Sur-Gard SG System II User manual

Operating Manual

version 2.0

WARNING: This manual contains information on limitations regarding

product use and function and information on the limitations as to

liability of the manufacturer. The entire manual should be carefully read.

Sur-Gard System II

Single Line Network Receiver

GENERAL DESCRIPTION of the EQUIPMENT and CLASSIFICATION.

SYSTEM II - SAFETY INSTRUCTIONS

The SYSTEM II equipment is a CLASS 1, DESK-TOP (MOV-

ABLE) or RACK-MOUNTED (FIXED - STATIONARY),

EQUIPMENT, PLUGGABLE TYPE A using a DETACHABLE

POWER SUPPLY CORD; it is designed to be INSTALLED,

OPERATED and MAINTAINED by SERVICE PERSONS

ONLY. [person having appropriate technical training and experi-

ence necessary to be aware of hazards to which that person may

be exposed in performing a task and of measures to minimize the

risks to that person or other persons]. The equipment SYSTEM II

shall be installed in RESTRICTED ACCESS LOCATIONS

within an environment that provides the Pollution Degree max 2,

and overvoltages category II – non-hazardous locations, indoor

only.

The POWER SUPPLY CORD serves as a means of disconnec-

tion from the MAINS. The OUTLET used to power the equip-

ment shall be installed near the equipment, and shall be easily

accessible. The equipment must be connected to a socket-outlet

with a protective earthing connection!

WHEN RACK-MOUNTED, IT IS THE RESPONSIBILITY OF

THE INSTALLER TO ENSURE THAT THE FINAL ASSEM-

BLY that includes SYSTEM II EQUIPMENT IS COMPLIANT

with the applicable requirements from the point of view of STA-

BILITY; the rack-mounted equipment must be secured to the

building structure before operation; all wiring and installation

shall be in accordance with electrical codes acceptable to the

authorities that have jurisdiction where the equipment is

installed, serviced and operated; not more than 3 (three) system II

units mounted within the same rack shall be powered from the

same branch circuit; use a different branch circuit for any group

larger than 3 (three) units.

Interconnecting cables shall be routed in a manner that prevents:

excessive strain on wire and on terminal connections; loosening

of terminal connections; damage of conductor insulation.

This product uses Lithium Batteries. Improper handling of lith-

ium batteries may result in heat generation, explosion or fire,

which may lead to personal injuries.

CONNECTION TO THE MAINS:

1. Connect first the DETACHABLE POWER SUPPLY CORD to

the IEC 320 connector located on SYSTEM II equipment.

CAUTION: The Ethernet communication lines must be con-

nected first to an Approved (acceptable to the local authorities)

type NID (Network Interface Device) before leaving the prem-

ises (e.g., UL installations, UL60950 Listed NID for ULC Instal-

lations CAN/CSA C22.2 No. 60950-1 Listed NID).

NO REPAIRS IN THE FIELD ARE ALLOWED. THE EQUIP-

MENT SYSTEM II MUST BE RETURNED TO THE MANU-

FACTURER FOR REPAIRS.

FCC Compliance Statement

CAUTION: Changes or modifications not expressly approved by Digital Security Controls

could void your authority to use this equipment.

This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with the instructions,

may cause harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment

off and on, the user is encouraged to try to correct the interference by one or more of the follow-

ing measures:

• Re-orient the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

• Consult the dealer or an experienced radio/television technician for help.

The user may find the following booklet prepared by the FCC useful: “How to Identify and

Resolve Radio/Television Interference Problems”. This booklet is available from the U.S. Gov-

ernment Printing Office, Washington D.C. 20402, Stock # 004-000-00345-4.

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

Table of Contents

Section 1 - Introduction........................................1

1.1 Features .............................................................. 1

1.2 Software Compatibility..................................... 1

1.3 Approvals ........................................................... 1

1.3.1 Industry Approvals ................................................1

1.4 Specifications ..................................................... 3

1.5 Out of Box .......................................................... 3

Section 2 - Installation..........................................4

2.1 Controls and Indicators ..................................... 4

2.2 Set Up and Testing ............................................. 6

Section 3 - Operation/Operating Modes..............7

3.1 Active Mode ....................................................... 7

3.2 Manual Mode ..................................................... 7

3.3 Program Category.............................................. 7

Password ..............................................................7

3.3.2 User Interface .......................................................7

3.3.3 Top Level Menu ....................................................7

3.3.4 System Functions Menu ........................................8

3.3.5 Miscellaneous LED Indicators.................................9

Section 4 - System Options.................................10

4.1 System Option Index ....................................... 10

4.2 System Options ................................................ 11

Option [001]: LAN IP Address ......................................11

Option [002]: LAN Subnet Mask Address .....................10

Option [003]: LAN Gateway.........................................11

Option [004]: Auto Update Time and Date ..................11

Option [005]: Contrast ................................................11

Option [006]: Password ...............................................11

Option [007]: Automation Baud Rate...........................11

Option [008]: Automation Data Bits.............................11

Option [009]: Automation Parity..................................12

Option [00A]: Serial Printer Format ..............................12

Option [00B]: Serial Baud Rate.....................................12

Option [00C]: Serial Data Bits ......................................12

Option [00D]: Serial Printer Parity.................................12

Option [00F]: B32 Headers...........................................12

Option [00F]: B32 Headers...........................................12

Option [012]: Heartbeat Timer.....................................12

Option [013]: Buzzer Tone ...........................................13

Option [014]: Receiver Number ................................... 13

Option [015]: Printer Test ............................................ 13

Option [020]: Mask UPS AC ........................................ 13

Option [021]: Mask UPS BAT.............................................13

Option [024]: Mask SG TCP/IP..................................... 13

Option [025]: Mask SG Serial ...................................... 14

Option [028]: Mask TCP Printer ................................... 14

Option [029]: Mask Parallel Printer .............................. 14

Option [02A]: Mask Serial Printer ................................ 14

Option [02F]: Automation Mode ................................. 14

Option [030]: Printer Mode ......................................... 16

Option [031]: ACK Wait .............................................. 16

Option [032]: Date Format .......................................... 16

Options [037] and [038]: Product ID Keys #1, #2 ......... 16

Option [039]: Mask USB Printer................................... 16

Option [03A]: Programmable I/O ................................. 16

Option [03B]: Last Message On ................................... 16

Option [03C]: LCD Backlight Colour............................ 17

Option [03D]: Key Backlight Colour............................. 17

Option [041]: System Number Length ......................... 17

Option [042]: Busy Out ............................................... 17

Option [043]: System Protocol ID................................. 17

Section 5 - System Options................................ 10

5.1 IP Option Index ................................................ 19

5.2 IP Options ......................................................... 19

Option [110]: Line Card Number - Table 1 ................... 20

Option [113]: Transmitter Failure Debounce Time ........ 20

Option [115]: Transmitter Restoral Debounce Time...... 20

Option [119]: Mask Transmitter Restoral...................... 20

Option [11A]: Mask Transmitter Failure........................ 20

Option [11B]: Mask Transmitter Swap.......................... 20

Option [11C]: Mask Transmitter Unencrypted.............. 20

Option [11D]: Mask Invalid Report ....................................20

Option [11E]: Mask Unknown Account ....................... 20

Option [11F]: Mask Supervised Acc Exceeded .............. 21

Option [120]: Mask Transmitter Deleted ...................... 21

Option [13A]: Account Port......................................... 21

Option [140]: Account Password ................................. 21

Option [144]: DNIS Replacement of RRLLL ................... 21

Option [146]: Account Digit Strip ................................ 21

Option [147]: SIM ID Output .............................................22

Appendix A - Events and Messages ........................... 23

Appendix B - Ports ....................................................... 25

WARNING Please Read Carefully

Note to Installers

This warning contains vital information. As the only individual in contact with system users, it is

your responsibility to bring each item in this warning to the attention of the users of this system.

System Failures

This system has been carefully designed to be as effective as possible. There are circumstances, how-

ever, involving fire, burglary, or other types of emergencies where it may not provide protection. Any

alarm system of any type may be compromised deliberately or may fail to operate as expected for a

variety of reasons. Some but not all of these reasons may be:

-Inadequate Installation

A security system must be installed properly in order to provide adequate protection. Every installa-

tion should be evaluated by a security professional to ensure that all access points and areas are cov-

ered. Locks and latches on windows and doors must be secure and operate as intended. Windows,

doors, walls, ceilings and other building materials must be of sufficient strength and construction to

provide the level of protection expected. A reevaluation must be done during and after any construc-

tion activity. An evaluation by the fire and/or police department is highly recommended if this ser-

vice is available.

