10

ТЕХНИЧЕСКИ ПАСПОРТ. ИНСТРУКЦИЯ за МОНТАЖ и ЕКСПЛОАТАЦИЯ

ТЕХНИЧЕСКИ ПАСПОРТ. ИНСТРУКЦИЯ за МОНТАЖ и ЕКСПЛОАТАЦИЯ

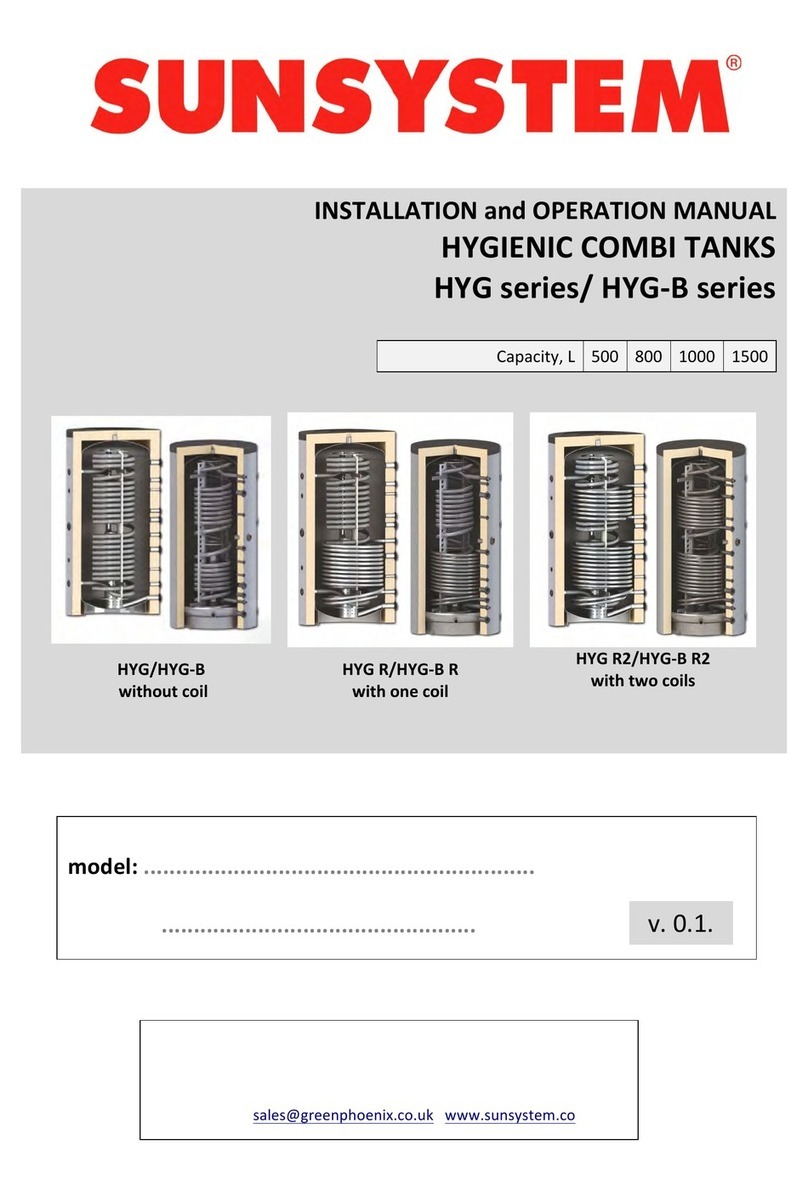

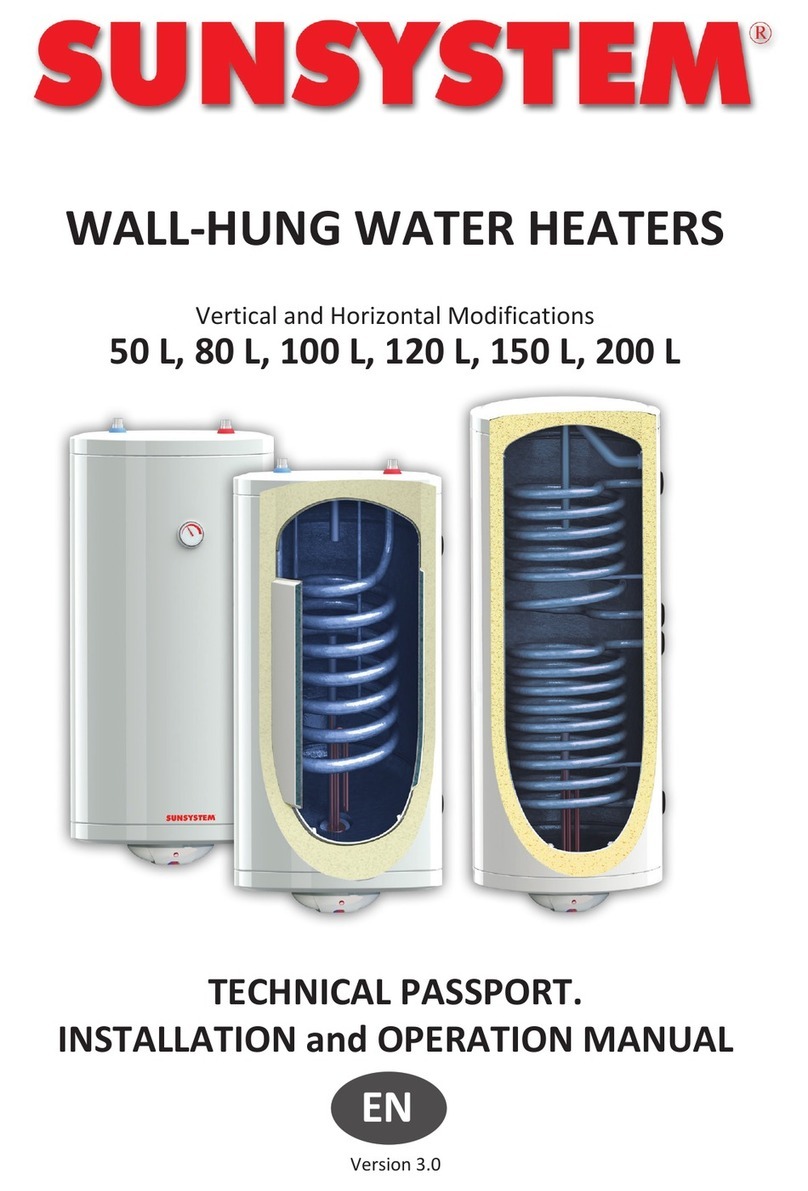

INSTALLATION and OPERATION MANUAL

INSTALLATION and OPERATION MANUAL

the Commercial Department. Aer decision

for sasfacon of the claim has been made,

the Purchase requision menoned above will

be annulled by issuing a receipt for returned

goods; with this receipt the customer can pur-

chase another product with the same price in

case the claim has proved grounded.

e) NES Ltd. reserves the right to make in situ

reports from the claims they have received

for the purpose of checking every aspect that

might be useful for beer consideraon of

warranty claims; for this reason the custom-

er shall not make any changes in installaon

condions which are reasons for the claim

without prior wrien consent of the Technical

Department.

6.4. Limitaon of liability

а) NES Ltd. is not liable before the cus-

tomer, neither directly nor indirectly, for any

non-fulllment or delay at applying the war-

ranty obligaons which might originate from

external pressure of other circumstances out-

side NES Ltd

b) The liability of NES Ltd. under this

Warranty Cercate is limited to the above-

menoned obligaons and up to the sum in

accordance with the purchase receipt of the

product to be claimed; excluded is any liabil-

ity for indirect damages such as loss of data at

informaon applicaons, loss of producon,

thermal variaons at the service, etc. which

do not violate the applicable regulaons of any

country concerning product liability.

c) Abovemenoned warranty limita-

ons will be applied in any cases, and when

they do not violate the regulaons in any

country concerning product liability. If this cir-

cumstance annuls some of preceding clauses,

annulment will refer only to this clause, while

the others will remain valid. In conclusion, ex-

