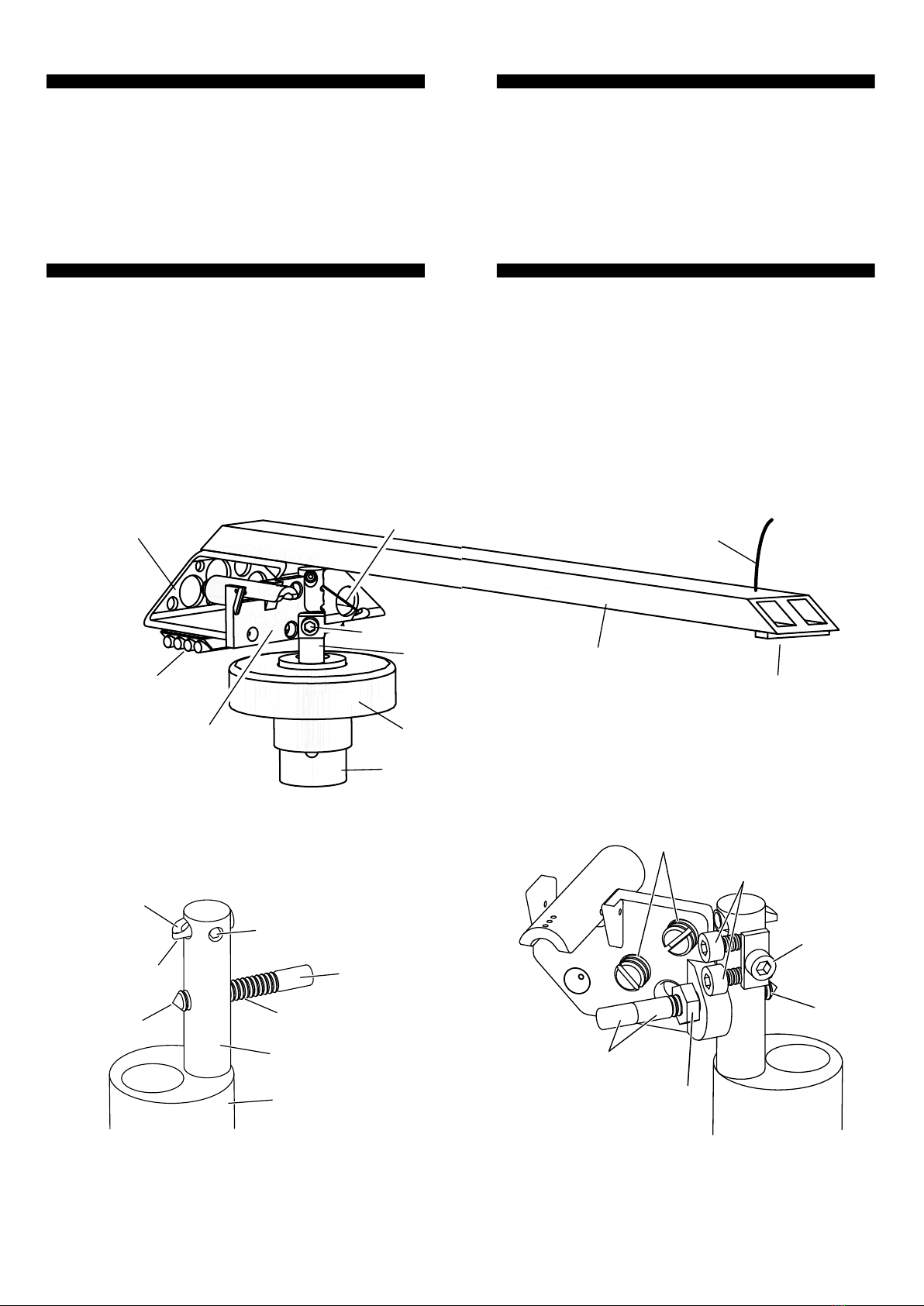

Arm-Rest Magnets

In the rest position the thrust box rests against

three 6mm grub screws in the bias rig. Two of

these have embedded magnets which capture

the thrust box, whereas the uppermost screw

relies on the arm’s downforce for contact, and

sets the rest level of the arm. They can be

advanced or withdrawn with an Allen key to

achieve a stable arm-rest position. Ideally both

rest magnets will make contact with the thrust

box when the arm is resting.

