Sullair SXT User manual

SAFETY WARNING

Users are required to read

the entire User Manual before

handling or using the product.

Keep the User Manual in a safe

place for future reference.

WARRANTY NOTICE

Failure to follow the instructions

and procedures in this manual or,

misuse of this equipment will

VOID its warranty!

MANUAL PART NUMBER:

02250247-389 R02

©SULLAIR LLC

USER MANUAL

SXT - SXCS - SXF - SXH

THREADED FILTERS

COALESCING FILTERS

User Manual | US-EN COALESCING FILTERS

2

02250247-389 R02

Subject to EAR. EAR99 and related export control restrictions.

Service Training Courses

Sullair training courses provide hands-on and classroom instruction for the proper operation,

maintenance, and servicing of Sullair products. Individual courses on Stationary compressors,

variable speed drive, compressor electrical systems, and dryers are offered at regular intervals

throughout the year of Sullair’s training facility located in Michigan City, Indiana.

Instruction includes training on the function and installation of Sullair service parts,

troubleshooting common faults and malfunctions, and actual equipment operation. These

courses are recommended for distributor service personnel. There is also a basic Stationary

compressor course available for end-users.

For details on course offerings, outlines, schedules, and cost information contact:

Sullair Training Department

1-888-SULLAIR or

219-879-5451 (ext. 5623)

training@sullair.com

www.SullairTraining.com

- Or Write -

Sullair

1 Sullair Way

Michigan City, IN 46360

Attn: Training Department.

Sullair Parts & Service

1-888-SULLAIR or

219-879-5451 (ext. 5623)

www.sullair.com

crc@sullair.com

Dryer Data Sheet

Model Number: _______________________________ Serial Number: __________________________

Date of Manufacture: ___________________________________________________________________

Ship Date: ___________________________________ Installation Date: _________________________

Distributer

Name: ____________________________________________________________________________

Address: __________________________________________________________________________

__________________________________________________________________________

COALESCING FILTERS User Manual | US-EN

302250247-389 R02

Subject to EAR. EAR99 and related export control restrictions.

User Manual | US-EN COALESCING FILTERS

4

02250247-389 R02

Subject to EAR. EAR99 and related export control restrictions.

1. General...............................................................................................................................................................................6

1.1 Installation information and operating manual .........................................................................................6

1.2 Additional valid documents...............................................................................................................................6

1.3 Explanation of symbols and pictograms used ............................................................................................7

1.3.1 In documentation......................................................................................................................................7

1.3.2 On the device..............................................................................................................................................8

1.4 Intended use............................................................................................................................................................9

1.5 Foreseeable misuse............................................................................................................................................ 10

1.6 Warranty and liability......................................................................................................................................... 10

1.7 Target audience and personnel..................................................................................................................... 11

1.8 Responsibilities of the operator..................................................................................................................... 11

2. Safety information ...................................................................................................................................................... 12

2.1 General information........................................................................................................................................... 12

2.2 Safety instructions .............................................................................................................................................. 13

3. Transport and storage............................................................................................................................................... 14

4. Product information................................................................................................................................................... 15

4.1 Product description............................................................................................................................................ 15

4.2 Product overview................................................................................................................................................ 15

4.3 Product identication........................................................................................................................................ 16

4.4 Functional description ...................................................................................................................................... 18

4.4.1 Filtration..................................................................................................................................................... 18

4.4.2 Condensate drainage through the oat drain............................................................................. 19

4.4.3 Condensate discharge by SULLIMAX™.................................................................. 20

4.5 Scope of delivery ................................................................................................................................................ 20

4.6 Name plate............................................................................................................................................................ 21

4.7 Filter element sticker ......................................................................................................................................... 22

4.8 Maintenance sticker for lter element exchange.................................................................................... 22

5. Technical data .............................................................................................................................................................. 23

5.1 Filter performance data.................................................................................................................................... 23

5.2 Filter element performance data .................................................................................................................. 24

5.3 Materials................................................................................................................................................................. 25

6. Dimensions.................................................................................................................................................................... 26

7. Installation ..................................................................................................................................................................... 28

7.1 Warning .................................................................................................................................................................. 28