- Criminal Knowledge

This system contains security features which were known to be effective at the time of manufacture.

It is possible for persons with criminal intent to develop techniques which reduce the effectiveness of

these features. It is important that a security system be reviewed periodically to ensure that its fea-

tures remain effective and that it be updated or replaced if it is found that it does not provide the pro-

tection expected.

- Access by Intruders

Intruders may enter through an unprotected access point, circumvent a sensing device, evade detec-

tion by moving through an area of insufficient coverage, disconnect a warning device, or interfere

with or prevent the proper operation of the system.

- Power Failure

Control units, intrusion detectors, smoke detectors and many other security devices require an ade-

quate power supply for proper operation. If a device operates from batteries, it is possible for the bat-

teries to fail. Even if the batteries have not failed, they must be charged, in good condition and

installed correctly. If a device operates only by AC power, any interruption, however brief, will ren-

der that device inoperative while it does not have power. Power interruptions of any length are often

accompanied by voltage fluctuations which may damage electronic equipment such as a security sys-

tem. After a power interruption has occurred, immediately conduct a complete system test to ensure

that the system operates as intended.

- Failure of Replaceable Batteries

This system’s wireless transmitters have been designed to provide several years of battery life under

normal conditions. The expected battery life is a function of the device environment, usage and type.

Ambient conditions such as high humidity, high or low temperatures, or large temperature fluctua-

tions may reduce the expected battery life. While each transmitting device has a low battery monitor

which identifies when the batteries need to be replaced, this monitor may fail to operate as expected.

Regular testing and maintenance will keep the system in good operating condition.

- Compromise of Radio Frequency (Wireless) Devices

Signals may not reach the receiver under all circumstances which could include metal objects placed

on or near the radio path or deliberate jamming or other inadvertent radio signal interference.

- System Users

A user may not be able to operate a panic or emergency switch possibly due to permanent or tempo-

rary physical disability, inability to reach the device in time, or unfamiliarity with the correct opera-

tion. It is important that all system users be trained in the correct operation of the alarm system and

that they know how to respond when the system indicates an alarm.

- Smoke Detectors

Smoke detectors that are a part of this system may not properly alert occupants of a fire for a number

of reasons, some of which follow. The smoke detectors may have been improperly installed or posi-

tioned. Smoke may not be able to reach the smoke detectors, such as when the fire is in a chimney,

walls or roofs, or on the other side of closed doors. Smoke detectors may not detect smoke from fires

on another level of the residence or building.

Every fire is different in the amount of smoke produced and the rate of burning. Smoke detectors can-

not sense all types of fires equally well. Smoke detectors may not provide timely warning of fires

caused by carelessness or safety hazards such as smoking in bed, violent explosions, escaping gas,

improper storage of flammable materials, overloaded electrical circuits, children playing with

matches or arson.

Even if the smoke detector operates as intended, there may be circumstances when there is insuffi-

cient warning to allow all occupants to escape in time to avoid injury or death.

- Motion Detectors

Motion detectors can only detect motion within the designated areas as shown in their respective

installation instructions. They cannot discriminate between intruders and intended occupants. Motion

detectors do not provide volumetric area protection. They have multiple beams of detection and

motion can only be detected in unobstructed areas covered by these beams. They cannot detect

motion which occurs behind walls, ceilings, floor, closed doors, glass partitions, glass doors or win-

dows. Any type of tampering whether intentional or unintentional such as masking, painting, or

spraying of any material on the lenses, mirrors, windows or any other part of the detection system

will impair its proper operation.

Passive infrared motion detectors operate by sensing changes in temperature. However their effec-

tiveness can be reduced when the ambient temperature rises near or above body temperature or if

there are intentional or unintentional sources of heat in or near the detection area. Some of these heat

sources could be heaters, radiators, stoves, barbeques, fireplaces, sunlight, steam vents, lighting and

so on.

- Warning Devices

Warning devices such as sirens, bells, horns, or strobes may not warn people or waken someone

sleeping if there is an intervening wall or door. If warning devices are located on a different level of

the residence or premise, then it is less likely that the occupants will be alerted or awakened. Audible

warning devices may be interfered with by other noise sources such as stereos, radios, televisions, air

conditioners or other appliances, or passing traffic. Audible warning devices, however loud, may not

be heard by a hearing-impaired person.

- Telephone Lines

If telephone lines are used to transmit alarms, they may be out of service or busy for certain periods

of time. Also an intruder may cut the telephone line or defeat its operation by more sophisticated

means which may be difficult to detect.

- Insufficient Time

There may be circumstances when the system will operate as intended, yet the occupants will not be

protected from the emergency due to their inability to respond to the warnings in a timely manner. If

the system is monitored, the response may not occur in time to protect the occupants or their belong-

ings.

- Component Failure

Although every effort has been made to make this system as reliable as possible, the system may fail

to function as intended due to the failure of a component.

- Inadequate Testing

Most problems that would prevent an alarm system from operating as intended can be found by regu-

lar testing and maintenance. The complete system should be tested weekly and immediately after a

break-in, an attempted break-in, a fire, a storm, an earthquake, an accident, or any kind of construc-

tion activity inside or outside the premises. The testing should include all sensing devices, keypads,

consoles, alarm indicating devices and any other operational devices that are part of the system.

- Security and Insurance

Regardless of its capabilities, an alarm system is not a substitute for property or life insurance. An

alarm system also is not a substitute for property owners, renters, or other occupants to act prudently

to prevent or minimize the harmful effects of an emergency situation.

Limited Warranty

Digital Security Controls warrants the original purchaser that for a period of twelve months from the

date of purchase, the product shall be free of defects in materials and workmanship under normal

use. During the warranty period, Digital Security Controls shall, at its option, repair or replace any

defective product upon return of the product to its factory, at no charge for labour and materials. Any

replacement and/or repaired parts are warranted for the remainder of the original warranty or ninety

(90) days, whichever is longer. The original purchaser must promptly notify Digital Security Con-

trols in writing that there is defect in material or workmanship, such written notice to be received in

all events prior to expiration of the warranty period. There is absolutely no warranty on software

and all software products are sold as a user license under the terms of the software license

agreement included with the product. The Customer assumes all responsibility for the proper

selection, installation, operation and maintenance of any products purchased from DSC. Cus-

tom products are only warranted to the extent that they do not function upon delivery. In such

cases, DSC can replace or credit at its option.

International Warranty

The warranty for international customers is the same as for any customer within Canada and the

United States, with the exception that Digital Security Controls shall not be responsible for any cus-

toms fees, taxes, or VAT that may be due.

Warranty Procedure

To obtain service under this warranty, please return the item(s) in question to the point of purchase.

All authorized distributors and dealers have a warranty program. Anyone returning goods to Digital

Security Controls must first obtain an authorization number. Digital Security Controls will not accept

any shipment whatsoever for which prior authorization has not been obtained.

Conditions to Void Warranty

This warranty applies only to defects in parts and workmanship relating to normal use. It does not

cover:

• damage incurred in shipping or handling;

• damage caused by disaster such as fire, flood, wind, earthquake or lightning;

• damage due to causes beyond the control of Digital Security Controls such as excessive voltage,

mechanical shock or water damage;

• damage caused by unauthorized attachment, alterations, modifications or foreign objects;

• damage caused by peripherals (unless such peripherals were supplied by Digital Security Con-

trols);

• defects caused by failure to provide a suitable installation environment for the products;

• damage caused by use of the products for purposes other than those for which it was designed;

• damage from improper maintenance;

• damage arising out of any other abuse, mishandling or improper application of the products.

Items Not Covered by Warranty

In addition to the items which void the Warranty, the following items shall not be covered by War-

ranty: (i) freight cost to the repair centre; (ii) products which are not identified with DSC's product

label and lot number or serial number; (iii) products disassembled or repaired in such a manner as to

adversely affect performance or prevent adequate inspection or testing to verify any warranty claim.

