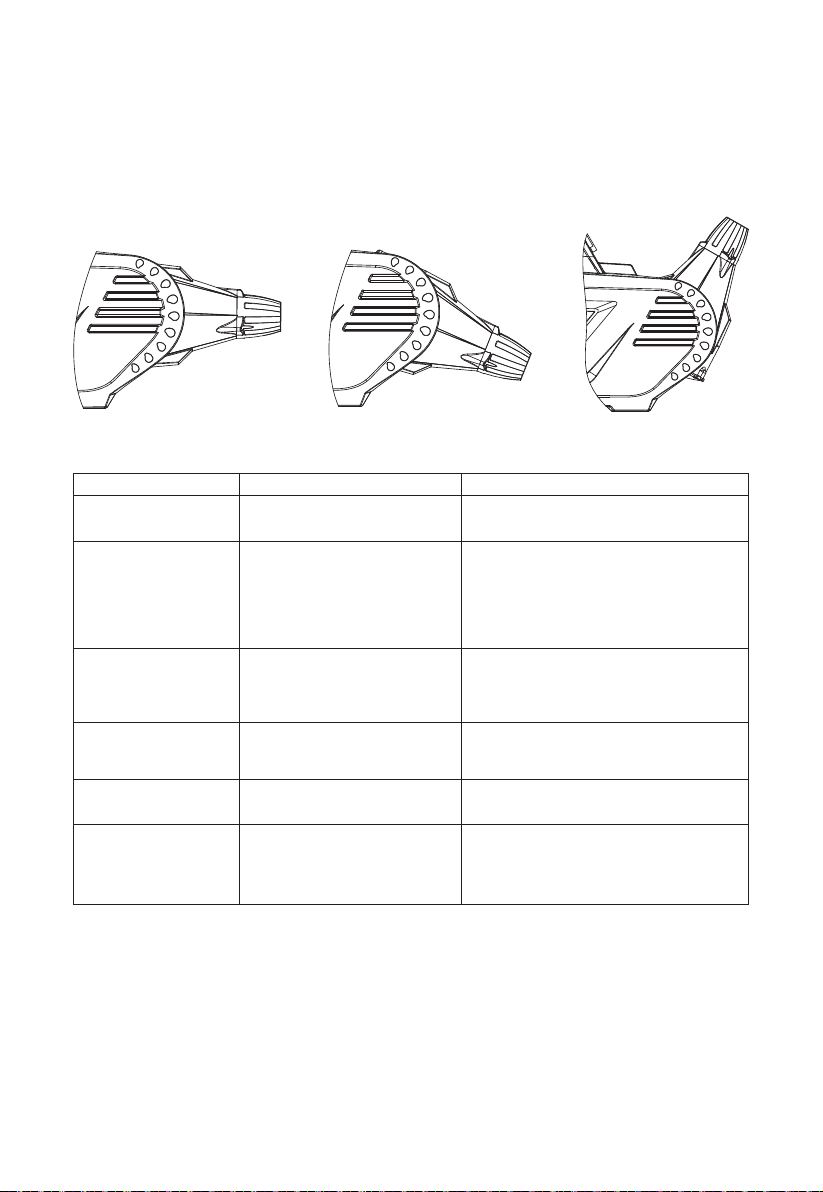

1. NO direct spraying highly toxic pesticides, undiluted pesticides, banned pesticides and

special chemicals. It should comply with the safety instructions provided by the pesticide

manufacturers when treating of pesticides.

2. On security grounds, the chemical tank cannot be added into inflammable and explosive,

highly volatile special chemicals, such as gasoline, alcohol, phenylacetone etc. Cannot add

highly corrosive liquid, such as caustic soda solution, hydrochloric acid etc. In case of injury

or fire and other major security incidents. (Warning: Keep the machine dry, wet hands are

prohibited to operate the power switch, to avoid electric shock.)

3. Warning signs to remind the worker should wear safety protection implements such as

protective clothing, gloves, safety glasses and masks.

