5

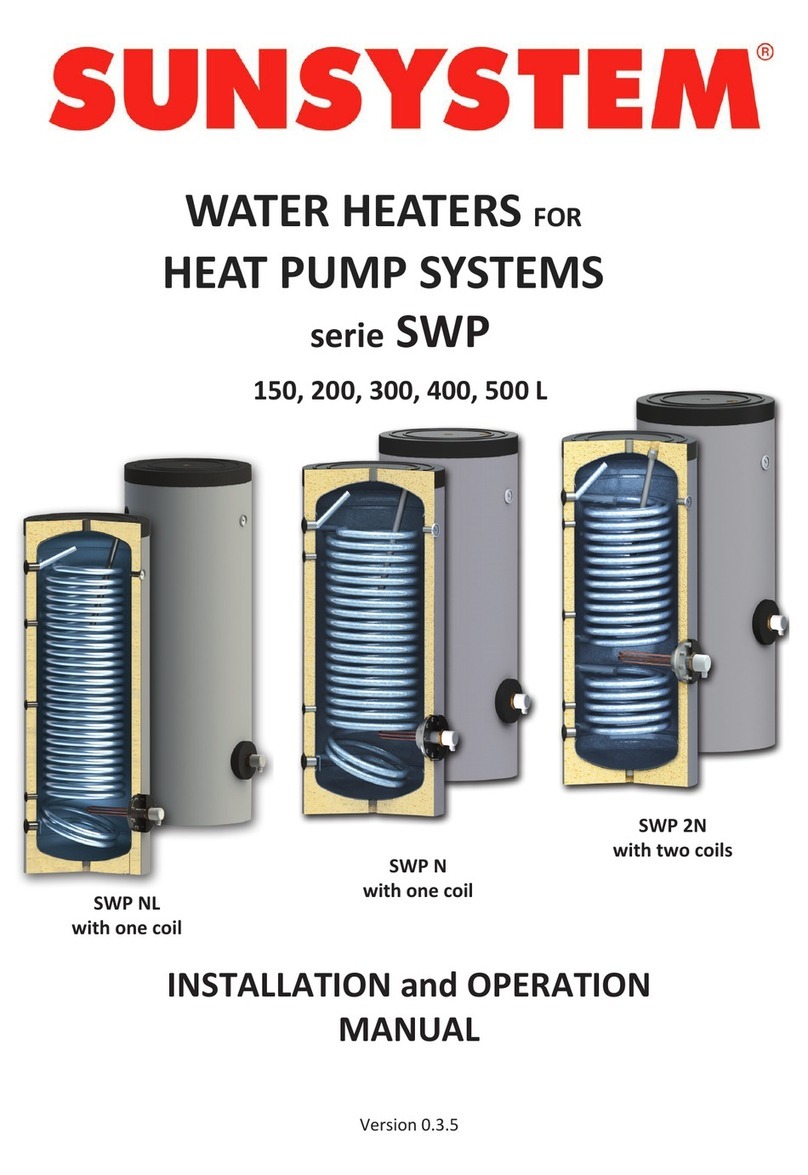

INSTALLATION and OPERATION MANUAL

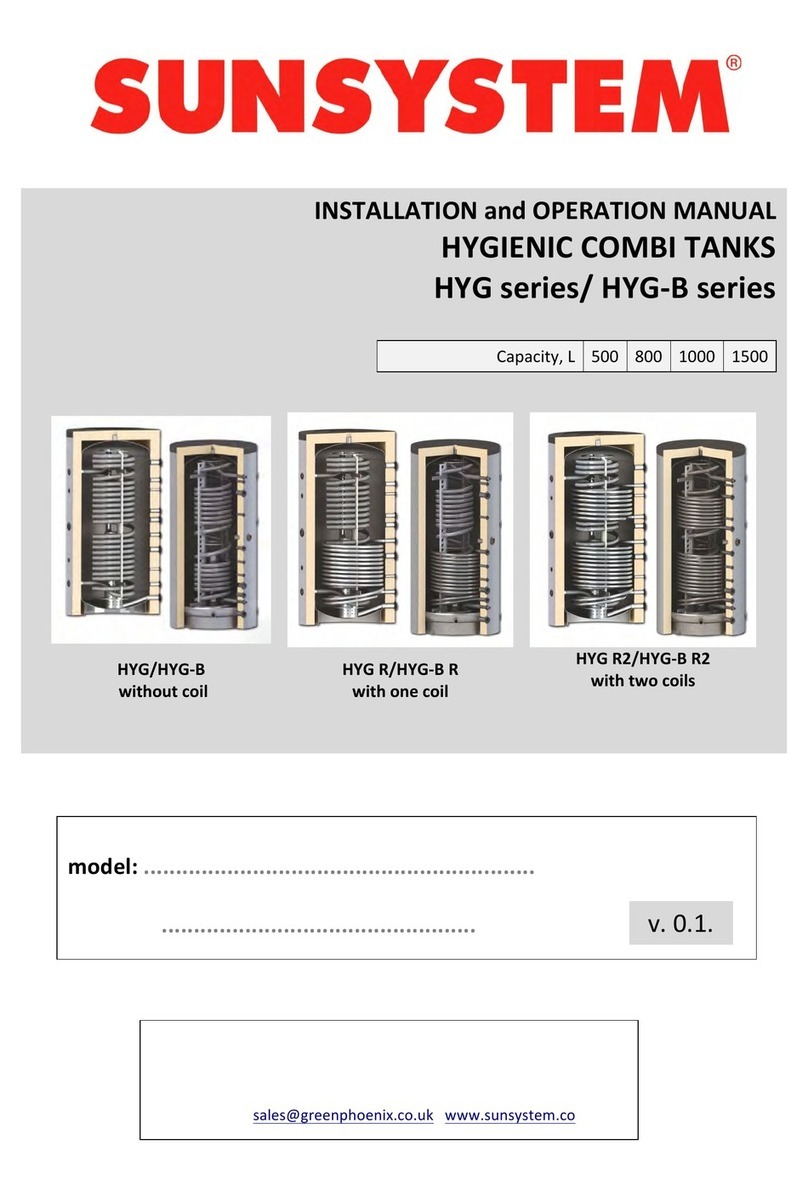

INSTALLATION and OPERATION MANUAL

• If there is a risk of water freezing in the water

tank: drain the water tank completely or let

the boiler run continuously.

• Pressure regulator. If the pressure in the

water supply network exceeds 0.5 MPa (5 bar),

it is desirable to install a pressure regulator

at the cold water inlet. We recommend that

the regulator be set to 0.4 MPa (4 bar), thus

ensuring the correct operation of the product

and its optimal service cycle.

• Expansion vessel. We recommend installing

an expansion vessel to absorb water expansion

when heated.

The volume and type are determined by a

qualied designer in accordance with the

technical data of the boiler, the system in place

and the local and European safety standards!

Installaon is carried out by a qualied

technician in accordance with his operang

instrucons.

• Pipe insulation. In order to optimize the

efficiency of the appliance, we recommend

that all its pipe terminals and the elements

connected to them be covered with a suitable

thermal insulation material.

• Before filling the boiler with water, check all

screw connections (bolts on the inspection

cover for flange, plugs and anode). In very rare

cases - during transport, loading and unloading

operations, it is possible for the bolted joints to

loosen. The tightening torque of the inspection

cover bolts is 160-190 Nm.

• Filling the boiler with water.

- The hot water tap on the

farthest mixer tap opens.

- The tap of the water entering the boiler is

opened.

- The system is expected to be deaerated, an

indicator of which is a dense and strong jet of

water from the open mixer.

- Make sure that there are no leaks in the

piping connections of the installation and the

bolted connections on the cover of the boiler

flange. If necessary - tighten.

- Check the safety valve by lifting its lever - a

thick and strong jet of water must flow through

its side opening for about a minute.

