Sumitomo Cyclo BBB4 User manual

5FMt4.$:$-0'BYCyclo® BBB4 Bevel Buddybox®

Right Angle Spiral Bevel Gearbox

with Cyclo® Reducer Input

Operation and

Maintenance

Manual

Manual 13.604.60.001

5FMt4.$:$-0'BY$PSPOB$"5FMt4.$:$-0'BY0BLWJMMF0OUBSJP$BOBEB--,5FMt'BY5FMt'BY#MWE%BOJFM+PIOTPO5FMt'BY5FMt'BY5FMt'BY5FMt'BY"W.BSRVÐTEF4ÍP7JDFOUF$K5FMt'BY5FMt'BY$BMMF.BO[BOB/4JUJP5FMt'BY$BNJOPB$PSPOFM,N.PEVMP"5FMt'BY*OH%FMQJOJ(SBOE#PVSH#VFOPT"JSFT"SHFOUJOB#,(#5FMt'BY5IJOL1BSL5PXFS0TBLJDIPNF5FMt'BY

ration and

Ope

i

M

Operation & Maintenance Manual 1

Cyclo® BBB4

Cyclo® BBB4

Important Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Inspection Upon Delivery . . . . . . . . . . . . . . . . . . . . . . 3

Nameplate Inspection . . . . . . . . . . . . . . . . . . . . . . . . 3

Lubrication Inspection . . . . . . . . . . . . . . . . . . . . . . . . 3

Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Storing and Transporting . . . . . . . . . . . . . . . . . . . . . . 6

Storage Location . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Storage Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Operation After Storage . . . . . . . . . . . . . . . . . . . . . . . 6

Transporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation Precautions. . . . . . . . . . . . . . . . . . . . . . . . 7

Installation Location. . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation Angle . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Severe Loading Conditions . . . . . . . . . . . . . . . . . . . . . 7

Installation onto the Driven Machine . . . . . . . . . . . . . . . 7

Installation onto Driven Shaft . . . . . . . . . . . . . . . . . . . 8

Taper-Grip® Bushing. . . . . . . . . . . . . . . . . . . . . . . . . . 8

Keyed Hollow Bore. . . . . . . . . . . . . . . . . . . . . . . . . . 12

Shrink Disc Type Hollow Bore . . . . . . . . . . . . . . . . . . . 14

Torque Arm Installation . . . . . . . . . . . . . . . . . . . . . . 16

Torque Arm Introduction . . . . . . . . . . . . . . . . . . . . . . 16

Flange Mount (Banjo) Type Torque Arm. . . . . . . . . . . . . 16

T-Type Torque Arm . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Removal from Driven Shaft . . . . . . . . . . . . . . . . . . . . 20

Cyclo® BBB4 with Taper-Grip® Bushing . . . . . . . . . . . . . 20

Cyclo® BBB4 with Keyed Hollow Bore . . . . . . . . . . . . . . 21

Cyclo® BBB4 with Shrink Disc . . . . . . . . . . . . . . . . . . . 22

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Lubrication Introduction . . . . . . . . . . . . . . . . . . . . . . 23

Lubrication Nomenclature . . . . . . . . . . . . . . . . . . . . . 23

Lubrication Method . . . . . . . . . . . . . . . . . . . . . . . . . 24

Bevel Gear Portion and Cyclo® Portion Recommended Oils . 25

Cyclo® Portion Recommended Greases . . . . . . . . . . . . . 25

Oil Quantities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Oil Supply Procedure . . . . . . . . . . . . . . . . . . . . . . . . 27

Oil Discharge Procedure . . . . . . . . . . . . . . . . . . . . . . 27

Grease Quantities . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Grease Replenishment and Draining Procedures . . . . . . . 29

Grease Replacement . . . . . . . . . . . . . . . . . . . . . . . . 29

Motor Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Wiring Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Measuring Insulation Resistance . . . . . . . . . . . . . . . . . 30

Motor Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Motor Wiring Method . . . . . . . . . . . . . . . . . . . . . . . . 31

Brake Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Varistor Selection . . . . . . . . . . . . . . . . . . . . . . . . . . 32

U.S. Standard and CSA Approved Motor Brake Wiring . . . . 33

Table of Contents

Models CMB-20 Brakes . . . . . . . . . . . . . . . . . . . . . . . 34

CE Motor Brake Wiring . . . . . . . . . . . . . . . . . . . . . . . 35

CE Motors Models FB-01A through FB-15B with Inverter . . 36

Brake Rectifiers and Power Modules . . . . . . . . . . . . . . . 37

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Cyclo® BBB4 Reducer Parts . . . . . . . . . . . . . . . . . . . . . 38

Cyclo® Planetary Reduction Component Parts

(Cyclo® Ratios 11 – 18:1). . . . . . . . . . . . . . . . . . . . 39

Cyclo® Reduction Component Parts

(Cyclo® Ratios ≥ 19:1) . . . . . . . . . . . . . . . . . . . . . 40

Bearings and Oil Seals. . . . . . . . . . . . . . . . . . . . . . . . 42

Bevel Gearing Parts and Tooth Count . . . . . . . . . . . . . . 43

Cyclo® BBB4 Screw Conveyor Options. . . . . . . . . . . . . . 44

Screw Conveyor Components . . . . . . . . . . . . . . . . . . . 44

Screw Conveyor Assembly Instructions . . . . . . . . . . . . . 44

Cyclo® Portion Disassembly/Assembly . . . . . . . . . . . . . 47

Cyclo® Portion - General Disassembly . . . . . . . . . . . . . . 47

Cyclo® Portion - General Reassembly . . . . . . . . . . . . . . 51

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Cyclo® BBB4

2Operation & Maintenance Manual Cyclo® BBB4

Important Notes

Safety Symbols

These safety symbols appear throughout this manual to indicate

important warnings:

DANGER: Incorrect handling of the unit and/or

failure to follow the instructions may cause physical

damage, serious personal injury, and/or death.

CAUTION: Incorrect handling of the unit and/or

failure to follow the instructions may cause physical

damage and/or personal injury.

Safety Precautions

Review and adhere to the instructions in this manual to ensure:

tUSPVCMFGSFF$ZDMP¥###PQFSBUJPOtZPVSSJHIUTUPNBLFBXBSSBOUZDMBJNRead this manual and all accompanying documents thoroughly

before use. Understand the machine, information on safety, and

all precautions for correct operation. Sumitomo recommends

that this manual is easily accessible for reference at the machine

location. tOnly properly trained personnel should

transport, install, align, wire, inspect, operate, and

maintain the unit.

t8IFOUIFVOJUJTUPCFVTFEJOBTZTUFNGPStransport of human beings, a secondary safety

device should be installed to guard against

accidents that may result in injury, death, or

damage to the system.

t8IFOUIFVOJUJTUPCFVTFEGPSBOFMFWBUPSJOTUBMMBsafety device on the elevator side to prevent it from

falling; otherwise, serious injury, death, or damage

to the elevator may result.

CAUTION:

t0QFSBUFUIFVOJUPOMZXJUIJOJUTEFTJHOBOEperformance specifications; otherwise, injury or

damage to the system may occur.

t,FFQIBOETBOEBMMGPSFJHOPCKFDUTGSPNUIFinternal moving parts of the unit; otherwise, injury

or damage to the system may occur.

t5BLFEBNBHFEVOJUTPõMJOFJNNFEJBUFMZBOEEPnot resume operation until properly repaired.

t.PEJmDBUJPOTPSBMUFSBUJPOTPGBOZLJOEUPUIFVOJUwill void the warranty and all subsequent claims.

t%POPUSFNPWFUIFSBUJOHQMBUFDisposal

Please refer to local, state, and federal regulations governing

disposal of:

Steel Scrap:

t)PVTJOH%VDUJMFBOE(SBZ$BTU*SPOt(FBSTt4IBGUTt#FBSJOHTLubricants:

t(FBS0JMt(SFBTF

Operation & Maintenance Manual 3

Cyclo® BBB4

Cyclo® BBB4

Delivery

Inspection Upon Delivery

t*OPSEFSUPBWPJEJOKVSZensure that the unit is in

a stable position before unpacking.

tVerify that the unit received matches your

order. Using the incorrect product may cause

equipment damage or personal injury.

tDo not remove the nameplate from the unit.

Upon delivery, inspect the unit for damage that may have

occurred during shipment. Notify the shipping company

immediately if you find any damage. Do not install or operate a

damaged unit.

Upon receipt of the reducer/gearmotor, verify that:

tUIFNPEFMOVNCFSPOUIFVOJUOBNFQMBUFNBUDIFTUIFpurchase order

tUIFVOJUXBTOPUEBNBHFEEVSJOHTIJQQJOHtBMMCPMUTBOEOVUTBSFGVMMZUJHIUFOFEPlease consult your Sumitomo agent, distributor, or sales office if

you find any defects or if you have any questions.