7.2 Installation work.................................................................................................................................................. 29

8. Commissioning............................................................................................................................................................ 31

8.1 Commissioning work......................................................................................................................................... 31

9. Maintenance and servicing ..................................................................................................................................... 32

9.1 Maintenance schedule...................................................................................................................................... 32

9.2 Cleaning.................................................................................................................................................................. 32

9.2.1 Warning...................................................................................................................................................... 32

9.2.2 Cleaning work.......................................................................................................................................... 33

9.3 Visual inspection ................................................................................................................................................. 33

9.4 Exchange the oat drain .................................................................................................................................. 34

9.5 Exchange the lter element............................................................................................................................ 38

9.6 Leak test.................................................................................................................................................................. 41

Content

COALESCING FILTERS User Manual | US-EN

502250247-389 R02

Subject to EAR. EAR99 and related export control restrictions.

10. Shutting down........................................................................................................................................................... 42

11. Disassembly................................................................................................................................................................ 43

11.1 Warning................................................................................................................................................................ 43

11.2 Disassembly work............................................................................................................................................. 44

12. Disposal........................................................................................................................................................................ 46

12.1 Warning................................................................................................................................................................ 46

12.2 Disposal work..................................................................................................................................................... 46

13. Spare parts and accessories.................................................................................................................................. 47

13.1 Replacement parts........................................................................................................................................... 47

13.2 Accessories top attachments ....................................................................................................................... 47

13.3 Accessories bottom attachments............................................................................................................... 48

14. Troubleshooting and repair / FAQ...................................................................................................................... 51

User Manual | US-EN COALESCING FILTERS

6

02250247-389 R02

Subject to EAR. EAR99 and related export control restrictions.

1. General

1.1 Installation information and operating manual

INFORMATION Copyright protection

iThe content of this installation and operating manual, in the form of text, images, photos,

drawings, diagrams, and other illustrations, is copyright protected by the manufacturer. This

applies in particular to copies, translations, microlm versions, and saving and processing this

document in electronic systems.

Publication date Revision version Reason for change Scope of change

10/31/18 R00 Change to standards and

directives Initial creation

11/09/19 R01 Changes to technical data

and images Changes

02/14/20 R02 Changes to technical data

and images Changes

This installation and operating manual, referred to in the following as the manual, must be legible and must be stored

near the product at all times.

The manual must be included if the product is sold or handed over to another party.

NOTE Observe the manual!

This manual contains all basic information required to safely operate the product, and operators

must read the manual before carrying out all work. Otherwise hazards could occur for personnel

or materials, and functional or operating disruptions could occur.

1.2 Additional valid documents

This manual describes all steps required to install and operate the coalescing lter.

Further information on installing and operating accessories is provided in the following installation and operating

manuals:

• SULLIMAX™

COALESCING FILTERS User Manual | US-EN

702250247-389 R02

Subject to EAR. EAR99 and related export control restrictions.

1.3 Explanation of symbols and pictograms used

The symbols and pictograms used in the following indicate important and safety-related information that must be

observed in handling the product and to ensure safe and optimal operation.

1.3.1 In documentation

Symbol/pictogram Description/explanation

General hazard symbol (danger, warning, caution)

Pressurized system

Observe the installation and operating manual

General instructions

Use FFP 3 respirator

Wear safety shoes

Wear protective gloves (liquid-resistant)

Wear hearing protection

Wear safety glasses with side protection (goggles)

General information

i

User Manual | US-EN COALESCING FILTERS

8

02250247-389 R02

Subject to EAR. EAR99 and related export control restrictions.

1.3.2 On the device

Symbol/pictogram Description/explanation

General hazard symbol (danger, warning, caution)

(This symbol is indicated on the type plate and maintenance sticker for lter element

exchange.)

Observe the installation and operating manual

(This symbol is only indicated on the type plate)

!

20

Maintenance sticker for lter element exchange

This sticker notes when the lter element should be exchanged next and indicates that the

installation and operating manual must be observed.

4042767

W1234567/001

Flow

330H

www.sullair.com

MADE IN GERMANY

02250244-273

Filter element sticker

(This sticker is on the base of the lter element and provides information on the lter

element).

