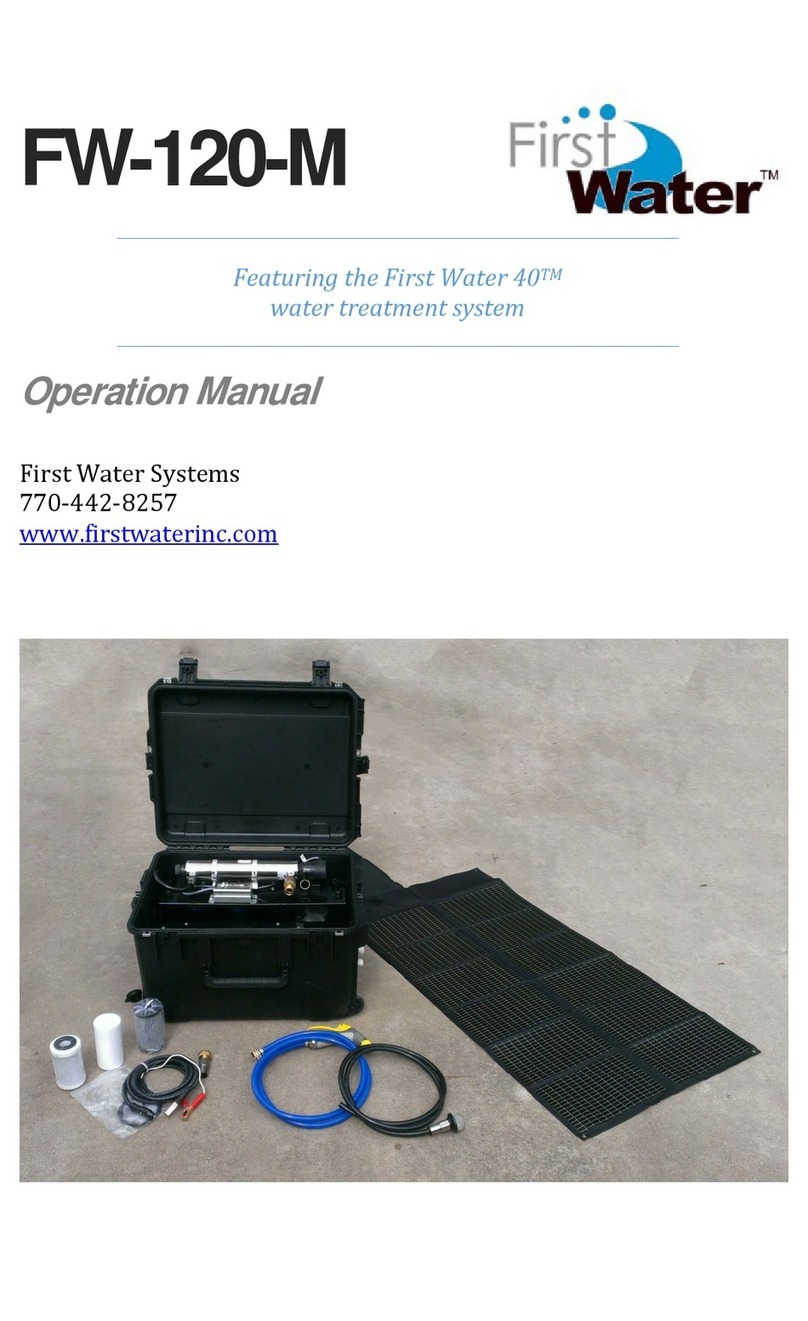

First Water FW-1200-M User manual

FW-1200-M

Operation Manual

First Water Systems

770-442-8257

www.firstwaterinc.com

Table of Contents

Operation Manual.....................................................................................1