Access cards or tags returned for replacement under warranty will be credited or replaced at DSC's

option. Products not covered by this warranty, or otherwise out of warranty due to age, misuse, or

damage shall be evaluated, and a repair estimate shall be provided. No repair work will be performed

until a valid purchase order is received from the Customer and a Return Merchandise Authorisation

number (RMA) is issued by DSC's Customer Service.

Digital Security Controls’s liability for failure to repair the product under this warranty after a rea-

sonable number of attempts will be limited to a replacement of the product, as the exclusive remedy

for breach of warranty. Under no circumstances shall Digital Security Controls be liable for any spe-

cial, incidental, or consequential damages based upon breach of warranty, breach of contract, negli-

gence, strict liability, or any other legal theory. Such damages include, but are not limited to, loss of

profits, loss of the product or any associated equipment, cost of capital, cost of substitute or replace-

ment equipment, facilities or services, down time, purchaser’s time, the claims of third parties,

including customers, and injury to property. The laws of some jurisdictions limit or do not allow

the disclaimer of consequential damages. If the laws of such a jurisdiction apply to any claim

by or against DSC, the limitations and disclaimers contained here shall be to the greatest

extent permitted by law. Some states do not allow the exclusion or limitation of incidental or

consequential damages, so that the above may not apply to you.

Disclaimer of Warranties

This warranty contains the entire warranty and shall be in lieu of any and all other warranties,

whether expressed or implied (including all implied warranties of merchantability or fitness for a

particular purpose) And of all other obligations or liabilities on the part of Digital Security Con-

trols Digital Security Controls neither assumes responsibility for, nor authorizes any other person

purporting to act on its behalf to modify or to change this warranty, nor to assume for it any other

warranty or liability concerning this product.

This disclaimer of warranties and limited warranty are governed by the laws of the province of

Ontario, Canada.

WARNING: Digital Security Controls recommends that the entire system be completely tested

on a regular basis. However, despite frequent testing, and due to, but not limited to, criminal

tampering or electrical disruption, it is possible for this product to fail to perform as expected.

Installer’s Lockout

Any products returned to DSC which have the Installer’s Lockout option enabled and exhibit no

other problems will be subject to a service charge.

Out of Warranty Repairs

Digital Security Controls will at its option repair or replace out-of-warranty products which are

returned to its factory according to the following conditions. Anyone returning goods to Digital

Security Controls must first obtain an authorization number. Digital Security Controls will not accept

any shipment whatsoever for which prior authorization has not been obtained.

Products which Digital Security Controls determines to be repairable will be repaired and returned.

A set fee which Digital Security Controls has predetermined and which may be revised from time to

time, will be charged for each unit repaired.

Products which Digital Security Controls determines not to be repairable will be replaced by the

nearest equivalent product available at that time. The current market price of the replacement product

will be charged for each replacement unit.

1

Section 1 - Introduction

1.1 Features

The SG-System II is a single line network receiver intended for remote monitoring of commercial fire and burglary systems. The system can be

configured for “desktop stand-alone” operation (vertical stacking of up to 4 systems) or rack mounting. The SG-System II can monitor up to

1536 accounts including 512 supervised accounts. An additional 1536 IP accounts may be purchased separately with the use of a License key.

NOTE: System must be rack mounted for UL and ULC Listed Installations.

The SG-System II real time clock and calendar stamps all received alarm data which is then transmitted to a central station computer via TCP/IP,

serial port; transmitted directly to a printer using the parallel printer port, serial printer port, USB port to Systems Console Software, TCP port

using Systems Console Software, and viewed on the LCD of the front panel. System configuration can be programmed using a PC with SG-Sys-

tems Console Software via TCP or USB connections or locally using the scroll buttons and LCD.

The SG-System II receives alarm information from panels over a LAN/WAN or internet network.

SG-System II features include the following:

• Provides higher line security than conventional dial up panels with the polling feature.

• Provides fast transmission since dialing or handshaking is not required.

• The control panel is the originator of the signals and as such will be the one requesting the ACK from the central station.

• Network trouble detection is displayed on LCD/Printer and automation software.

• Disconnect trouble detection.

• Static IP for programming of the network protocols.

• Data network polling environment for replacement of an existing DVACS network.

• SIA event descriptors are used to transmit information to the central station from the control panel through the PC-Link connection.

• 4 and 10 digit Contact ID.

• A security function communicates to the central station when a module is removed and replaced.

• USB 1.1 connection for Console

• Two IP account tables. The second table adds another 1536 accounts of which 512 can be supervised.

NOTE: For UL/ULC Listed applications maximum 512 supervised accounts can be used.

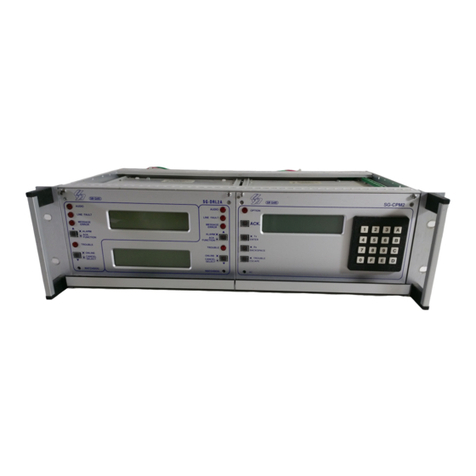

Figure 1: SG-System II Receiver

1.2 Software Compatibility

The following examples of Central Station automation software are compatible with the SG-System II interface.

Refer to the DSC website “http://www.dsc.com/index.php?n=MonitoringStations” for a comprehensive list of compatible Automation Software

Manunufacturers:

• MAS • MicroKey • GENESYS

• IBS • SIMS II • Bold

• DICE • ABM • S.I.S.

NOTE: Automation connections are considered supplementary per UL864 listing. Compatibility with the central sta-

tion automation software is intended to be handled under a separate UL1981 software and/or site certification

evaluation.

NOTE: Software version 2.0 of SG-system II must be used with the SG-Systems Console software version 1.1

1.3 Approvals

1.3.1 Industry Approvals

The System II meets the requirements of the following standards:

• UL 1610 Central Station Burglar Alarm Units

• UL 864 Standard for Control Units and Accessories for Fire Alarm Systems

• CAN/ULC-S304-06 Signal Receiving Centre and Premises Burglar Alarm Control Units

• CAN/ULC-S559-04 Equipment for Fire Signal Receiving Centres and Systems

• EN60950-1:2001 Standard for Information Technology Equipment.

• AS/NZS 60950:2000 Information Technology Equipment - Safety

• CISPR22 Information Technology Equipment - Radio Disturbance Characteristics - Limits and Methods of Measurements

• EN50130-4 Immunity requirements for components of fire, intruder and social alarm systems.

2

This equipment shall be installed in accordance with the requirements of NFPA72, NFPA70, and the authority having jurisdiction.

The Equipment is ULC listed for active communication channel security level A4 when used in conjunction with compatible communicators, ULC

listed for the same level of line security (DSC Models T-Link TL250, T-Link TL300, TL265GS, GS2065, TL260GS, GS2060).

Compatible Communicators:

• MAS • MicroKey • GENESYS

• TL150 • TL250 * • BFSM-100M

• TL300 * • GS3055 * • GS3060 *

• TL26X * • GS206X * • KNet

* ULC Listed

For ULC Installations the equipment shall be installed in accordance with the requirements of ULC-S561 and ULC-S301 Standards and the author-

ity having jurisdiction.

UL864 Programming Requirements

Parallel Printers:

For UL and ULC Listed applications the following UL Listed printers can be used with the SG-System II:

• Seiko DPU-414

Serial Printers:

For UL and ULC Listed applications the following UL Listed printer can be used with the SG-System II:

• Seiko DPU-414

NOTE: Do NOT use printer cables that have only 1 common ground wire.