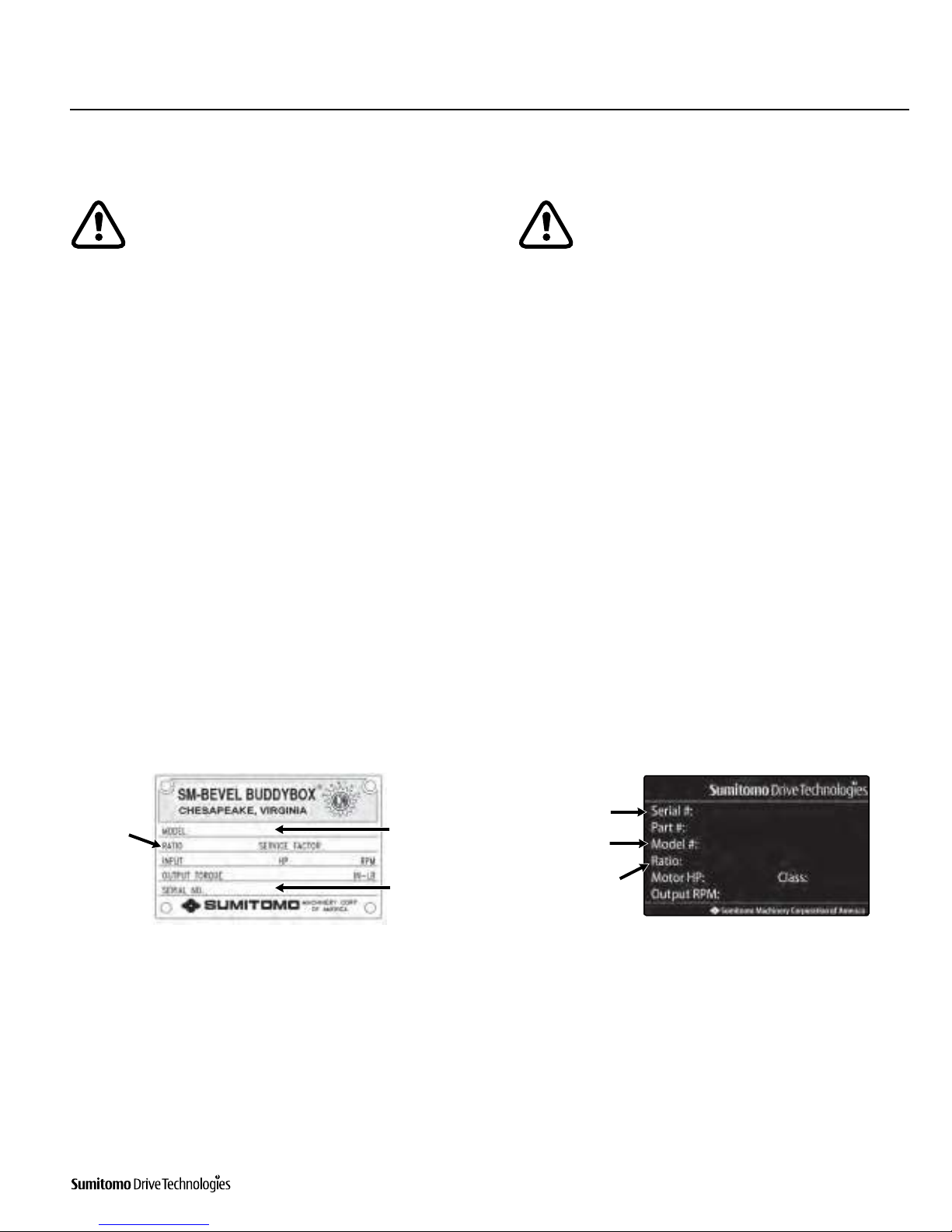

Nameplate Inspection

When contacting Sumitomo about this product, please be

prepared to provide the following information from the reducer/

gearmotor nameplate:

tSFEVDFSPSHFBSNPUPSNPEFMOVNCFSOPNFODMBUVSFtSFEVDUJPOSBUJPtTFSJBMOVNCFSLubrication Inspection

tOil lubricated units are shipped without oil,

unless the customer specified otherwise when

the unit was ordered. Always fill the unit with

the correct type and quantity of lubricant prior to

operation.

tCertain models must be filled with lubricant in

two separate locations, the Bevel Gear portion

(output) and the input portion.

Refer to the lubrication section in this manual for detailed

lubrication information.

Nominal

Reduction

Ratio

Unit Model

Number

Unit Serial

Number

TESA Nameplate

Nominal

Reduction

Ratio

Unit Serial

Number

Unit Model

Number

Metal Nameplate

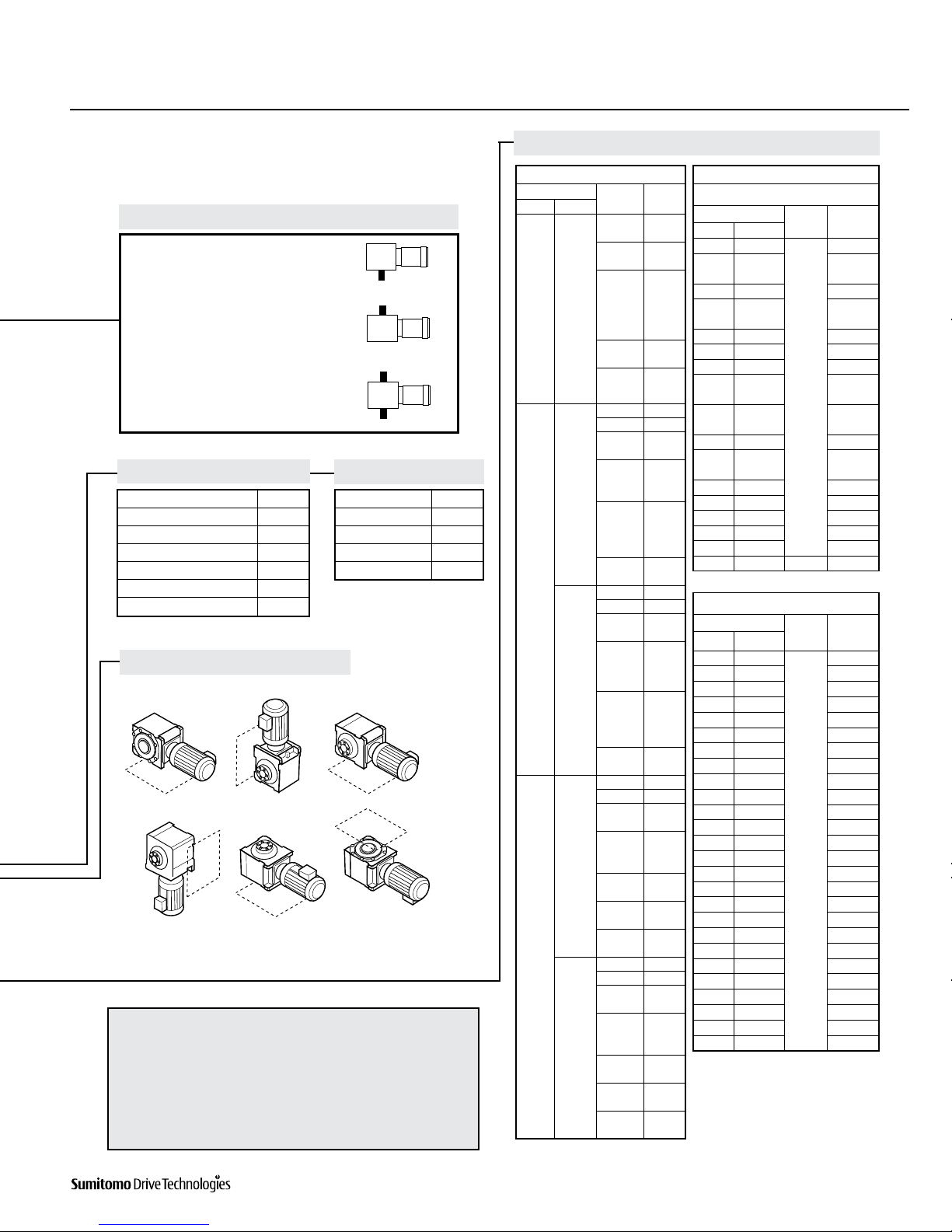

Cyclo® BBB4

Type Prefix

Unit built with special mods S

Shrink Disc S

No special mods applied

Cyclo® BBB4

4Operation & Maintenance Manual4Operation & Maintenance Manual

Type of Input Reducer

Prefix

Gearmotor

Prefix

Gearmotor M

Free Input Shaft

w/ Input Adaptor J JM

w/Quill Adaptor X XM

Nomenclature

Nomenclature

Motor Power

(applies only to

1750 RPM)

Modification

Output Shaft Orientation

Frame Size

Shaft Specifications

AGMA Class

#SBLF(FBSNPUPS0OMZInput Connection

Mounting Style

Modification (Special feature) Mounting position and optional specification (as required)

Input connection Gearmotor or Reducer Specification

Mounting style AGMA class (Gearmotor only)

Output shaft orientation Shaft specification

Cyclo® BBB4 product code (always“L”)

Motor Power

Symbol (1750 RPM)

Frame Size Brake Ratio

HP (kW) Symbol

1/8 (0.1) 01

1/4 (0.2) 02

1/3 (0.25) 03

1/2 (0.4) 05

3/4 (0.55) 08

1(0.75) 1

1.5 (1.1) 1H

2(1.5) 2

3(2.2) 3

5(3.7) 5

7.5 (5.5) 8

10 (7.5) 10

15 (11) 15

20 (15) 20

25 (18.5) 25

30 (22) 30

40 (30) 40

50 (37) 50

60 (45) 60

75 (55) 75

Single Reduction

4A100 4B125 4C170 4E175

4A105 4B140 4C175 4E180

4A110 4B145 4D160 4E185

4A115 4B160 4D165 4E190

4A120 4B165 4D170 4E195

4A125 4C140 4D175 4F180

4A140 4C145 4D180 4F185

4A145 4C160 4D185 4F190

4B120 4C165 4E170 4F195

Double Reduction

4A10DA 4B16DA 4C17DC 4E17DC

4A12DA 4B16DB 4D16DA 4E18DA

4A12DB 4B16DC 4D16DB 4E18DB

4A14DA 4C14DA 4D16DC 4E19DA

4A14DB 4C14DB 4D17DA 4E19DB

4A14DC 4C14DC 4D17DB 4F18DA

4B12DA 4C16DA 4D17DC 4F18DB

4B12DB 4C16DB 4D18DA 4F19DA

4B14DA 4C16DC 4D18DB 4F19DB

4B14DB 4C17DA 4E17DA

4B14DC 4C17DB 4E17DB

Type Prefix

Horizontal H

Vertical V

Vertical Up (Solid Shaft) W

Type Prefix

Shaft Mount (Hollow Shaft) Y

Housing U

Flange (Solid Shaft) F

Foot (Solid Shaft) H

Input

Shaft

Hollow Output

Shaft Suffix

mm Key (mm)

Inch Key (Inch) K

mm Taper-Grip® M

Inch Taper-Grip® Y

Class Suffix

I A

II B

III C

Suffix

With Brake B

No Brake

LHYMS 5 - 4 A 1 2 5 YY1 - B - 28

Output shaft direction (shafted model only)

B

Our nomenclature details specific information about our proucts. Verify that the nomenclature of the unit delivered matches your order.

