1

INDEX

1. Product specification introduction ----------------------------------------------------------------------------------- 02

2. Appearance -------------------------------------------------------------------------------------------------------------- 03

2.1 Panel ----------------------------------------------------------------------------------------------------------------- 03

2.2 Bottom --------------------------------------------------------------------------------------------------------------- 03

2.3 Upper cover --------------------------------------------------------------------------------------------------------- 03

3. First page ---------------------------------------------------------------------------------------------------------------- 04

4. Setting ------------------------------------------------------------------------------------------------------------------- 06

4.1 Login ----------------------------------------------------------------------------------------------------------------- 06

4.2 Normal --------------------------------------------------------------------------------------------------------------- 07

4.2.1 Tree View ---------------------------------------------------------------------------------------------------- 07

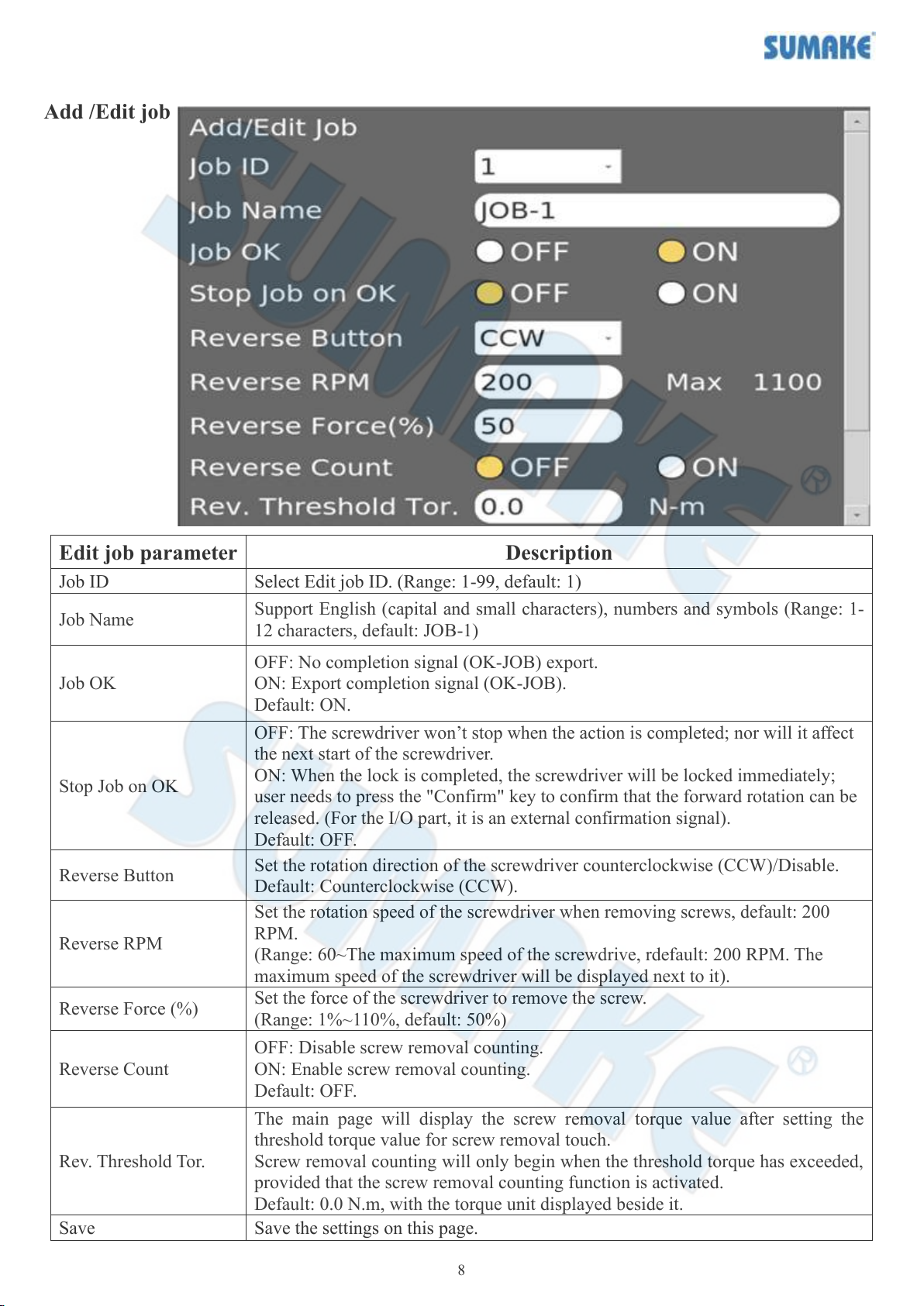

4.2.2 Edit job ------------------------------------------------------------------------------------------------------ 07

4.2.3 Sequence ----------------------------------------------------------------------------------------------------- 09

4.2.4 Torque -------------------------------------------------------------------------------------------------------- 11

4.2.5 Angle --------------------------------------------------------------------------------------------------------- 13

4.3 Advanced ------------------------------------------------------------------------------------------------------------ 15

4.3.1 Tree View ---------------------------------------------------------------------------------------------------- 15

4.3.2 Edit job ------------------------------------------------------------------------------------------------------ 15

4.3.3 Sequence ---------------------------------------------------------------------------------------------------- 17

4.3.4 Step ---------------------------------------------------------------------------------------------------------- 18

4.4 Tool ------------------------------------------------------------------------------------------------------------------ 21

4.5 Controller ----------------------------------------------------------------------------------------------------------- 22

4.6 Import --------------------------------------------------------------------------------------------------------------- 23

4.7 Export --------------------------------------------------------------------------------------------------------------- 24

4.8 System --------------------------------------------------------------------------------------------------------------- 25

4.8.1 Permissions ------------------------------------------------------------------------------------------------- 25

4.8.2 Date/time ---------------------------------------------------------------------------------------------------- 26

4.8.3 Screen Setting ---------------------------------------------------------------------------------------------- 26

4.8.4 System management -------------------------------------------------------------------------------------- 27

4.8.5 Firmware updating ---------------------------------------------------------------------------------------- 28

5. Edit job / Sequence ---------------------------------------------------------------------------------------------------- 29

6. Data ---------------------------------------------------------------------------------------------------------------------- 30

6.1 Historic data -------------------------------------------------------------------------------------------------------- 30

6.2 Data export --------------------------------------------------------------------------------------------------------- 31

6.3 Import/export configuration file --------------------------------------------------------------------------------- 32

6.4 Export Graph Data(USB) ----------------------------------------------------------------------------------------- 32

7. Chart -------------------------------------------------------------------------------------------------------------------- 33

8. Barcode ----------------------------------------------------------------------------------------------------------------- 34

9. Information ------------------------------------------------------------------------------------------------------------- 36

10. Description of external export control ----------------------------------------------------------------------------- 38

11. Description of external import control ----------------------------------------------------------------------------- 38

12. Description of display status code ---------------------------------------------------------------------------------- 39

12.1 Abnormal messages from controller/screwdriver/lock information --------------------------------------- 39

12.2 System messages ------------------------------------------------------------------------------------------------- 40

12.3 Fasten Status ------------------------------------------------------------------------------------------------------ 40

13. Modbus Instruction---------------------------------------------------------------------------------------------------- 41