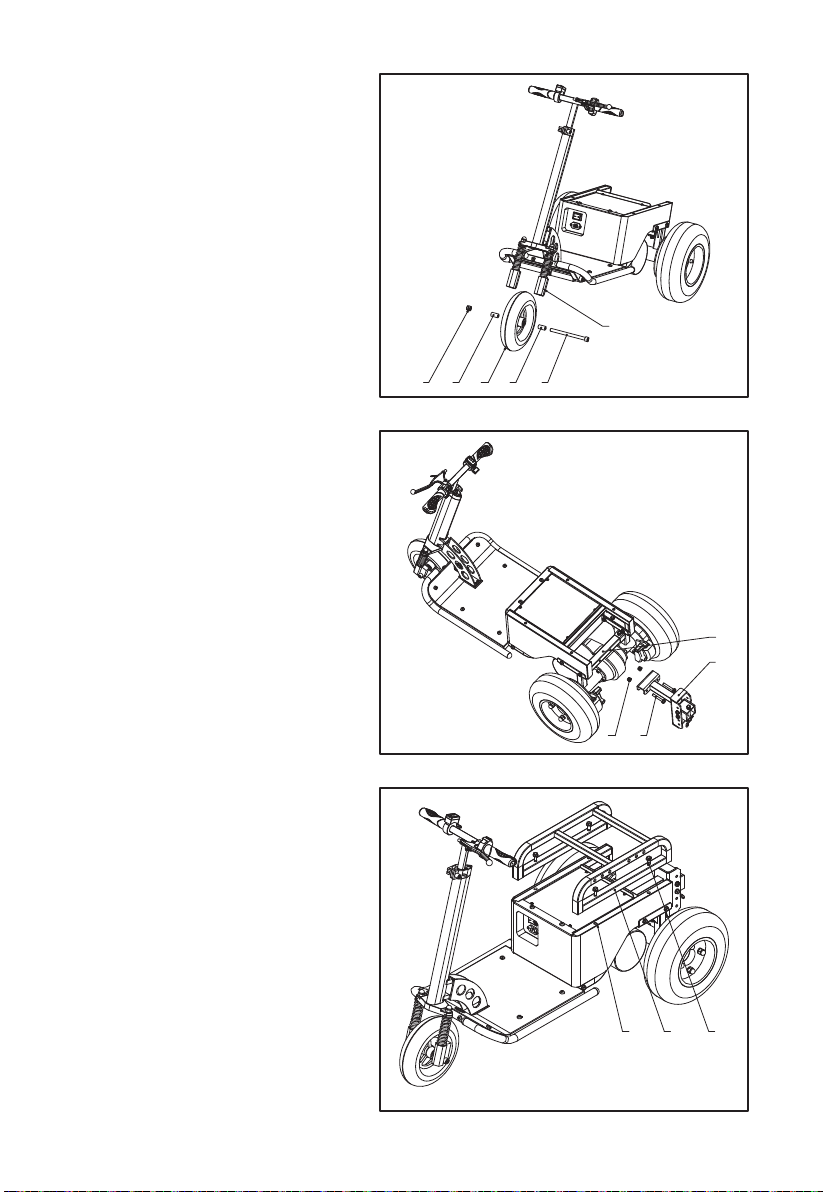

9

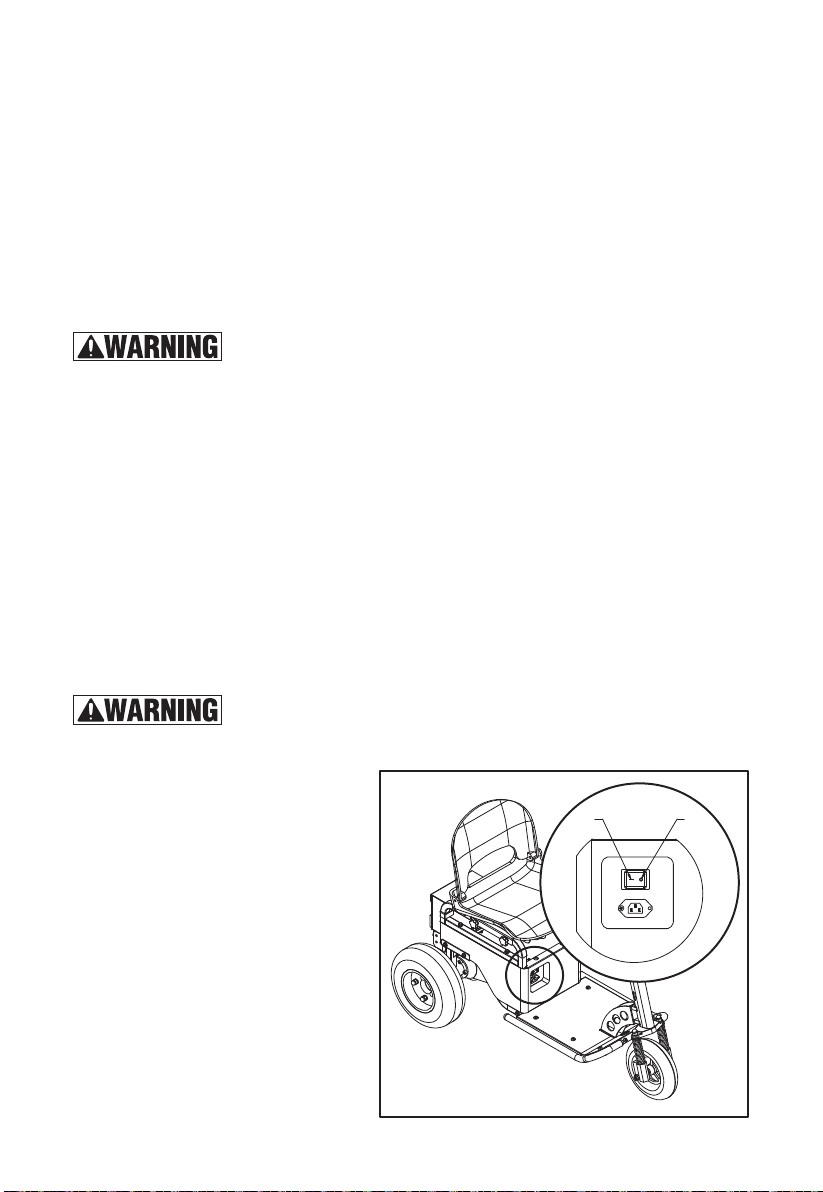

For the power supply of the console, the red knob in left hand

side is the power switch. Push on it, power is On. Push on

again, power is off. (See Fig. 14)

5.4 BATTERY LEVEL INDICATOR (See Fig. 15)

LED on battery also shows battery capacity:

1. One LED: 0~40% battery capacity.

2. Two LED: 40%~70% battery capacity.

3. Three LED: 70%~100% battery capacity.

Soft Riding Condition. When the battery is nearly depleted,

a “soft” riding condition can occur. A “soft” riding condition

means the tugger can move forward at lower speed

compared with fully charged battery. When this happens,

turn the tugger back on and drive the tugger under low

speed until you can recharge the battery.

