I

TABLE

0,F

CONTENTS

-

......................................

lntroduct~on page

2

.........................

General information page 2

Location and clearances

..................

page

3

Installation

.....................................

a

3

Framing dimensions

........................

page 3

......................

Appliance dimensions page

5

..................

Outside wall termination page 6

Gas connections

...........................

-...page

8

....................

High elevation derating page

8

....................

Finishing requirements page 10

......................................

Accessories page

11

...........................

Operation and care page 11

Maintenance age 11

Partslcomponents

..........................

page 12

Troubleshooting guide

.....................

page 13

Replacement parts list

.....................

page 14

.......................

Liahtino instructions paqe 16

. .

Warranty.

-I

I

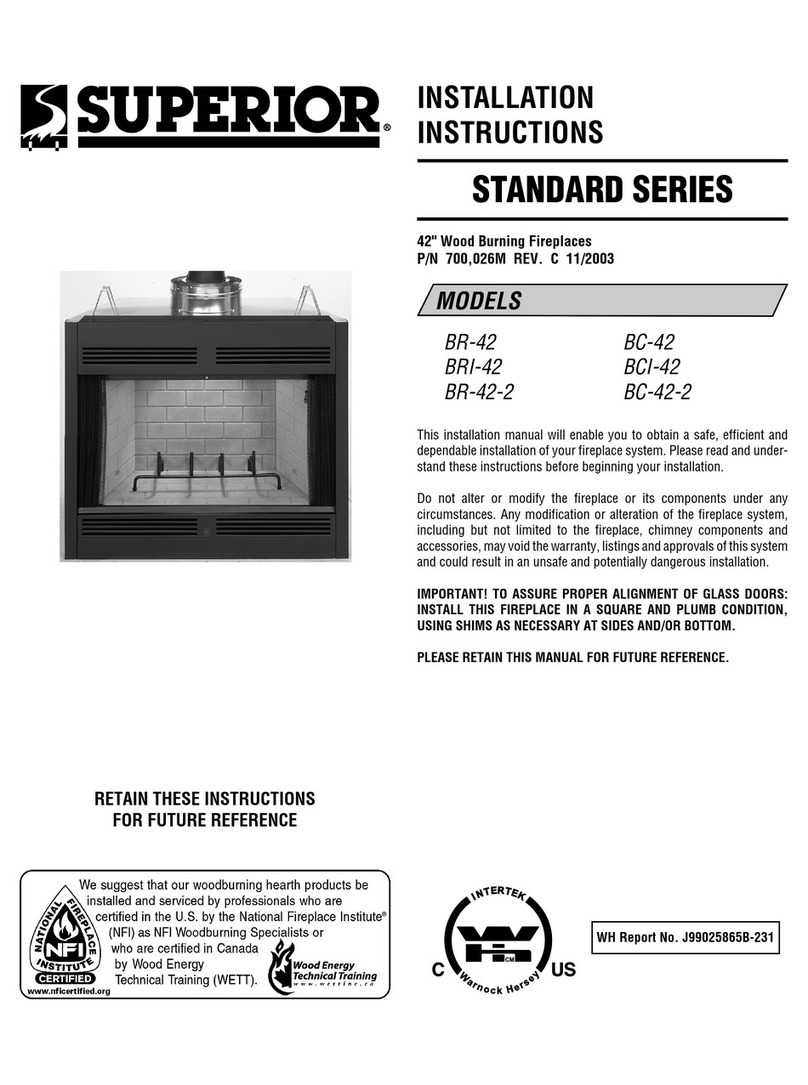

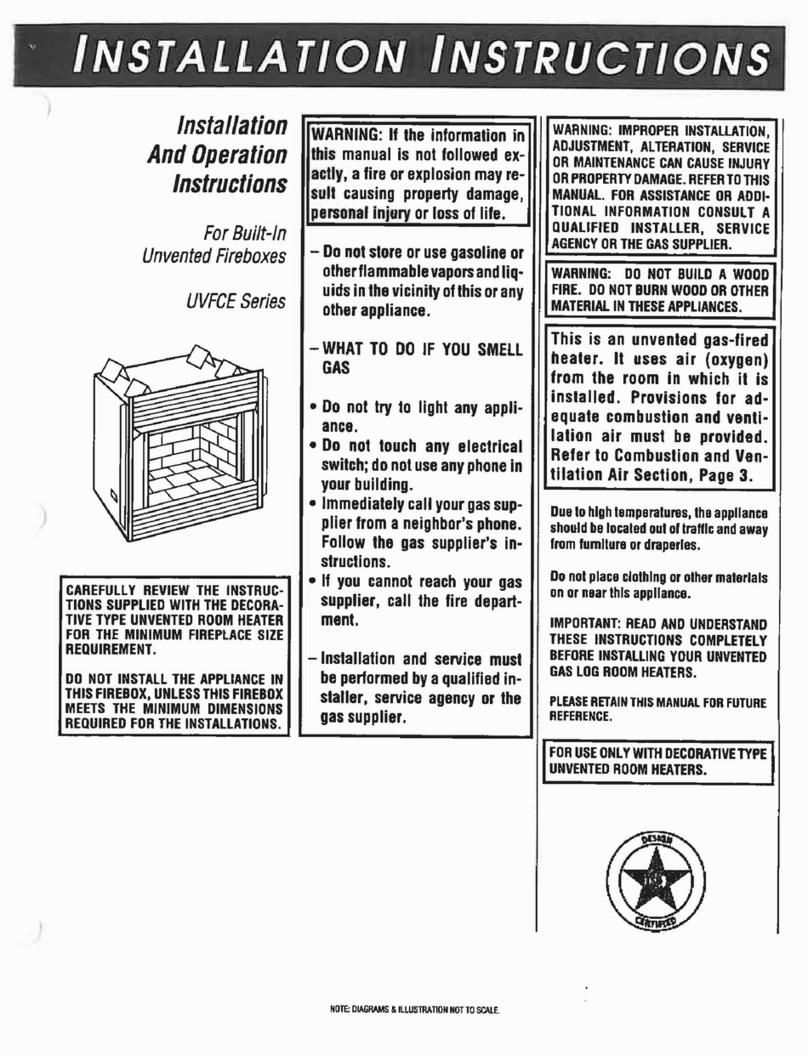

TYPICAL

INSTALLATION

This installation manual will help you obtain a

safe,

efficient,

dependable installationfor your

fireplace and vent system. Please read and

understand these installation instructions be-

fore beginningyour installation.

INTRODUCTION

The DS-36Risasealed combustion, alr circu-

lating, gas appliance for residential applica-

tions. The unit is designed such that combus-

tion air (intake) is taken directly from outside

the structure while combustion gases are dis-

charged to the outside.

The appliance must be installed on an outslde

wall using a DSR-HTK Vent Termination Kit.

Extension pipe andlor 45Vlbow sections ac-

commodate varying wallthickness

and

corner

1

(diagonal) installations.

Operation is achieved through an automatic

pilot valve with a millivolt operated relay and

piezo ignition system. No external electrical

power is required.

This appliance complies with National Safety

Standardsand is tested and listed by Warnock

Hersey International lnc. to ANSI

Z21.50b

-

1990 as a vented decorative gas appliance.

(In

Canada,CAN/CGA-2.22-M89.lR:41-1991