Operation & Maintenance Manual 5

Cyclo® BBB4

Cyclo® BBB4

Nomenclature, continued

Gearmotor Specification Reducer Specification

Mounting Positions

Nomenclature Example:

LHYMS-5-4A125-YBY1-B-28

L- Cyclo® Bevel Buddybox

H- Horizontal

Y- Shaft Mount (Hollow Shaft)

M- Gearmotor

S- Special Modifications

5 - 5 HP (3.7kW), 1750 RPM

4A125 - Frame Size

Y- Inch Shaft Specification

B- AGMA Class

Y1 - Mounting Position

B- Brake (gearmotor only)

28 - Ratio

Specification Suffix

Three-Phase Motor

Single-Phase Motor SG

AF Motor (Adj. Frequency) AV

Servo Motor SV

DC Motor DV

Torque Limiter TL

Type Suffix

Standard

Baseplate BP

Shovel Base SB

DC Motor DV

Nominal and Exact Ratio

Y1

Projects to Left Side L

Projects to Right Side R

Projects to Both Left/Right Sides T

Output Shaft DirectionTIBGUFENPEFMPOMZY4

Y2 Y3

Y5

Y6

BBB with Planetary Input

Nominal Ratio Frame

Size

Exact

Ratio

Input Overall

3 11

4A10 10.50

4A12

4A14 10.89

4B14

4B16

10.85

4C16

4D16

4D17

4E17

4E18 10.50

4F18

4E19 10.82

4F19

4

13

4A10 12.99

4A12 12.80

4A14 12.95

4B14

4B16

12.804C16

4D16

4D17

13.09

4E17

4E18

4F18

4E19 13.01

4F19

14

4A10 14.21

4A12 14.00

4A14 14.16

4B14

4B16

14.004C16

4D16

4D17

14.32

4E17

4E18

4F18

4E19 14.23

4F19

5

16

4A10 15.36

4A12 15.65

4A14 16.00

4B14

4B16

16.264C16

4D16

4D17 16.17

4E17

4E18 15.63

4F18

4E19 15.47

4F19

18

4A10 16.80

4A12 17.12

4A14 17.50

4B14

4B16

17.784C16

4D16

4D17 17.68

4E17

4E18 17.10

4F18

4E19 16.92

4F19

BBB with Cyclo Input

Single Reduction

Nominal Ratio Frame

Size

Exact

Ratio

Input Overall

6 21

All

21.0

722 22.4

25 24.5

8 28 28.0

11 35 35.2

39 38.5

13 46 45.5

15 53 52.5

17 60 59.5

21 67 67.2

74 73.5

25 80 80.0

88 87.5

29 102 101.5

35 112 112.0

123 122.5

43 151 150.5

51 179 178.5

59 207 206.5

71 249 248.5

87 305 304.5

119 417 4A10 416.5

Double Reduction

Nominal Ratio Frame

Size

Exact

Ratio

Input Overall

104 364

All

364.0

121 424 423.5

143 501 500.5

165 578 577.5

195 683 682.5

231 809 808.5

273 956 955.5

319 1117 1116.5

377 1320 1319.5

473 1656 1655.5

559 1957 1956.5

649 2272 2271.5

731 2559 2558.5

841 2944 2943.5

1003 3511 3510.5

1247 4365 4364.5

1479 5177 5176.5

1849 6472 6471.5

2065 7228 7227.5

2537 8880 8879.5

3045 10658 10657.5

3481 12184 12183.5

4437 15530 15529.5

5133 17966 17965.5

6177 21620 21619.5

7569 26492 26491.5

Cyclo® BBB4

6Operation & Maintenance Manual Cyclo® BBB4

Storing and Transporting

Storage Location

t4UPSFUIFVOJUJOBDMFBOESZBSFBtDo not store outdoors or in an area with high humidity, dust,

sudden temperature changes, or corrosive gases.

Generally, the Cyclo® BBB4 gearbox is to be stored indoors, in an

ordinary factory or a warehouse. The unit should be sealed,

wrapped in plastic and additionally packed with desiccant.

Desiccant should be replaced periodically to keep the inside

of the box dry. Use of color changing desiccant will aid in

identifying when desiccant should be changed.

Storage Period

tDo not store the unit for longer than 3 months without

following long-term storage procedures recommended by

Sumitomo.

t$POTVMU4VNJUPNPXIFOTUPSJOHUIFVOJUGPSNPSFUIBOmonths. Rust proofing procedures are required.

t$POTVMU4VNJUPNPXIFOFYQPSUJOHUIFVOJU3VTUQSPPmOHprocedures may be required.

If the Cyclo® BBB4 gearbox will be inactive for a long period of

time, long-term storage preparation is required to prevent rust

or other degradation to the gearbox.

LONG-TERM STORAGE SPECIFIED WITH ORDER:

If long-term storage is specified at the time of order entry, Shell

VSI Circulating Oil #32 or NP-20 [JIS] equivalent rust preventative

is already sprayed into the Cyclo® BBB4 reducer and the air vent is

replaced with a sealing plug before shipping the reducer from

Sumitomo factory. External machined surfaces are coated with a

suitable NP-19 [JIS] petroleum base corrosion preventative such

as Black Bear Par-Al-Ketone, Houghton Rust Veto 342, Daphne

Ever Coat No.1 or equivalent.

Consult Sumitomo for Long Term Storage procedures:

t4UPSBHFXJUIPVUGBDUPSZQSFQBSBUJPOTt0OHPJOHNBJOUFOBODFEVSJOHTUPSBHFQFSJPEOperation After Storage

Before operating the unit after an extended storage period, flush

unit of rust preventative and ensure that non-metal parts, i.e., oil

seals, o-rings, air breather, have not deteriorated. Non-metal parts

may deteriorate easily from exposure to ambient conditions (i.e.,

extreme temperatures, UV rays). Replace deteriorated parts with

new before unit start-up.

After starting the unit, verify that there is no abnormal noise,

vibration, and/or temperature rise. Immediately stop the unit and

call your local distributor, Original Equipment Manufacturer or

Sumitomo directly if you observe any abnormality.

Transporting

tDo not stand directly under a unit suspended by a

lifting mechanism. Injury or death may occur if the

unit is dropped.

tBefore lifting the unit, determine its weight (refer

to catalog, packing list, etc.) and ensure that the

moving equipment will support the unit’s weight.

tNever hoist or move a unit that exceeds the

moving equipment’s rated capacity or else

personal injury and/or equipment damage may

occur.

tDo not allow the unit to drop or fall while moving.

Always use the eye bolts attached to the gear

housing (and on motor if supplied) when moving

the unit. After securing the unit to the machine,

remove the moving hooks/straps from the

eyebolts.

Operation & Maintenance Manual 7

Cyclo® BBB4

Cyclo® BBB4

Installation Notes

Installation Precautions

t%POPUVTFUIFSFEVDFSHFBSNPUPSGPSTQFDJmDBUJPOTother than those shown on the nameplate or in the

manufacturing specification documents. Personal

injury and/or equipment damage may occur.

t%POPUQMBDFDPNCVTUJCMFNBUFSJBMPOPSBSPVOEthe unit; fire may occur.

t%POPUQMBDFBOZPCKFDUTBSPVOEUIFVOJUUIBUXJMMprohibit proper ventilation. Inadequate ventilation

may lead to high unit temperature and/or fire.

t%POPUTUFQPOPSIBOHGSPNUIFVOJU&YDFTTJWFweight may cause component breakage leading to

personal injury and/or equipment damage.

t%POPUUPVDIUIFTIBGULFZXBZPSNPUPSGBOXJUIbare hands; injury may occur.

t'PSBQQMJDBUJPOTJOXIJDIMVCSJDBOUMFBLTDPVMEBEWFSTFMZBõFDUPQFSBUJPOTJFQBDLBHFIBOEMJOHfood processing), place an oil pan below the unit to

protect against contamination that may occur if oil

seals become damaged or worn.

t%POPUSFNPWFUIFFZFCPMUGSPNUIFNPUPS4IPVMEthe eye-bolt need to be removed for any reason,

install a replacement bolt in the tapped hole to

prevent water from entering the motor.

Installation Location

Ambient Temperature Range: 14° - 104°F (-10° - 40°C)

Ambient Humidity: 85% or less

Ambient Conditions: 14°F minimum

Altitude: 3,280 feet (1,000 m) or less

Atmosphere: The location should not contain corrosive gas,

explosive gas, or steam. The location should be free

of dust and well ventilated.

Location: Indoor – free of dust and water

Consult Sumitomo when the unit will operate in conditions other

than those specified above. Special unit modifications may be

required.

Units manufactured according to customer specified application

requirements (i.e. outdoor modifications, high-temperature

modifications) are designed to operate within the specified

environment.

Install the unit so inspection and/or maintenance procedures may

be easily performed. Install all units that are not shaft mounted

on a sufficiently rigid base.

Torque arm clearance with machine structure is required to allow

for machine shaft run out. Refer to the Torque Arm Installation

section in this manual for additional information.

Installation Angle

Mount the unit in the specified position for which it was

ordered. Confirm the mounting position from the gearbox

nameplate.

Consult your local distributor, Original Equipment Manufacturer

or Sumitomo directly if the mounting angle is to be other than

horizontal or vertical.

Severe Loading Conditions

For applications with severe vibration and/or frequent starts and

stops, Sumitomo recommends the use of high-strength mounting

bolts of Grade 8.8 (or greater).

Installation onto the Driven Machine

t#FGPSFDPVQMJOHUIFSFEVDFSHFBSNPUPSUPUIF

machine, verify the appropriate/desired rotation of

UIFNBDIJOF%JõFSFODFTJOUIFSPUBUJPOBMEJSFDUJPOmay cause personal injury and/or equipment dam-

age.

t#FGPSFPQFSBUJOHUIFVOJUFOTVSFUIBUBMMTBGFUZguards around the rotating components are

in-place and secure. Failure to do so may result in

personal injury.

t8IFOKPJOJOHUIFSFEVDFSPSHFBSNPUPSUPUIFMPBEensure that the center alignment, belt tension, and/

or parallelism of the coupling device are within the

coupling manufacturer’s established recommendations.

For applications with a belt, ensure that the belt is

properly tensioned to the manufacturer’s specification,

and the bolts securing the pulley and couplings

are sufficiently tightened. Failure to follow these

precautions may result in personal injury and/or

equipment damage.

8Operation & Maintenance Manual

Cyclo® BBB4

Cyclo® BBB4

Installation onto Driven Shaft

Taper-Grip® Bushing

Taper-Grip® Bushing Introduction

The keylessTaper-Grip® bushing system provides a simple and reliable shaft attachment

for Sumitomo speed reducers and gearmotors. This system allows bi-directional shaft

rotation operation with a powerful, slip-free grip.To assure peak performance of your

equipment, please read, understand and follow these installation instructions.

