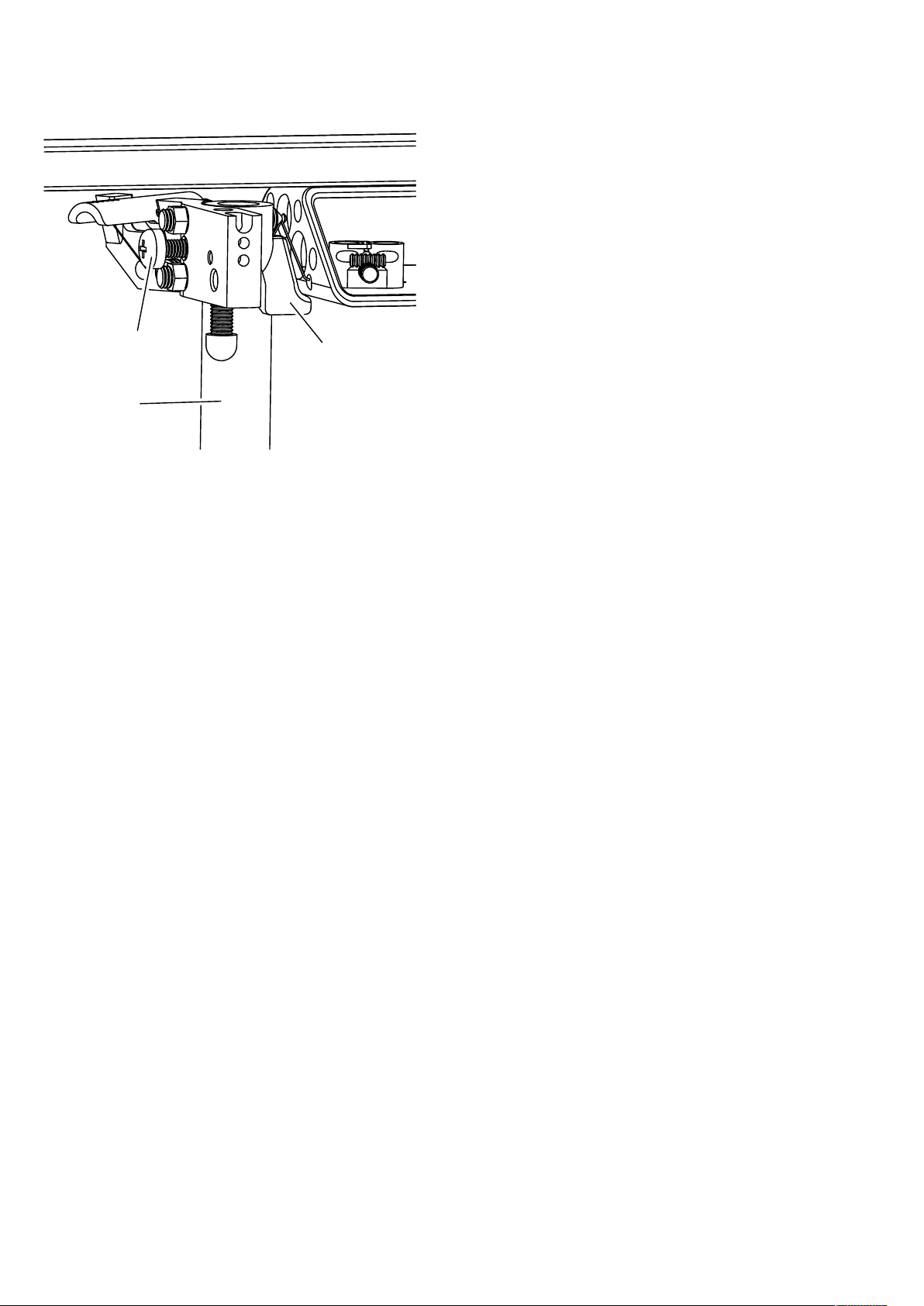

Remove Transport Bolt

Once the arm is installed on the turntable and

the pillar is secure, you can unscrew the

transport bolt and remove the transport spacer.

Take care not to strain or abrade the electrical

wires and hoists when removing the spacer. It

can help to lift the whole arm upwards a little

while keeping it level.

If None, Install Cartridge

If you did not install your cartridge before

mounting the arm, place a folded tissue

between the pivot and thrust box to protect

them during cartridge installation.

For a three-bolt mounting, remove the finger-

lift and use its hole to access the third bolt with

an Allen key or screwdriver.

