2

INDEX

1 INTRODUCTION .............................................................................................................................................................................. 3

2 GENERAL INFORMATION .............................................................................................................................................................. 3

2.1 USING THIS MANUAL .......................................................................................................................................................... 3

2.2 INFORMATION ON THE MACHINE ...................................................................................................................................... 4

2.3 NAME PLATE ........................................................................................................................................................................ 4

2.4 CHARACTERISTICS OF THE MACHINE .............................................................................................................................. 4

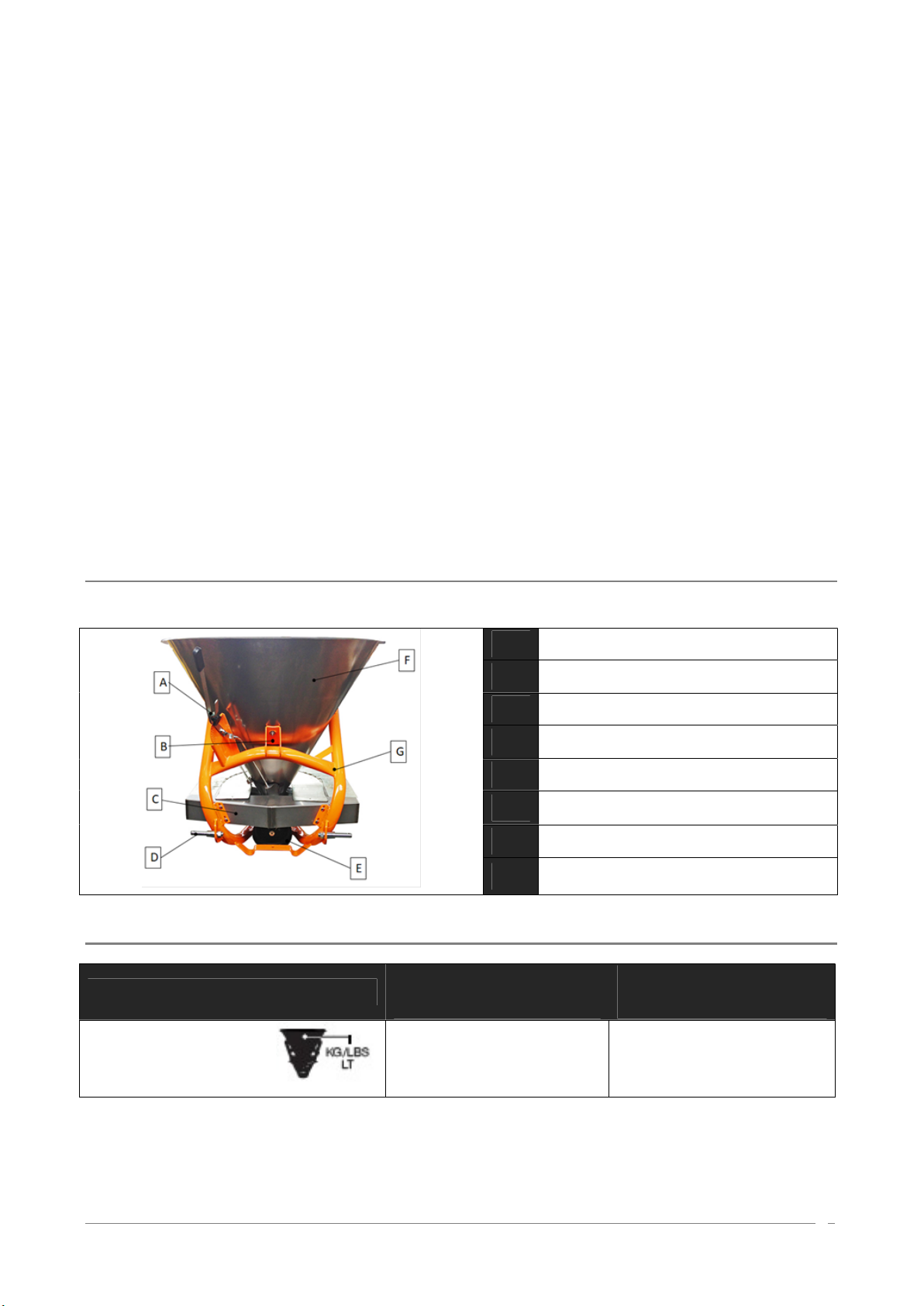

2.5 IDENTIFICATION OF COMPONENTS .................................................................................................................................. 5