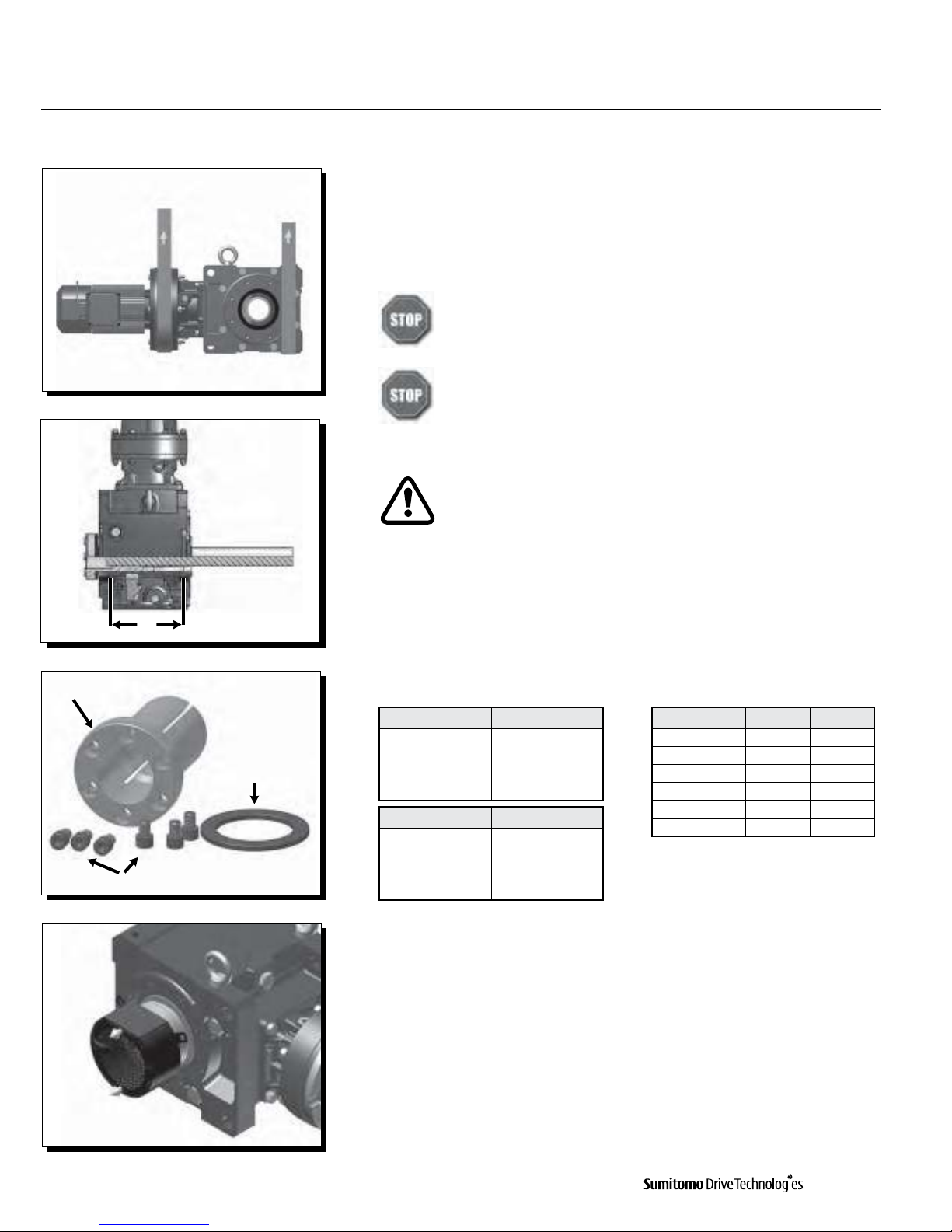

Prior to installation of the Cyclo® BBB4 onto the driven shaft, ensure that

the shaft length meets or exceeds the minimum shaft engagement value

“TT” detailed in Table 1.

Do not operate unit until the torque arm has been attached to the unit

and fixed to a rigid structure. The torque arm prevents counter-rotation

during unit operation. Refer to torque arm installation section in this

manual for instructions.

CAUTION: The Cyclo® BBB4 must be externally supported prior to

insertion of driven shaft into bushing. External support MUST be

maintained until all bushing socket head cap screws have been

tightened to the appropriate operational torque.

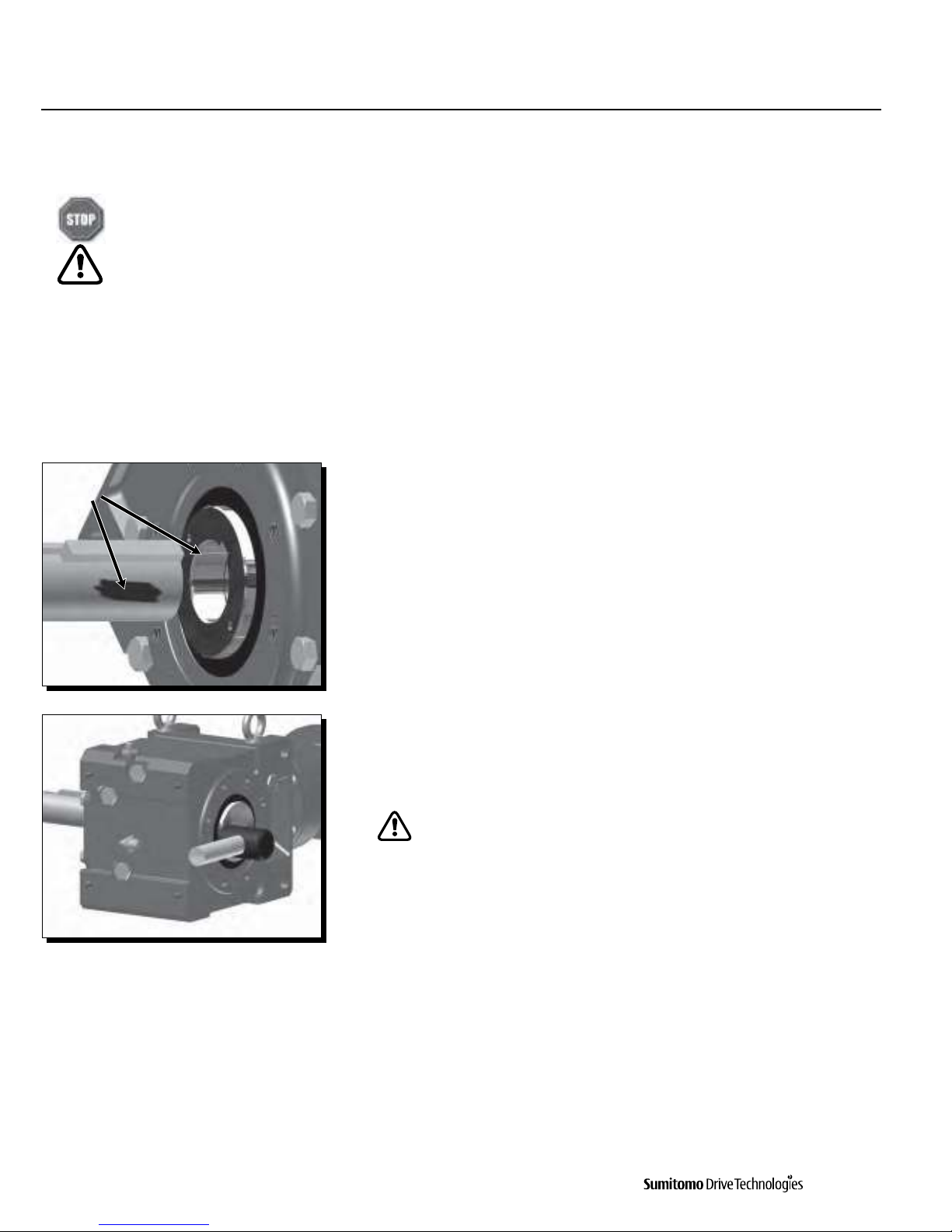

Components of Taper-Grip® Bushing

As shown in the figure on the left, the Taper-Grip® bushing includes the bushing,

thrust collar, and socket head cap screws.

Table 1. Driven Shaft Tolerance [1] and Minimum Shaft Engagement

Taper-Grip® Bushing Installation onto Driven

Shaft

1

Remove bushing cover if unit was supplied with one.

Taper-Grip® Bushing

Socket Head Cap Screws

Thrust Collar

TT 4IBGU%JBNFUFSJO5PMFSBODFJO1-3/16 – 1-15/16 +0 / -0.0015

2 – 3-1/8 +0 / -0.0018

3-3/16 – 4-11/16 +0 / -0.0021

4-3/4 – 6-1/2 +0 / -0.0025

Cyclo® BBB4 Size 55JOTT (mm)

4A 7.79 (198)

4B 9.33 (237)

4C 10.16 (258)

4D 11.82 (300)

4E 13.94 (354)

4F 16.22 (412)

Shaft Diameter (mmTolerance (μm)

(30 - 50) (+0 / -39)

(50 - 80) (+0 / -46)

(80 - 120) (+0 / -54)

(120 - 180) (+0 / -63)

Note: [1] Based on ISO/JIS/DIN h8

Cyclo® BBB4

Operation & Maintenance Manual 9

Cyclo® BBB4

Installation onto Driven Shaft, continued

Taper-Grip® Bushing

Clean Driven

Shaft

2

Loosen socket head cap screws.

3

Remove (unscrew) Taper-Grip® bushing from the unit.

4

Clean all grease, oil and/or anti-seize grease from the driven shaft. Failure to do so

could result in damage to shaft.

Slide Taper-Grip® bushing onto driven shaft.

5

Inspect and test Taper-Grip® bushing on shaft.

t$IFDLTIBGUGPSburrs, corrosion, or warpage. Repair or replace shaft

as necessary.

t4MJEFCVTIJOHCBDLBOEGPSUIBMPOHTIBGUDIFDLJOHGPSTVSGBDFJSSFHVMBSJUJFT

and fit.

t7FSJGZCVTIJOHJTTJ[FEDPSSFDUMZGPSUIFTIBGUEJBNFUFS

10 Operation & Maintenance Manual

Cyclo® BBB4

Cyclo® BBB4

Installation onto Driven Shaft, continued

Taper-Grip® Bushing

Apply thin layer of

anti-seize grease to male

threads of bushing only.

Do not apply anti-seize

grease to the female

threads in the hub.