4. The machine can only be operated by a person who is familiar with the performance and

operation method of the machine, and has the knowledge of relevant safety operation, the

following personnel operation is PROHIBITED strictly.

4.1 Children or the elderly.

4.2 Mental illness or sick deformed and weak people.

4.3 Drinking people.

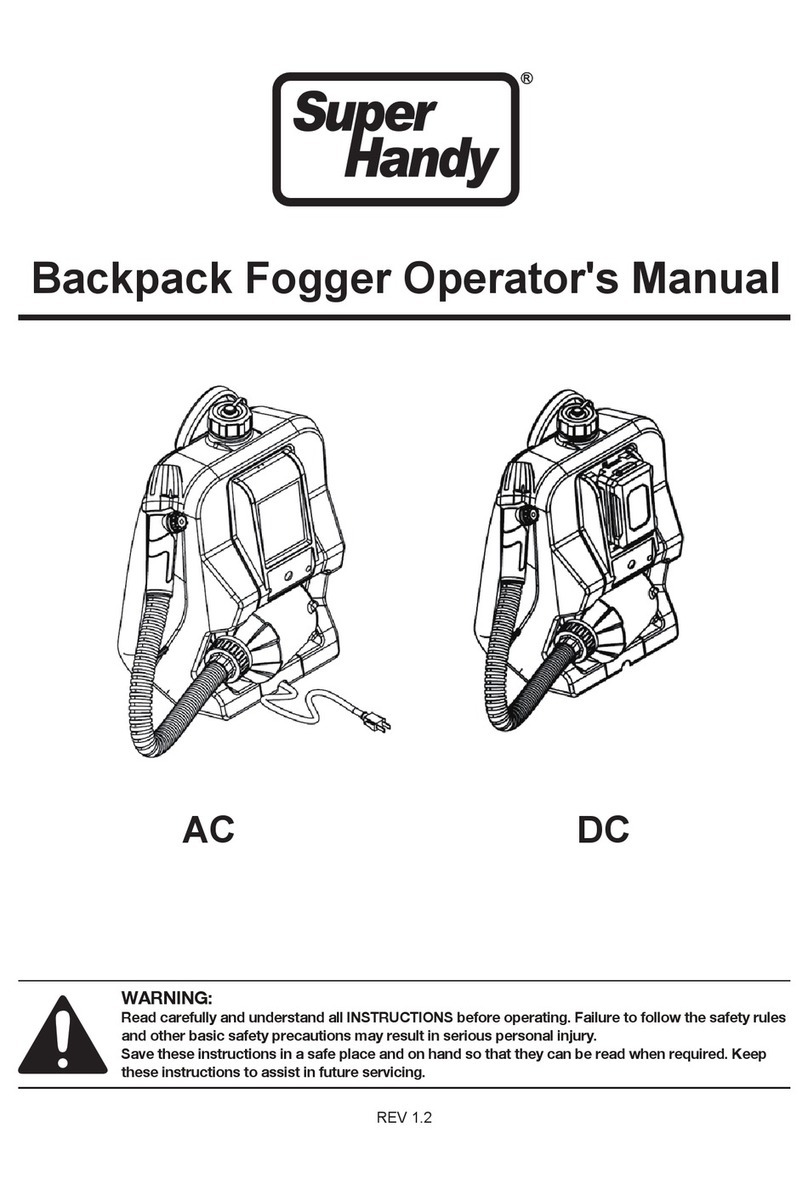

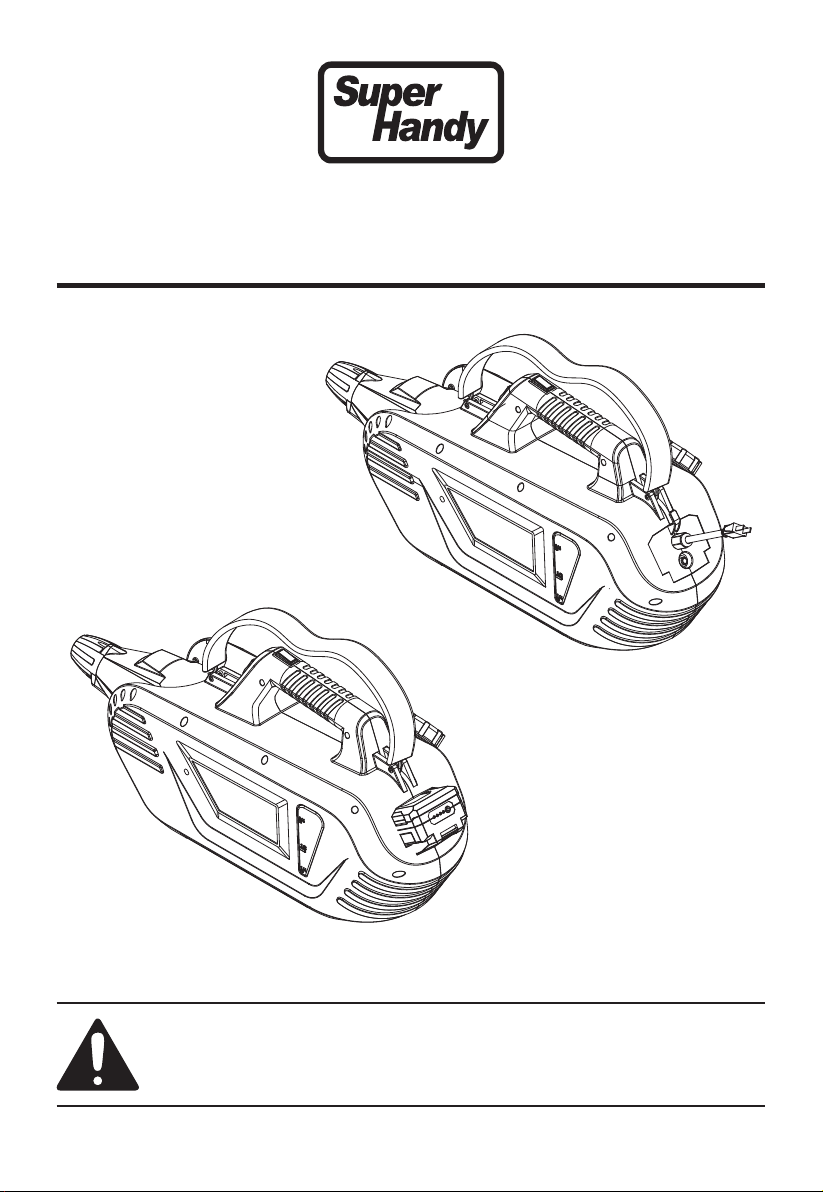

OPERATION

1. Preparation: Plug into power; turn on the power switch to check the motor if running

2. Power on: Turn on the power switch (ON), adjust the spray volume to appropriate correctly;

add the chemical after filtered with the filter funnel, tighten screw the tank lid as required,

then start to spray.

3. Power off: Raise the spray nozzle higher than chemical tank, turn OFF power switch,

keeping 2-3 seconds. The purpose is to let the remaining liquid in the pipe reflux into the

tank, to avoid the chemicals back up into the pipe and cause the motor moisture damage.

Lastly turn off the adjusting nut, to prevent the chemical outflow when adding liquid next

time.

4. During the sprayer working, the high-speed gas flow will cause the gun and pipe heating, it is

a normal phenomenon.

