Cause

1. Pump not vented after installation.

2. Air leakage on the suction hose or pump.

3. Oil level too low.

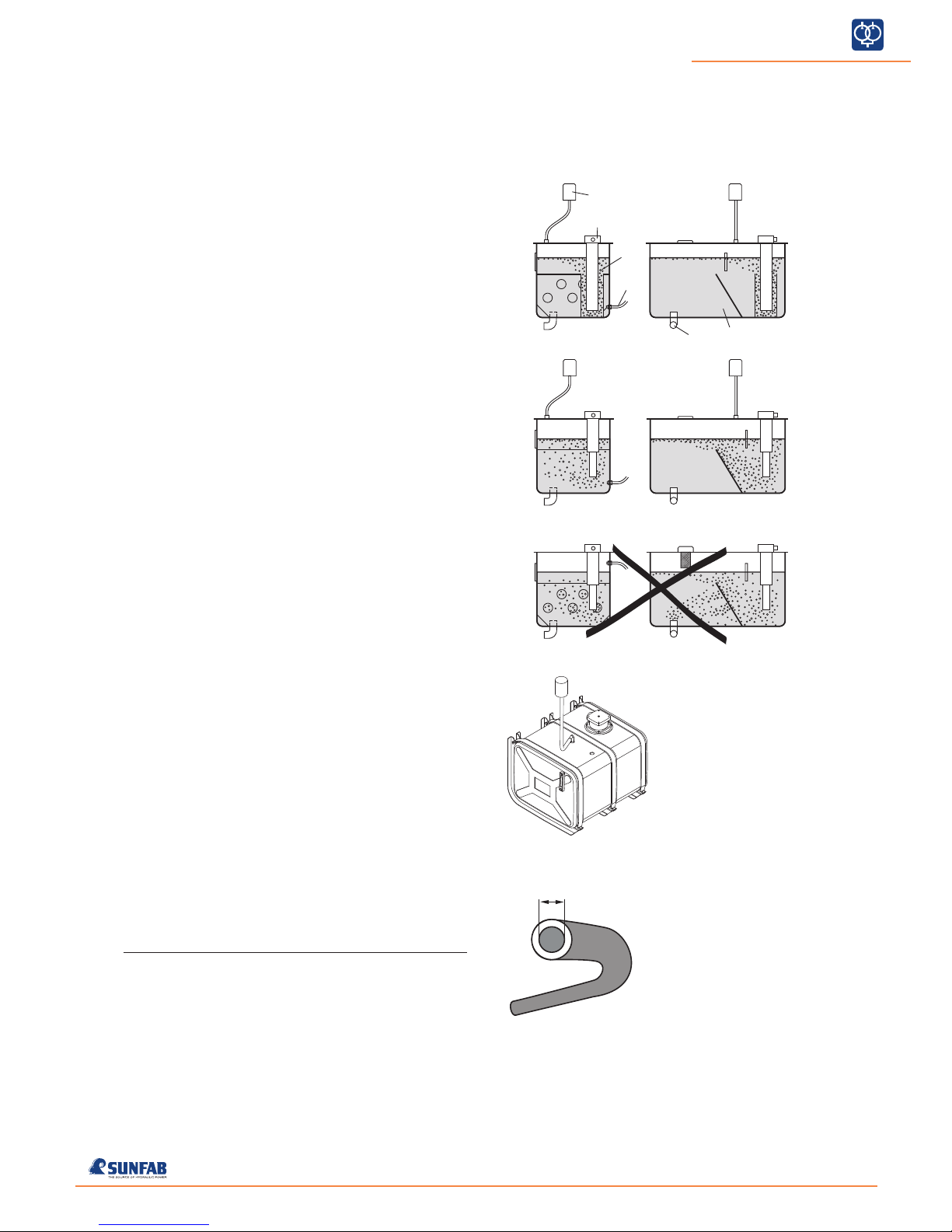

4. Not optimal designed tank for separa-

tion of air from the oil.