Table 6: Table 1: UL864 Programming Requirements

Option number and name Page Permitted in

UL 864? (Y/N)

Possible

settings

Settings

permitted (UL 864)

Option [013]: Buzzer Tone..............................................13 N Default, Buzzer Off, 1490

Hz, 1990 Hz, 2103 Hz,

2650 Hz, 3149 Hz, 3965

Hz, 4270 Hz, 4530 Hz

ON

Option [020]: Mask UPS AC ...........................................13 N ON/OFF OFF

Option [021]: Mask UPS BAT ..........................................13 N ON/OFF OFF

Option [024]: Mask SG TCP/IP ........................................13 N ON/OFF OFF

Option [025]: Mask SG Serial..........................................14 N ON/OFF OFF

Option [028]: Mask TCP Printer......................................14 N ON/OFF OFF

Option [029]: Mask Parallel Printer .................................14 N ON/OFF OFF

Option [02A]: Mask Serial Printer....................................14 N ON/OFF OFF

Option [039]: Mask USB Printer......................................16 N ON/OFF OFF

Option [042]: Busy Out...................................................17 N ON/OFF OFF

Option [113]: Transmitter Failure Debounce Time ..........20 N 001E-FFFF (30-65535 sec) 05A (90 sec)

Option [115]: Transmitter Restoral Debounce Time........20 N 001E-FFFF (30-65535 sec) 3C (60 sec)

Option [119]: Mask Transmitter Restoral.........................20 N ON/OFF OFF

Option [11A]: Mask Transmitter Failure ..........................20 N ON/OFF OFF

Option [11B]: Mask Transmitter Swap ............................20 N ON/OFF OFF

Option [11C]: Mask Transmitter Unencrypted ................20 N ON/OFF OFF

Option [11D]: Mask Invalid Report..................................20 N ON/OFF OFF

Option [11E]: Mask Unknown Account..........................20 N ON/OFF OFF

Option [11F]: Mask Supervised Acc Exceeded ................21 N ON/OFF OFF

3

1.4 Specifications

Electrical

• Input Voltage ................................................................................................................................................100-240VAC, 50-60Hz.

• Input Current ...................................................................................................................................................................0.7A (Max)

• Backup Power Supply...............................................................................................................................External UPS (not supplied)

Environmental

• Temperature........................................................................................................................................................32 - 122°F (0-50°C)

• Humidity ................................................................................................................................................... 93%RH, Non Condensing

Dimensions

• Width ........................................................................................................................................................................ 12in. (305mm)

• Length .................................................................................................................................................................. 12.25in. (311mm)

• Height....................................................................................................................................................................... 1.75in. (45mm)

• Weight................................................................................................................................................................... 7.92lbs (3.58 Kg)

Ethernet Interfaces

• Automation Port .......................................................................................................................................................................1025

• Printer Port................................................................................................................................................................................1027

• Command Port (Console Interface)............................................................................................................................................1024

• Audit Port .................................................................................................................................................................................1030

• TFTP Port.......................................................................................................................................................................................69

• Account Port (Default)...............................................................................................................................................................3064

Accounts

• Number of Accounts ............................................................................................................................ 1536 per account table Max.

• Number of Supervised Accounts............................................................................................................. 512 per account table Max.

NOTE: Second account table may be added with the purchase of software license.

1.5 Out of Box

Verify that you have received the following:

SG-System II

SG-System II Receiver............................................................................................................................................................ Qty 1

SG-Systems Console ............................................................................................................................................................. Qty 1

SG-System II Quick Install Guide............................................................................................................................................ Qty 1

Rubber Feet.......................................................................................................................................................................... Qty 4

screw in adjustable feet ......................................................................................................................................................... Qty 2

SG-System II Rack Mount Kit (Optional)

Brackets................................................................................................................................................................................ Qty 2

Rails (Mounting) ................................................................................................................................................................... Qty 4

Screws.................................................................................................................................................................................. Qty 8

Quick Install Sheet ................................................................................................................................................................ Qty 1

Additional Equipment Required (Not Supplied)

IEC Power Line Cord ............................................................................................................................................................. Qty 1

CAT-5 Ethernet Cable for WAN Interface Support ................................................................................................................. Qty 1

CAT-5 Ethernet Cable for LAN Interface Port or USB cable for Console Communication ........................................................ Qty 1

DB9 terminated RS232 Serial Cable ...................................................................................................................................... Qty 1

DB25 terminated Parallel printer Cable ................................................................................................................................. Qty 1

4

Section 2 - Installation

2.1 Controls and Indicators

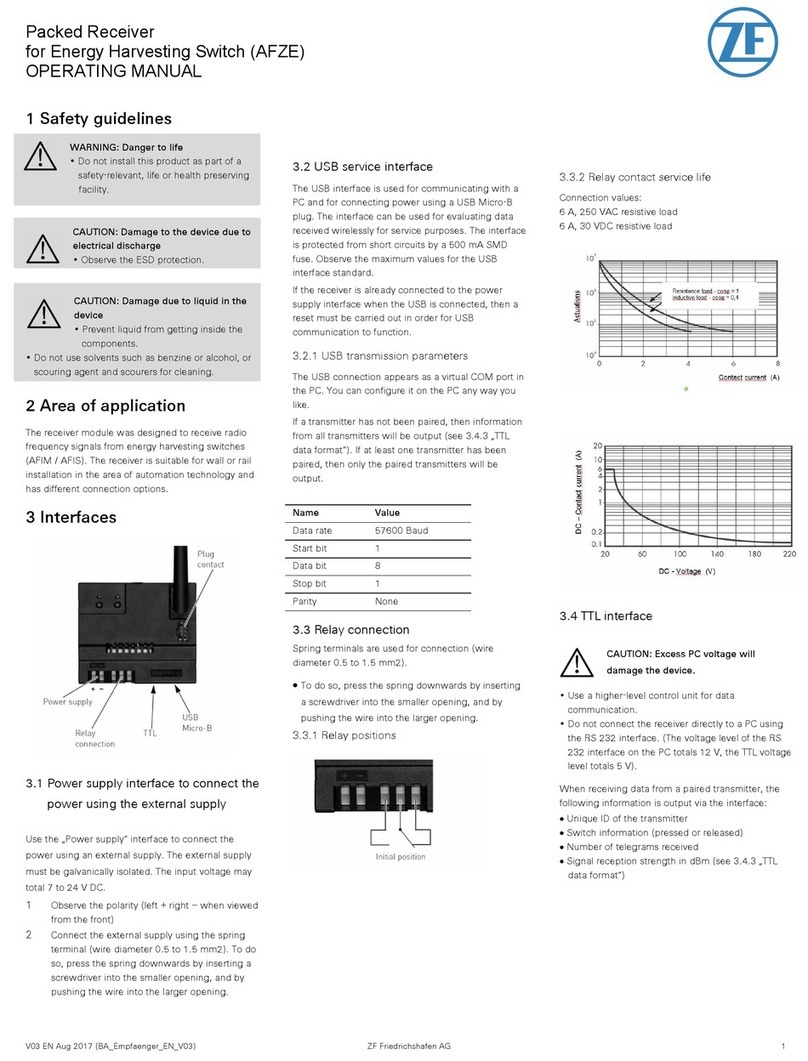

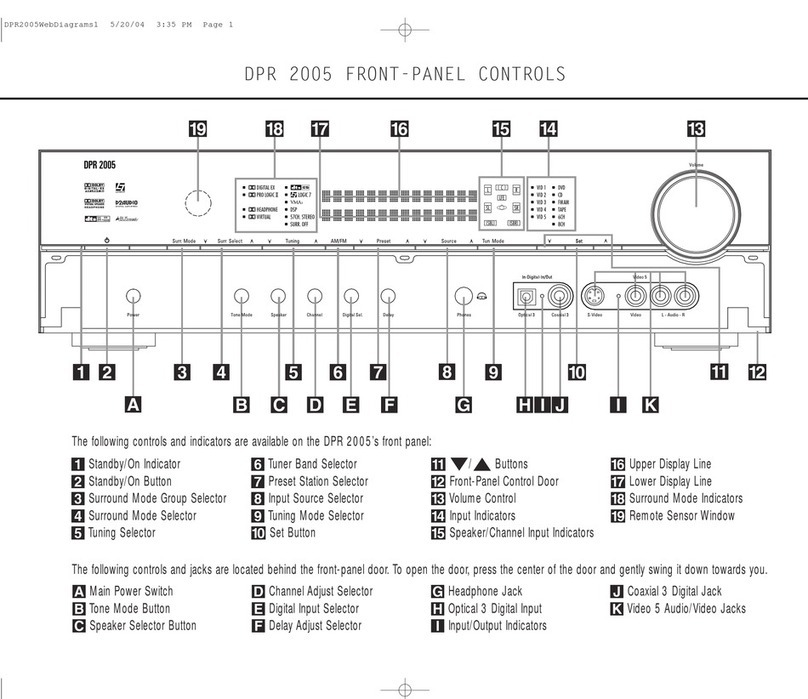

Figure 2: Controls and Indicators

Table 7: SG-System II Front and Rear Panel Descriptions

Item No. Indicator/ Control/ Connector State/Pin Description

1NETWORK Green LED ON

OFF

Network Absent

Network Present

Follows the network interface that receives T-Link signals.