1 Introduction ................................................................................................1

1.1 Style Conventions..............................................................................1

2 Unpacking ....................................................................................................2

2.1 Inventory .............................................................................................2

2.2 Storage ..................................................................................................3

3 Startup and Operation.............................................................................4

3.1 Water Source ......................................................................................4

3.2 Component Layout ...........................................................................5

3.3 Connections.........................................................................................5

3.4 Startup ..................................................................................................6

3.5 Operation.............................................................................................8

4 Post Operation Care ..............................................................................10

4.1 Flushing System.............................................................................. 10

4.2 Removing Filters ............................................................................ 10

4.3 Cleaning System..............................................................................10

4.4 Preparing for Storage...................................................................11

5 Special Procedures ................................................................................12

5.1 Maintenance Intervals .................................................................12

5.2 Replacing Filters ............................................................................12

5.3 Replacing UV Lamp........................................................................ 13

5.3 Replacing Quartz Sleeve .............................................................. 13

5.4 UV Lamp Disposal .......................................................................... 14

6 Troubleshooting ..................................................................................... 15

6.1 Pump will not move water.......................................................... 15

6.2 Water not flowing from Clean Water Hose ........................... 15

6.3 Water leaks from top of Canisters ...........................................15

6.4 Water leaks UV Chamber ............................................................15

Operation Manual FW-1200-M

© 2012 First Water Systems, Inc pg. 1

1 Introduction

The Operator’s Manual has been prepared to acquaint the

owner/operator with this water filtration unit, its various controls,

maintenance, and safety instructions. It is valuable for the proper

use of The FW-1200-M and should be kept with the unit at all times.

Make sure you read and understand the content of the Operator’s

Manual.

First Water Systems offers water treatment experts to assist you in

your water operation plans. You may contact us at any time to

discuss your needs. The FW-1200-M is designed to provide

microbiologically safe water for human consumption from fresh

water sources.

Used in conjunction with the Supply Station, Filling Station and Aqua

Bags, The FW-1200-M provides a complete water solution to a

variety of applications.

1.1 Style Conventions

The following style conventions will be used throughout this

operation manual.

Note: Notes present information that will enhance operator

experience.

Warning: Warnings present information that is critical to the safety

of the operator and equipment.

Operation Manual FW-1200-M

© 2012 First Water Systems, Inc pg. 2

2 Unpacking

Upon delivery of your FW-1200-M, please inspect for damage and

inventory all components.

2.1 Inventory

The FW-1200-M includes the following components:

(1) Water Purification Unit

(1) Pump

(1) Operation Manual

(1) Maintenance Kit (0.5oz silicone grease & 4 x Canister O-

Rings)

(1) Filter Wrench

(1) Filter Set, installed in canisters

(1) Filter Set, spare (FW-1200-M Bundle Only)

(2) UV/Quartz Sleeve sets, (1) installed/(1) spare

(1) 20’ Source Water Hose (green / with foot valve)

(1) 20’ Transfer Hose (green)

(1) 20’ Clean Water Hose (clear / food grade)

(1) Cam Lock to Female Garden Hose fitting

(1) Cam Lock to Male Garden Hose fitting

(2) 25’ Power Cords

(1) GFCI Pigtail

Operation Manual FW-1200-M

© 2012 First Water Systems, Inc pg. 3

2.2 Storage

The FW-1200-M should be stored ready for deployment. The

following checklist will ensure that your FW-1200-M is properly

stored.

Used filters discarded

New filters installed

Unit clean and dry

Canister O-Rings lubricated and in place

UV Lamp operational

Hoses and Accessories accounted for

Replacement filters re-ordered

Operation Manual FW-1200-M

© 2012 First Water Systems, Inc pg. 4

3 Startup and Operation

3.1 Water Source

The FW-1200-M produces microbiologically safe water from fresh

(non-saltwater) water sources. The Virus Media Filtration utilizes

adsorption properties to remove microbiology to an effective size of

0.2 microns. Microbiology removed includes viruses, bacteria, and

cysts.

Source water can come from a variety of locations. Ideal water

sources are free of sediment and turbidity and come from a

relatively known environment. As the scope of an event escalates,

less ideal water sources may be utilized.