5. Oil tank with too small air venting area.

1. Too small diameter on the suction hose.

2. Crushing or restriction of the suction

hose.

3. Oil too thick.

4. Underpressure in the oil tank.

1. Too small a diameter or restriction in

the pressure or return hoses.

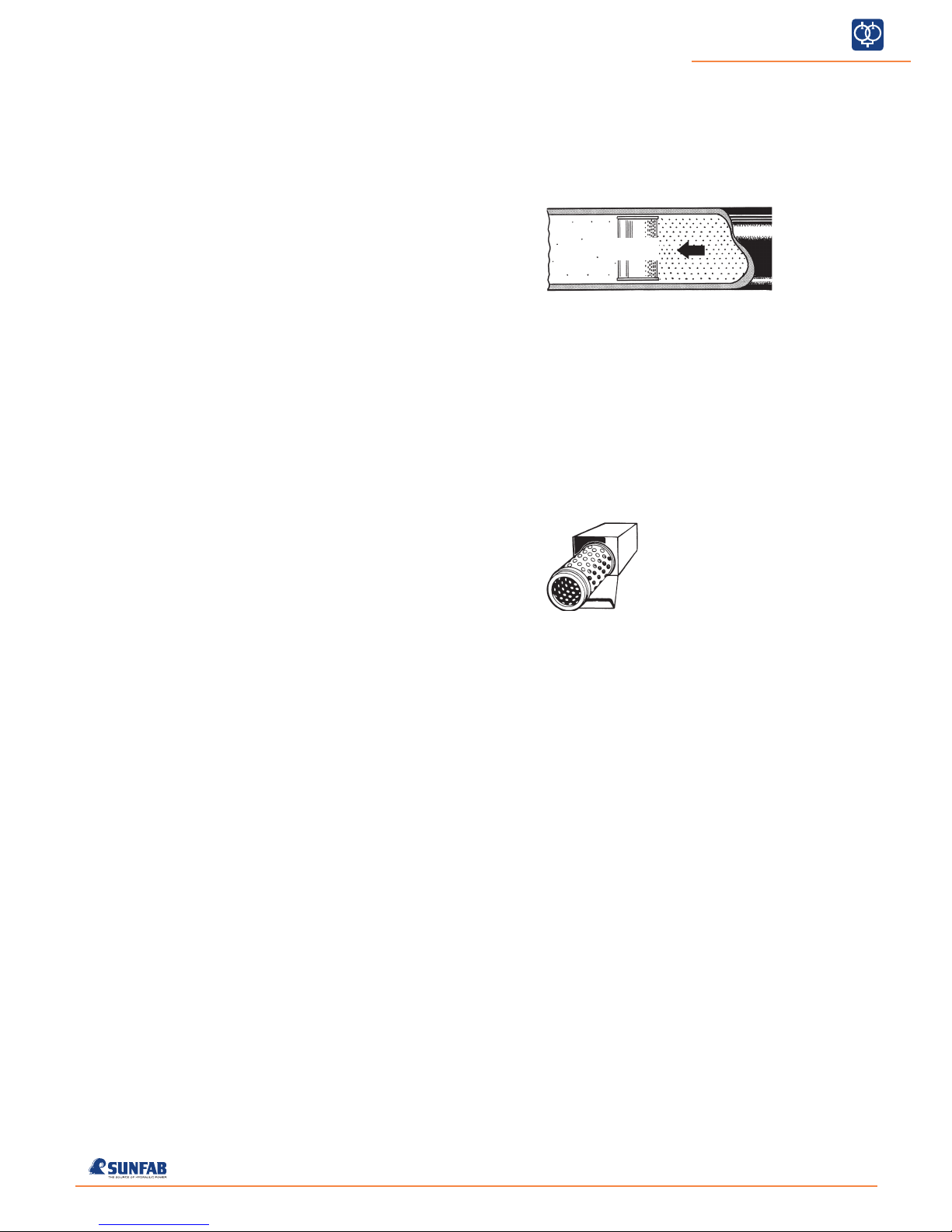

2. Clogged pressure or return filter.

3. Oil flow too great.

4. Pressure relief valve tripped at too low

a pressure.