COALESCING FILTERS User Manual | US-EN

902250247-389 R02

Subject to EAR. EAR99 and related export control restrictions.

1.4 Intended use

Coalescence lter and accessories

The air lter, also referred to in the following document as the lter, serves to lter aerosols and solid particles from gas

pressurized systems.

Any other use besides that described in this manual is deemed improper and poses a risk to personnel and the

environment.

• Only use the lter and accessories within the operating parameters and agreed delivery conditions indicated in the

technical data.

• Only use the lter and accessories in a pipeline system designed to handle the technical data indicated, with

appropriate connections, pipe diameters and installation space.

• Only use the lter and accessories to process uid group 2 compressed air free from aggressive and corrosive

components in accordance with Pressure Directive 2014/68/EU.

• Only use the lter and accessories in non-explosive areas.

• Only use the lter and accessories in areas not exposed to direct sunlight or heat sources and in areas not in danger

of frost.

• Only combine the lter and accessories with recommended products indicated in the manual from Sullair

Corporation.

Before using the lter, the operator must ensure that all conditions and requirements for the intended use have been

fullled.

The lter is designed only for stationary use in a commercial or industrial area. All work described for mounting,

installation, operating, removal and disposal may only be carried out by qualied professional technicians.

User Manual | US-EN COALESCING FILTERS

10

02250247-389 R02

Subject to EAR. EAR99 and related export control restrictions.

1.5 Foreseeable misuse

If the lter or accessories are used in a manner other than as described in the“Proper use” chapter, this is considered

foreseeable misuse. Foreseeable misuse includes using the product in a manner not intended by the manufacturer or

suppliers, but which may occur due to foreseeable human behavior.

Foreseeable misuse includes:

• Completing modications of all kinds, in particular changing the design or process technology, since this may result

in personal injury and property damage as well as functional and operating disruptions.

• Disabling or failing to use available or recommended safety equipment.

• Using compression for preparations that are not included in uid group 2 in accordance with DGRL 2014/68/EU or

contain aggressive components. In case of doubt, complete a condensate analysis.

This list does not claim to be exhaustive, since it is not possible to indicate all possible misuses in advance. If the

operator knows of misuses of the lter or accessories that are not listed here, the manufacturer must be informed of

these promptly.

1.6 Warranty and liability

The operator and user must take the proper use into consideration. The operator shall be solely responsible for any

action not described here and any use going beyond that described as proper use.

All warranty shall be voided, if the lter is used improperly, for a purpose other than the intended or is operated outside

the limits specied in the technical data. In such cases, the manufacturer shall also reject any liability for damages.

Improper operation includes:

• Technically inappropriate installation, commissioning, maintenance or operation

• Use of defective components

• Failure to observe the safety-relevant information, usage steps and instructions included in this manual

• Completing modications of any kind, in particular design or process technology changes to the product

• Use of third-party spare parts or accessories that have not been approved by the manufacturer in completing

maintenance and repair work

• Failure to observe maintenance and inspection intervals

COALESCING FILTERS User Manual | US-EN

11 02250247-389 R02

Subject to EAR. EAR99 and related export control restrictions.

1.7 Target audience and personnel

This manual is directed towards the following professional technicians assigned to work on the lter or accessories.

INFORMATION Personnel requirements

iPersonnel may not complete any work on or with the lter or accessories if they are under the

inuence of drugs, medications, alcohol or other substances that could impair their awareness.

Professional technicians - Transport and storage

Transportation and storage technicians are personnel whose training, professional experience and qualications

have given them all the skills necessary to safely complete any actions associated with transportation, to recognize

potential hazards independently and take measures to prevent those hazards.

These skills include, in particular, experience in handling hoists, forklifts and lifting equipment and devices as well as

an understanding of regional applicable laws, standards and directives related to transportation and storage.

Compressed technology technicians

Compressed technology technicians are personnel whose training, professional experience and qualications have

given them all the skills necessary to safely complete any actions associated with compressed and pressurized

systems, to recognize potential hazards independently and take measures to prevent those hazards.