Large head cartridge bolts or large nuts will not

fit in the headshell. It is possible to file large

bolt-heads and nuts in a drill or by hand.

Contact SUPATRAC if you are unable to

procure compatible bolts.

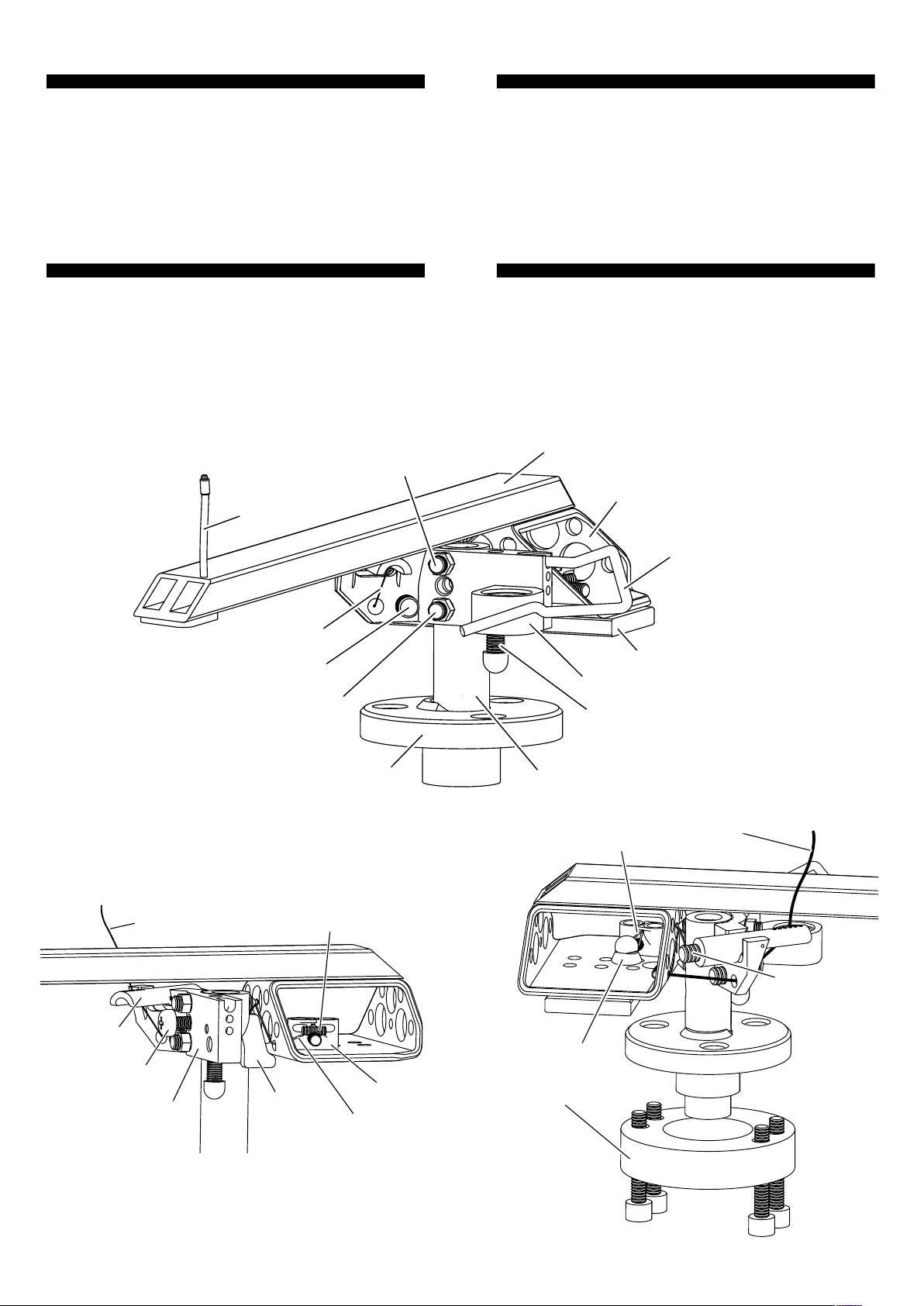

Attach Counterweight

When setting downforce, always obstruct

movement of the arm by holding it in your left

hand while adjusting the counterweight with

your right. Attach a magnetic counterweight

under the thrust box and squeeze it forwards

for more downforce or backwards for less. Keep

the counterweight centred on the axis of the

arm by pinching the thrust box from both sides

between thumb and fingers. You can centre the

counterweight by feel. Very small adjustments

of counterweight from left to right allow very

fine adjustment of lean (azimuth).

