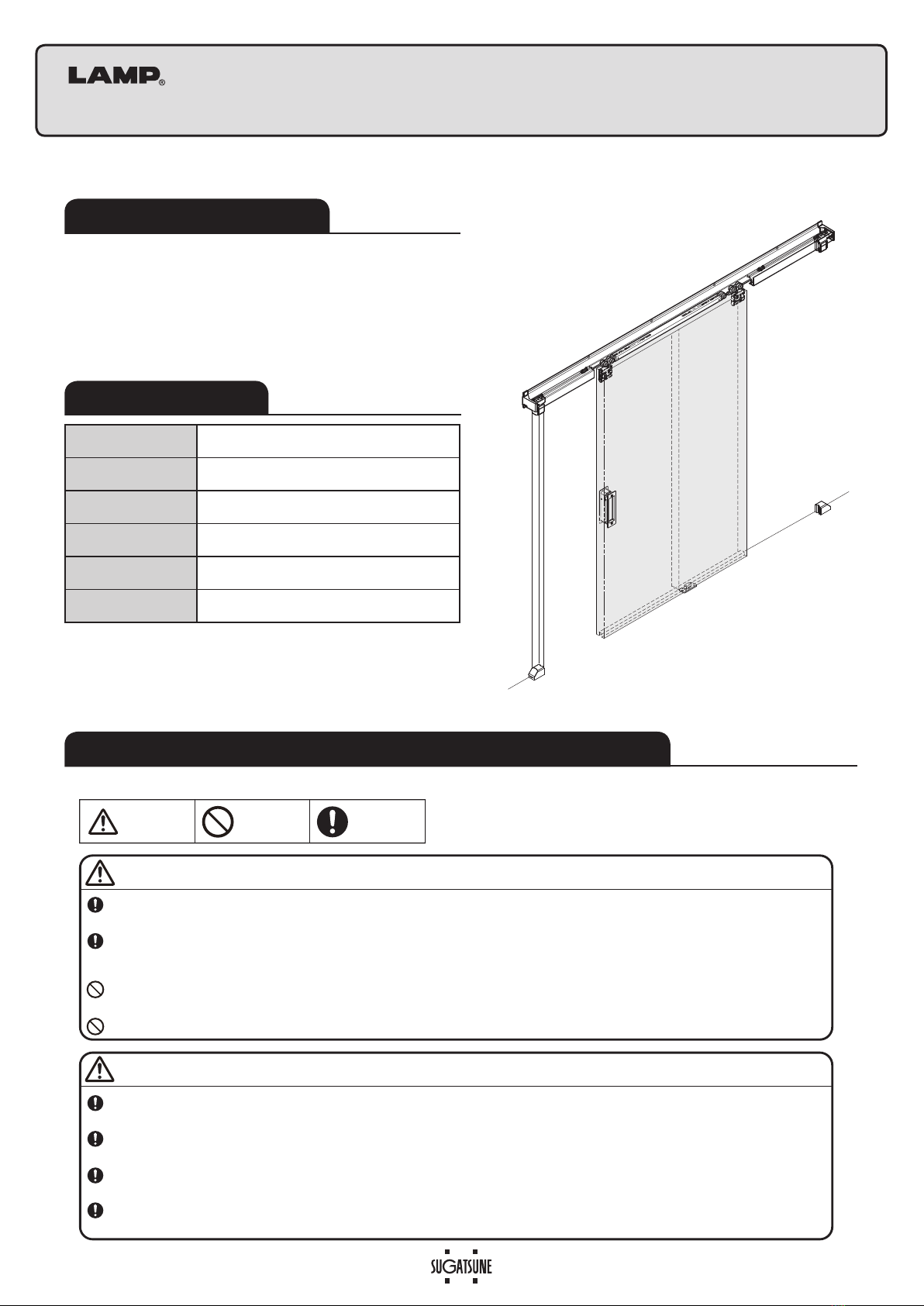

This product is a part for architectural fittings. After installation, make sure to test the finished product thoroughly to ensure

that it is well-functioning and safe. Please inform the end user about general precautions and safety to prevent improper use.

Make sure to check the screws for slack at regular intervals (one month from first usage, half a year, and then one time

every year is recommended).