These skills include, in particular, experience in handling measurement, control and regulation technology as well as

an understanding of regional applicable laws, standards and directives related to compressed technology.

1.8 Responsibilities of the operator

The responsible operator must ensure the following to avoid accidents, faults and environmental impacts:

• Check before all actions whether this manual matches the product.

• Ensure the product is used, maintained, and repaired properly.

• Ensure that all applicable legal specications, safety provisions and accident prevention regulations are complied

with.

• Ensure that all specications and operating instructions for safe work and instructions for how to respond to

accidents and res are accessible at the work site to personnel at all times.

• Ensure the product is used with recommended and functional safety equipment and that this equipment has not

been deactivated.

• Ensure all assembly, installation and maintenance work is only carried out by qualied professional technicians.

• Ensure the recommended personal protective equipment is available and is used.

• Ensure suitable technical safety measures are taken to ensure the permitted operating parameters are not exceeded

and are met.

User Manual | US-EN COALESCING FILTERS

12

02250247-389 R02

Subject to EAR. EAR99 and related export control restrictions.

2. Safety information

2.1 General information

Safety information warns of hazards related to handling the product. In the instructions, warning information is stated

before the steps that could pose a hazard to personnel or the surrounding area.

This safety and warning information must always be observed to avoid accidents, personal injury and property damage,

and operational disruptions.

Structure of the safety information

Content of the safety information structured according to the SAFE principle:

S - Safety symbol and signal word

A - Type and source of danger

F - Possible consequences for failure to observe the hazard in the order of severity

E - Measures to avoid the hazard

Structure of the safety information:

SIGNAL WORD Type and source of danger!

Safety indications

Possible consequences if the hazard is not observed

• Measures to avoid the hazard

Signal words according to ISO 3864 and ANSI Z.535.6

DANGER Imminent danger

Consequences of non-compliance: Death or severe personal injury

WARNING Imminent danger

Consequences of non-compliance: Death or severe personal injury are possible

CAUTION Potential danger

Consequences of non-compliance: injury and/or damage to property

NOTICE Additional notes, tips and hints

Consequences of non-compliance: Disadvantages in operation and during handling and

maintenance.

No hazard to personnel or safe operation.

COALESCING FILTERS User Manual | US-EN

13 02250247-389 R02

Subject to EAR. EAR99 and related export control restrictions.

2.2 Safety instructions

Always observe the safety and warning information provided to avoid accidents, personal injury and property damage,

and operational disruptions.

The personal protective equipment indicated in the safety information must be selected by the operator based on the

system parameters and properties and must be provided.

DANGER Operating outside of permitted limit values!

Operating the product outside of the permitted limit values and parameters and prohibited

modications and changes pose the risk of death or a hazard of severe injuries.

• Observe the limit values, operating parameters and maintenance intervals and set-up and

ambient conditions indicated on the type plate and in the manual to ensure safe operation of

the product.

• Check whether operating parameters are changed or restricted through the use of

accessories.

• Only use the product according to its intended use.

DANGER Pressurized system!

The risk of death or severe injuries exists in case of contact with fast or sudden exiting

compressed air or due to bursting system parts.

• Only work on the system when it is depressurized and secure the system against unintended

restart.

• Set up a safety zone around the system when carrying out any assembly, installation,

maintenance and repair work.

• Before pressurizing the system, check and tighten all pipe connections.

• Pressurize the system slowly.

• Avoid pressure surges and high pressure dierentials.

• Install all pipelines without mechanical tension. Avoid vibrations occurring in the pipeline

network by using vibration dampers.

• Carefully observe the installation and operating instructions in this manual.

• Carefully observe inspection and maintenance intervals.

• Permanently install inlet and outlet lines.

• Do not make modications on the product.

DANGER Use of incorrect replacement parts, accessories or installation materials!

The use of incorrect replacement parts, accessories or installation material or operating and

auxiliary materials may result in death or severe injuries. This may also cause functional or

operating disruptions or material damage.

• Only use undamaged original parts, auxiliary and operating materials for all installation and

maintenance work as indicated by the manufacturer.

• Only use ttings and connection elements permitted for the specic application and suitable

tools in proper condition.

