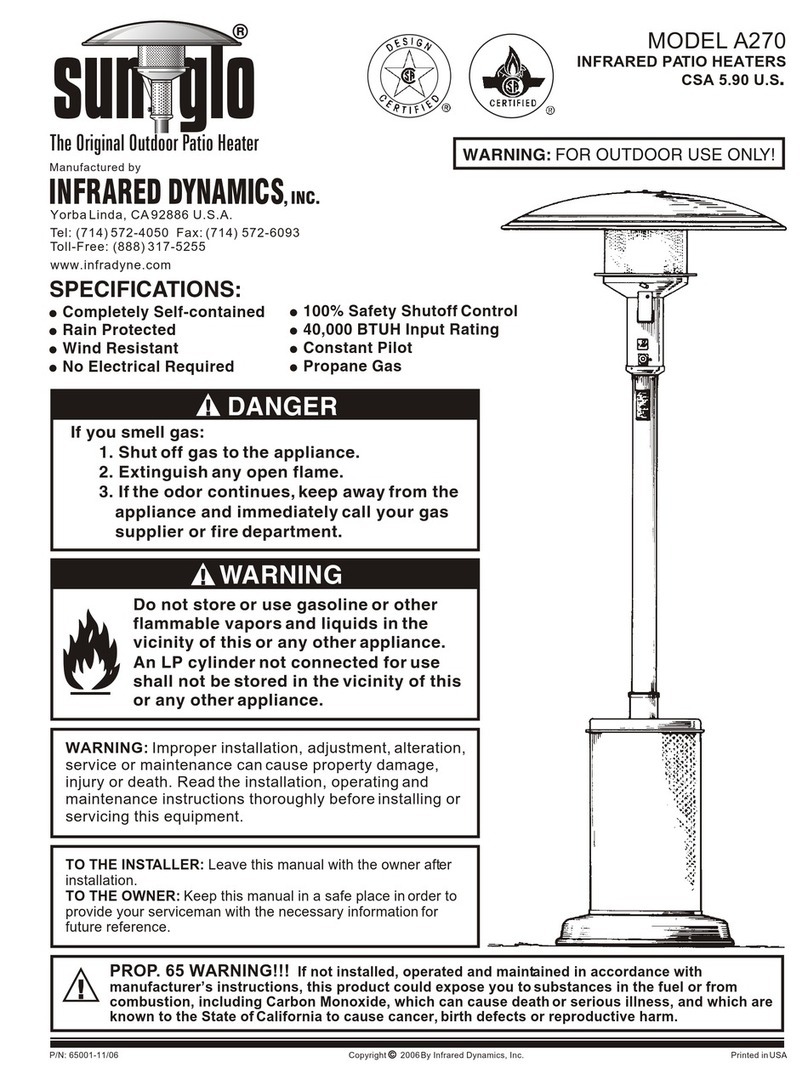

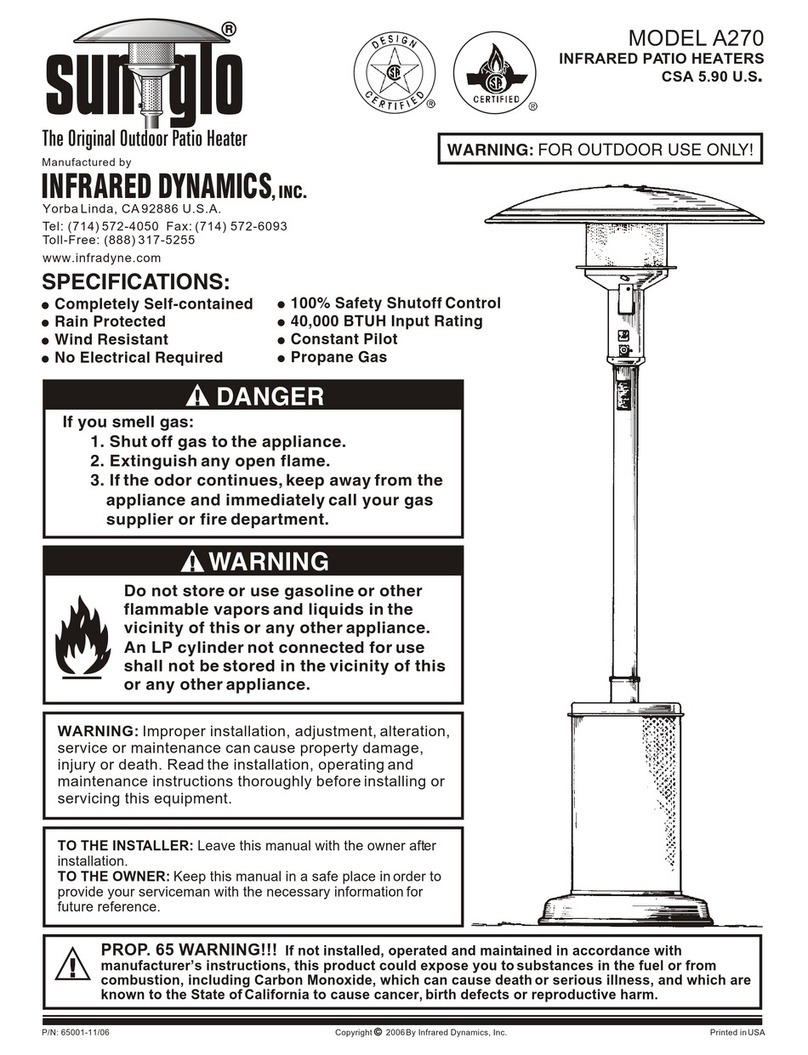

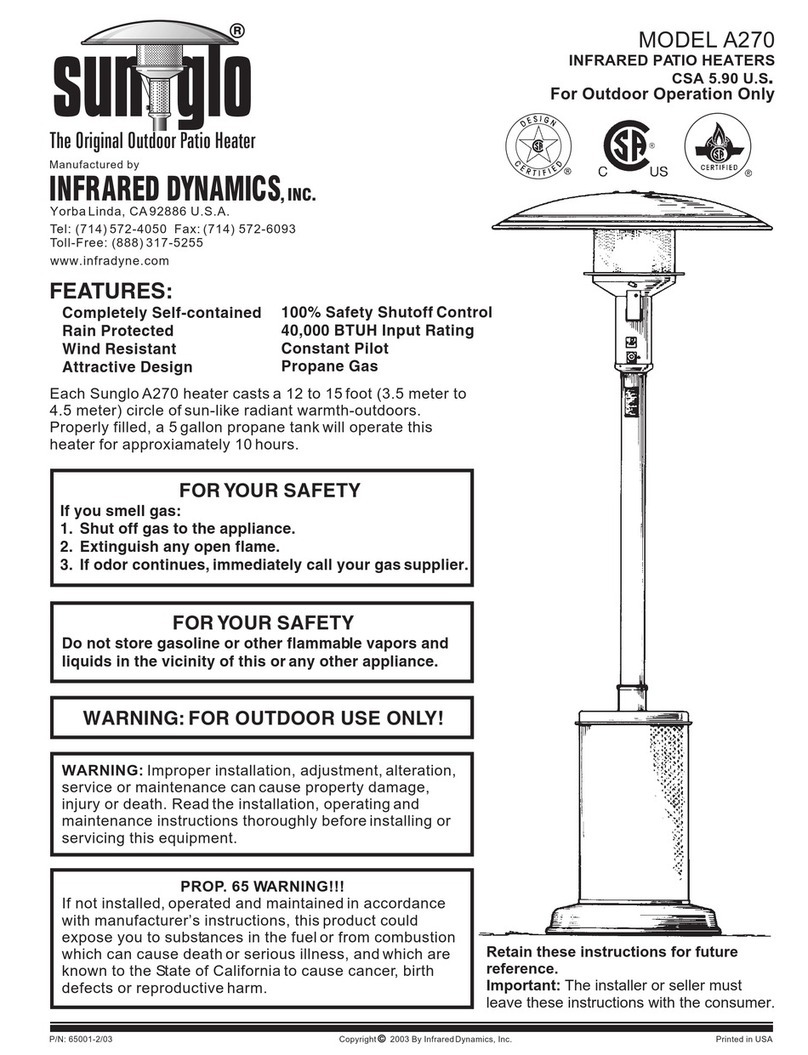

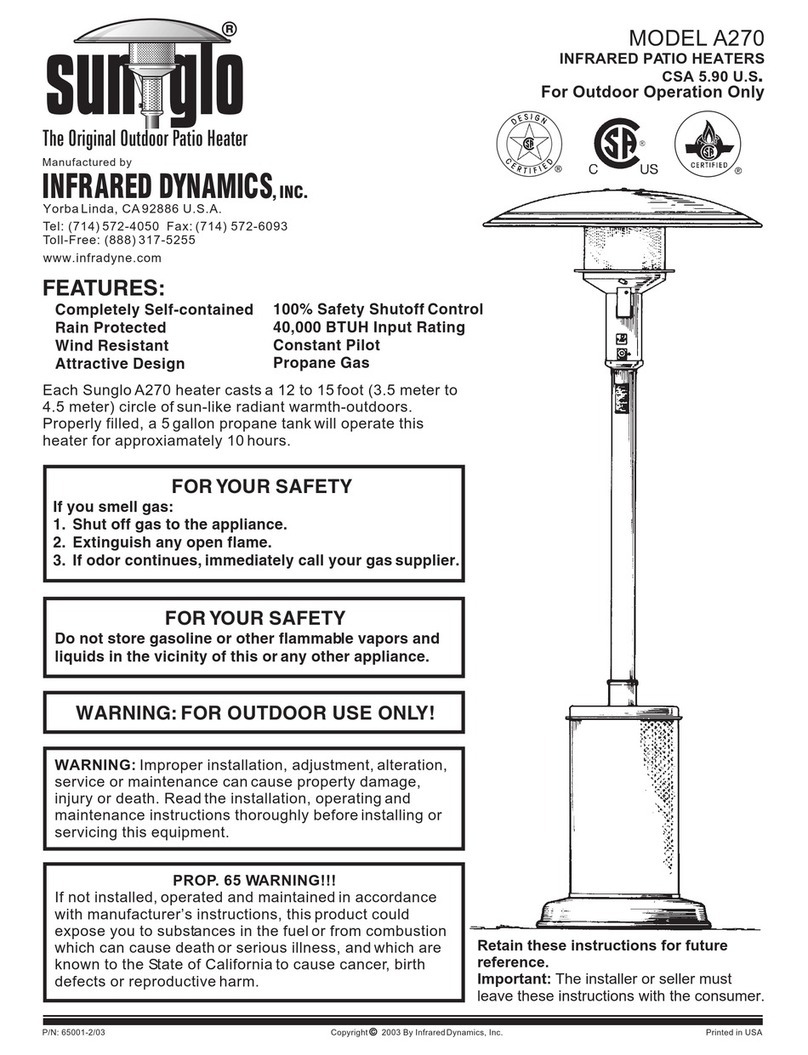

Sunglo Infrared Heaters

™

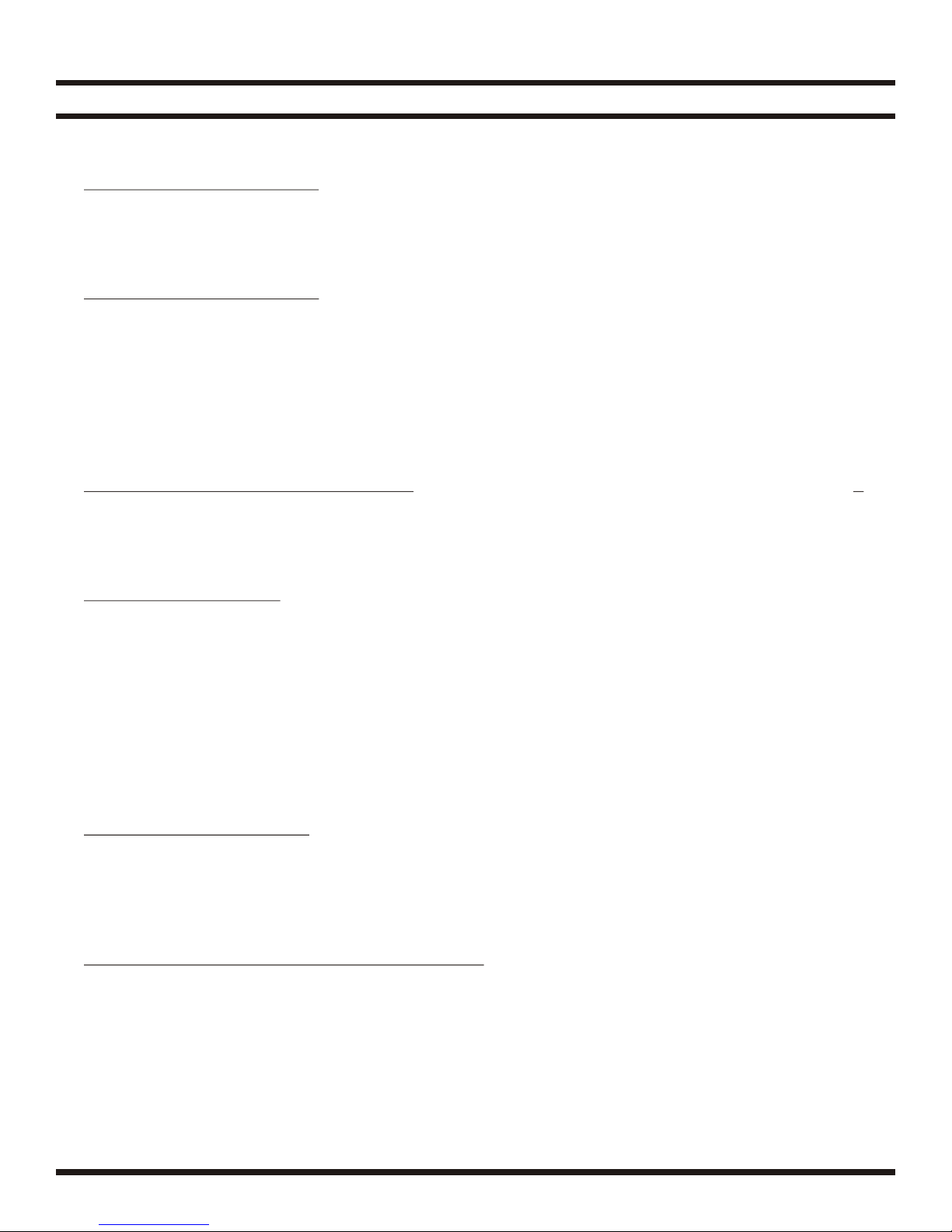

HEATER LAYOUT AND PATIO DESIGN

There are a number of WHERE TO LOCATE PATIO

considerations in determining the HEATERS:

type and number of heaters to be TM

Sunglo Heaters naturally attract

used and their location on your people to their infrared warm glow.

outdoor patio. Locate heaters where people can

readily gather, sit or stand comfortably,

and where furnishings can easily be

Concept of Patio Heating: Hot air is moved to best accommodate the

not an option for heating an outdoor radiating warmth.

patio so a patio heater uses radiant

heat like we receive from the sun.

Radiant Heat: Is the type of heat you