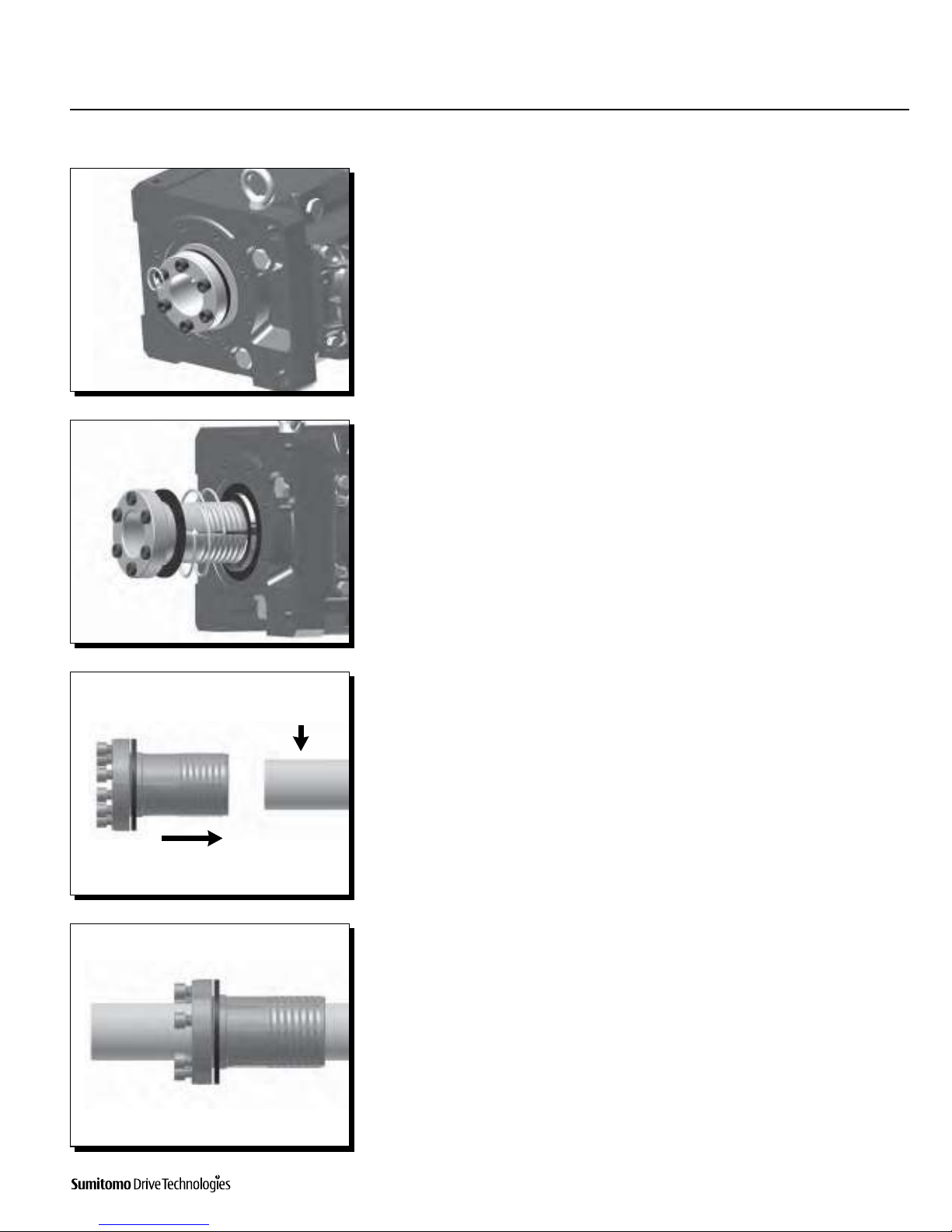

6

Remove Taper-Grip® bushing from driven shaft.

7

Apply a thin layer of anti-seize grease to the male threads of the Taper-Grip®

bushing only.

Ensure that the anti-seize grease does not enter the Taper-Grip®

bushing bore.

Do not apply anti-seize grease to the female threads in the hub.

8

Screw Taper-Grip® bushing into Cyclo® BBB4 leaving approximately 1 mm gap

between the bushing flange and thrust collar.

Do not apply grease, oil, or anti-seize grease to the driven shaft or the

bushing bore before placing the unit onto driven shaft. Use of these friction-

NJOJNJ[JOHQSPEVDUTXJMMBEWFSTFMZBõFDUUIFBCJMJUZPGUIFVOJUUPUSBOTNJUtorque.

CAUTION: The Cyclo® BBB4 must be externally supported prior to insertion

of driven shaft into bushing. External support MUST be maintained until all

bushing socket head cap screws have been tightened to the appropriate

operational torque.

9

Mount or slide the Cyclo® BBB4 onto the driven shaft to the desired location.

Do not rock or pry the unit.

Cyclo® BBB4

Operation & Maintenance Manual 11

Cyclo® BBB4

Installation onto Driven Shaft, continued

Taper-Grip® Bushing

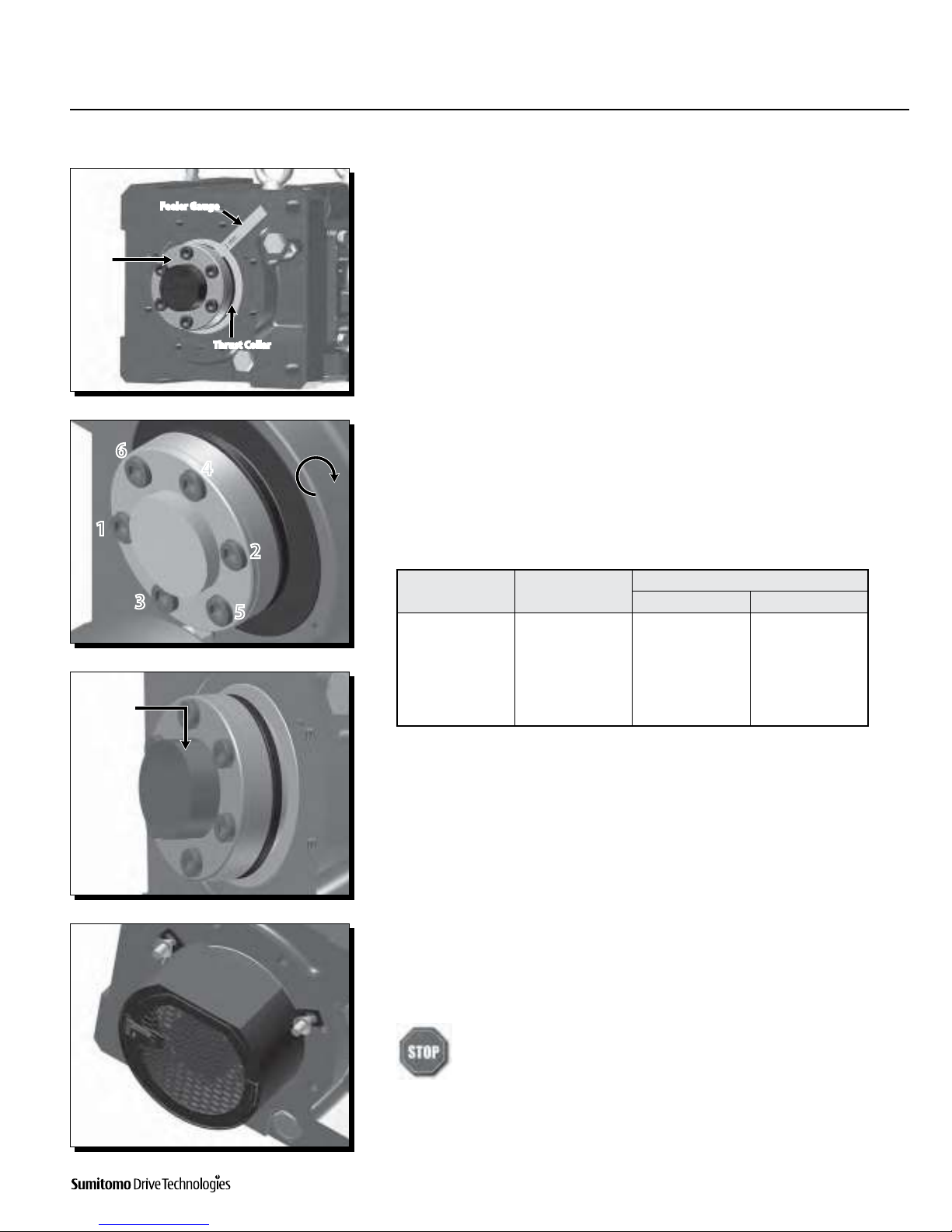

Bushing

Flange

Feeler Gauge

Thrust Collar

1

64

2

5

3

Apply grease

to exposed

portion of

driven shaft.

10

Screw Bolts into Taper-Grip® bushing.

t-JHIUMZPJMUISFBETPGFBDICPMUCFGPSFJOTFSUJOHt'JOHFSUJHIUFOFBDICPMUUPTFDVSFJOQMBDFt#FTVSFUPmaintain the 1 mm (approximate) gap between the thrust collar

and the bushing flange.

11

Tighten bushing bolts to the correct torque value.

t'PMMPXJOHBTUBSQBUUFSOVTFBUPSRVFXSFODIUPgradually tighten each socket

head cap screw in 20% increments.

t3FGFSUPTable 2, Taper-Grip® Bushing Bolt Tightening Torques, for the correct

operational screw torques.

Table 2. Taper-Grip® Bushing Bolt Tightening Torques

12

In order to prevent corrosion, apply grease to the exposed portion of the driven shaft.

tAfter installing and tightening the bushing bolts with a torque wrench, apply

grease or an anti-corrosion product to the exposed portion of the shaft.

13

For units that include a bushing safety cover, reinstall the guard over the

Taper-Grip® bushing.

Do not operate unit until the torque arm has been attached to the unit and

fixed to a rigid structure. The torque arm prevents counter-rotation during

unit operation. Refer to torque arm Installation section in this manual for

instructions.

Cyclo® BBB4 Size Screw Qty x Size

Screw Torque

MCtGU/tN4A 6 x M12 56 (75)

4B 6 x M12 104 (140)

4C 6 x M16 185 (250)

4D 6 x M16 223 (300)

4E 8 x M16 223 (300)

4F 10 x M16 223 (300)

12 Operation & Maintenance Manual

Cyclo® BBB4

Cyclo® BBB4

Installation onto Driven Shaft, continued

Keyed Hollow Bore

Keyed Hollow Bore Installation

Do not operate unit until the torque arm has been attached to the unit and fixed to a rigid structure. The torque arm prevents

counter-rotation during unit operation. Refer to torque arm Installation section in this manual for instructions.

CAUTION: The Cyclo® BBB4 must be externally supported prior to insertion of driven shaft into hollow bore.

Bore and Shaft Tolerance Specifications

t6OMFTTPUIFSXJTFTQFDJmFEUIFUPMFSBODFPGUIF)PMMPX4IBGU#PSFDPOGPSNTUP+*4)t*GBQQMJDBUJPOJOWPMWFTIJHITIPDLMPBEJOHBOEPSMBSHFSBEJBMMPBETBTIBGUUPMFSBODFPG+*4KTPS+*4LJTSFDPNNFOEFEGrease

Keyed Hollow Bore Installation

onto Driven Shaft

1

Apply anti seize compound to the driven shaft surface and inside the reducer keyed

hollow bore.

2

Align the driven shaft with the reducer/gearmotor bore and carefully slide unit onto

the driven shaft to the desired location.