Multiple counterweights are supplied to cater

for a wide range of cartridge weights,

compliances and tracking weights (downforces).

To measure downforce, place the supplied

downforce scale on the bare platter with either

a penny, a cent or a centime as a balancing

weight in the appropriate bed. The dimples in

the scale represent 1/10 gram increments in the

range 1.2g - 4g. Adjust the counterweight until

the scale almost balances with your stylus

resting in the dimple corresponding to your

desired downforce.

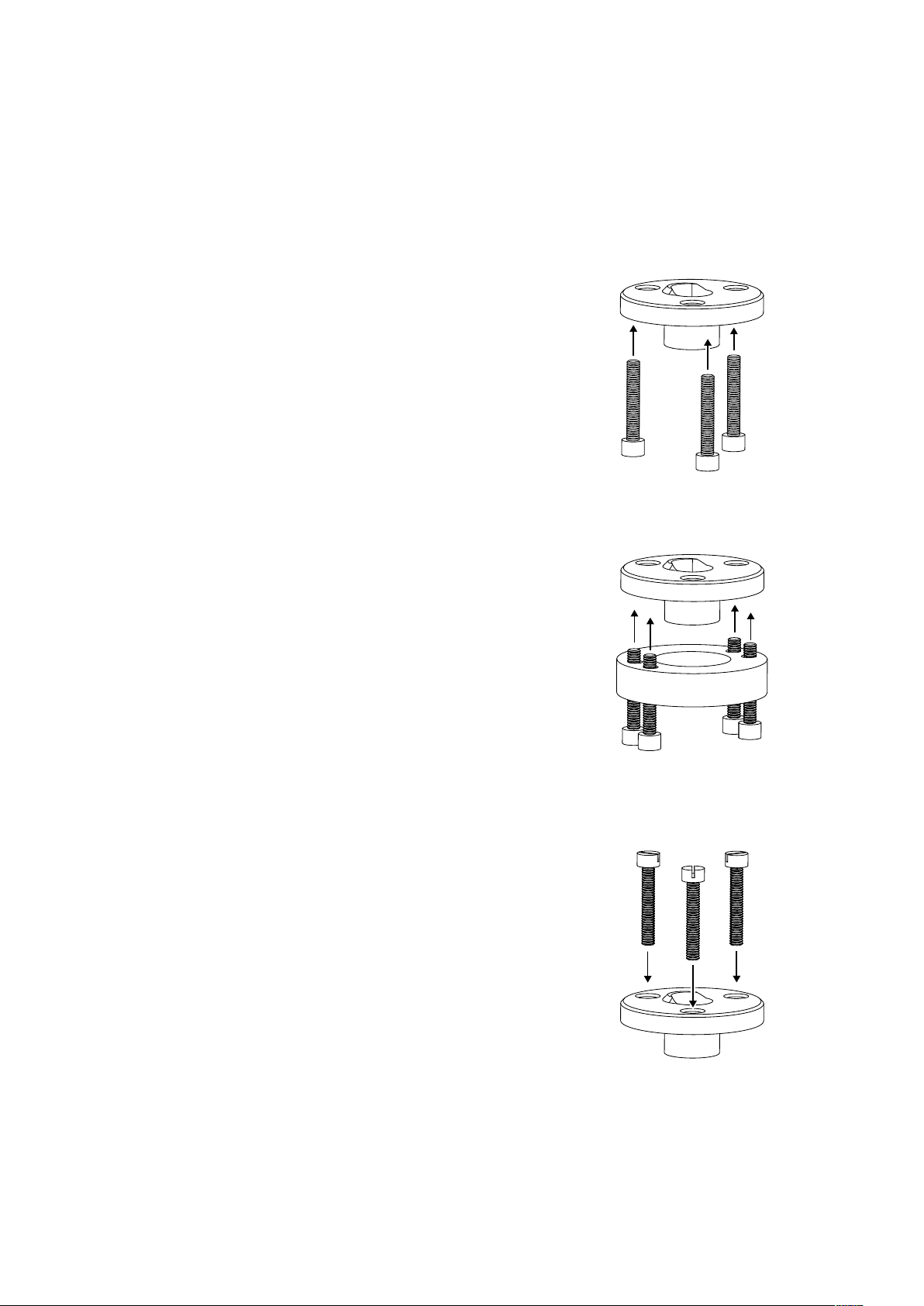