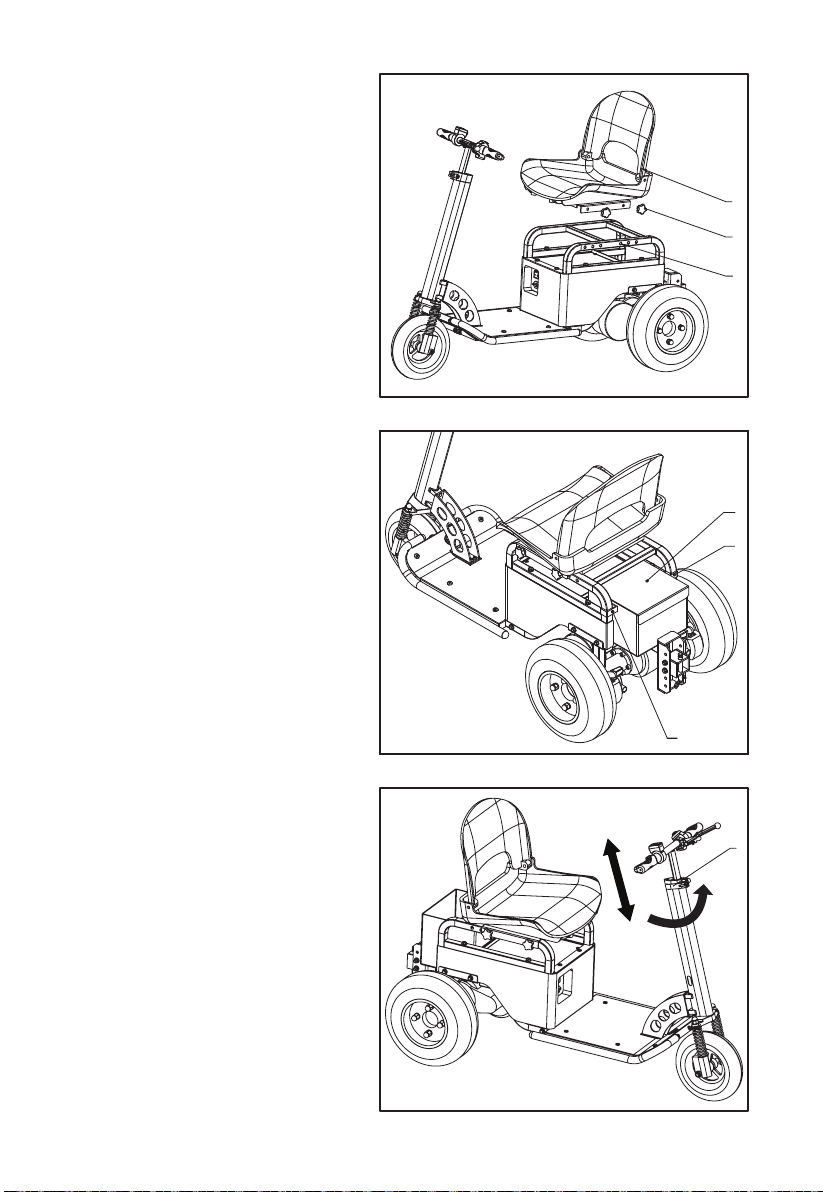

5.5 Forward/Reverse Swtich (See Fig. 16)

Control knob in left hand side. Push upward, tugger driving

direction is forward. Push downward, driving direction is

reverse. It is normal that you engage the tugger after one

second when switch between forward/reverse. This one

second is the protection of electrical system.

Always be alert to the area around your driving path to avoid

hurting people or hitting objects!

Reversing the tugger is allowed only when nothing is being

towed. Do not reverse backwards when towing multiple trailers,

turn forward and make a U-turn!

Always bring the unit to a complete stop before shifting from

forward to reverse or from reverse to forward.

5.6 Accelerator (See Fig. 17)

Use the right thumb to control the accelerator,Slowly push the

accelerator knob to control the driving speed until reach the

desired speed. If the accelerator knob is back to the neutral

position, the controller slows the tugger until it stops.

【WRANING】Never operate at speeds that are not consistent

with operating conditions. Always limit speed to ensure adequate

time for braking in an emergency.

5.7 Turn

It is essential to slow down to a reasonably slow speed before initiating a turn. Use extreme

caution when turning on slanted or uneven surfaces. Occasionally you may find yourself

negotiating a curve or corner too fast and the inner rear wheel starts to lift off the ground. If this

happens, immediately reduce your speed, lessen the steering angle and shift your upper body

toward the wheel that is lifting off the ground.

Always be alert to the area around your driving path to avoid hurting people or hitting objects!

Fig. 14

Fig. 15

Fig. 16

Fig. 17