Prohibited

Warning

Caution Required

Meaning of symbols

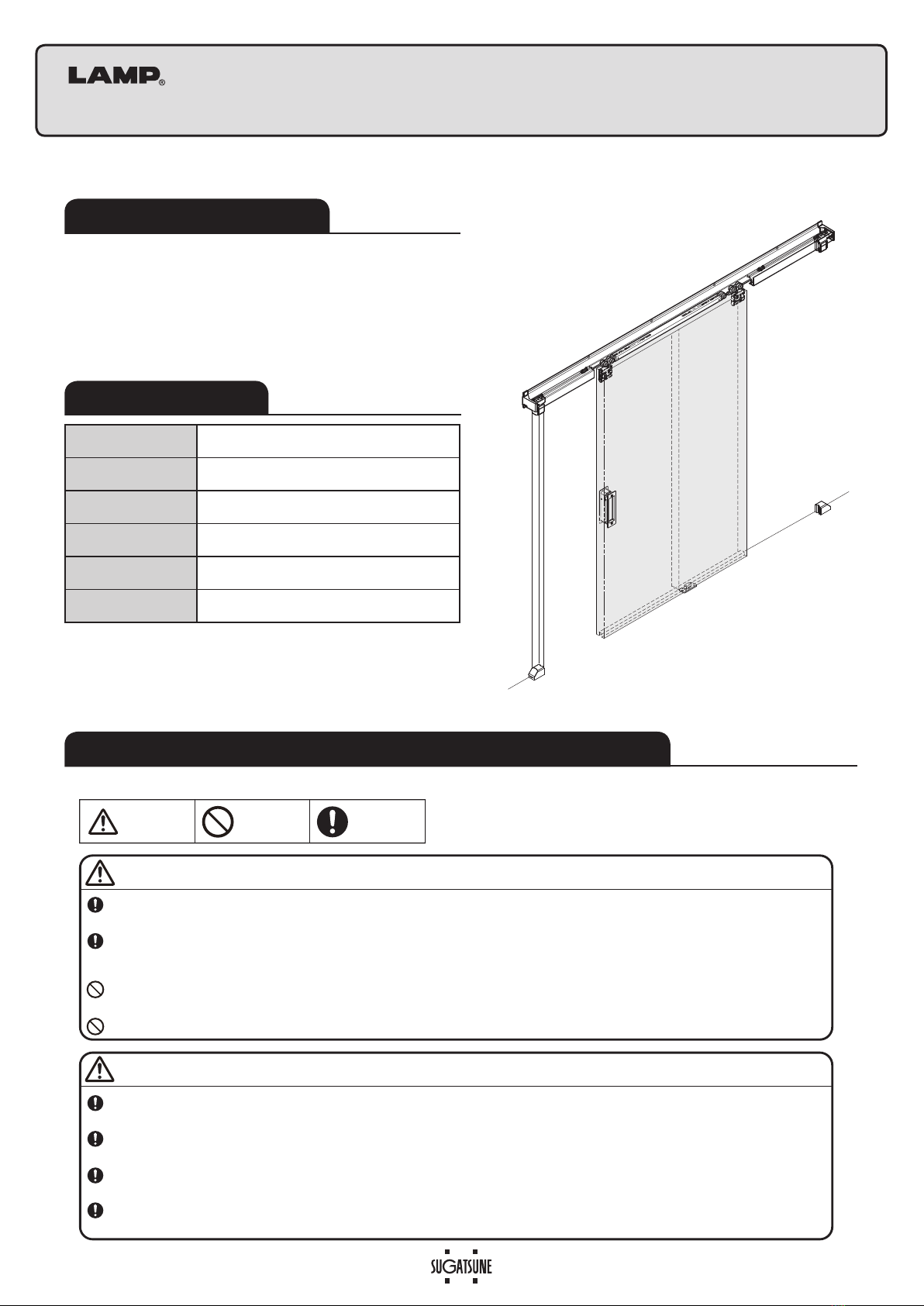

FD50H SLIDING DOOR SYSTEM Installation Manual

2XWVHW7\SHZLWK7ZRZD\VRIWFORVH

PartNo:FD50DHCP-AK

●

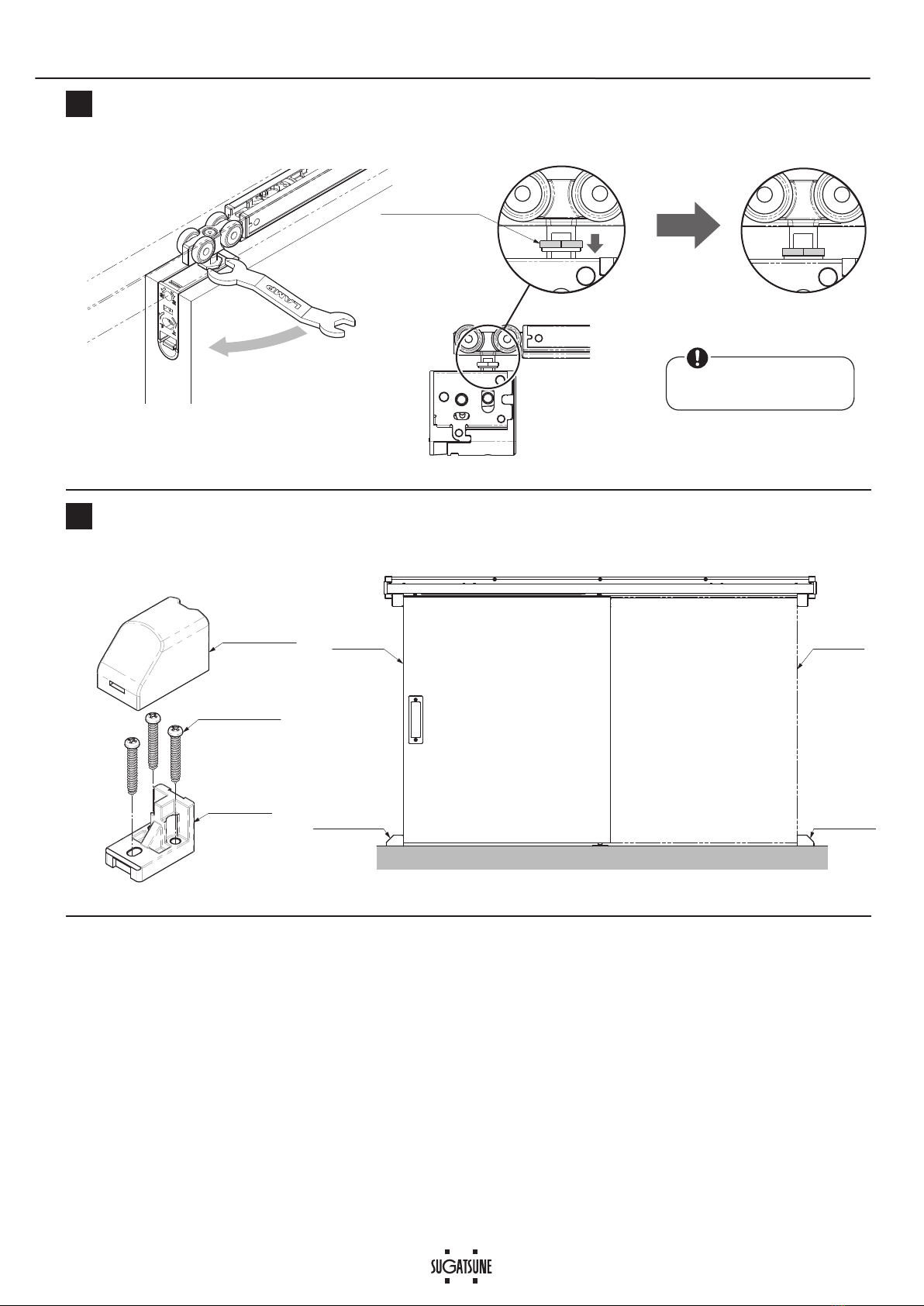

This product is a parts set for an overlay indoor sliding door

system.

●

The door closes in a 2 soft motion steps; first slow, then

fast, and opens with a 1 step soft motion.

●

Easy door installation and adjustment.

Thank you for selecting our product. Before starting installation, please read this manual thoroughly to ensure correct installation.

Please keep this manual at hand for future reference.

Max. Door height

2400mm

Max. Door width

680 − 1500mm

0LQ'RRUWKLFNQHVV

30

−

36mm

Max. Door weight 50kg※1

9HUWLFDODGMXVWPHQW

3mmupward,4mmdownward

)URQWUHDUDGMXVWPHQW

± 2mm

ABOUT THE PRODUCT

SPECIFICATIONS

FOR YOUR SAFE WORK AND CORRECT INSTALLATION

The closing speed of the soft closing type door may change due to

ambient temperature, operating method or installation quality.

・

Recommended ambient temperature range is 5 to 40°C.

※1

If a light weight door is applied, you may feel the resistance

of the soft closer when opening the door.