• Only use cleaned pipelines free from dirt and corrosion.

WARNING Failure to use personal protective equipment!

The failure to use personal protective equipment or the use of defective personal protective

equipment may result in accidents or injuries while working on the product.

• Wear personal protective equipment recommended for the specic task in proper condition

when completing any work on the product.

• Regularly check personal protective equipment for proper function and replace damaged

parts promptly.

WARNING Insucient qualication!

If personnel have insucient qualications, this may result in accidents, personal injury and

property damage as well as operating disruptions while working on the product.

All work on the product may only be carried out by suciently qualied professional technicians.

User Manual | US-EN COALESCING FILTERS

14

02250247-389 R02

Subject to EAR. EAR99 and related export control restrictions.

3. Transport and storage

WARNING Insucient qualication!

If personnel have insucient qualications, this may result in accidents, personal injury and

property damage as well as operating disruptions while working on the product.

The work on the product described in the following may only be carried out by transportation

and storage technicians and must be documented.

CAUTION Improper transportation or storage!

Improper transportation or storage may result in personal injury or property damage.

• Always wear gloves when working with packaging materials.

• Use personal protective equipment, check it regularly for proper function and replace

damaged parts promptly.

• The product must only be transported and stored by transportation and storage technicians.

• Handle the packaging and product carefully.

• Package all parts with suitable materials in a shock-resistant manner.

• Transport and handle packaging according to the label (observe hoist attachment points and

center of gravity, keep alignment vertical, do not throw, etc.)

• Use proper, functional transportation equipment and hoists.

• Observe permitted transportation and storage parameters.

• Do not store the product exposed to direct sunlight and heat sources.

For permitted storage and transportation conditions see“4.8 Maintenance sticker for lter element exchange”on

page 22.

NOTICE Handling packaging materials!

The improper disposal of packaging materials may result in environmental damage.

• The packaging material is recyclable.

• Dispose of packaging materials in accordance with the regional laws, directives and

guidelines of the country of use.

NOTICE Transportation and storage notices!

The product must

• be stored in the original packaging in a closed, dry, and frost-free room. The ambient

conditions, transportation and storage parameters may not exceed or fall below the

information in the Technical Data chapter.

• Even when packaged, protect the device against the elements.

• While in storage, secure the device so that it cannot topple over or fall, and protect it

against vibration.

COALESCING FILTERS User Manual | US-EN

15 02250247-389 R02

Subject to EAR. EAR99 and related export control restrictions.

4. Product information

4.1 Product description

Coalescing lters are used to lter aerosols and solid particles in compressed systems.

Depending on requirements, lter elements with dierent ltration levels may be used to achieve the desired

compressed class in accordance with ISO 8573-1.

The condensate collected during ltration can be drained manually or automatically.

