INTRODUCTION

Congratulation . You have ju t purcha ed an advanced preader from C-Dax Ltd. C-Dax Ltd i committed to

providing you, the farmer, with quality applicating y tem .

DESCRIPTION

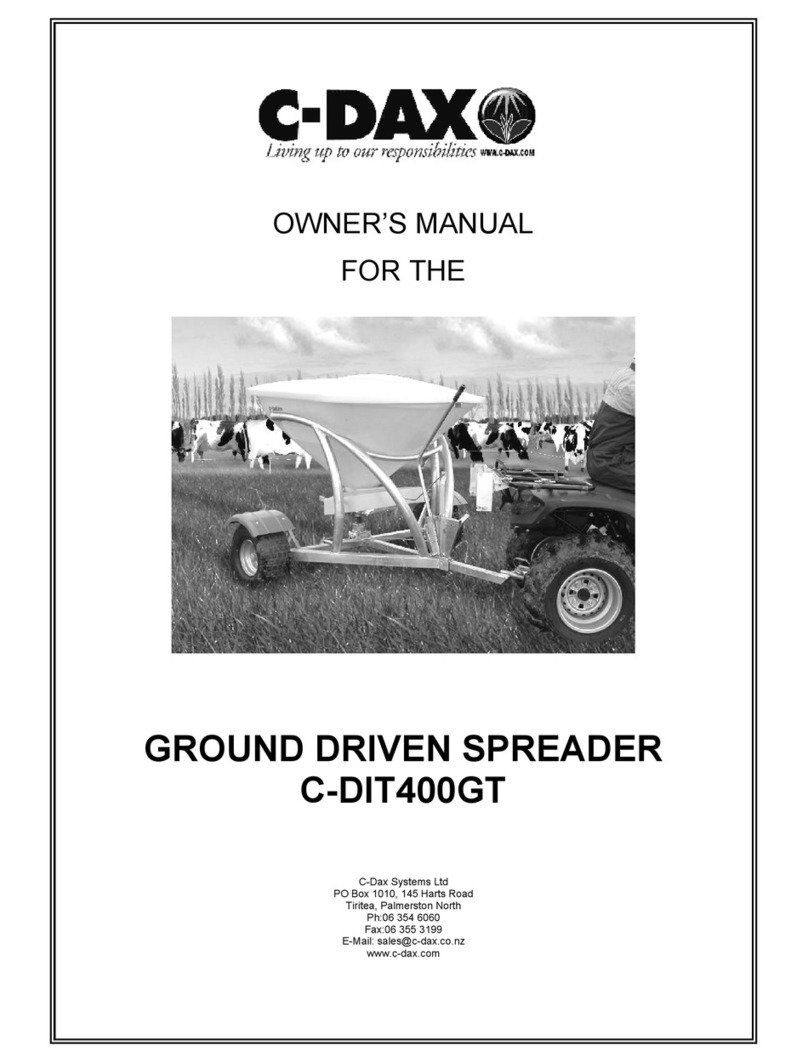

The C-Dax C-DIT400 i a ground-driven preader de igned for application of pelleted fertili er . It can al o

be u ed for application of other product uch a gra eed and magne ium oxide. The uniquely de igned

400-litre tran lucent non-corro ive polyethylene hopper i pecially profiled for good product flow and ea e of

filling. The convenient polyethylene cover i ea y to remove, in tall and tore if not required. A high-quality

tainle teel agitator and hutter en ure even flow of product to the pinner. A unique pinner de ign

en ure wide, even pread of product over 180 degree (Urea). The heavy-duty galvani ed frame i fitted

with knobbly turf tyre a tandard equipment. The drive train u e high quality teel and a double ealed

elf-aligning bearing and heavy-duty gearbox for maximum durability. While eated, the operator ha acce

to the control handle. Thi handle allow di engagement and engagement of the clutch and etting of

product feed rate all in one motion. Al o tandard are mudguard , wivel tow-hitch and a fully hrouded

polyethylene front deflector to further protect the operator from product being thrown off the pinner.

Specification

(Specification ubject to change without notice)

Dry Weight 120 Kg

Dimen ion W1900mm, H1400mm, L1850mm

Capacity 400 litre (320Kg Urea)

Drive Ground driven ( ingle wheel)

Wheel 18x950x8 knobbly turf tyre

Tyre pre ure 15PSI (100Kpa)

Clutch Lever operated mechanical clutch

Control Adju table tainle teel lide with index handle

Agitator Mechanical arm, tainle teel

Spinner Galvani ed teel with three-po ition adju table vane

Hopper Non-corro ive polyethylene, ergonomically de igned for ea e of filling and

in pection

Hopper cover Polyethylene pla tic

Frame Galvani ed teel

Gearbox Heavy duty with double ealed bearing

Gearbox oil 400ml SAE30

Axle Bearing Sealed ball race

Clutch bearing Heavy-duty pho phor-bronze bu h

Axle grea e General Purpo e

Application Rate 140Kg per hectare @ 10 kph (nominal, Urea)

Spread width 18M (nominal, Urea @ 15 Kph)

Towing peed 15 Kph (Maximum recommended)

NZ , AUST & UK

Order Information

Standard CDIT400 P/N 3004

WARRANTY

C-Dax Ltd warrant to the original purcha er that the equipment i old free from defect in material and

workman hip for a period of 12 month from date of retail ale (6 Month from date of retail ale for all

equipment old in the U.K.).

Accordingly, C-Dax Ltd undertake to repair the equipment, or at our option replace, without co t to the

original purcha er either for material , part or labour, any part which within the pecified warranty period

from time of delivery i found to be defective. PROVIDED that the equipment ha been u ed for normal

purpo e in accordance with the in truction , and ha not been ubject to neglect, mi u e or accident, and

ha not been repaired, erviced or di mantled by any per on other than a ervice agent or per on authori ed

by C-Dax Ltd.

The warranty doe not extend to cover: con equential damage; repair or replacement of part due to fair

wear and tear; or damage re ulting from neglect, mi u e, accident or hireage. SPECIFICALLY the warranty

exclude battery damage, damage ari ing from chemical attack, and unit built to cu tomer pecification .

All good returned to C-Dax Ltd are freight paid by the ender and if ubject to a warranty claim, mu t be

accompanied by a completed warranty claim form. Warranty claim form are available from C-Dax dealer .