If the fit is tight, strike on the keyed hollow bore with a wooden or hard rubber

mallet to assist in the assembly.

If using a mallet during installation, strike only against the unit’s steel keyed

hollow bore. Do not strike the reducer housing or oil seal as damage to the

bearings, housing and/or seals may occur.

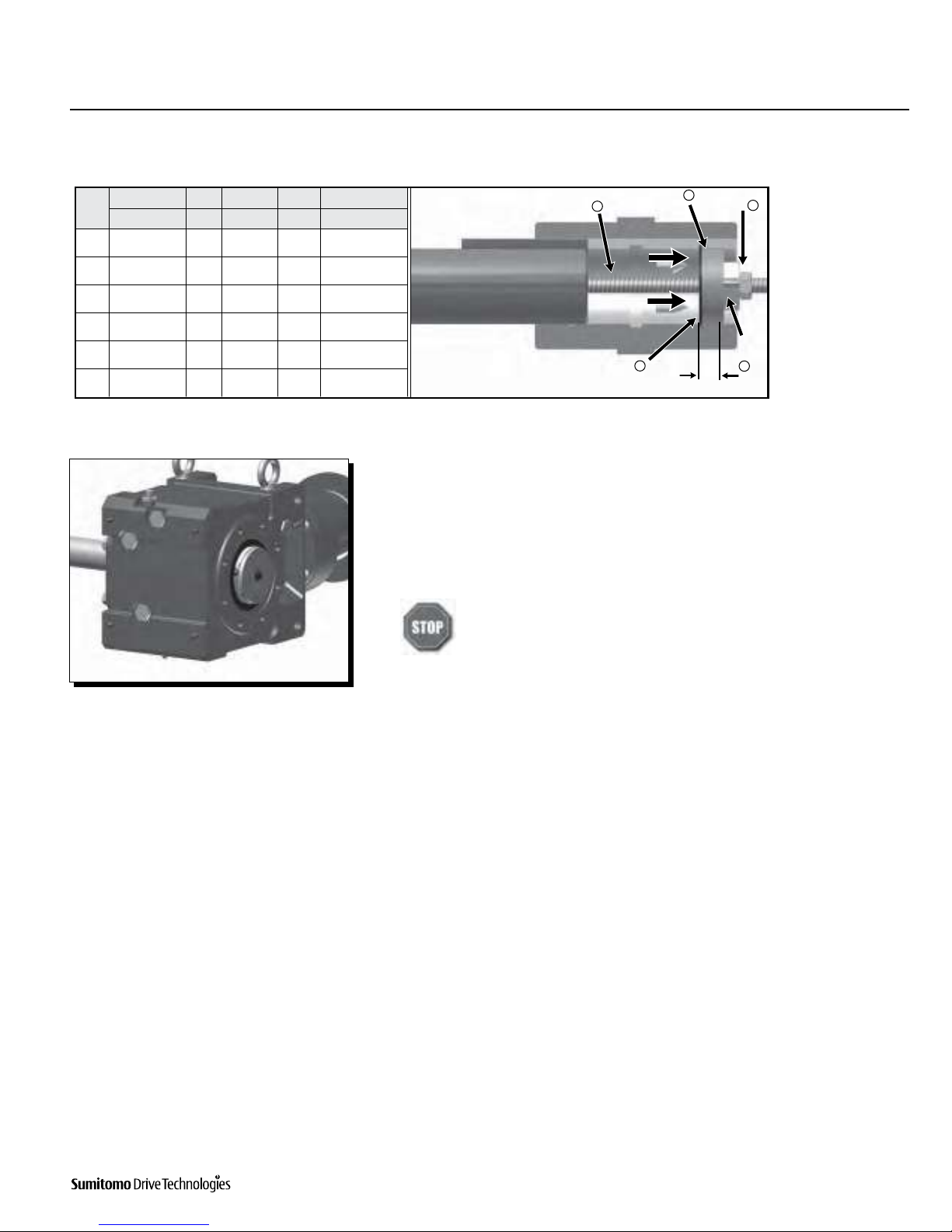

Note: If the fit is tight, use a jig such as the one shown in Table 3 to ease

assembly. Sumitomo does not supply a mounting jig. This information

is provided for reference only.

3

Once driven shaft has been completely inserted into the unit’s keyed hollow bore,

secure the shaft in place using a keeper plate as shown to the left, or some other

means of securing the unit to the driven shaft.

Do not operate unit until the torque arm has been attached. Refer to

the Torque Arm Installation section in this manual for instructions.

Cyclo® BBB4

Operation & Maintenance Manual 13

Cyclo® BBB4

Installation onto Driven Shaft, continued

Keyed Hollow Bore

Size a b c d e

$$*40+*4A2 Bearing Nut Threaded Rod

4A 3 25 51104 M16 M16 x 250

4B 65 25 51105 M20 M20 x 300

4C 75 25 51105 M20 M20 x 300

4D 85 35 51107 M24 M24 x 400

4E 100 35 51107 M24 M24 x 400

4F 120 46 51109 M30 M30 x 450

5BCMF+JH%JNFOTJPOT(mm)

Spacer b

Retaining Ring a

Ball

Bearing

c

Threaded Rod e Nut d

A2

14 Operation & Maintenance Manual

Cyclo® BBB4

Cyclo® BBB4

Shrink Disc Type Mounting Introduction

The keyless Shrink Disc provides a reliable commodity shaft attachment for Sumitomo speed reducers and gearmotors. This system allows

bi-directional shaft rotation operation with a powerful, slip-free grip.

To assure peak performance of your equipment, please read, understand and follow these installation instructions.

Do not operate unit until the torque arm has been attached to the unit and fixed to a rigid structure. The torque arm prevents

counter-rotation during unit operation. Refer to torque arm Installation section in this manual for instructions.

CAUTION: The Cyclo® BBB4 must be externally supported prior to insertion of driven shaft into hollow bore. External support

MUST be maintained until all shrink disc socket head cap screws have been tightened to the appropriate operational torque.

Bore and Shaft Tolerance Specifications

t3FGFSUPUIFDFSUJmFEPVUMJOFESBXJOHPS$ZDMP¥###$BUBMPHGPSSFDPNNFOEFENBDIJOFTIBGUEJNFOTJPOTt6OMFTTPUIFSXJTFTQFDJmFEUIFUPMFSBODFPGUIF4ISJOL%JTD#PSFDPOGPSNTUP+*4)t*GBQQMJDBUJPOJOWPMWFTIJHITIPDLMPBEJOHBOEPSMBSHFSBEJBMMPBETBTIBGUUPMFSBODFPG+*4KTPS+*4LJTSFDPNNFOEFEShrink Disc Type Hollow Bore Installation onto Shaft

Before placing unit onto driven shaft, do not apply grease, oil, or anti-seize grease to the entire driven shaft or to the bore of

the shrink disc. 6TFPGUIFTFGSJDUJPONJOJNJ[JOHQSPEVDUTXJMMBEWFSTFMZBõFDUUIFBCJMJUZPGUIFVOJUUPUSBOTNJUUPSRVFInstallation onto Driven Shaft, continued

Shrink Disc Type Hollow Bore

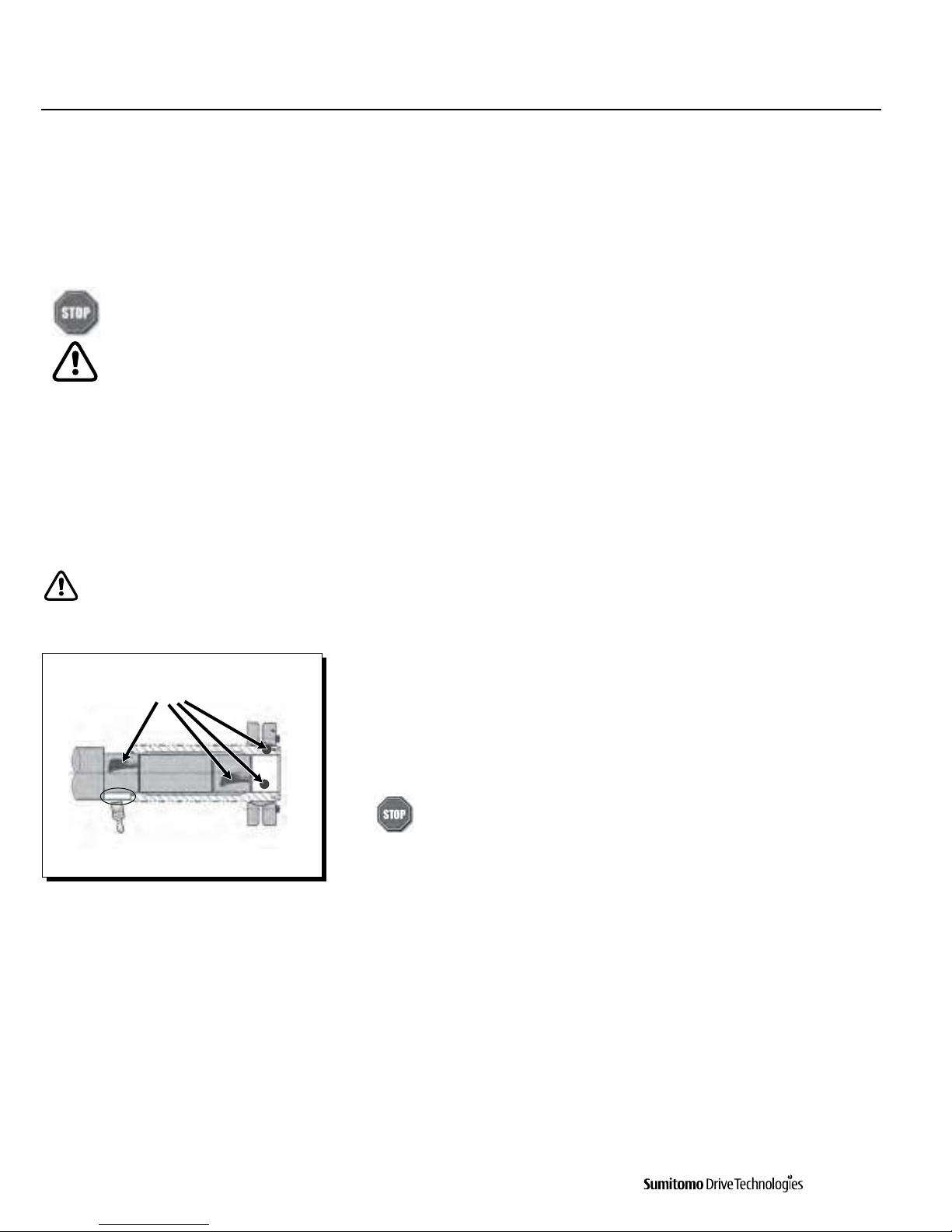

1

Clean and degrease contact surfaces; reducer shaft and bore, and the machine

driven shaft.