receive from a fireplace, potbelly

stove, or the sun. It is an infrared wave

length that heats objects without first

heating the intervening air. Unlike

ultra violet light there is no sunburn or CONTROL SYSTEMS:

sun tanning affect. Infrared will not Sunglo™ heaters are available with a

attract insects. variety of control systems from

m a n u a l c o n t r o l s r e q u i r i n g n o

Patio Heater: Is an unvented gas-

electrical connections to a 24 VAC

fired infrared heater designed to GENERAL RULES FOR fully automatic ignition and control

concentrate radiant heat in outdoor LOCATING HEATERS: s y s t e m ( s e e B a s i c L i g h t i n g

areas. TM

A Sunglo Patio Heater can operate I n s t r u ct i o n s o n p a g e 6 ) . I t i s

effectively to maintain comfort even in

Definition of Outdoors (For the recommended that when multiple

completely exposed areas, although

purposes of these instructions). An heaters are used, that the electrical

w e a t h e r p r o t e c t e d a r e a s a r e

ap p l i an ce i s c o n si de re d to be circuitry be arranged so heaters can

d e s i r a b l e . W e a t h e r a n d w i n d

outdoors if installed with shelter no be switched individually or in groups

protection allows the surrounding air

more inclusive than: to provide maximum flexibility for

to be warmed to enhance the direct

1. With walls on all sides, but with no heating the patio.

radiant warming effect.

overhead cover. Breezy Conditions:

2. Within a partial enclosure which TM

Sunglo heaters are designed to

includes an overhead cover and no work well under a variety of outdoor

more than two side walls. These conditions, however under certain

side walls may be parallel, as in a conditions they work better than

breeze way, or at right angles to others and under some conditions

each other. they should not be operated at all. The

heater can be operated under breezy

3. Within a partial enclosure which

conditions when the cross wind is 0-

includes an overhead cover and

10 mph. If heaters are mounted on the

three side walls, as long as 30

edge of a precipice or sea cliff where

percent or more of the horizontal

wind is directed upwards into the

periphery of the enclosure is

reflector hood, damage to the heater

permanently open.

can occur. Upward thrusts of wind can

also be caused by wind walls or

EFFECTIVE RANGE architectural elements near the

(COVERAGE): heater. The patio must be designed to

The comforting warmth from a single protect against this type of condition.