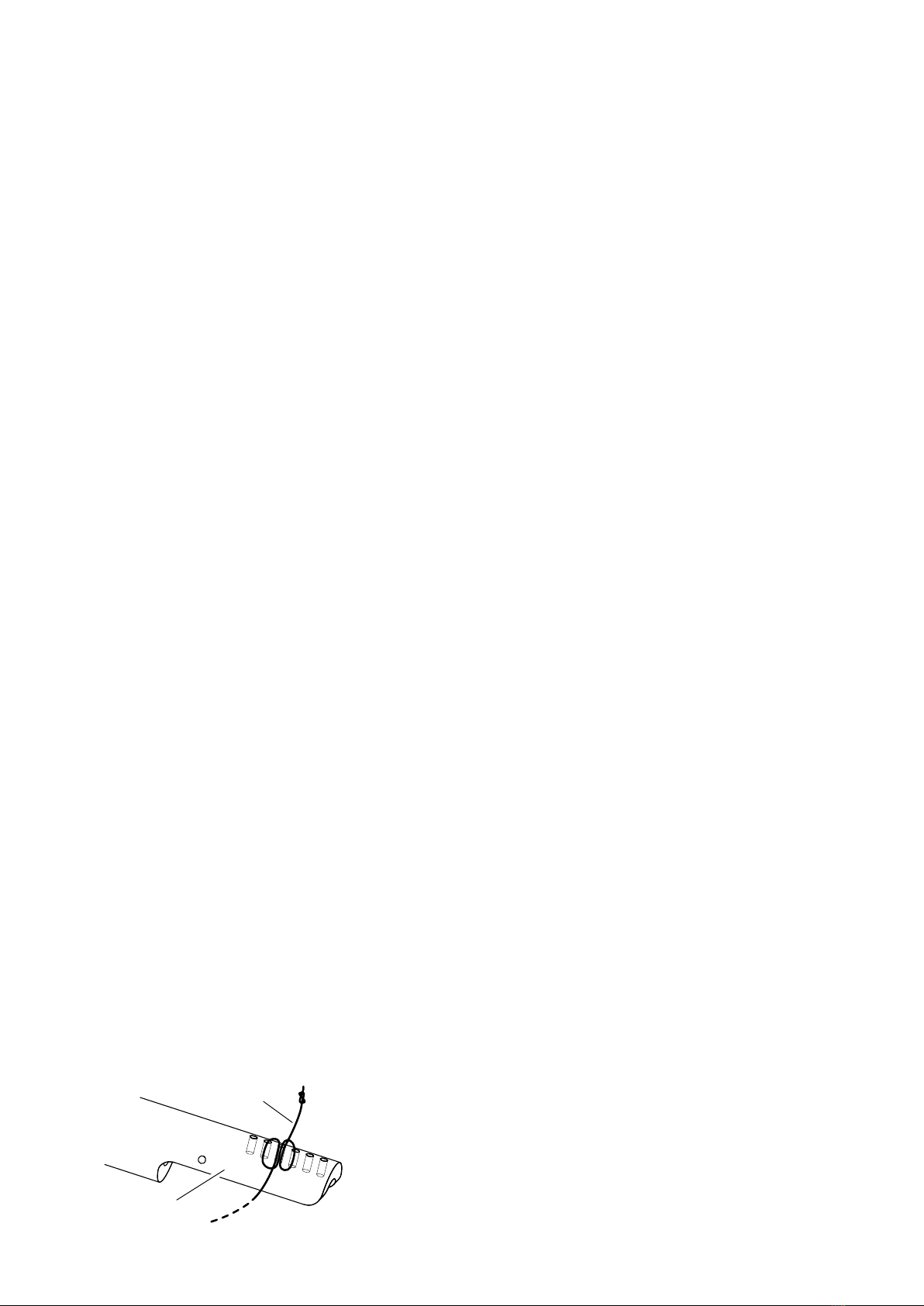

Alignment

A protractor is included to establish optimal

spindle-to-pivot distance, cartridge overhang

and null point alignment.

If it is difficult to set these distances optimally

on your turntable, you can slightly adjust

spindle-to-pivot distance by withdrawing or

extending both the pivot bolt and hoist pipe in

equal measure. If this is done, the pillar will no

longer conserve geometry when it is rotated in

the base, in which case configurations involving

large rotations of the arm pillar will slightly

alter the spindle-to-pivot distance. Please use

your own geometry calculators as the broad

subject of arm geometry optimisation is capable

of lengthy analysis.

SET-UP & FINE-TUNING

As with other tone arms, inaccurate

configuration can produce poor results,

whereas precise tuning will enable you to get

the best from your records. Please ensure that

your turntable is level before fine-tuning.

As the suspension settles in, it is worth

regularly checking bias, suspension height, lean

(‘azimuth’) and adjusting the arm’s geometry to

ensure that all are optimal.

Downforce & Inertia

Adjusting the inertia to suit the cartridge

suspension is important. Good results can be

achieved by trial and error, or by calculation.