2TROUBLE Orange LED ON

OFF

Indicates any System Trouble not related to network or alarm (Note that the

LCD backlight will override the programmed colour and change to Yellow).

No System Trouble

3STATUS Yellow LED FLASHING

OFF

Two flashes to indicate system busy out has occurred - caused by one of the

following conditions.

· On power up, the SG-System II clock is not set

· SG-System II firmware update (downloading)

· Either the printer or the computer buffer was full

· Checksum failed for any one of the flash ROM files

· Channel buffer corruption

· System In manual mode and option 042 is set to 4.

Normal Operation

4WATCHDOG Blue LED FLASHING

STEADY

Normal Operation (Software watchdog toggles every 200msec).

SG-System II Line Card Fault

5LCD Display 40x2 character LCD display.

Top line displays current Operating Mode.

Bottom line displays Trouble or received messages in Manual mode.

Alarm: If an alarm is present while the system is in Manual mode, the LCD

backlight will change to Red - overriding the programmed colour - and the

ACK button will flash. In addition, a buzzer will sound with each flash of the

ACK button.

Alarms received but not yet displayed are identified by a solid arrow symbol on

the far right edge of the LCD.

6DOWN Interface Button Scrolls down through menu options

SG-System II

5

1234

13 14 15 16

10 12

11

17 18

8

7

69

5

For ULC Installations, the equipment shall be rack mounted and energized by a permanently wired supply in accordance with C22.1, Canadian

Electrical Code, Part 1, Safety Standard for Electrical Installations, section 32.

NOTE: The LED indicators and the LCD can be tested for integrity by accessing the following in the main program-

mingmenu: item 3 - System Functions > item 5 - Visual Indicators Test.

7ACK Interface Button/LED FLASHING

OFF

Indicates unit is in Manual Mode and waiting for acknowledgement.

There are no alarm events requiring acknowledgement.

The ACK button is used to acknowledge an alarm event in Manual Mode. It

cannot acknowledge all alarms with one press, but must be pressed for each

individual alarm. The ACK button also acts as ENTER in Programming Mode.

8UP Interface Button Scrolls up through menu options

9ENTER Interface Button Selects a menu option

10 AUTOMATION Port (COM1) DB9 Sends automation messages to central station computer (e.g., Heartbeat if no

activity)

NOTE: Maximum Cable length is 1.8m (6ft). Longer cables may

impair performance. Use at own risk.

11 PARALLEL PRINTER Port DB25 (Female) Sends events to local printer (DB25 Female)

NOTE: Maximum Cable length is 1.8m (6ft). Longer cables may

impair performance. Use at own risk.

12 SERIAL PRINTER Port (COM2) DB9 RS232 Serial Printer Port. Sends events to local printer.

NOTE: Maximum Cable length is 1.8m (6ft). Longer cables may

impair performance. Use at own risk.

13 USB Port USB Type B USB Type B

NOTE: Maximum Cable length is 1.8m (6ft). Longer cables may

impair performance. Use at own risk.

14 WAN Interface Port CAT-5 Alarm port when system configured in dual NIC mode; Ethernet Cable (1.8m/

6ft)

NOTE: Longer cables may impair performance. Use at own risk

15 LAN Interface Port CAT-5 This interface is used for Console, Automation and Local (same subnet) T-Link

connections. Connects to LAN via CAT5 Ehernet Cable (1.8m/6ft)

NOTE: Longer cables may impair performance. Use at own risk.

16 DEBUG RJ-45 RJ-45 NOTE: Maximum Cable length is 1.8m (6ft). Longer cables may

impair performance. Use at own risk.

17 I/O Port ( Use AWG 18-22 wire) 1

2

3

4

5

6

7

8

9

10

11

12

13

Input

COM

Input

Input

COM

Input

Ouput

COM

Output

Output

COM

Output

Earth

UPS AC Failure (toggles from ground to open on failure)

Common (ground)

UPS DC Failure (toggles from ground to open on failure)

Remote ACK button - identical functionality to ACK button on LCD

Common (ground)

Future Use

Output 1 Follow Buzzer; Toggle to ground following the Buzzer

~ COMMON (ground)

Output 2 Toggle to ground following the CPM trouble LE

Output 3 Future Use

~ COMMON (ground)

Output 4 Future Use

~ EARTH GROUND

NOTE: Maximum Cable length is 1.8m (6ft). Longer cables may

impair performance. Use at own risk.

18 Mains Supply Connector 120/240VAC /0.7A/ 50-60Hz

Connection to Interruptible Power Supply (UPS recommended) with minimum

24 Hr standby capability required.

Refer to Section 2.2. Setup & Testing

Table 7: SG-System II Front and Rear Panel Descriptions

Item No. Indicator/ Control/ Connector State/Pin Description

6

2.2 Set Up and Testing

DSC recommends testing the receiver before actual installation. Becoming familiar with the connections and setup of the unit on the workbench

will make final installation simpler.

The following items are required:

• IEC Power Supply cord

• CAT5 Ethernet Cable

• One or more T-Link modules

• Hub/router or network connection

NOTE: When a Hub or Router/Gateway is used with the SG-System II, 24 Hr Standby Power is required for these

devices (i.e., UL Listed UPS, Battery Backup, or engine driven generator).

1. Unpack the SG-System II components.

NOTE: Carefully unpack the receiver and inspect for shipping damage. If there is any apparent damage, notify the

carrier immediately.

2. Install the rack-mount brackets or the rubber feet in the indents as required.

3. Connect a CAT5 Cable (not supplied) .

4. Connect the main power using a standard computer IEC cable (not supplied).

Figure 3: Wiring Diagram

5. The LCD will power up and display internal troubles (printer, computer).

NOTE: Internal diagnostics may require more than one minute during the power up sequence.

6. Send a signal from a control panel to the receiver. The signal will be displayed on the LCD. Press the ACK button to silence the buzzer and

clear the signal from the LCD.

WARNING:

To reduce the risk of electrical shock, the

SG-System II is equipped with a grounding type

power supply IEC receptacle.

Connect SG-System II using an appropriate IEC

cable to a grounded receptacle.

Connect SG-System II to UPS dry contact connec-

tions only.

Do NOT connect to a receptacle contrrolled by a

switch.

NOTES:

For UL Installations

Mains Supply: 120VAC/60Hz

UPS Output Rating: 120VAC/60Hz, 2.5A. Use UL

listed UPS (uninterrupted power supply) for protec-

tive-signalling systems and listed burglar alarm

power supply as applicable.

For CE Installations

Mains Supply: 240VAC/50Hz

UPS Output Rating (non UL): 240VAC 50Hz

NOTES:

Install External Devices connected to item (10)-(17) in the same room as the

SG-System II.

Maintain 1/4” (6.5mm) separation between power limited and non-power limited

circuits. Use power limited, supervised circuits only/

I/O Terminal is Open collector 20mA switched to ground. Wire with 18-22 AWG.

Common

AC Out

AC In

UPS

UPS Low Bat (normally closed)

UPS AC Trouble (normally closed

To SG-System II I/O

From AC Mains

I/O Open Collector, 20 mA (Max)

Use 18-22 AWG (0.5 - 1.0mm) wiring

To SG-System II

IEC grounded receptacle

Pin 1

Pin 2

Pin 3

7

Section 3 - Operation/Operating Modes

There are two main categories of operating modes, Native and Program Modes.

3.1 Active Mode

Active Mode is the normal operating mode. The SG-System II is in Active mode when any of the Automation Ports are present and respond-

ing to signals.

3.2 Manual Mode

This mode normally occurs when automation is lost or has been programmed out (all automation ports disabled). Changing from Active

mode to Manual mode is automatic.