2.6 TECHNICAL DETAIL ............................................................................................................................................................. 5

3 SAFETY INFORMATION .................................................................................................................................................................. 6

3.1 GENERAL ADVICES ............................................................................................................................................................. 6

3.2 CONNECTION OF THE MACHINE TO THE TRACTOR ........................................................................................................ 8

3.3 OPERATION ON THE MACHINE .......................................................................................................................................... 9

3.4 TRANSFER ON THE ROAD ................................................................................................................................................ 10

4 SAFETY SIGNALS ......................................................................................................................................................................... 10

5 ASSEMBLY AND SET-UP ............................................................................................................................................................. 12

5.1 TRACTOR REQUIREMENTS AND 3-POINT HOOK-UP ..................................................................................................... 12

5.2 CONNECTION TO THE 3-POINT HITCH OF THE TRACTOR ............................................................................................ 13

5.3 DRIVELINE INSTALLATION................................................................................................................................................ 14

6 SALT SPREADER USE ................................................................................................................................................................. 15

6.1 RECCOMENDATIONS FOR A CORRECT DISTRIBUTION ................................................................................................ 15

6.2 ADJUSTMENTS .................................................................................................................................................................. 15

6.3 HOW TO ADJUST THE SPREADING VANES .................................................................................................................... 16

6.4 SPREAD PATTERN ............................................................................................................................................................ 16

6.5 HOPPER LOAD ................................................................................................................................................................... 18

6.6 SPREADING WIDHT ADJUSTMENT .................................................................................................................................. 18

6.7 SPREADING CHART AND PROFESSIONAL LIMITER SPREADING ADJUSTMENT ......................................................... 20

7 SPREADING MISTAKES ............................................................................................................................................................... 21

7.1 MISTAKES OF USE ............................................................................................................................................................ 21

7.2 MISTAKES DUE TO SALT .................................................................................................................................................. 21

7.3 MISTAKES DUE TO THE SPREADER ................................................................................................................................ 21

8 MAINTENANCE ............................................................................................................................................................................. 21

8.1 LUBRIFICATION ................................................................................................................................................................. 23

8.2 REPLACMENT OF DISTRIBUTOR VANES......................................................................................................................... 23

8.3 LONG-TERM STORAGE ..................................................................................................................................................... 24

8.4 SPARE PARTS ................................................................................................................................................................... 24

9 WARRANTY ................................................................................................................................................................................... 24

10 PARTS BREAKDOWN ................................................................................................................................................................... 26

10.1 GENERAL VIEW ................................................................................................................................................................. 26

10.2 GEAR BOX – 322.029 ......................................................................................................................................................... 28

10.3 SPREADER DISC WITH DISTRIBUTOR VANES – 610.119 ............................................................................................... 29

10.4 SALT AGITATOR – 620.108 ................................................................................................................................................ 30

10.5 STANDARD LIMITER – 620.122 ........................................................................................................................................ 31

10.6 RIGHT LEVER – 618.026 ................................................................................................................................................... 32

10.7 LEFT LEVER – 618.027 ..................................................................................................................................................... 33

11 OPTIONAL PARTS BREAKDOWN ................................................................................................................................................ 34

11.1 GENERAL VIEW ................................................................................................................................................................. 34

11.2 WHEELS KIT – 613.301 ...................................................................................................................................................... 35

11.3 LIGHTS AND SUPPORTS KIT – 620.187 ............................................................................................................................ 36

11.4 STAINLESS PROGRESSIVE LIMITER KIT – 620.163 ........................................................................................................ 37

11.5 HYDRAULIC OPENING SYSTEM – 619.111 ....................................................................................................................... 38

11.6 SHOVEL SUPPORT KIT – 613.350 ..................................................................................................................................... 39