Apply Molykote 321 or an equivalent dry film lubricant to the driven shaft shoulder

opposite from the shrink disc.

Do Not apply any friction minimizing compound to the driven shaft at or

near the shrink disc.

Degrease

these areas

Apply Molykote 321

to this shaft area only

Cyclo® BBB4

Operation & Maintenance Manual 15

Cyclo® BBB4

Installation onto Driven Shaft, continued

Shrink Disc Type Hollow Bore

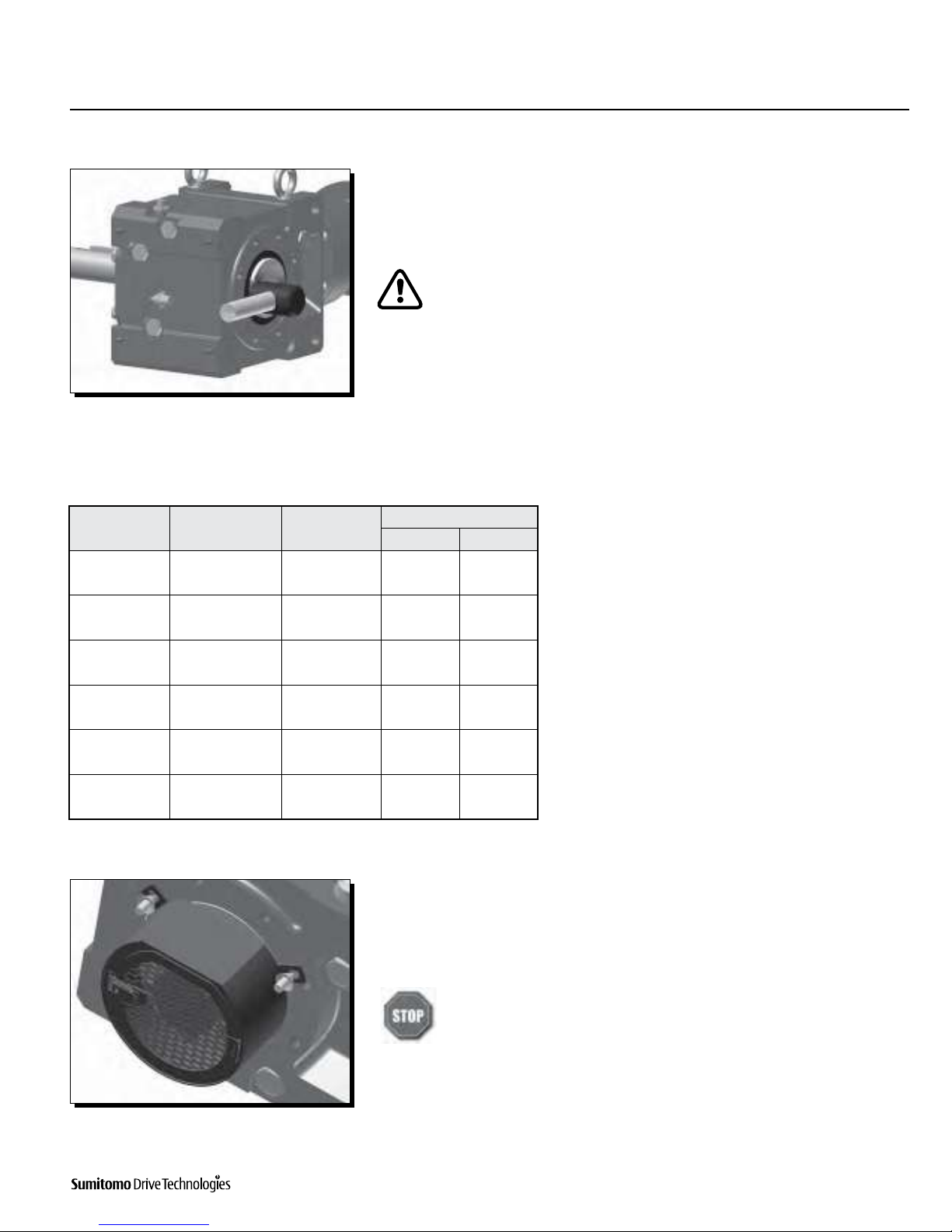

Size Model

5ZQJDBMBolt Bolt Torque

MCtGU/tN4A TAS-3071-55x68 10 x M6x25

ISO/JIS grade 10.9 9(12)

4B TAS-3071-65x80 7 x M8x30

ISO/JIS grade 12.9 26 (34)

4C TAS-3071-75x100 12 x M8x35

ISO/JIS grade 12.9 26 (34)

4D TAS-3071-85x110 9 x M10x40

ISO/JIS grade 12.9 51 (68)

4E TAS-3071-100x140 10 x M12x45

ISO/JIS grade 12.9 87 (118)

4F TAS-3071-120x165 8 x M16x55

ISO/JIS grade 12.9 214 (290)

Table 4. Shrink Disc Bolt Tightening Torques

4

For units with a safety cover, install the guard over the shrink disc.

Do not operate unit until the torque arm has been attached. Refer to the

Torque Arm Installation section in this manual for instructions.

3t4FUUIFVOUJHIUFOFETISJOLEJTDPOUIFSFEVDFSshaft.

t'PSQJFDFEFTJHOTISJOLEJTDNBLFTVSFUIBUboth plates are parallel when tightening bolts.

t"GUFSDPOmSNJOHUIBUUIFTISJOLEJTDJTTFU

correctly, tighten the bolts uniformly, in a

clockwise pattern while keeping both plates

parallel (not diagonally or ‘star’ pattern).

t*UJTSFDPNNFOEFEUPUJHIUFOSFTQFDUJWFCPMUTCZ30 degrees each time – until the specified torque

is reached.

2

Align the driven shaft with the bore of reducer/gearmotor bore and carefully slide unit

onto the driven shaft to the desired location.

t*GUIFmUJTUJHIUTUSJLFPOUIFSFEVDFSIPMMPXCPSFXJUIBXPPEFOPSIBSESVCCFSmallet to assist in the assembly.

If using a mallet during installation, strike only against the unit’s steel

hollow bore. Do not strike the reducer housing or oil seal, as damage to the

bearings, housing, and/or seals may occur.

If the fit is tight, use a jig such as the one shown in the Keyed Hollow Bore

Installation section to ease assembly. Sumitomo does not supply a

mounting jig. This information is provided for reference only.

16 Operation & Maintenance Manual

Cyclo® BBB4

Cyclo® BBB4

Torque Arm Installation

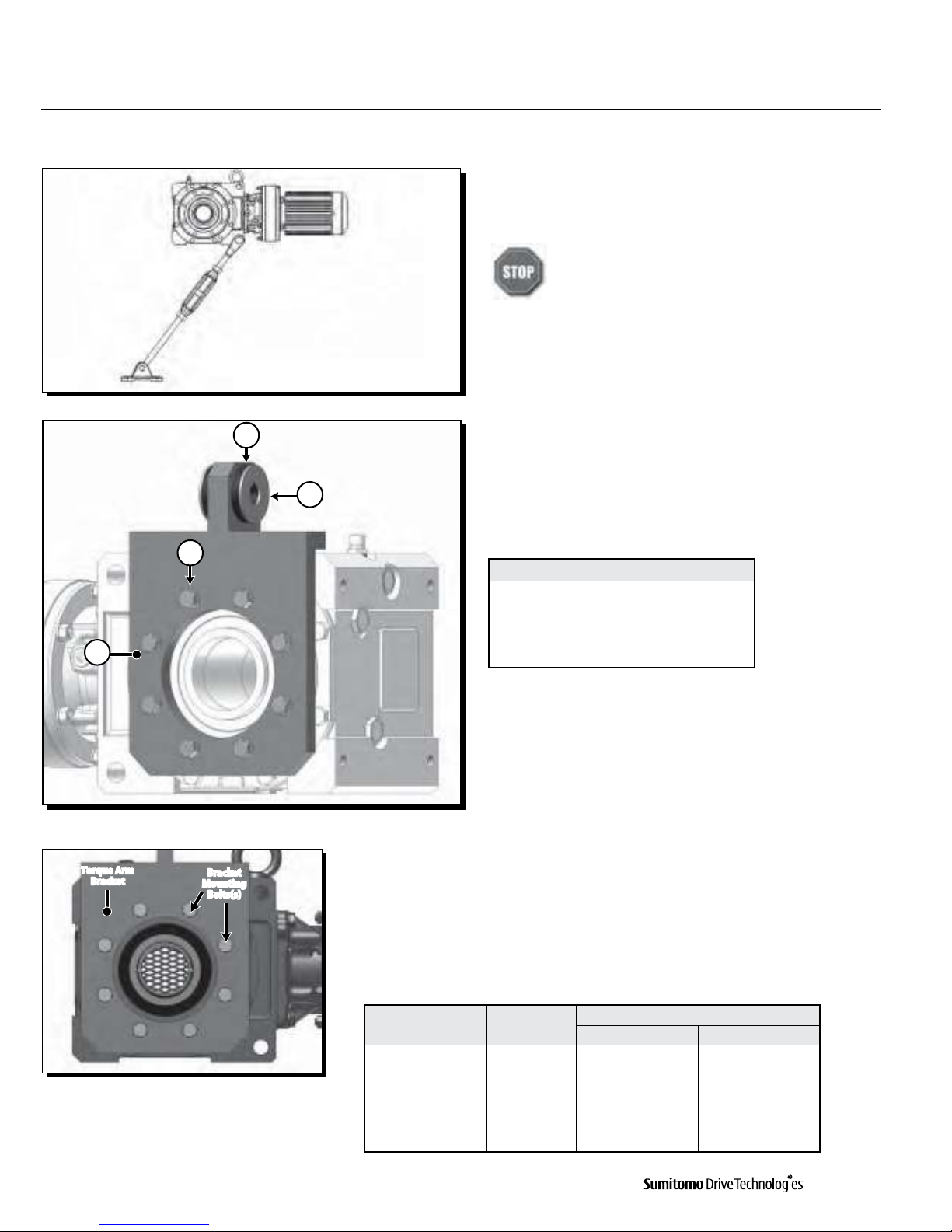

5PSRVF"SN*OUSPEVDUJPO'MBOHF.PVOU#BOKP5ZQF5PSRVF"SN1

2

4

3

Torque Arm

Bracket Bracket

Mounting

#PMUTTBracket

Bolt Size[1]

Torque

MCtGU/tN4A 8 x M10 34 – 38 (46 – 51)

4B 8 x M12 59 – 65 (80 – 88)

4C 8 x M16 152 – 167 (206 – 227)

4D 8 x M20 290 – 319 (392 – 431)

4F 8 x M24 507 – 558 (686 – 755)

Item Number Description

1 Torque Arm Bracket

2 Bracket Hardware

3 Rubber Bushing (qty 3)

4 Washer (qty 2)

5BCMF'MBOHF.PVOU#BOKP5ZQFTorque Arm Components

5BCMF'MBOHF.PVOU#BOKP5PSRVF"SN#PMU5JHIUFOJOHNote: [1] Bolt ISO/JIS Class 8.8

Torque Arm Introduction

A torque arm is a device used to prevent counter-rotation of the

shaft mounted reducer/gearmotor during operation.