In manual mode, the SG-System II can receive signals (unless the buffer is full) and attempts to output the first signal in the buffer if there are

any and if the automation is programmed on some ports. The unit displays the message on the LCD screen, activates the buzzer and the

acknowledge LED. To stop the buzzer and the acknowledge LED, the ACK button must be pressed and released for every signal not

acknowledged in the buffer. The messages are only the printer message. For messages greater than 40 characters, the first 40 characters are

displayed. Press the ENTER button to toggle between the rest of the message. The alarm printer and automation buffers reside in the

SG-System II.

3.3 Program Category

The Program category is accessed in order to program the SG-System II or to view its condition. Sixteen users in total can have access to the unit.

User ‘0’ is the Administrator, and has full permissions with regard to using and configuring the unit. All other users - ‘1~F’ - may view system

information only, in addition to having the ability to change the time and date displayed on the LCD.

NOTE: All alarms must be acknowledged via the Ack button before entering Program mode from Manual mode.

3.3.1 Password

A password must be entered before the Program category can be accessed. Take the following steps:

1. Press the ENTER button while the unit is in either of the Operation modes (Active / Manual) to call up the password field.

2. Enter your 4-digit hexidecimal password on the bottom line (use the UP and DOWN arrow buttons to scroll through the characters). Note

that the default password is ‘CAFE’.

3. Press the ENTER button to select the desired value and move along to the next digit.

4. Continue until the four spaces are filled. Pressing the ENTER button after selecting the fourth digit will automatically present the password

to the system for acceptance / rejection.

Assuming that the password is correct, the SG-System II will enter Program category and generate the corresponding printer and automation sig-

nals. Should the password be incorrect, the unit will produce an error tone and return to a Base category (Active mode or Manual mode). Press

the ENTER button once more to return to the Password screen.

The password can be set in the following manner:

1. Enter the Program category.

2. Scroll to View or Change Options > CPM Options > Option 006.

3. Scroll to the user whose password is to be changed. Enter the new password. Press the ENTER button. The new password is set.

3.3.2 User Interface

The SG-System II unit’s LCD and button interface give the user the ability to program the unit and scroll through the printer buffer and the trouble

list. The upper line displays the device mode (in the example below, ‘Manual’). The lower line displays the system information (in the example

below, ‘System Trouble’).

3.3.3 Top Level Menu

View or Change Options

In View or Change Options, use the UP and DOWN arrow buttons to locate the configurable option categories. These categories are: CPM

Options / Channel-1 Options / Channel-2 Options / Channel-IP Options / Exit Menu. Please refer to Section 4 for a detailed list of the system

options available within each category.

8

Select the Exit Menu and press the ENTER button. You will return to the View or Change Options level. Pressing the UP and DOWN buttons simul-

taneously - regardless of your place within View or Change Options - will take you to the Top Level menu.

View Printer Buffer

The bottom line of the LCD is cleared when View Printer Buffer is entered. The oldest message in the buffer, including those that have been

acknowledged, will be displayed first. Use the UP button to review the older messages and the DOWN button to review the newer messages. In

the case of a lengthy message, the first 39 characters will be displayed. Press the ENTER button to show the remainder of the message.

This view is available only in Manual mode to review acknowledge messages.

Pressing the UP and DOWN buttons simultaneously to go to the Top Level menu.

System Functions

System Functions provides access to the System Functions Menu, which consists of System Information / Change Date and Time / Default

SG-System II Options / Reset SG-System II / Visual Indicator Test / Exit Menu.

Exit Programming

Pressing the ENTER button while in Exit Programming will take the user back to the Base mode or the Manual mode.

3.3.4 System Functions Menu

System Information

System Information provides a wealth of detail regarding the user’s setup of SG-System II. These details include:

• Version • SW Checksum • Manufacture Date

• ID • CPLD Version • Country of Manufacture Code

• LAN MAC • DSP Checksum • AHS Table

• LAN IP • DSP Version • IP Accounts

• Gateway IP • WAN IP • WAN Subnet

• WAN MAC • IP Accounts 2 • LAN subnet

NOTE: The number in parentheses represents the number of times the value has been changed or the size of a par-

ticular table.

To return to System Information while viewing any of the above, press the UP and DOWN buttons simultaneously. Pressing the UP and DOWN

buttoms once more will take you to the Top Level menu.

Change Date and Time

Having chosen to enter Change Date and Time by pressing the ENTER button, the unit’s LCD appears as below:

1. Changes to the time and date begin at the far left of the screen with the hour, and proceed to the right. The UP button will increase the

value of the digit; the DOWN button will decrease its value.

2. Having made a change, press the ENTER button to advance to the next digit on the right. Pressing the ENTER button without having made

any changes will also move the cursor to the next digit on the right.

3. Once the Day has been entered and the ENTER button pressed, the user will be asked by the SG-System II to confirm the changes: N? for

no; Y? for yes. Use the UP and DOWN buttons to navigate between yes and no.

4. Press the ENTER button to save your changes.

NOTE: At any point before the time and date have been saved, pressing the UP and DOWN buttons simultaneously

will cancel any unsaved changes and return the user to the System Functions Menu.

Default SG-System II Options

When Default SG-System II Options is selected, the LCD will prompt the user to confirm that the entire system is to be reset. Selecting Y? for yes

will reset the system; selecting N? for no will leave system settings as they are. Either of the UP and DOWN buttons can be used to cycle between

answers.

Visual Indicator Test

Selecting the Visual Indicator Test turns on all of the LCD pixels and the unit’s buzzer, to confirm that they are in good working order.

Exit Menu

When in Top Level Menu > Exit Menu, pressing the ENTER button will take the user back one level to the Base (Active mode or Manual mode)

level. When in System Functions Menu > Exit Menu, pressing the ENTER button will take the user back one level to Top Level Menu > Sys-

tem Functions. While in System Functions, navigate to Exit Programming. Pressing the ENTER button will take the user back to the Base (Active

mode or Manual mode) level.

9

3.3.5 Miscellaneous LED Indicators

View Trouble

To enter View Trouble, the unit must first be in Active mode or Manual mode, and have no events to be acknowledged in Manual mode. Press

the UP and DOWN buttons simultaneously to enter View Trouble. Once there, the UP and DOWN buttons can be used to review the list of trou-

bles. Should there be no troubles, the LCD will flash NO TROUBLE for a few seconds and return to the previous level of operation. A list of pos-

sible troubles can be found below.

Trouble List

The following trouble and status lists are monitored by the system. Individual troubles can be disabled in the Program category. Both the trouble

list and the status list are fully enabled by default.

Trouble:

• Parallel Printer • Serial Automation • UPS AC

• Serial Printer • TCP Automation • Time and Date Not Set

• TCP Printer • UPS Battery • Network absent

• USB Printer

Status:

• Clock Not Set • Checksum Failed - Software

• Printer Buffer Full • System Absent - Channel 1

View Network / Watchdog

Please refer to Set Up and Testing on page 6 for detailed Network information.

View Status

Please refer to Set Up and Testing on page 6 for detailed Status information.

10

Section 4 - System Options

4.1 System Option Index

Steps required to access an option and change its setting or value

The steps required to access an option and change its setting or value are very nearly uniform from option to option. The procedure detailed

below will match satisfy the majority of options. Those it does not will accept close, intuitive variations of it. Please refer to the steps below

when programming system options.

To change an option’s setting or value, take the following steps:

1. Turn on the SG-System II.

2. Use the UP and DOWN buttons to select the user. User ‘0’ has full administrative powers; all other users may only review system settings,

in addition to changing the time and date.

3. Press the ENTER button. This initiates the password sequence, placing a flashing cursor underneath the first digit of the four-digit pass-

word.

4. Use the UP and DOWN buttons to select the appropriate value. Press the ENTER button. The cursor will advance to the next digit.

5. Repeat step 4 for all four digits. If the password you have entered is correct, you now have access to SG-System II. If not, re-enter your

password.

6. View or Change Options appears on the LCD. Press the ENTER button.

7. Use the UP and DOWN buttons to locate which section of options is valid for your configuration of SG-System II: CPM Options / Chan-

nel-IP Options / Exit Menu.