Example water sources, from most ideal to least ideal:

1. Facility plumbing under boil water advisory.

2. Swimming or therapy pools.

3. Irrigation wells.

4. Shuttled water from fire trucks or tankers.

5. Rain water collected from roof runoff.

6. Surface water from retention ponds, lakes or streams.

The FW-1200-M does not remove chemical contaminants from water

sources. Care should be taken in using a water source from

unknown locations or uncontrolled environments.

Water supplies with known chemical additives should never be used.

Examples include water from boilers and chillers.

Water sources with high turbidity, sediment or tannin levels will

cause filters to be expended more rapidly. There is no impact on the

quality of clean water produced.

Operation Manual FW-1200-M

© 2012 First Water Systems, Inc pg. 5

3.2 Component Layout

Arrange components in the following order, flowing from source

water to water outlet:

1Water Source

2Source Water Hose (green w/ foot valve)

3Pump (Remove from Purification Unit mount and place as close

to water source as possible)

4Transfer Hose (green)

5Water Purification Unit

6Clean Water Hose (clear/food grade)

7Clean water distribution

Included Cam Lock to Garden Hose Thread adaptors may be used to

convert to conventional garden hoses at the inlet and outlet. See

section 3.3

3.3 Connections

The FW-1200-M uses 1” Cam Lock fittings as standard. Adaptors are

provided to convert to standard garden hose fittings.

Cam Lock to Female Garden Hose Thread (GHT) Fitting

oUsed on the end on the Transfer Hose (green). Using

this fitting to treat water from a pressurized source,

bypassing the pump.

Cam Lock to Male Garden Hose Thread (GHT) Fitting

oUsed at the end of the Clean Water Hose (clear).

Adapts the system outlet to standard garden hose

thread.

You may bypass the pump and treat water from existing building

pressure when under a boil water advisory or similar circumstance.

Operation Manual FW-1200-M

© 2012 First Water Systems, Inc pg. 6

3.4 Startup

Power

oSupply 120 volt power to the Pump.

oSupply 120 volt power to the UV Lamp at the Water

Purification Unit.

oThe Pump has several buttons and lights:

Power Switch: Turns Pump on and off.

Reset Button: Restarts Pump after it has gone

into alarm mode. In some cases, it may be

necessary to disconnect power to reset Pump.

Line Voltage Indicator: Illuminates when

Pump is receiving power.

Pump Operation Indicator: Illuminates when

Pump is operating.

Water Flow Alarm: Illuminates when Pump

stops due to water flow interruption.

Power must be supplied through a Ground Fault Circuit Interrupter

(GFCI) that is properly grounded. If a GFCI circuit is not available,

use the included GFCI Pigtail.

Prime

oDrop Foot Valve into water source.

oFill Source Water Hose with water from open end

opposite Foot Valve.

oAttach filled Source Water Hose to Pump Inlet.

oAttach Transfer Hose to Pump Outlet.

oOpen Pump Priming Port and fill with water.

oTurn Pump on and ensure that water flows at full

pressure.

oYou will need to repeat the Hose/Pump filling

process until a sufficient prime is established.

Operation Manual FW-1200-M

© 2012 First Water Systems, Inc pg. 7

The Foot Valve must not rest on the surface of the source water

container, especially if you are drawing from a location with heavy

sediment. Ideally, the Foot Valve is suspended several inches below

the surface of the water.

If the water source is depleted and the pump is allowed to run dry, it

will be necessary to repeat the priming process.

Water Flow

oTurn off Pump.

oConnect Transfer Hose to the Water Purification Unit

Inlet.

oOpen Main Valve and any down stream valves.

oEnsure that UV Lamp is operating by visually

inspecting the indicator light on the UV Control Box

(located in the Top Storage Compartment).

oTurn Pump on.

oWait for system to fill and water to flow from Outlet.

oLoosen each Filter Canister slightly, allowing air to

escape. Use Filter Wrench if necessary. Do Not

remove Canisters completely.

oWhen water flows from Canister threads, tighten just

enough to stop the flow (hand tight only).

Allow the system to run for 5 to 10 minutes prior to distributing

clean water. This will ensure all carbon particles are flushed and the

UV lamp has the proper contact time with water.