The torque arm must be mounted in tension when

torque arm mounting point is greater than 6 inches

(150mm) from machine mounting point or, tie-rod or

turn buckle type torque arm is used.

Sumitomo Supplied Components of

'MBOHF.PVOU#BOKP5ZQF5PSRVF"SN'MBOHF.PVOU#BOKP5ZQF5PSRVF"SNInstallation Procedure

1

Attach the Flange Mount (Banjo) Torque Arm Bracket to the Cyclo® BBB4 using

mounting hardware.

Torques

Unit Size

Cyclo® BBB4

Operation & Maintenance Manual 17

Cyclo® BBB4

2

Place washer and rubber bushing on bolt.

Insert torque arm bolt (supplied by customer) through mounting tab on Banjo

torque arm.

Make sure bolt is parallel to Flange Mount (Banjo) Type Torque Arm surface

when fully installed.

3

Follow these steps to attach the customer supplied mounting bracket.

t1MBDFSVCCFSCVTIJOHBOENPVOUJOHBOHMFCSBDLFUPOCPMUt7FSJGZUIBUUIFNPVOUJOHBOHMFCSBDLFUIPMFJTUIFDPSSFDUEJBNFUFSTFF5BCMFin Step 1).

t1MBDFSFNBJOJOHCVTIJOHXBTIFSBOEUXPOVUTPOUIFCPMUDo not over-tighten nuts. Tighten to point where rubber bushings can

still be hand rotated.

4

Confirm that the rubber bushings can still be rotated by hand. This indicates the

bushing has not been over tightened.

Compressed bushings will not allow the bushings to properly absorb the

loads of the shaft mounted gearbox. This can lead to premature failure.

Mounting Angle Bracket must be secured to the machine structure.

5

Confirm the mounting angle bracket

does not interfere with the torque

arm. There should be no metal-to-

metal contact between the two during

a complete revolution of the driven

equipment.

Metal-to-Metal contact

between these two components

may lead to catastrophic failure

of the reducer/gearmotor.

Torque Arm Installation, continued

'MBOHF.PVOU#BOKP5ZQF5PSRVF"SNWhen installed,

bolt must be

parallel to this

surface

Rubber

Bushing

Washer

Washer

Mounting Angle

#SBDLFU$VTUPNFS4VQQMJFERubber Bushings

Nuts

$VTUPNFS4VQQMJFEDuring full rotation of driven shaft, there must be

no metal-to-metal contact between mounting angle

bracket and torque arm.

Unit Size Bracket Tab Bore Typical Bolt Size [1]

4A Ø18mm M16

4B Ø18mm M16

4C Ø22mm M20

4D Ø26mm M24

4E Ø33mm M30

4F Ø39mm M36

5BCMF'MBOHF.PVOU#BOKP5PSRVF"SN#PMU%JNFOTJPOTNote: [1] Bolt class should be greater or equal to ISO/JIS Class 8.8. Application with multiple start/stops and/or shock

loading should use ISO/JIS 10.9 at a minimum.

Torque Arm Bolt

$VTUPNFS

4VQQMJFE

18 Operation & Maintenance Manual

Cyclo® BBB4

Cyclo® BBB4

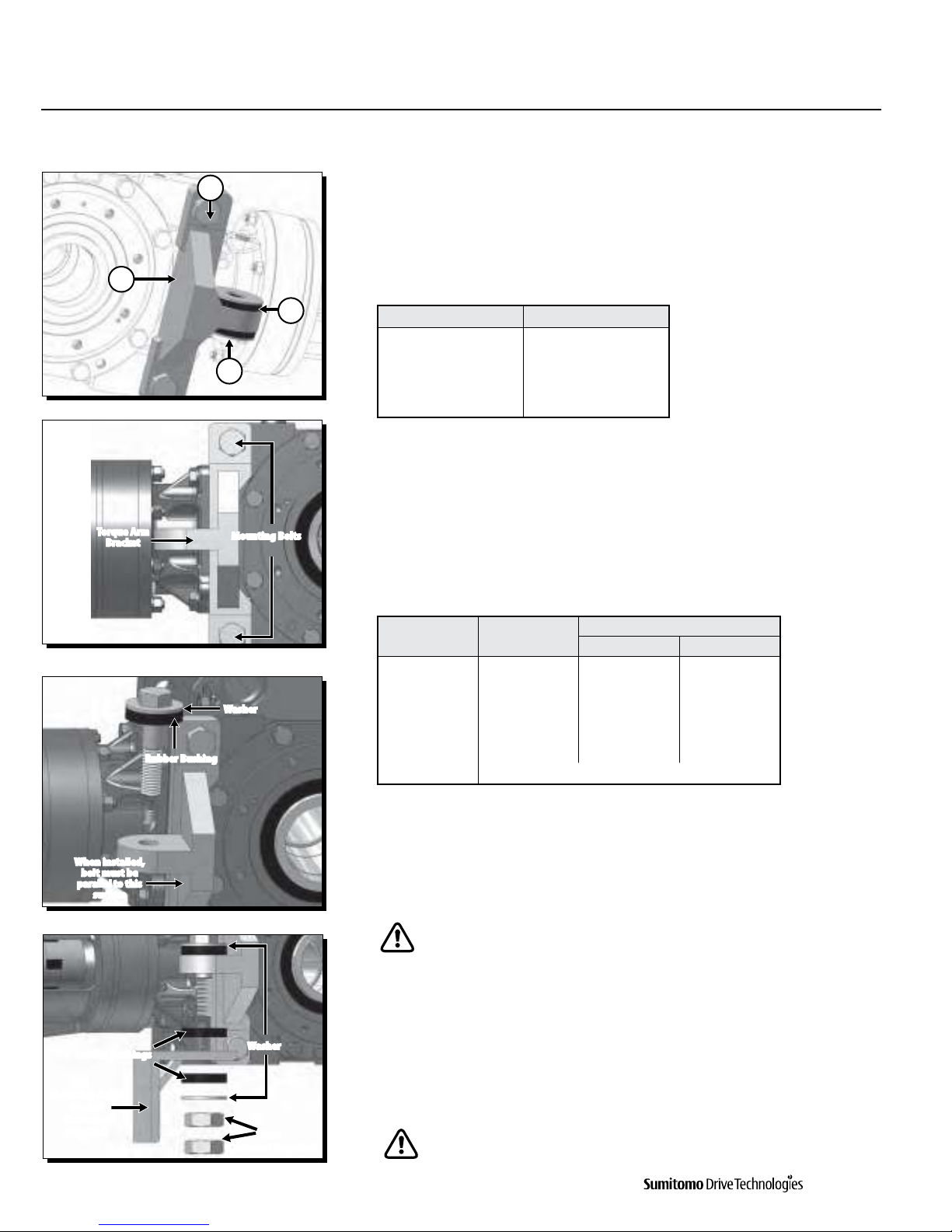

T-Type Torque Arm

Sumitomo Supplied Components for T-Type

Torque Arm

T-Type Torque Arm Installation Procedure

1

Attach the T-Type Torque Arm Bracket to the Cyclo® BBB4 using the supplied

mounting hardware.

Tighten mounting bolts according to the values listed in Table 9:

Table 9. T-Bracket Bolt Torques

2

Place washer and rubber bushing on bolt.

Insert torque arm bolt (supplied by customer) through mounting tab on Banjo

torque arm.

Make sure bolt is parallel to T-Type Torque Arm side when fully installed.

3

Follow these steps to attach the mounting angle bracket:

t1MBDFSVCCFSCVTIJOHBOENPVOUJOHBOHMFCSBDLFUPOCPMUt7FSJGZUIBUUIFNPVOUJOHBOHMFCSBDLFUIPMFJTUIFDPSSFDUEJBNFUFSGPSDVTUPNFSsupplied bolt.

t1MBDFSFNBJOJOHCVTIJOHXBTIFSBOEUXPOVUTPOUIFCPMUDo not over-tighten nuts. Tighten to point where rubber bushings can

still be hand rotated.

Torque Arm Installation, continued

T-Type Torque Arm

1

2

3

4

Torque Arm

Bracket

Mounting Bolts

Washer

Rubber Bushing

When installed,

bolt must be

parallel to this

surface

Nuts

$VTUPNFS4VQQMJFERubber Bushings Washer

Mounting Angle

Bracket

$VTUPNFS4VQQMJFEItem Number Description

1 Torque Arm Bracket

2 Bracket Hardware

3 Rubber Bushing (qty 3)

4 Washer (qty 2)

BBB4 Size Bracket

Bolt Size[1]

Torque

MCtGU/tN4A 2 x M16 152 – 167 (206 – 227)

4B 2 x M20 290 – 319 (392 – 431)

4C 2 x M24 507 – 558 (686 – 755)

4D 2 x M24 1014 – 1115 (1373 – 1510)

4E 2 x M24 1014 – 1115 (1373 – 1510)

4F T-Type Not Available

Table 8. T-Type Torque Arm Components

Note: [1] Bolt ISO/JIS Class 8.8

Cyclo® BBB4

Operation & Maintenance Manual 19

Cyclo® BBB4

Torque Arm Installation, continued

T-Type Torque Arm

Top View

4

Confirm that the rubber bushings can still be rotated by hand. This indicates the

bushing has not been over tightened.

Compressed bushings will not allow the bushings to properly absorb the

loads of the shaft mounted gearbox. This can lead to premature failure.

Mounting angle bracket must be secured to the machine structure.

5

Confirm the mounting angle bracket does not interfere with the torque arm.

There should be no metal-to-metal contact between the two during a complete

revolution of the driven equipment.

Metal-to-Metal contact between these two components may lead to

catastrophic failure of the reducer/ gearmotor.

Other manuals for Cyclo BBB4

5

Table of contents