Remote Connections

Your booth incorporates advanced circuitry allowing it to connect and communicate with

most remote control systems. If a remote system is to be used, the type of system you are

using must first be determined.

Warning: The remote connection is not designed to supply or accept high voltage,

nor can it provide power to an external timer. Only use remote systems that incorporate an

isolated contact or relay, or the ComputaTAN™or T-Max®remote systems. Failure to do so

will void your warranty and may damage the booth.

Caution: Remove the bypass plug when using a remote system except for the

case when the booth is at the end of a ComputaTAN™or T-Max®Manager series.

ComputaTAN™ or T-Max®Manager Remote Systems

The ComputaTAN™and T-Max®Manager remote systems offer the ultimate in booth con-

trol, while allowing the tanner easy straightforward operation. Your booth is already config-

ured to directly connect to these systems. To connect your booth to either of this systems

follow the instructions that came with your remote system, noting the hints listed below. If

you still have questions call ETS at the phone number listed at the back of this guide.

Setting the address Before connecting your booth to either the ComputaTAN™or

T-Max®Manager series, the address or “id” of your booth must first be set. Each

booth connected to the series must have a different “id” number . To set the

address,

1. Verify that the booth display is indicating a “0”.

2. Press and hold the stop button located on the booth display for three sec

onds and release. The display should indicate an “id” number from 1 to 99.

3. Set the “id” to a unique number by pressing the timer button until the desired

number is achieved. Holding in the timer button will increase the “id” scroll rate.

4. Press the stop button to return to the normal display mode.

Note: If you are having trouble getting into the “id” mode, it is probably because

you have already attempted to connect your booth to the remote system.

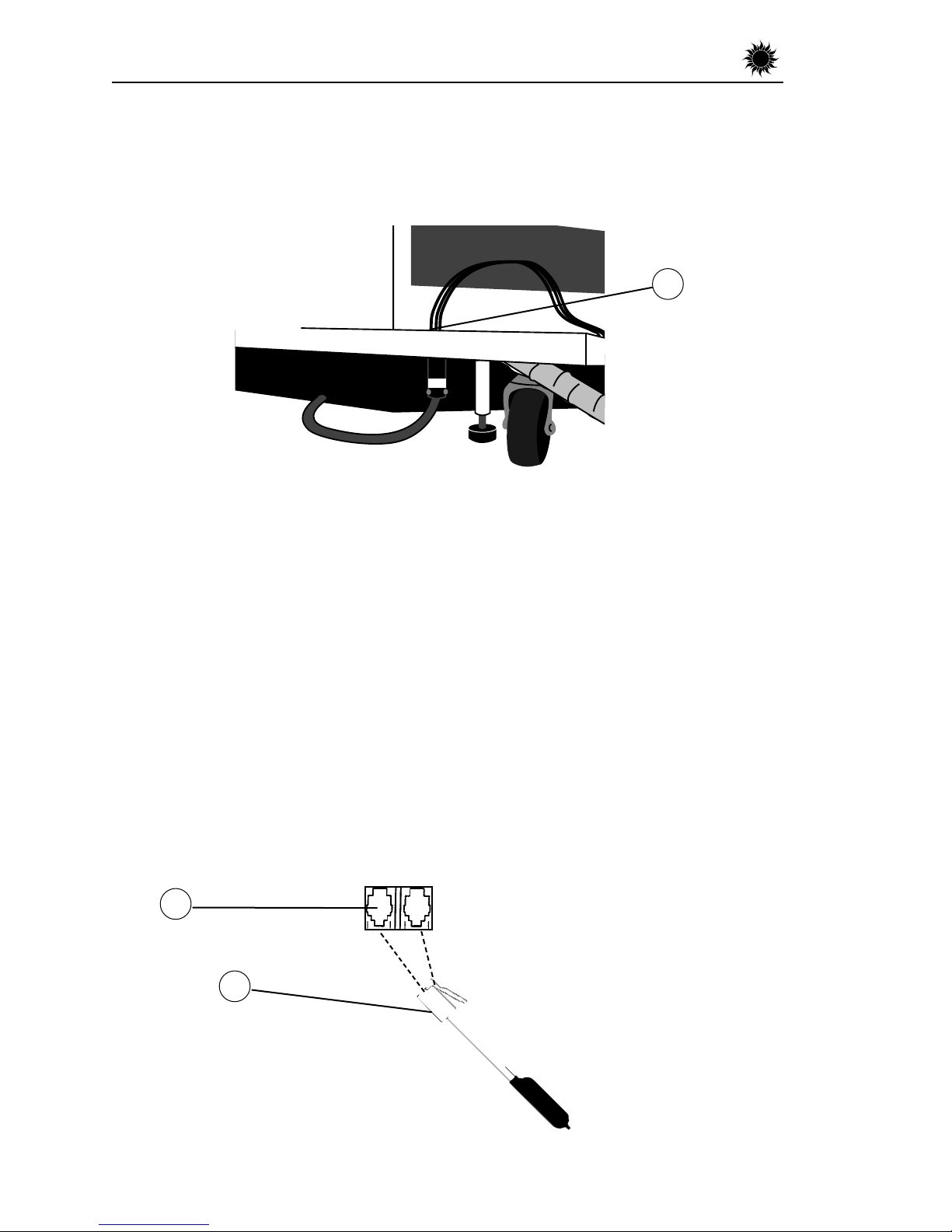

Disconnect the remote plug(s) from the ports located on the top right hand corner

of the rear of the booth, wait 90 seconds and try again.

T-Max®Manager The T-Max®1A is not needed when connecting your booth to

the T-Max®Manager series. The circuitry inside your booth eliminates the need for

the T-Max®1A. Simply connect the RJ-22 Modular cable(s) described in the T-

Max®Manager manual directly into the port(s) located on the top right hand cor

ner of the rear of the booth You can place your booth at any location in the series.

Remember the last connection in the series requires a terminator plug.

5

Installation–Remote Connections