8. Press the ENTER button. The options applicable to your system are to available for you to access.

9. Navigate to Option [XXX]. Press the ENTER button. The current value is displayed on the LCD.

10. Press the ENTER button. The value may now be changed.

11. Use the UP or DOWN button to scroll to the desired value.

12. Having made a selection, press the ENTER button.

13. The LCD will prompt you to accept (Y?) or to decline (N?) your changes.

14. Use the UP and DOWN buttons to select your response. Press the ENTER button.

15. Your changes have been saved.

Page

Option [001]: LAN IP Address.........................................11

Option [002]: LAN Subnet Mask Address.......................11

Option [003]: LAN Gateway...........................................11

Option [004]: Auto Update Time and Date.................... 11

Option [005]: Contrast................................................... 11

Option [006]: Password..................................................11

Option [007]: Automation Baud Rate ............................11

Option [008]: Automation Data Bits...............................11

Option [009]: Automation Parity....................................12

Option [00A]: Serial Printer Format ................................ 12

Option [00B]: Serial Baud Rate.......................................12

Option [00C]: Serial Data Bits......................................... 12

Option [00D]: Serial Printer Parity...................................12

Option [00F]: B32 Headers............................................. 12

Option [012]: Heartbeat Timer.......................................12

Option [013]: Buzzer Tone..............................................13

Option [014]: Receiver Number......................................13

Option [015]: Printer Test ...............................................13

Option [020]: Mask UPS AC........................................... 13

Page

Option [021]: Mask UPS BAT..........................................13

Option [024]: Mask SG TCP/IP........................................13

Option [025]: Mask SG Serial .........................................14

Option [028]: Mask TCP Printer......................................14

Option [029]: Mask Parallel Printer .................................14

Option [02A]: Mask Serial Printer ...................................14

Option [02F]: Automation Mode....................................14

Option [030]: Printer Mode ............................................16

Option [031]: ACK Wait .................................................16

Option [032]: Date Format .............................................16

Options [037] and [038]: Product ID Keys #1, #2 ...........16

Option [039]: Mask USB Printer......................................16

Option [03A]: Programmable I/O....................................16

Option [03B]: Last Message On......................................16

Option [03C]: LCD Backlight Colour...............................17

Option [03D]: Key Backlight Colour ...............................17

Option [041]: System Number Length............................17

Option [042]: Busy Out...................................................17

Option [043]: System Protocol ID ...................................18

11

4.2 System Options

Option [001]: LAN IP Address

Default (10.0.7.100)

Enter the IP address of the SG-System II. The IP address must be entered as a dotted decimal number (e.g. 255.255.001.000). Each three-digit

segment of the IP address must be within a valid range of 000 to 255.

NOTE: The SG-System II must be restarted for these changes to take effect.

Option [002]: LAN Subnet Mask Address

Default (255.255.0.0)

Enter the LAN Subnet Mask address of the SG-System II. The address must be entered as a dotted decimal number (e.g. 255.255.001.000). Each

three-digit segment of the address must be within a valid range of 000 to 255.

NOTE: The SG-System II must be restarted for these changes to take effect.

Option [003]: LAN Gateway

Default (0.0.0.0)

Enter the LAN Gateway address of the SG-System II. Take care to ensure that the address is unique to your system. The address must be entered

as a dotted decimal number (e.g. 255.255.001.000). Each three-digit segment of the address must be within a valid range of 000 to 255. The

gateway is used in the event that the data being sent is not on the same network as the SG-System II. The data will need to be sent through a

router device. This is the address of that router device.

NOTE: The SG-System II must be restarted for these changes to take effect.

Option [004]: Auto Update Time and Date

Default (0)

This option enables the automation to update the SG-System II’s time via the TCP/IP port. If the SG-System II fails to get the time and date within

a twenty-four-hour period (started after the last update is received), it will generate a status message to the printer and automation, following the

internal trouble protocol. The Trouble status on the SG-System II display will not be affected.

Printer message: “Time&Date Update Fail”

Automation message: [#0000|NRU0000]

Option [005]: Contrast

Default (45)

Use this option enables to adjust the contrast of the unit’s LCD. Press the UP and ENTER buttons simultaneously to increase the level of contrast;

press the DOWN and ENTER buttons simultaneously to decrease the level of contrast. Contrast can be adjusted in both Active and Manual

modes.

Option [006]: Password

Default (CAFE)

Use this option to change or delete SG-System II users and their passwords. Sixteen users with 4-digit passwords are available for use on the

SG-System II. User 0 is the Master user, with complete administrative control over the system. Users 1 through F may be assigned to individuals

within your organization; these sixteen users are able to review system settings but not change them, with the exception of the Time and Date.

To delete a user, programe the password for that user to ‘FFFF’.

NOTE: User 0 can not be deleted.

To change your password, take the following steps:

1. Navigate to Option [006].

2. Press the ENTER button. The user designation (e.g. ‘0’, ‘F’) is displayed, in addition to the current password in the form of ‘XXXX’.

3. Press the ENTER button to begin the process of changing the password.

4. Use the UP and DOWN buttons to make your selection and press the ENTER button. The cursor advances to the next digit.

5. On selecting the fourth digit and pressing the ENTER button, the unit LCD will will prompt you to accept (Y?) or to decline (N?) your

changes.

6. Press the ENTER button again to accept or to decline your changes.

Option [007]: Automation Baud Rate

Default (9600)

This option determines the baud rate at which the SG-System II will communicate to the automation software via serial port 1. As a general rule,

the faster the baud rate, the better the unit’s performance. Older automation software packages can not, however, manage a fast baud rate and

will require a slower baud rate in order to perform at an optimal level. Valid selections are: 1200, 2400, 4800, 9600, 19200, 38400, and 57600.

NOTE: The SG-System II must be restarted for these changes to take effect.

Option [008]: Automation Data Bits

Default (8)

This option determines the number of data bits the SG-System II will use to communicate to the automation software via serial port 1. Valid selec-

tions are seven or eight, to indicate seven data bits or eight data bits. As a general rule, the higher the number of data bits, the better the unit’s

performance.

NOTE: The SG-System II must be restarted for these changes to take effect.

12

Option [009]: Automation Parity

Default (0)

This option determines the parity of serial port 1.

NOTE: The number of stop bits can not be changed and will always be 2.

NOTE: The SG-System II must be restarted for these changes to take effect.

Option [00A]: Serial Printer Format

Default (0)

This option regulates how data is formatted when sent to a serial printer and how the serial port is supervised. CTS will need to be set high and

print to both HyperTerminal and physical serial printer. By setting Option [00A] to ‘02’ (note that this will be displayed as ‘DCD’ in programming

mode), DCD will need to be set high. This option affects how the COM2 serial port is supervised and how the data is formatted. The default value

disables the option, blocking the printing of data.

NOTE: The SG-System II must be restarted for these changes to take effect.

Option [00B]: Serial Baud Rate

Default (57600)

This option determines the baud rate at which the SG-System II will communicate to the automation software via serial port 2. As a general rule,

the faster the baud rate, the better the unit’s performance. Older automation software packages can not, however, manage a fast baud rate and

will require a slower baud rate in order to perform at an optimal level. Valid selections are: 1200, 2400, 4800, 9600, 19200, 38400, and 57600.

NOTE: The SG-System II must be restarted for these changes to take effect.

Option [00C]: Serial Data Bits

Default (8)

This option determines the number of data bits the SG-System II will use to communicate to the automation software via serial port 2. Valid selec-

tions are seven or eight, to indicate seven data bits or eight data bits. As a general rule, the higher the number of data bits, the better the unit’s

performance.

NOTE: The SG-System II must be restarted for these changes to take effect.

Option [00D]: Serial Printer Parity

Default (0)

This option determines the parity of serial port 2. ‘0’ represents no parity, ‘1’ represent odd parity, and ‘2’ represent even parity.

NOTE: The number of stop bits can not be changed and will always be 2.

NOTE: The SG-System II must be restarted for these changes to take effect

Option [00F]: B32 Headers

Default (00)

This option enables compatibility with MAS B32 Automation Software through TCP/IP. To enable this option, change the value to ‘01’.

NOTE: The SG-System II must be restarted for these changes to take effect

Option [012]: Heartbeat Timer

Default (30)

Use this option to determine the time interval - measured in seconds - the heartbeat transmission is sent to Serial Automation and TCP/IP port

1025. The heartbeat times is used to ensure that any communication through Serial Automation and TCP/IP is functioning normally when there is

no traffic from the receiver. Note that any traffic from the receiver will reset the heartbeat timer. Therefore, the heartbeat transmission will be sent

only if there is no signal sent during the time specified in Option [012].