Such a check for the serviceability of the

installation.

• The orientation for mounting the water heater

contained in the model name - V - vertical and

H - horizontal mounting, should not be changed.

Horizontal models are always mounted with the

electrical part on the left.

• The boiler is fixed to the wall of the room by

means of steel bolts (studs) with a diameter of

10-12 mm, which are firmly fixed in the wall.

It is forbidden to install the water heater to

decorative walls.

1.2. Connecting the boiler to the plumbing.

• The installation to which the boiler is connected

and the elements included in it must withstand a

continuous temperature of 85 ° C and a pressure

twice as high as the operating temperature of the

appliance.

• It is MANDATORY to install a safety valve

(included in the product set) on the cold water

pipe, observing the arrow on its housing,

showing the direction of water flow through it.

IMPORTANT! There must be no shut-

off or non-return valve between

the safety valve and the boiler.

Do not block the side opening

and / or block the valve lever.

Failure or incorrect installation of the

safety valve is grounds for voiding

the appliance‘s warranty.

• Drain connection (hose) of safety valve.

When the boiler is running, in some cases it

is possible to release a small amount of water

from the relief valve as a result of a linear

expansion of the water. For this reason, it is

necessary to build a diversionary connection,

which is to be comply with local and European

standards and safety provisions! It must be of

sufficient inclination for water drainage. Both

ends must be open to the atmosphere and be

provided with anti-freeze. At pipe installation,

take safety measures from valve firing burns.

• Do not exceed the working pressure of 0,8

MPa (8 bar).

• If the pipes of the plumbing system are made

of copper or other metal, other than steel, as

well as when using brass connecting elements,

it is mandatory to install dielectric fittings at

the inlet and outlet of the water heater.