FORM NO. 660868 REV. B PAGE 2

TABLE OF CONTENTS

DISCLAIMER OF LIABILITY

These assembly and installation instructions have been provided by SunStream Corporation® at the

request of the potential installer and/or assembler. If you are not an authorized SunStream® Dealer and

are not a reasonably-skilled mechanic, please contact SunStream® so that we can refer you to a local

dealer who can skillfully and safely perform the assembly and installation of your SunStream® boatlift. It is

the potential installer and/or assembler’s responsibility to determine whether he or she has the necessary

skills, knowledge, and tools to properly and safely assemble and/or install the SunStream® lift described

herein. Improper assembly and/or installation may cause the lift to function improperly or not to function.

Improper assembly and/or installation may additionally cause a risk to personal safety or property.

If the assembler and/or installer is confused or has questions or concerns about a particular assembly

or installation, he or she should contact SunStream® by telephone at (253) 395-0500 before proceeding

further. The information contained in these instructions does not constitute a warranty or guarantee

of any kind.

An assembler’s and/or installer’s failure to correctly follow these assembly and installation instructions

constitutes a waiver of the assembler and/or installer’s rights against SunStream® regarding any

Subsequent damages to property or personal injury caused by the assembler’s and/or installer’s improper

assembly and/or installation.

Safety Instructions………………………………………………………3

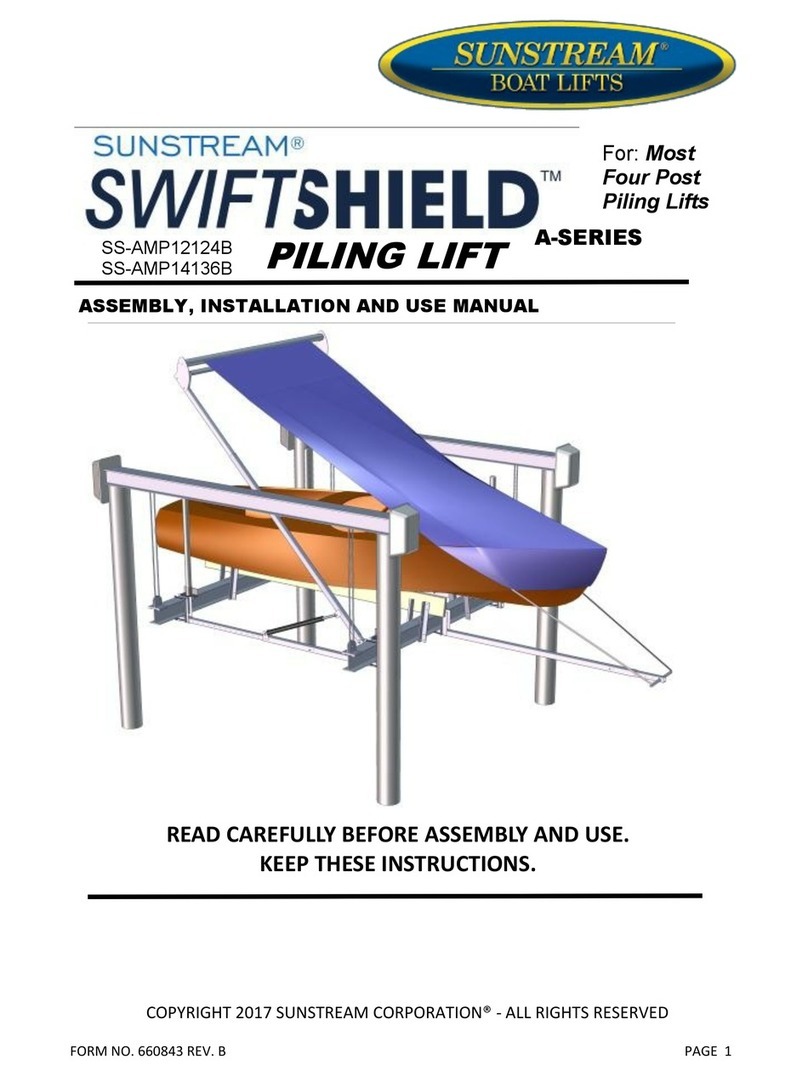

Overview………………………………………………………………..4-5

Tools Required…………………………………………………………..6

Installation and Assembly………………………………………….7-26

Bow Sprit…………………………………………………………...8-9

Guides and Clamps …………………………………………...10-12

Frame……………………………………………………………..13-15

Hydraulic Hoses and Power Pack…………………………..16-17

Arms and Roller…………………….……………………….….18-21

Installing and Adjusting the Cover………………………….22-28

Removing the cover…………………………………………...29-31

Quick Tips……………………………………………………………….29

Maintenance ……………………………………………………………30

Troubleshooting………………………………………………………..31

Accessories……………………………………………………………..32

Warranty……………………………………………………………. 33-34