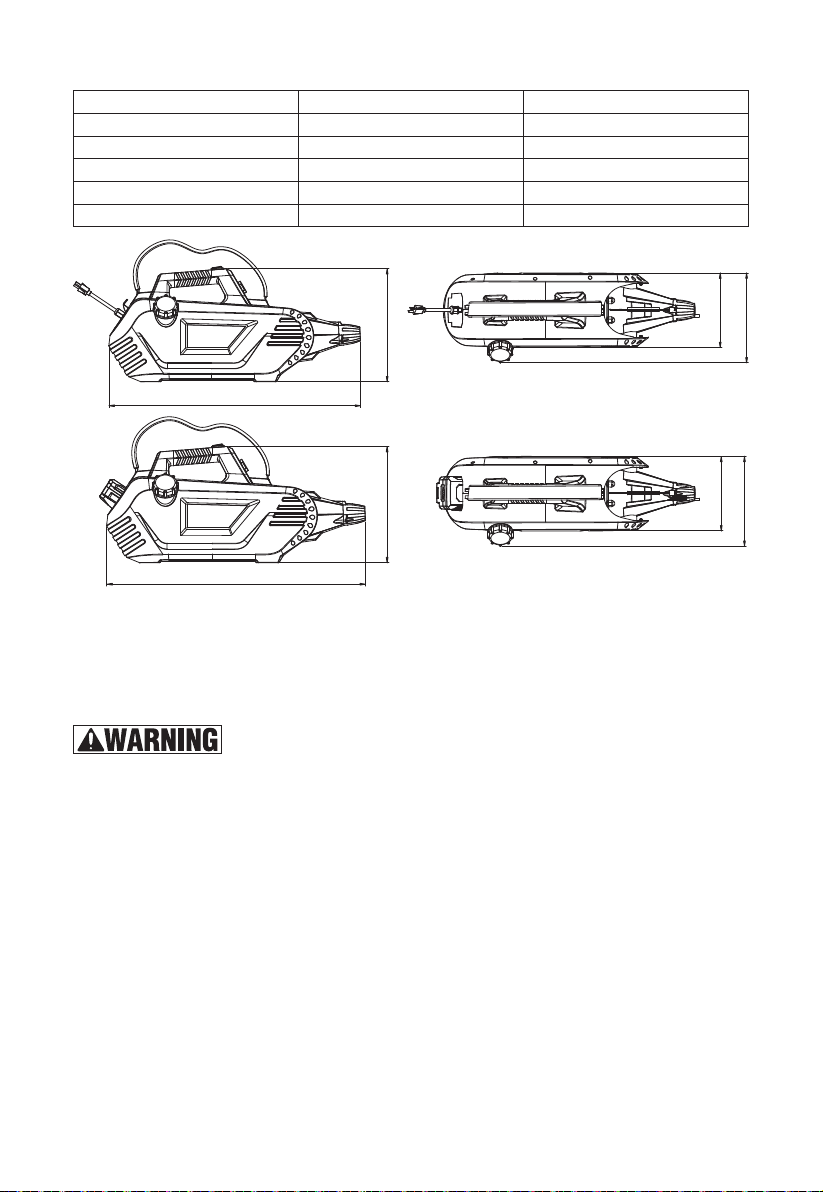

USE DIRECTION

1. The supply voltage should match the machine’s requirements.

2. Do not make the power wire knotted and pull off forced; Prevent breakage of wire core and

circuit broken; Avoid the sharp objects to scratch the cable insulation layer and cause

leakage.

3. Do not make the pipe folded and extruded, avoid the metal or other sharp objects puncture

the pipe.

4. Do not turn on and off power switch frequently, avoid damage the switch and motor. When

there is abnormal sound or small during working, shut down immediately, cut off the power,

and contact professional personnel to repair. If cannot resolve the problem locally, please

contact our company directly (1-866-493-0524), non-professionals is strictly prohibited

disassemble.

5. If not using for long time under the high humidity environment or in hot and rainy season, it

should always turn on for warm-up to eliminate humidity, prevent internal corrosion damage.

6. If not using for long time, please keep in dry and cool place, do not let children play with the

machine, to avoid danger.

7. Keep the machine dry, wet hands are prohibited to operate the power switch, to avoid

electric shock.

5