No. 7, Road 12, Industrial Zone, Taichun

Cit

407, Taiwan

Tel: 886-4-2359-1190 Fax: 886-4-2359-3409

2

SAFETY PRECAUTIONS

IMPORTANT:

It is the duty of both employer and employees to acquaint themselves with the

safe working practices contained in this manual and ensure that all operators

adopt these practices.

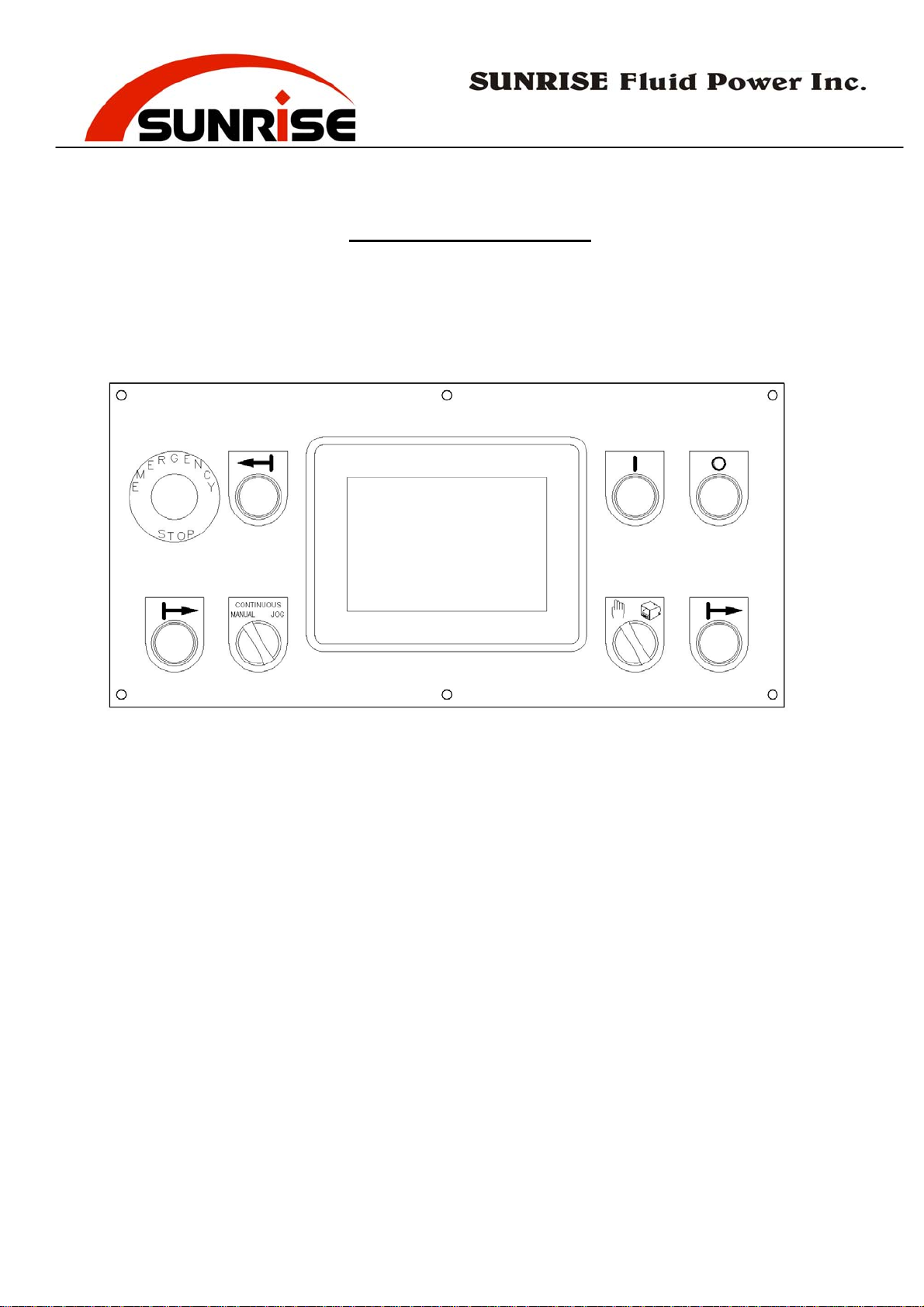

To ensure safe operation, two-hands switch should be used to avoid accidents of

hand/finger injury. The foot paddle is also provided as an option to be used only by

authorize personnel and with safety guards installed.

This equipment, if not operated and maintained properly, has the potential to cause

serious injury or death. A thorough knowledge of the machine and operating with

carefulness is the best protection against accidents.

The operator should be familiar with the control and function of the switches before

perform the operation.

Warning labels are fixed on the machine. NEVER REMOVE THESE LABELS.

Be sure to follow these warnings to avoid injury.

Please also pay attention to the following general rules:

1. Only one operator is allowed to operate on the HBM bending machines. Before

each operation, make sure no other person is near the machine.

2. Operator must wear Protective Glasses during operation to protect the eyes.

3. Use of optional attachments/tooling should have proper guards installed.

4. Any maintenance/repair of electrical/hydraulic circuit; change/adjust of tooling

should be done only by qualified engineers or personnel.

5. Always turn off power and disconnect electric supply before doing any tool

change or maintenance work.

6. Keep hands clear of all moving parts at all times.

7. Do not bend, punch, or shear parts that are too small for safe operation.