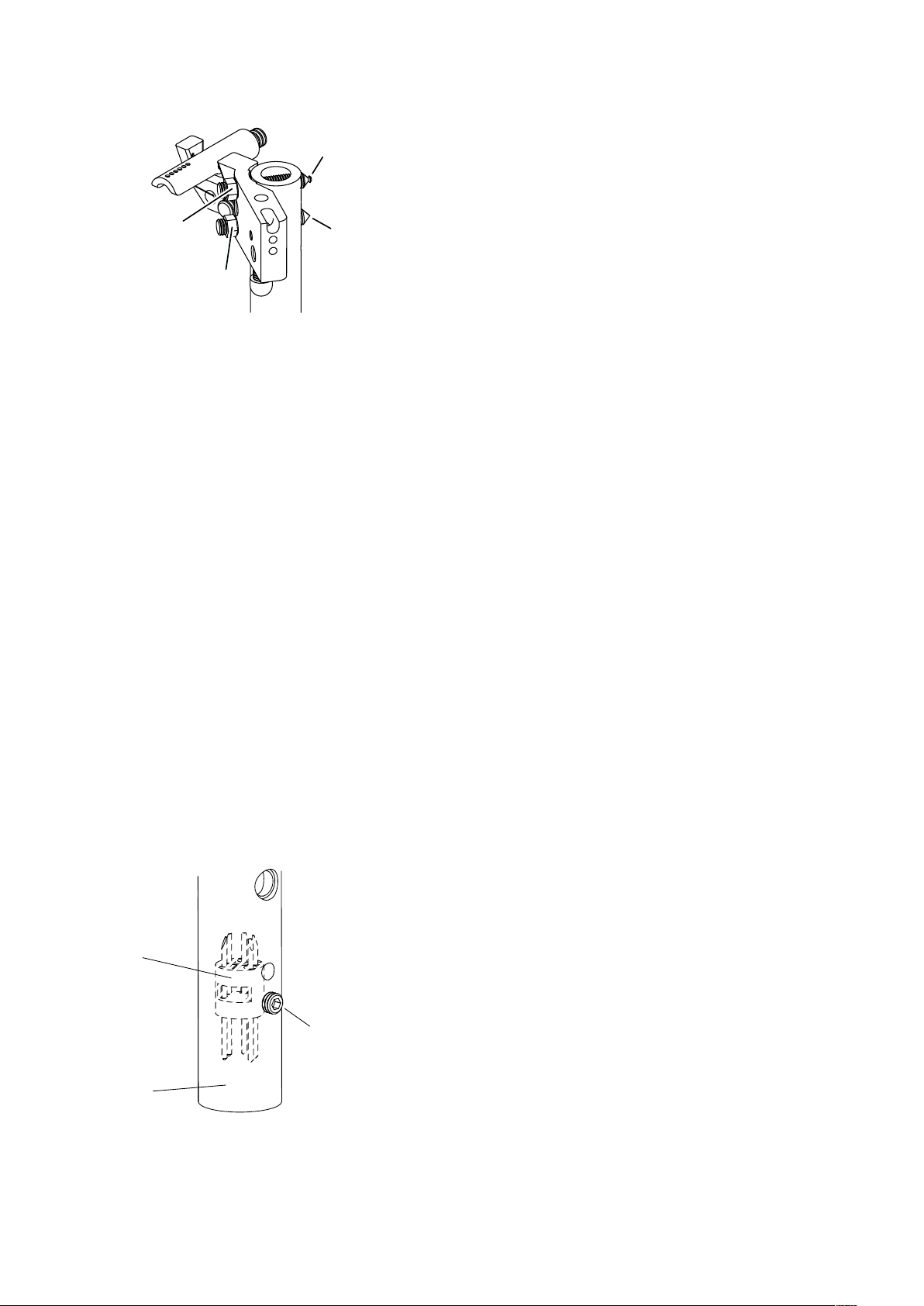

Level Arm (VTA)

The ‘Vertical Tracking Angle’ or arm level can be

set by raising or lowering the pillar. Take care to

set the arm level control screw to an

appropriate height. Guide the pillar up or down

using the level control screw and tighten the

pillar locking screw gently. The tightness of the

pillar locking screw can affect the sound, so

adjust it to taste. Tighter may not be better.

It may be necessary to re-adjust arm level after

optimising counterweights or hoists.