1. WARNING

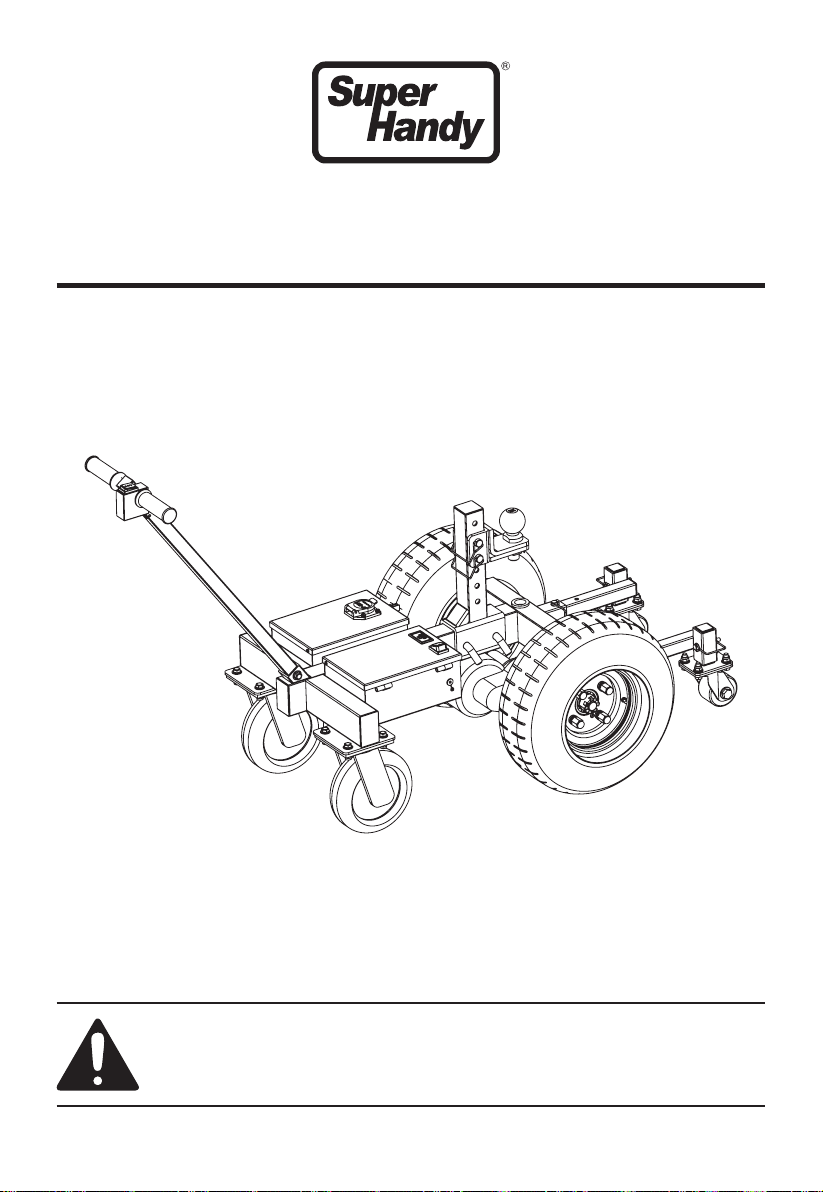

DO NOT USE THIS PRODUCT TO MOVE TRAILER LOADED OR UNLOADED ACROSS

ANYTHING OTHER THAN LEVEL PAVED SURFACES WITH LESS THAN A 4° GRADE.

DO NOT USE ON A SLOPED DRIVEWAY.

DO NOT ATTEMPT TO USE THIS PRODUCT ON A BOAT LAUNCH.

THIS PRODUCT IS NOT INTENDED TO REPLACE YOUR VEHICLE.

• Thoroughly review the "Installation and Operation Guidelines" and familiarize yourself with

your electric dolly and its operation.

• Never store the battery pack together with nails, screws, keys and other metallic or sharp

objects. These items may cause short circuit of the battery terminal resulting in damage to the

battery and may cause a fire, endangering personal safety.

• Avoid contact with any fluid that leaks from the battery. Dispose of all batteries in appropriate

manner as these batteries will be dangerous and should no longer be used.

• Be sure to dispose of or recycle the battery according to local regulations.

• Before disposal, be sure to protect the terminal with insulating tape to prevent short circuit.

• Do not to disassemble or tamper with the battery in any way. Any such tampering will

automatically void your product warranty.

• Do not attempt to charge a damaged battery pack. Replace it immediately. Adamaged battery

pack may cause a short circuit or fire.

• Battery packs are covered by manufacturers product warranty and will be replaced by vendor

if product is still under warranty.

• Do not burn the battery pack.

• Do not operate the dolly in an environment containing explosive or combustible materials.

• When the dolly is not in use, be sure to cut off the battery power.

• Be sure to use the charger and lead-acid battery packs provided by Superhandy only. Other

types of batteries may burst and cause personal injury.

• Do not to use chargers with damaged wires or plugs. Chargers with such issues should be

replaced immediately.

• Do not to use the charger provided by Superhandy to charge other batteries.

• Do not charge the battery in a humid environment, and do not cover the charger with clothes

or other items during charging.

• The use of accessories not recommended or provided by the charger manufacturer may lead

to the risk of fire, electric shock or personal injury.

• Always charge the battery at a temperature of 32°F-120°F (0°C-49°C).

• Always store the battery at a temperature of 32°F-86°F (0°C-30°C).

• Be sure to disconnect the charger when the battery is fully charged.

• Be sure not to completely discharge the battery. If not in use, be sure to charge the battery

every 3 months.

• DO NOT exceed the maximum Tow limit of this Trailer Dolly.

• Check that the hitch ball and the trailer coupler are securely mounted, and that the brake

control system of your trailer is in good working order before connecting it to the Trailer Dolly.

NEVER pull a RV, yacht or any other trailerwhich has no brake or has faulty brakes.

• Always use factory approved mounting hardware, components and fittings.

• NEVER pull a load with this Trailer Dolly on any steep grade or non-paved road. Always make

sure theroad surface is paved, level and less than a 4 degrees grade.

• Do not use the dolly to move people.

• Do not operate this dolly under the influence of alcohol or drugs.

• Be sure to remove any objects or obstacles that may hinder the safe operation of the dolly.

• When assembling, maintaining or prepping the dolly for storage, be sure to disconnect the

power supply from the dolly.

• DO NOT operate or install the dolly without reading or understanding the operator's manual.

• Do not operate this dolly if you are under 16 years old.

EN 1