Water coming from the Outlet is clean, but any down stream

distribution components may be compromised. Any components

beyond the FW-1200-M should be cleaned with a 3:1 bleach solution

or other appropriate disinfectant then thoroughly rinsed before

clean water is distributed.

Operation Manual FW-1200-M

© 2012 First Water Systems, Inc pg. 8

3.5 Operation

Once water is flowing, very little maintenance is required. Someone

should be present to monitor the following:

Source water does not deplete.

Clean water storage does not overflow.

Water flow does not stop.

Filters needing to be changed.

Pausing Operation

The FW-1200-M may be turned off and on throughout an event. To

stop the flow of water, turn Main Valve to the off position. The

Pressure Switch on the Pump will automatically stop the pump

motor. If desired, you may turn off the power to the Filtration Unit to

shut off the UV Lamp.

If the system will be down for more than 4 hours, flush with clean

water for 1 minute before turning off. Do not leave standing water in

the unit for more than 36 hours.

Resuming Operation

After a pause in operation, the system may be restarted by turning

all power back on and opening the Main Valve. It may be necessary

to re-prime the Pump and bleed air from the system. It may be

necessary to reset the Pump by pressing the Reset button on the

Pump.

Filter Maintenance During Operation

Filter life will vary greatly based on the turbidity of source water.

Under optimal water conditions, a complete filter set should be

replaced every 50,000 gallons. Optimal water conditions are defined

as micro-biologically contaminated water sources with low levels of

sediment, turbidity or tannins. Increased levels of sediment,

Operation Manual FW-1200-M

© 2012 First Water Systems, Inc pg. 9

turbidity or tannins will require more frequent changes of the

sediment filter identified by observable drops in water flow. When

you notice the flow rate decrease, follow the steps below to check

filters:

Disconnect all power from the unit.

Check Foot Valve and Pump Strainer Basket for debris.

Replace the Sediment Filter in housing #1.

Restart unit and observe flow rate. If flow rate has not

improved, replace the Carbon Block Filter and Virus Media

Filter.

Operation Manual FW-1200-M

© 2012 First Water Systems, Inc pg. 10

4 Post Operation Care

4.1 Flushing System

As soon as possible after an event, flush the system by

pumping clean water for at least 5 minutes.

Remove the Source Water Hose from the source and allow

the system to pump until no water is flowing.

Disconnect all power from the Filtration Unit and Pump.

4.2 Removing Filters

Open Main Valve to relieve pressure on the Canisters.

Unscrew each Canister, using the Filter Wrench where

necessary.

Retain Canister O-Ring.

Remove and discard used Filters.

Drain water from Canisters and dry.

4.3 Cleaning System

Follow instructions above to flush and drain the system.

If sediment remains in the system, replace empty Canisters

and flush with clean water from a garden hose. Note: The UV

Lamp must be powered on for water to flow through.

Follow steps above to remove and dry filter Canisters.

Remove and drain all hoses.

Drain the UV Chamber by opening the Drain Valve located

next to Canister #4, tilt unit slightly to allow water to flow

out of the UV Chamber.

Operation Manual FW-1200-M

© 2012 First Water Systems, Inc pg. 11

Drain Pump:

oRemove Pump Strainer Basket

oRemove Pump Drain Port.

oRemove Pump Priming Port.

Discard used filters.

Rinse and dry all components.

Leaving Canisters open, allow system to air dry for at least 8

hours, longer if necessary to ensure the unit is completely

dry.

4.4 Preparing for Storage

Visually inspect the UV Bulb and Quartz Sleeve.

Inspect and lubricate each (4) Canister O-Rings with Silicone

Grease or other food grade lubricant.

Place new filters in each Canister and screw the Canisters

back on the unit.

oTighten Canisters hand tight only.

Coil and store all hoses and accessories.

The FW-1200-M should be stored ready for deployment. The

following checklist will ensure that your FW-1200-M is properly

stored.