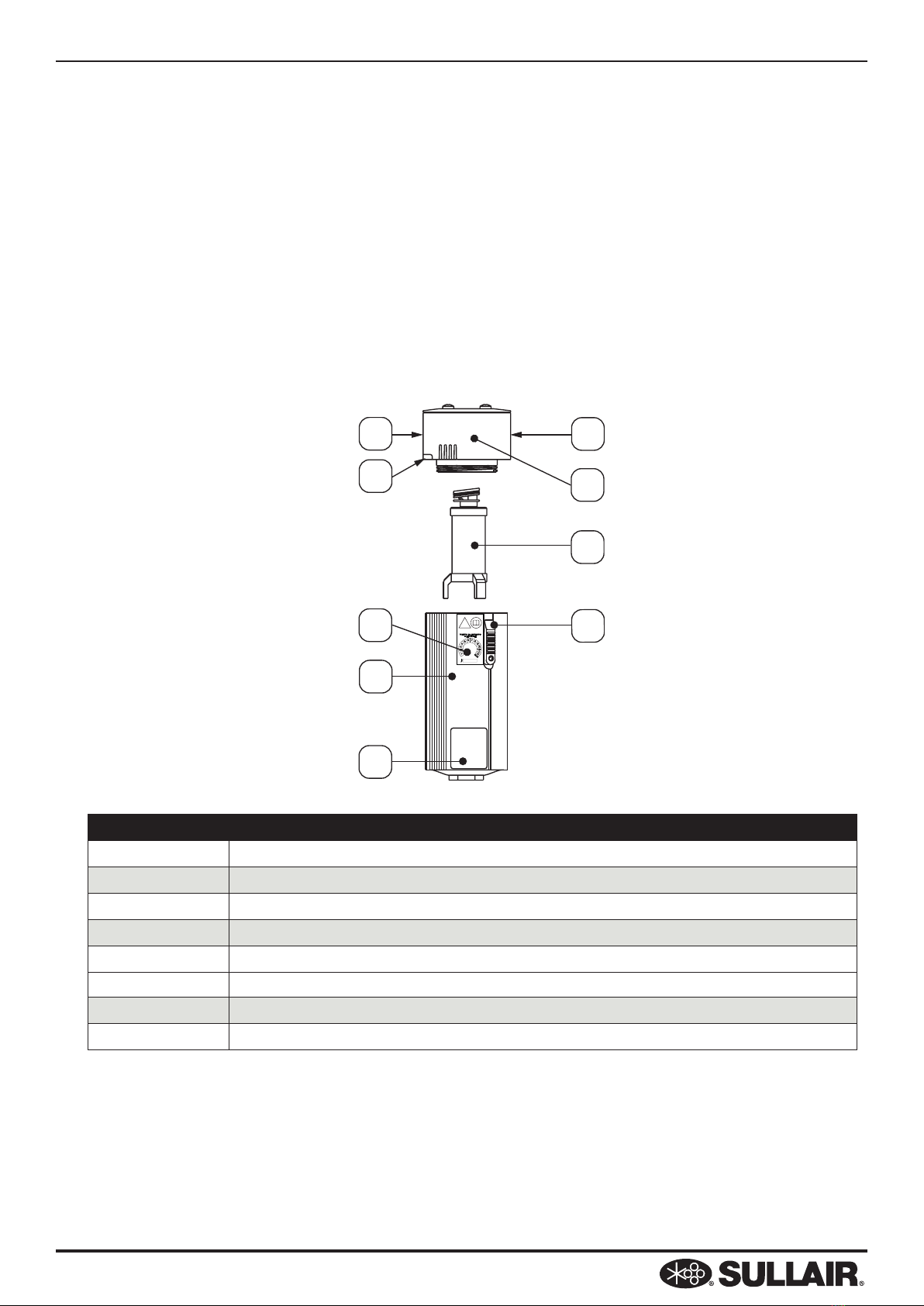

4.2 Product overview

The lter consists of the following components:

4

5

7

8

Fine filter

Type:

Material-no.:

Lot:

Year:

Element:

Elementmat.-no.:

Min./max.working

temperatureTS:

Max.working

pressurePS:

Volume:

Testpressure PT:

Connection:

S040FWF

4002618

201420

2014

04F

4002707

+2... 60 °C / +35 ... +140 °F

1,5.. 16 bar / 22 ... 232 psi

asd

23bar / 334 psi

pipeG 3/8

drainG 1/2

Fluidgroup2

PED97/23/EC / Cat. -

Beko TECHNOLOGIES

http://www.beko-technologies.com

2

6

3

1

1a

!

20

Position no. Explanation / description

[1] Inlet on lter head, also marked by 1a

[2] Outlet on lter head

[3] Filter head

[4] Filter element

[5] Safety runner with locking screw

[6] Name plate

[7] Filter housing with internal sealing ring

[8] Maintenance sticker for lter element exchange

User Manual | US-EN COALESCING FILTERS

16

02250247-389 R02

Subject to EAR. EAR99 and related export control restrictions.

4.3 Product identication

The product designation is indicated on the name plate and consists of numbers and an abbreviation. Each

abbreviation stands for a lter component and is divided into the following categories:

[1] = Filter elements

[2] = Size: Housing

[3] = Bottom attachments

The following section explains the product designation using the example“SXTH0025F”:

SXT H 0025 F

1

1

2 3

3

2

Anbauteile unten

Anbauteile oben

Filterelemente

Baugröße: Gehäuse 0025

0030

0050

0080

0100

0125

0160

0200

0250

0330

0450

0500

0600

0800

1000

1300

1500

1900

Z F

H F CS

COALESCING FILTERS User Manual | US-EN

17 02250247-389 R02

Subject to EAR. EAR99 and related export control restrictions.