TM

Sunglo Heater will cover a 12' to 20'

TM

circle. The Sunglo is a “comfort” WHEN MULTIPLE

heater,” and the coverage is the area HEATERS ARE USED:

in which people will received a When more than one heater is used in

comforting amount of warmth. Some an area, it is generally preferable to

people will require more or less locate them close together. Multiple

warmth than others to be comfortable heaters located on 8' to 15' centers

and will either turn the heater up or give over lapping hea t p atterns

down, or move closer or farther away increasing the overall effective

as they desire. coverage for each heater.

7

15 Ft. 15 Ft.

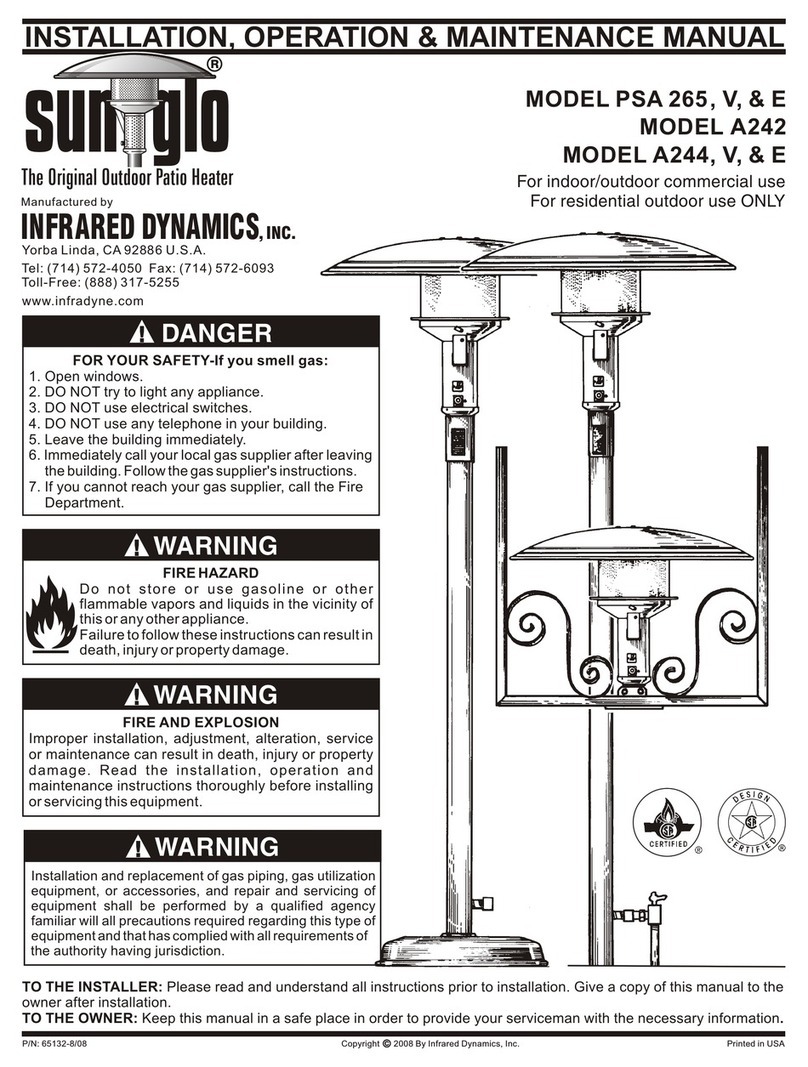

SUGGESTED SPACING WHEN

MULTIPLE HEATERS

ARE USED:

Spacing For: WELL PROTECTED AREAS

AND MILD CLIMATIC CONDITIONS

12 Ft. 12 Ft.

Spacing For: SEMI EXPOSED AREAS

WITH AVERAGE WEATHER CONDITIONS

8 Ft. 8 Ft.

Spacing For: COMPLETELY EXPOSED AREAS

WITH SEVERE WEATHER CONDITIONS