Used filters discarded

New filters installed

Unit clean and dry

Canister O-Rings lubricated and in place

UV Lamp operational

Hoses and Accessories accounted for

Replacement filters re-ordered

Operation Manual FW-1200-M

© 2012 First Water Systems, Inc pg. 12

5 Special Procedures

5.1 Maintenance Intervals

During Operation

oClean Foot Valve and Pump Strainer Basket as

needed.

oReplace Sediment Filter as needed.

oReplace Filter Set every 50,000 gallons, or as needed

based on flow rate.

During Storage

oEvery 6 Months: Visually inspect UV Lamp operation.

oEvery 6 Months: Open Canisters to ensure unit is

stored dry.

5.2 Replacing Filters

Disconnect power from the Pump and Filtration Unit.

Open Main Valve to relieve pressure on the Canisters.

Unscrew each Canister, using the Filter Wrench where

necessary.

Retain Canister O-Ring.

Remove and discard used Filters.

Insert new Filters into Canisters.

oCanister 1: White, Solid, Sediment Filter.

oCanister 2: White, Solid, Carbon Block Filter. (Heaver

than Sediment Filter)

oCanister 3: Black, Pleated, Virus Media Filter.

oCanister 4: Empty. Specialized filter optional.

Inspect and lubricate each (4) Canister O-Rings with Silicone

Grease or other food grade lubricant.

Tighten Canisters hand tight only

Operation Manual FW-1200-M

© 2012 First Water Systems, Inc pg. 13

5.3 Replacing UV Lamp

Disconnect power from the Pump and Filtration Unit.

Loosen nut and remove PVC End Cap from UV Lamp

Chamber.

Withdraw UV Lamp approximately 2 inches.

While holding Lamp end, carefully remove Lamp socket.

Remove Lamp from Chamber.

Reinstall Lamp in reverse order.

Lamp and Quartz Sleeve are easily damaged. Exercise care when

removing or replacing lamp.

Never look directly at an illuminated UV Lamp.

5.3 Replacing Quartz Sleeve

Disconnect power from the Pump and Filtration Unit.

Shut off water supply.

Follow steps in “Replacing the UV Lamp” to remove lamp.

Unscrew Chamber Cap from each end of Chamber.

Remove Washer from both ends of the Quartz Sleeve.

Carefully remove Quartz Sleeve from Chamber. NOTE: It is

advisable to support the quartz sleeve on the opposite end

with your finger so that it does not drop to the bottom of the

chamber as it slides into the chamber.

If removing a broken Quartz Sleeve, follow the steps below:

oCarefully remove as much of the broken quartz sleeve

as possible, from each end of the chamber.

oTo remove fragments of quartz sleeve, position the

Purification Unit vertically and shake. The quartz

fragments will break and drop out of the Chamber.

oFlush water through chamber being careful to

remove all quartz fragments from the interior of the

chamber

Operation Manual FW-1200-M

© 2012 First Water Systems, Inc pg. 14

Once the quartz sleeve is removed, clean with alcohol or a

mild, non-abrasive detergent. Stubborn stains usually can be

removed with a diluted hydrochloric acid.

Reassemble in reverse order. Make sure the quartz sleeve

protrudes an equal distance past each threaded nipple.

Tighten End Caps firmly by hand only, DO NOT USE HAND

TOOLS. Tightening with hand tools is likely to cause Quartz

Sleeve to break.

Slowly restore water supply and check for leaks.

If no leaks occur, reinstall lamp.

5.4 UV Lamp Disposal

Germicidal ultraviolet lamps, like standard fluorescent lamps contain

small amounts of mercury. Mercury added lamps should not be

placed in the trash. Dispose of properly.

For further information regarding the disposal and recycling of

lamps containing mercury, along with Federal and State

requirements visit http://www.lamprecycle.org.