Table 8: Automation Parity

Value Degree of Parity

0 No parity

1 Odd parity

2 Even parity

13

Option [013]: Buzzer Tone

Default (00)

A tone will sound when the SG-System II, having received an alarm, is unable to forward the alarm message to either the Serial or TCP/IP automa-

tion paths (while in Manual mode). You are able to manipulate this tone via Option [013]. The tone generated will continue to pulse until all

unacknowledgedevents have been acknowledged by the user; this can be done by pressing the Ack button for each event, or the unit itself trans-

fers from Manual mode to Active mode. If Option [013] is set to OFF, no buzzer tone will sound on receipt of an alarm. Any other value will pro-

duce a tone.

To set the buzzer tone, take the following steps:

1. Navigate to Option [013]. Press the ENTER button. The current value is displayed on the LCD.

2. Press the ENTER button. The value may now be changed.

3. Use the UP and DOWN buttons to scroll to the desired value.

NOTE: As each tone is selected the SG-System II will sound that tone for a period of 250 msec, allowing the user

the opportunity to judge each tone as it is selected.

1. Having made a selection, press the ENTER button.

2. The LCD will prompt you to accept (Y?) or to decline (N?) your changes.

3. Use the UP and DOWN buttons to select your answer. Press the ENTER button.

NOTE: Refer to UL864 Programming Requirements on page 2 if changing the default setting.

Option [014]: Receiver Number

Default (01)

The receiver number is used to identify the receiver (or, unit) when communicating to the TCP/IP Automation, the Serial Automation, and any

connected printer. This receiver number applies to all traffic, unless overridden by another option. In the event that such overriding takes place, it

will most likely be a Fallback / Recovery Strategy option.

Option [015]: Printer Test

Default (ON)

When this option is enabled, a test signal is sent to all active printers at 0500 hrs and 1700 hrs of every day.

Sample printer message: 26 Nov 2003 16:41:25 - 26 Nov 2003-16:41:25-00/00-SG-01-000-0000--Printer Test Message

Option [020]: Mask UPS AC

Default (ON)

Use this option to enable the UPS AC Shelf 1 trouble mask. If enabled, trouble conditions are not reported.

OFF - Condition reported

ON - Condition not reported (masked)

NOTE: Refer to UL864 Programming Requirements on page 2 if changing the default setting.

Option [021]: Mask UPS BAT

Default (ON)

Use this option to enable the UPS Battery Shelf 1 trouble mask. If enabled, trouble conditions are not reported.

OFF - Condition reported

ON - Condition not reported (masked)

NOTE: Refer to UL864 Programming Requirements on page 2 if changing the default setting.

Option [024]: Mask SG TCP/IP

Default (OFF)

Use this option to enable the SG TCP/IP trouble mask. If enabled, trouble conditions are not reported.

OFF - Condition reported

ON - Condition not reported (masked)

NOTE: Refer to UL864 Programming Requirements on page 2 if changing the default setting.

Table 9: Buzzer Tone

IDX Frequency (Hz)

20 1490

25 1990

26 2103

30 2650

33 3149

37 3965

38 4270

39 4530

14

Option [025]: Mask SG Serial

Default (OFF)

Use this option to enable the SG Serial trouble mask. If enabled, trouble conditions are not reported.

OFF - Condition reported

ON - Condition not reported (masked)

See UL864 Programming Requirements on page 2.

Option [028]: Mask TCP Printer

Default (OFF)

Use this option to enable the TCP Printer trouble mask. If enabled, trouble conditions are not reported.

OFF - Condition reported

ON - Condition not reported (masked)

See UL864 Programming Requirements on page 2.

Option [029]: Mask Parallel Printer

Default (OFF)

Use this option to enable the Parallel Printer trouble mask. If enabled, trouble conditions are not reported.

OFF - Condition reported

ON - Condition not reported (masked)

NOTE: Refer to UL864 Programming Requirements on page 2 if changing the default setting.

Option [02A]: Mask Serial Printer

Default (OFF)

Use this option to enable the Serial Printer trouble mask. If enabled, trouble conditions are not reported.

OFF - Condition reported

ON - Condition not reported (masked)

NOTE: Refer to UL864 Programming Requirements on page 2 if changing the default setting.

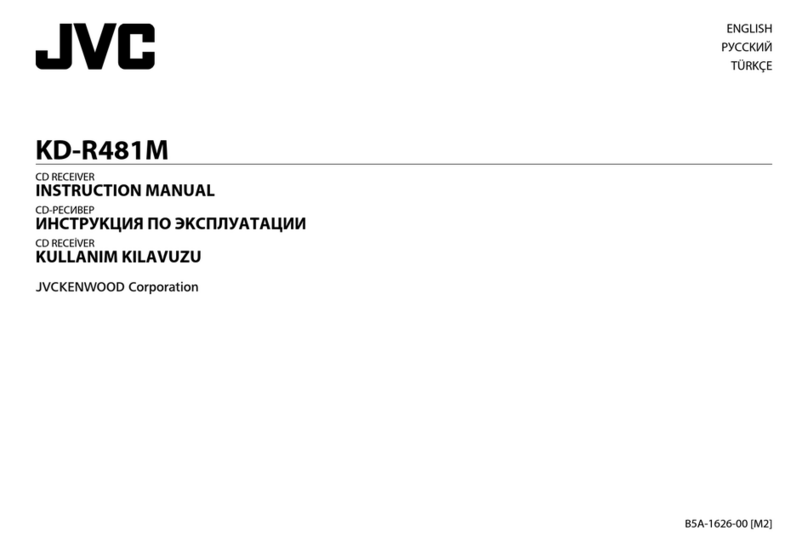

Option [02F]: Automation Mode

Default - Fallback (01)

The TCP/IP connection is the primary output of the SG-System II for automation computer alarms. It is expected that sockets may appear and dis-

appear regularly as processes are terminated and reconstituted. After five seconds of socket loss, a socket loss is declared and automation output

is shifted to the next connection level, which is the serial automation output connection. There are five levels of automation:

•Loop (00)

At startup, the SG-System II will send to the TCP/IP until it fails, proceed to the RS232 until it fails, proceed back to the TCP/IP until it fails,

and so on. Please refer to the Automation Mode workflow diagrams below.

NOTE: This value will not generate an automation absent message.

•Fallback (01)

If both outputs are present, the system will send to the TCP/IP connection until it fails, proceeding next to the RS232 connection. It will con-

tinue to send to the serial connection without stop, or until the reset fallback command is generated from the console, in which case it will

re-try the TCP/IP connection. Please refer to the Automation Mode workflow diagrams below.

•Automatic IP Fallback (04)

This mode is similar to Fallback, save that when the TCP/IP connection is restored the SG-System II will return to the TCP/IP port to send

events. This eliminates the need for the Reset SG Fallback from the SG-System II Console. Please refer to the Automation Mode workflow

diagrams below.

NOTE: The SG-System II must be restarted for these changes to take effect.

15

Figure 4: Loop (00), Automatic IP Fallback (04)

Figure 5: Fallback (01)

Figure 6: All (02)

Power Up /

Restart

SG-System I TCP

Port Active?

\SG-System I

Serial 1 P ort

Active?

Poll

Automation

Manual Re -start

from Consol e

(Res et Fallb ack )

Manual Re -start

from Consol e

(Res et Fallb ack )

NO

YES

NO

Automatic Falback

mode (4)

Power Up /

Restart

SG-System I Port

Active?

SG-System I Serial

1 Port Ac tive?

Poll

Automation

M anu al R e -st art

from C ons ole

(R eset Fallbac k)

M anu al R e -st art

from C ons ole

(R eset Fallbac k)

NO

YES

NO

Power Up /

Restart

SG- System I TCP

Port Active?

SG-System I Serial

1 Port Active?

Poll

Automation

YES

YES

NO

NO

16

Option [030]: Printer Mode

Default (LOOP)

You can configure this option with an approach similar to the automation outputs of Option [02F] above, except that Fallback (01) and Auto-

matic IP Fallback (04) are not available. The acceptable value is Loop (00). Note that Loop (00) transmits printer messages to each port in turn.

The first port to respond will be used to process subsequent printer messages until it is no longer able to do so, at which point the next port in the

loop will be employed.

NOTE: The order of sequence is: TCP, Parallel, USB, and Serial. DSC does not recommend changing the default set-

ting unless using more than one printer.