Set downforce and inertia using the

counterweights which attach magnetically to

the underside of the thrust box, and the mass

adaptor which sits across the arm between the

cartridge and pivot. The further both weights

are from the pivot, the higher will be the arm’s

inertia (‘effective mass’). High compliance

cartridges work better with low inertia, whereas

low compliance cartridges work better with

higher inertia. With long arms and heavy

cartridges it may be necessary to place an

additional counterweight inside the thrust box.

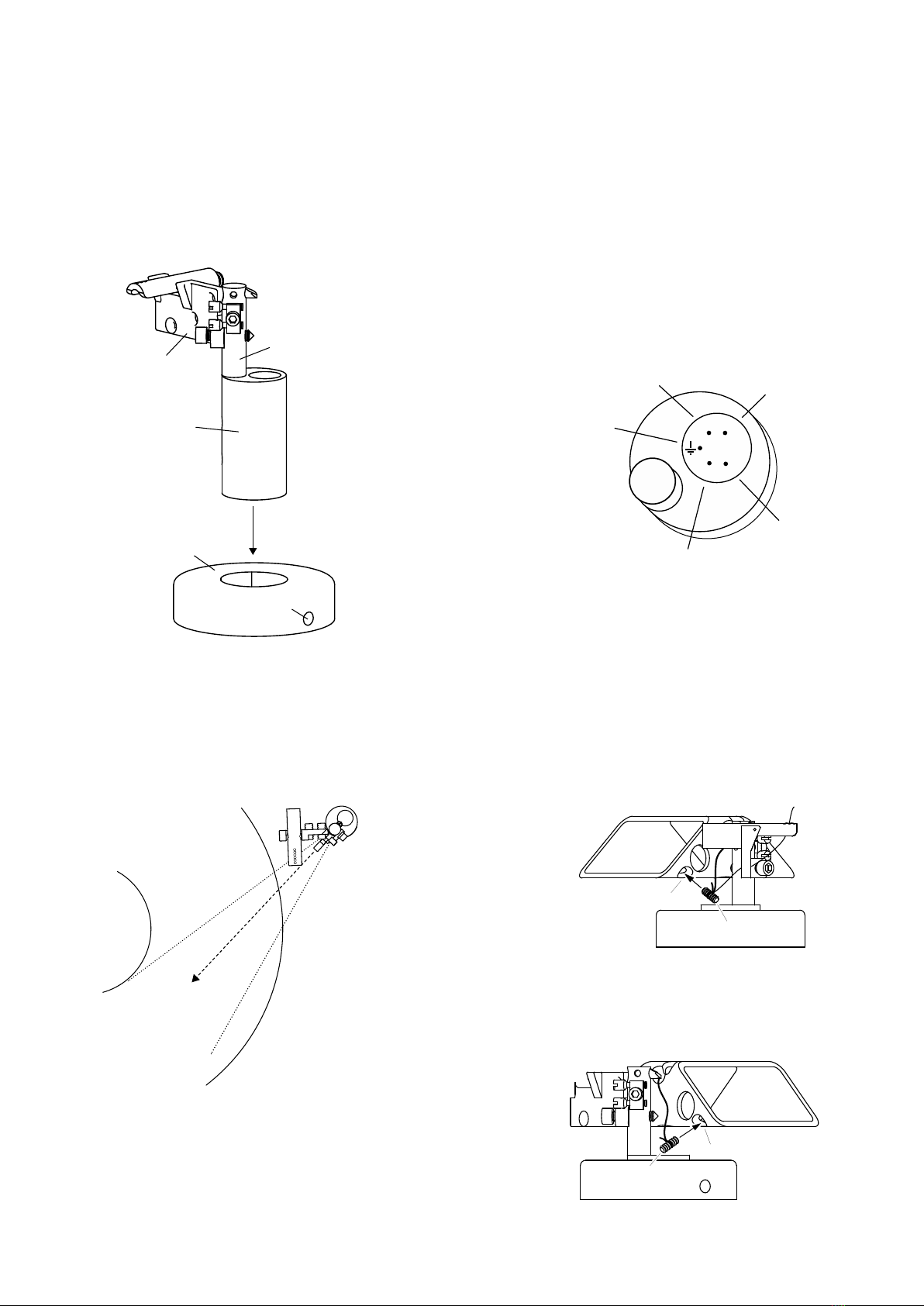

Downforce Scale Use

Place the supplied downforce scale on the

platter. The coin-sized rebates accommodate a

UK penny, a US cent or a Euro centime as the

balancing weight. The dimples represent 1/10

gram increments in the range 1.2g - 4g. Adjust

the counter-weight until the scale balances with

your stylus resting in the dimple corresponding

to your desired downforce.