Top attachments

Abbreviation Designation

SXT Filter with threaded connection

Filter elements

Position no. Abbreviaiton Designation 99.9% solid

particle

separation

rate [μm]

Residual

oil content

[mg/m³]

Compressed air

class in accordance

with

(ISO 8573 - 1)

Long Description

[1]

CS Coarse lter 2 ... 5 < 5 [4: - :4] Coarse lter

F Fine lter 0.5 ... 1 < 0.05 [2: - :2] General purpose lter

H Micro lter 0.1 ... 0.3 < 0.005 [1: - :2]*1Oil removal lter

*1depending on ambient conditions and operating parameters, class [1: - :1] may be achieved.

Size: Housing

Position no. Size Designation

[2]

0025

Filter housing

0030

0050

0080

0100

0125

0160

0200

0250

0330

0450

0500

0600

0800

1000

1300

1500

1900

Bottom attachments

Position no. Abbreviation Designation

[3] Z SULLIMAX™condensate drains

F Float drain, open when depressurized (NO - normally open)

User Manual | US-EN COALESCING FILTERS

18

02250247-389 R02

Subject to EAR. EAR99 and related export control restrictions.

4.4 Functional description

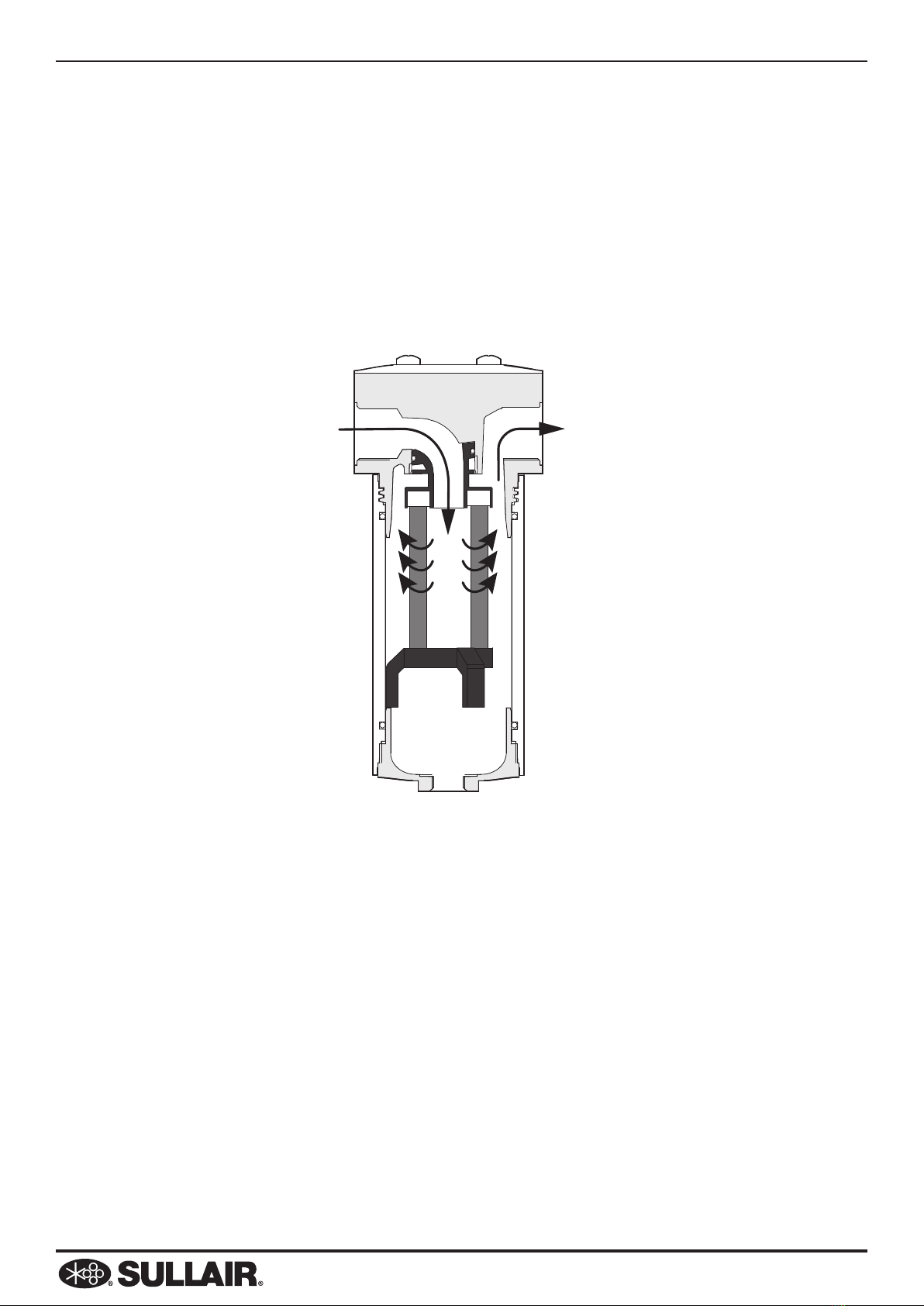

4.4.1 Filtration

Medium ows through the coalescing lter from the inside to the outside. Compressed air enters the interior of the

lter element and from there passes through the lter element and into the lter container. The solid materials and oil

and water droplets in the lter material are separated. Gravity causes the liquid part of the lter material to move down,

drip and collect below in the lter container. From there, it is manually or automatically drained. Over time, particles

build up in the lter material. The ow resistance (dierential pressure) of the lter element increases as a consequence.

The degree of particle load or contamination of the lter element can be read o on a dierential pressure gauge.

Further information is provided in the installation and operating manual included with the dierential pressure gauge.

COALESCING FILTERS User Manual | US-EN

19 02250247-389 R02

Subject to EAR. EAR99 and related export control restrictions.

4.4.2 Condensate drainage through the oat drain

Float drains are mechanical automatic condensate drains whose closing mechanism is triggered by the buoyancy of a