Operation Manual FW-1200-M

© 2012 First Water Systems, Inc pg. 15

6 Troubleshooting

6.1 Pump will not move water

Check the 120 volt power source

Check the Pump Strainer Basket for debris

Check that the Pump is primed

6.2 Water not flowing from Clean Water Hose

Follow troubleshooting steps for “Pump will not move water”

Check that Main Valve is open

Check power source to Purification Unit

Check Foot Valve for excessive debris

Check the UV Lamp and replace if necessary (The FW-1200-

M will not allow water through the system if the UV Lamp is

not operating)

6.3 Water leaks from top of Canisters

Check that each Canister O-Ring is in place and lubricated

Hand tighten Canister

A small, dripping leak is not abnormal

6.4 Water leaks UV Chamber

Inspect Quartz Sleeve for damage

Inspect Quarts Sleeve O-Rings and Washers (See “Replacing

Quartz Sleeve”)

Tighten UV Canister End Cap

Table of contents

Other First Water Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Filters itm

Filters itm SEMI AUTO FL user manual

Atlas Filtri

Atlas Filtri HYDRA Instruction for installation and maintenance

Jandy

Jandy AquaPure Installation and operation manual

Zoo Med

Zoo Med Turtle Clean 15 instructions

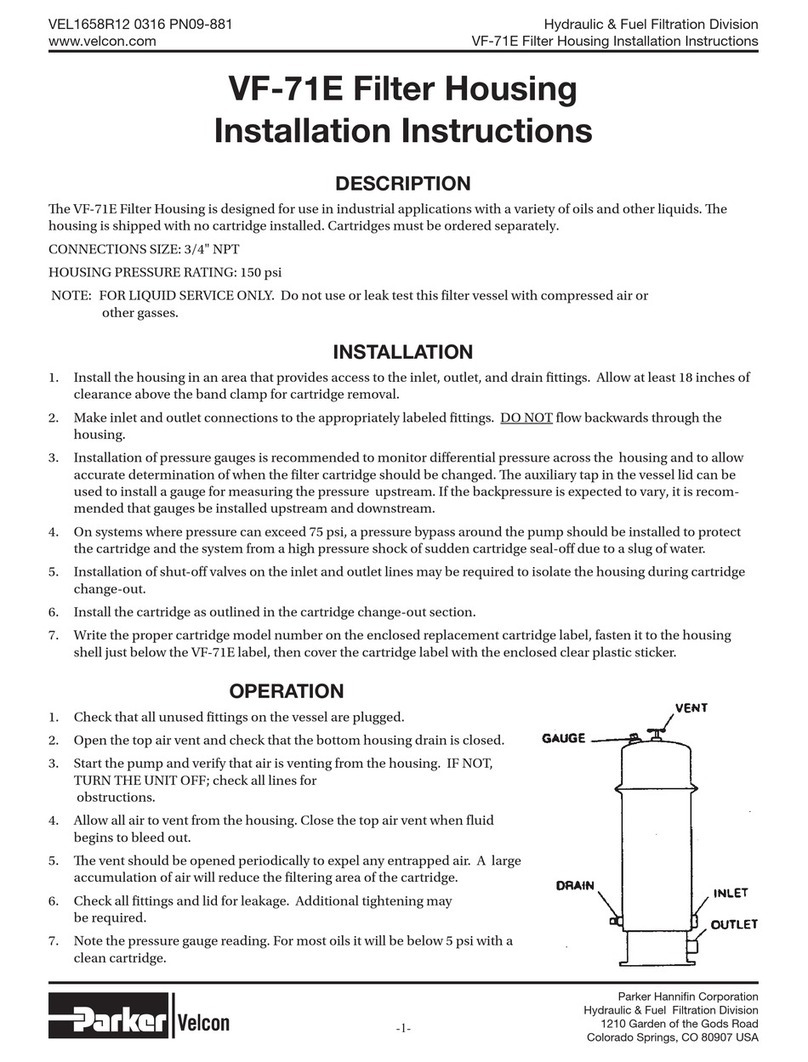

Velcon

Velcon VF-71E installation instructions

Katadyn

Katadyn PowerSurvivor 40E owner's manual

Purofilter

Purofilter 53-WF-02PF installation instructions

Watts

Watts SmartStream UV WB002 Installation, operation and maintenance manual

ENBIO

ENBIO Magic Filter user manual

Antunes

Antunes 9700901 quick start guide

Triton

Triton IXC-850 Series User & service manual

Zen Water

Zen Water Filter and Purifier System user guide