cluded is applicaon of any Regulaon pointed

out in this Warranty which violates the Law

23/July 10, 2003 and Direcve 1999/44/EU

concerning water heaters and their use on the

territory of the EU.

blurred, or cannot be expressly aested.

c) Damages in the appearance of products

shall not be considered as defects except for

those ones which cause losses during opera-

on or change technical characteriscs of wa-

ter heaters set forth in brochures.

d) NES Ltd. preserves the right, in case of re-

placement, to deliver another model of water

heater in order to fulll approved warranty

claims when the original model is not being

manufactured.

6.3. Claiming warranty

Every customer who has purchased a water

heater from NES Ltd., and who has good rea-

sons to lay a warranty claim, shall proceed as

follows:

a) Immediately nofy in wring:

1) The installer, or the company that has sold

the water heater to him, or

2) The distributor rm, or

3) The commercial representave of NES Ltd.

in the region.

For this purpose the claimant shall ll out a

claim form; the laer shall be accompanied by

the document proving the purchase of the wa-

ter heater (invoice) with the date of purchase

in it.

b) Aer receiving the claim form, NES Ltd. con-

siders it and makes decision whether the claim

has grounds, and whether the defect is with-

in the scope of the warranty set forth in this

cercate for limited warranty; aer which in-

forms the customer as to its decision and the

steps he shall do.

c) The return of a product cannot be done

without wrien authorizaon issued by the

Quality Department. The return procedure

shall be according to RMA (Return Material

Authorizaon).

d) If on customer’s request, and when there

is reason for urgency, the customer demands

immediate replacement of the product he

has claimed warranty for, before making the

decision as to the claim, said request shall be

accompanied by a Purchase requision from