oat body [1]. When the condensate [2] in the container raises above a certain level, the buoyant lift of the oat body

[1] opens the outlet channel [3] for the condensate. The oat closes again when the condensate [1] drops below a

certain level: A small amount of condensate remains in the container.

The following oat drain is used to drain the condensate:

• Open when depressurized ([NO] normally open) - at an operating pressure ≤ 7.25 psi(g) the oat drain opens

Float drain opens Float drain closes

3

2

1

3

2

1

The oat drain is delivered in the position >>Automatic drainage<<.The knurled-head screw is screwed down to the stop.

To test the drainage function or release pressure to the lter to complete maintenance, the oat drain can be set to the

position >>mechanically open<<. To do so, unscrew the knurled-head screw counterclockwise (left-hand turn) to stop.

Automatic drain Mechanically open

INFORMATION Condensate discharge!

iCondensate discharge is dependent on the product combination and may vary.

For further information on possible product combinations see“4.3 Product identication”on page 16.

User Manual | US-EN COALESCING FILTERS

20

02250247-389 R02

Subject to EAR. EAR99 and related export control restrictions.

4.4.3 Condensate discharge by SULLIMAX™

Condensate may also be discharged via the automatic SULLIMAX™steam trap.

Further information is provided in the SULLIMAX™installation and operating manual.

4.5 Scope of delivery

The following table shows the scope of delivery for the lter.

Image Description/explanation

Filter

INFORMATION Possible product combinations!

iThe scope of delivery may vary depending on the product combination.

For further information on possible product combinations see“4.3 Product identication”on page 16.

This manual suits for next models

3

Table of contents

Other Sullair Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Honeywell

Honeywell HM600XROF1/U Installation operation & maintenance

Brita

Brita Tap user manual

Master Water Conditioning

Master Water Conditioning MP-MCA Series Installation and operation manual

Judo

Judo MAFI Series Installation and operating instructions

ACO

ACO Oleosmart-C-OST Operating and maintenance instructions

Microline

Microline T.F.C.-4 Installation, operation & service manual