Introduction User Manual

- 8 -

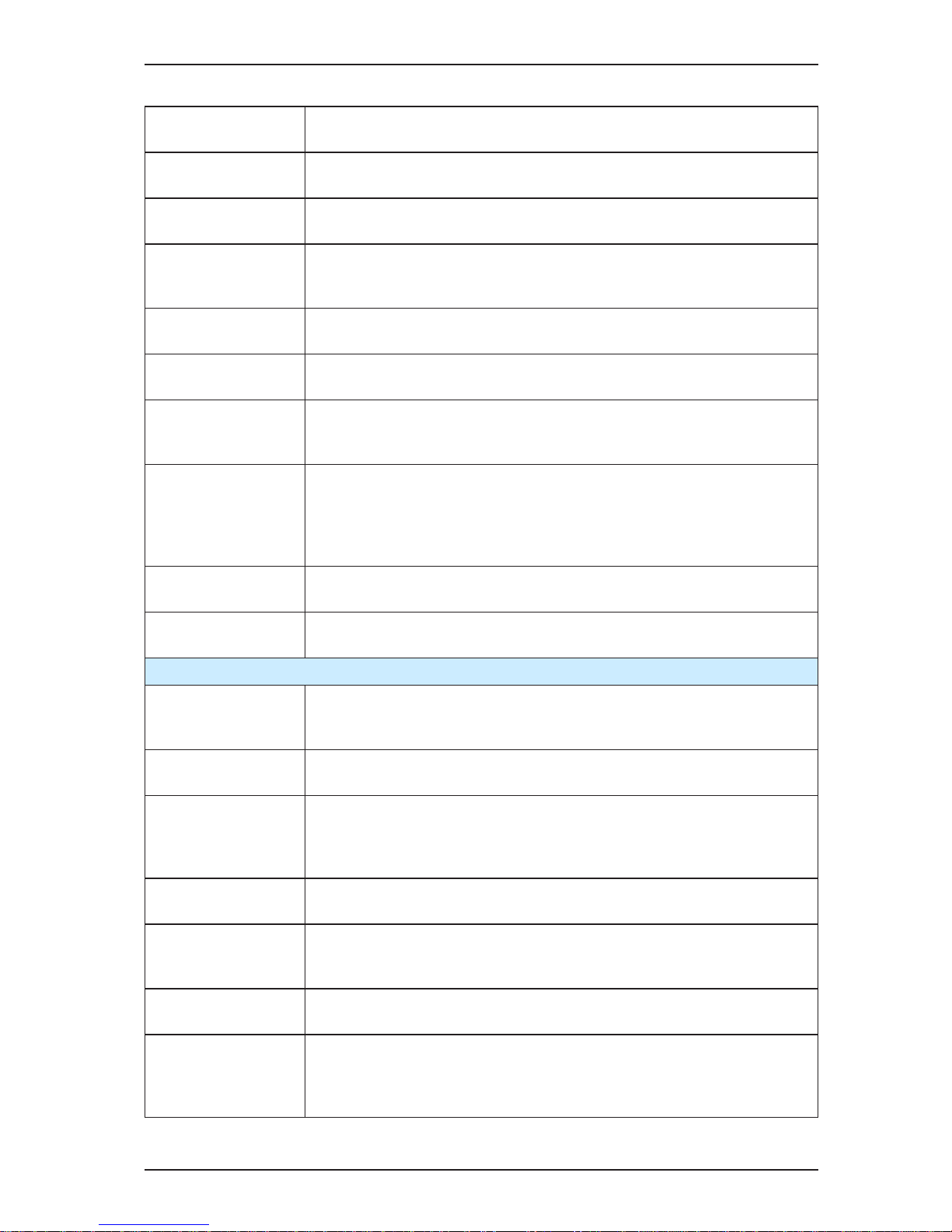

Dual-speed for

inspection

Considering inaccurate running control at high inspection speed but

a long running time at low inspection speed, the system provides the

dual-speed curve for inspection, which greatly improves the efciency

at inspection.

Test running

The test running includes the fatigue test of a new elevator, car call

oor test, hall call test, and tests such as hall call response forbidden,

door open/close forbidden, terminal oor limit switch shielded, and

overload signal shielded.

Fire Emergency and Security Functions

Returning to

base oor at re

emergency

After receiving a re emergency signal, the elevator does not respond

to any call but directly runs to the re emergency oor and waits.

Fireghter running

After the elevator enters the reghter running mode, door open/close

is implemented by the jog operation (optional) by using the door open

and close buttons rather than automatically. In addition, the elevator

responds to only car calls and only one call can be registered once.

Security oor

After the security oor function is enabled, the security oor is used at

10:00 p.m. to 6:00 a.m, and the elevator runs to the security oor rst

every time, stops and opens the door, and then runs to the destination

oor.

Elevator lock

In automatic running state, when the elevator lock switch acts or the

set elevator time is reached, the elevator cancels all registered calls,

returns to the elevator lock oor, stops running, and turns off the lamp

and fan in the car.