IR 643-1992, and CANICGA-2.17-M91).

2

1

Figure

1

NOTE DiAcRAMs

8

UusrnArIoUsUoT

To

SCALE

Installation mustconformtolocal codes. Inthe

absence of local codes, installation mustcom-

ply with the current National Fuel Gas Code,

3

ANSI 2223.1. 1992. (In Canada, the current

CAN-1 8149 installation code.)

Donotanempttoalterormoditytheconstmc-

tion of the fireplace or its components. Any

modification or aiteration may void the war-

ranty, certification and approvals of this unit.

GENERAL INFORMATION

Note:

Installation

and repair should be

per-

formed

by

a

qualified sennceperson.

The appiianceshould be inspectedannually by

a oualified orofessionai service oerson. More

frequent lnipections and cleanings may

by

required due to excessive lint from carpeting,

bedding material. etc.

It

is imperative that the

control compartment, burners and circulating

air passagewaysoftheappllance bekeptclean.

Provide adequate clearancesaround air open-

ings and adequate accessibility clearance for

service and proper operation. Never obstruct

the front openings of the appliance.

Thlsappliance 1s deslgnedtooperateonnatural

-

or propane gas only The use of other fuels or

comb~nat~onof fuels

will

degrade the perfor-

.

manceof thls system

Input of appliance is 21,000 BTUiHR for both

natural and propane gases.

A 118' NPT plugged tap isprovided on the gas

control valveadjacent to the outletto the main

burner fortest gage connection.

Mtn~muminlet gas pressure is4.5incheswater

column for natural gas and 11 Inches water

column for propane for the purpose of input

adjustment.

Maximuminletgassupplypressureis7.Oinches

water column for natural gas and 13.0 inches

water column for propane.

The appliance must be isolated from the gas

supply plpingsystem (by closing itsindividual

manual shut-off valve) during any pressure

testing of the gas supply piplng system at test

pressures equal to or less than 112 psig (3.5

kPa).

The applianceand its individual shut-off vaive

must be disconnected from the gas supply

piping system during any pressure testing of

that system at test pressures in excess of 112

-'

psig

(3.5

kPa).