5. Oil too thin.

6. Oil tank too small.

7. Oil level too low.

8. High continuous power output.

1. Pressure relief valve tripped at too low

a pressure.

2. Defective directional control valve.

1. Pressure relief valve tripped at too

low a pressure.

2. Worn pump.

1. Too small diameter on the suction hose.

2. Crushing or restriction of the suction

hose.

3. Oil too thick.

4. Underpressure in the oil tank.

5. Worn pump.

1. Leakage from the suction connection.

2. Leakage from the shaft seal.

3. Leakage from the plugs/fittings.

1. Play on intermediate shaft.

2. Incorrect joint angle on intermediate

shaft.

3. Imbalance on intermediate shaft.

4. The universal joints are not in line with

each other.

Rectifying a malfunctioning hydraulic system

Action

1. Vent the pump.

2. Repair the air leakage.

3. Fill with oil.

4. Replace the return filter with an oil

pipe or tank with solid baffle plate.

5. Change to a tank with a greater air

venting area.

1. Change to a suction hose with a

larger diameter.

2. Remove the restriction.

3. Change to an oil with a lower viscosity.

4. Change the air filter.

1. Change to hoses with a larger diam-

eter; rectify the restriction.

2. Replace the filter.

3. Lower the speed or change to a

smaller pump.

4. Adjust the valve or replace if necessary.

5. Change to an oil with a higher viscosity.

6. Change to a larger oil tank.

7. Fill with oil.

8. Fit an oil cooler.

1. Adjust the valve or replace if necessary.

2. Replace the directional control valve.

1. Adjust the valve or replace if necessary.

2. Replace the pump.

1. Change to a suction hose with a

larger diameter.

2. Remove the restriction.

3. Change to an oil with a lower viscosity.

4. Change the air filter.

5. Replace the pump.

1. Replace the O-rings and tighten the

hose clips.

2. Replace the shaft seals.

3. Replace the plugs/fittings and

tighten carefully (15 Nm).

1. Replace the intermediate shaft.

2. Ensure that the spindle on the power

take off and pump shaft are parallel.

3. Rectify the intermediate shaft.

4. Loosen and turn the spline coupling

so that the universal joints are

aligned with each other.

Troubleshooting

Check whether the flow in the pressure

hose from the pump pulsates. Oil spots

on the pump and suction hose can

indicate an air leakage.

Check the oil level in the tank.

Check whether the oil foams.

Check whether the pump cavitates.

This is noticeable through flow pulsa-

tions and noise from the pump stopping

when the speed is lowered.

Run the pump unloaded at working

speed and measure the counter pres-

sure. Connect a pressure gauge to the

pressure hose close to the pump. The

pressure must not exceed 2 MPa.

Check whether the pressure rises to

the correct value when a function is run

towards the stop.

Check whether the pressure rises to

the correct value when a function is run

towards the stop.

Connect a flow meter close to the

pump. Check the flow.

1. The correct flow is obtained when

loaded.

2. Abnormally low flow obtained when

loaded.

1-5. Check whether the pump cavitates

This is indicated by the noise stop-

ping when the speed drops.

Check whether the noise propa-

gates in the hydraulic system.

6. Check whether the noise can be

heard at all speeds.

Localise the oil leakage.

Check whether the pump shakes,

despite the flow not pulsating, i.e. the

attachment does not jerk.

Fault

The equipment works

jerkily.

The equipment works

jerkily when starting and

at a high pump speed.

The oil has an abnormally

high temperature.

The equipment has a lack

of power.

The equipment runs

abnormally slowly when

loaded.

Noise from the pump.

Oil leakage from the

pump.

The pump shakes (inter-

mediate shaft assembly).

If oil leakage has occurred via a damaged shaft seal,

ensure that no hydraulic oil has entered the gearbox!