Troubleshooting

based on fault level

Faults are classied into different levels based on the severity. Different

levels of faults are rectied using different methods.

Runaway

prevention

The system detects the running state of the elevator in real time. If the

elevator speed exceeds the limit, the system immediately stops running

of the elevator.

Automatic

identication of

power failure

The system automatically identies power failure and outputs the relay

signal for emergency evacuation automatic switchover to implement

emergency evacuation at power failure.

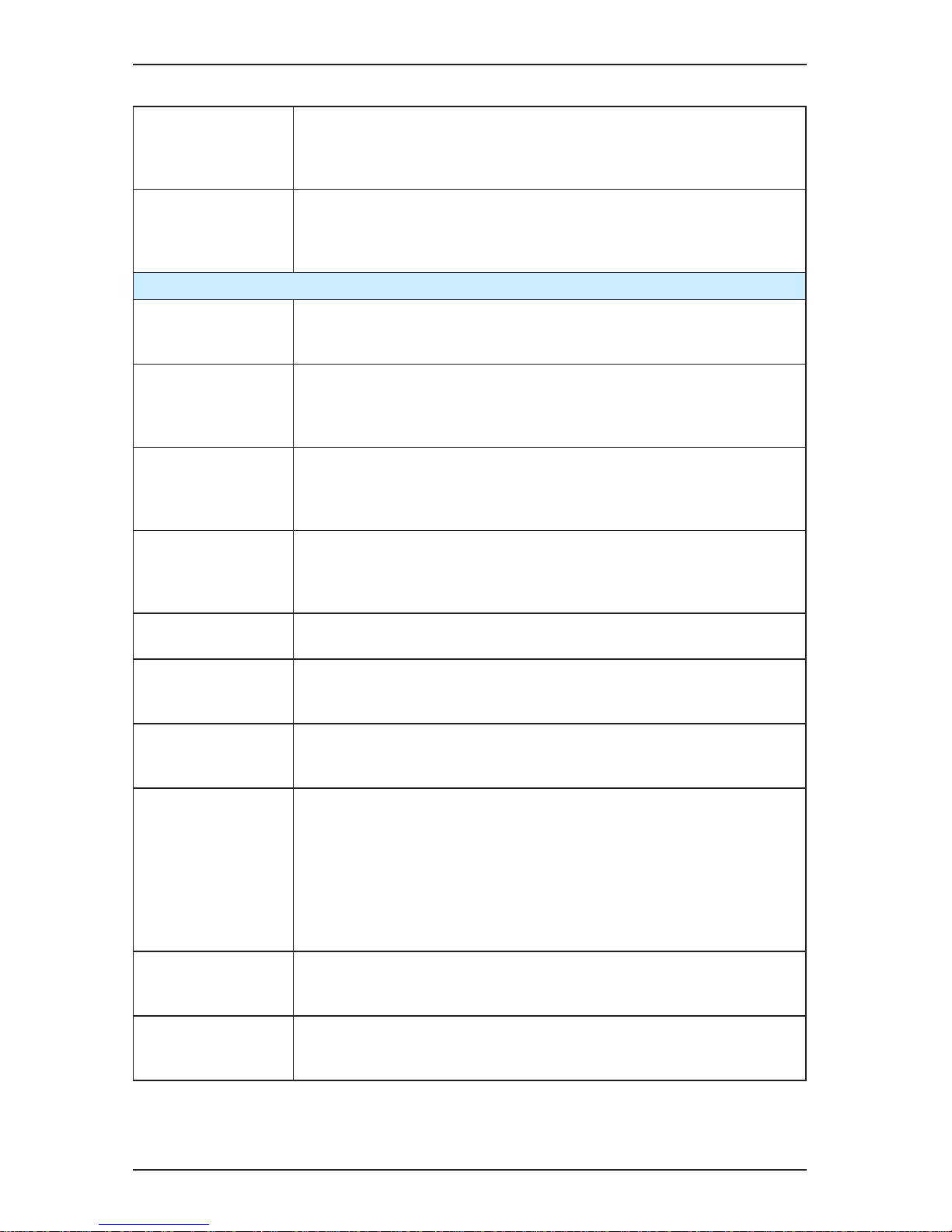

Automatic running

mode switchover at

power failure

For the synchronous motor, when the power supply is interrupted, the

system can perform automatic switchover between shorting stator

braking mode and controller drive mode, implementing quick and stable

self-rescue.

Shorting stator braking mode: Upon power failure, UPS is used, the

motor stator is shorted, and the brake is automatically released, making

the car move slowly under the effect of the weighing difference between

the car and the counterweight.

Running direction

self-identication at

power failure

When the power supply is interrupted, the system can automatically

identify the current car load and determine the running direction.

Base oor

verication

After detecting a position abnormality, the system runs the elevator to

each oor until reaching the terminal oor for verication, guaranteeing

system security.