1 MA_141_142_A10-6-7-3-6-5_130617_en

Mechanic’s instructions

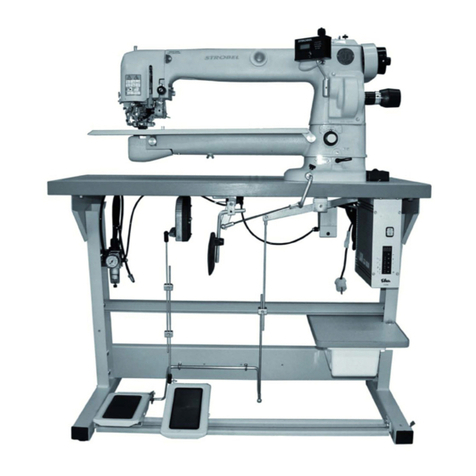

STROBEL Classes 141-23EV, -30, -40, -50, 142-30, -40

Contents

1General notes on safety............................................................................................5

2General .....................................................................................................................7

2.1 Operating instructions.....................................................................................7

2.2 Class identification, serial number and orientation of the machine.................7

2.3 Range of application and intended use..........................................................7

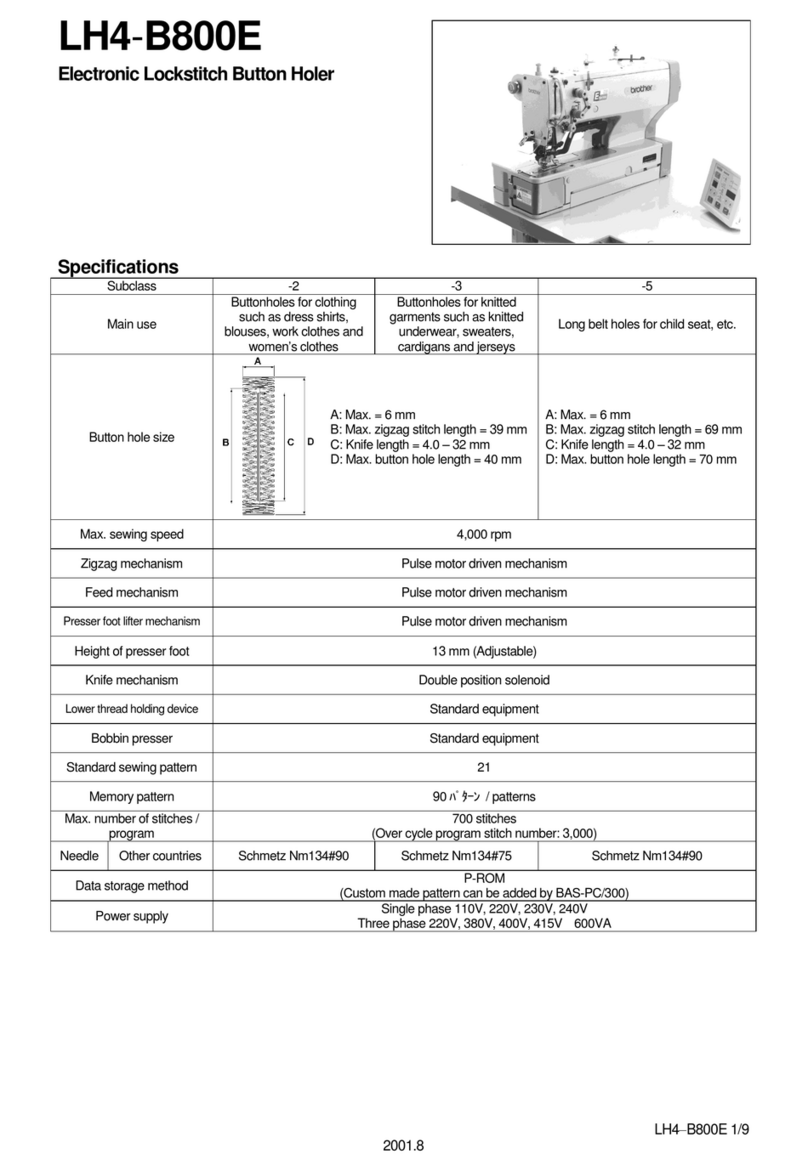

2.4 Technical Data................................................................................................9

2.5 Brief setting instructions ...............................................................................10

3Disassemble the machine.......................................................................................11

3.1 Disassemble the main shaft (Fig. 1 and Fig. 2)............................................11

4Assemble the Machine............................................................................................13

4.1 Mount the shaft (Fig. 1) ................................................................................13

4.2 Mount stitch regulating eccentric 353.0031..................................................13

4.3 Adjust stitch regulating bolt 137.0014 for stitch adjustment..........................15

4.4 Adjust needle- and feed motion....................................................................15

4.5 Looper motion...............................................................................................16

4.5.1 Adjust the looper motion..................................................................16

4.5.2 Adjust the looper eccentric (on single thread machines)..................17

4.5.3 Adjust the looper eccentric (on two tread machines) .......................17

4.5.4 Adjust the front crank.......................................................................18

4.5.5 Set the looper in its front position to the feed cup............................19

4.5.6 Adjust stroke of loop ........................................................................19

4.5.7 Adjust the front bearing block...........................................................19

4.5.7.1 Basic dimensions for front and rear bearing block...........19

4.5.8 Adjust the rear bearing block ...........................................................20

4.6 Adjust height of rear feed cups.....................................................................20

4.7 Mount the front feed cup ..............................................................................20

4.8 Length adjustment of bar 133.0851 between stitch regulation rod and free

wheeling .......................................................................................................20

4.9 Thread lifting mechanism at needle bar head ..............................................20

4.10 Spring tension at feed cup support arm 333.0114........................................21

4.10.1 Plate arm lifting ................................................................................21

4.11 Needle setting...............................................................................................22

4.11.1 Adjusting needle height (Fig. 10 and Fig. 11)...................................22

4.12 Chaniging the looper ....................................................................................23

4.13 Maintenance.................................................................................................24

4.14 General Data................................................................................................24

218.05.10