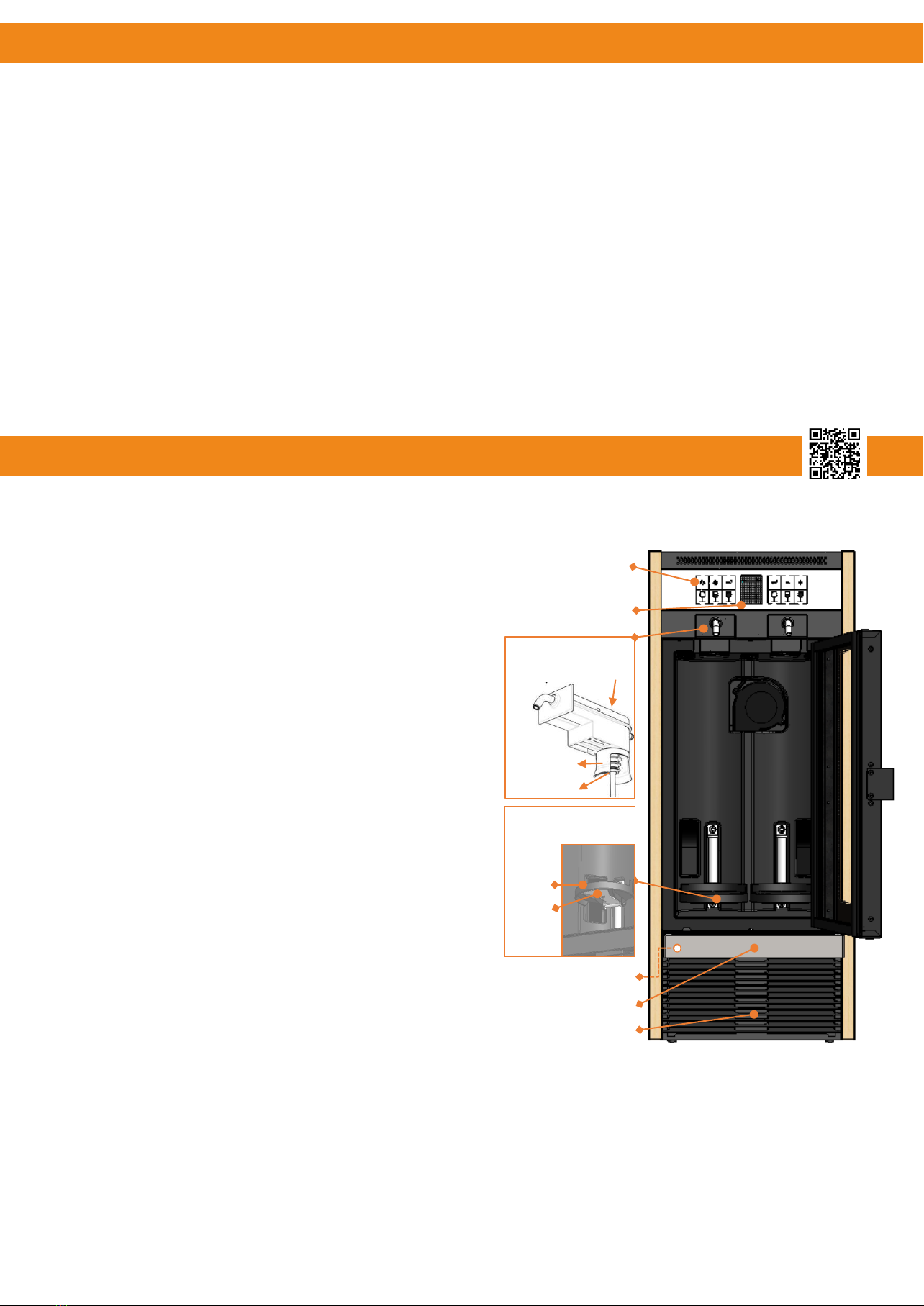

Keyboard

(see page 8 for details)

Display

Dispense head

Moveable

bottle plate

Keyhole

(behind the drip tray)

Ventilation slits

Seal

Tensioning

spring

Spring

Plate

Plug

Drip tray

7

10. Change the gas bottle

A full disposable gas cylinder has a pressure of approx. 100 bar. The pressure displayed on

the manometer of the pressure regulator falls to „0“when the gas cylinder is empty.

Disposable gas cylinders seal by themselves when you unwind them. You can disconnect

the gas supply at any time by unscrewing the cylinder from the pressure regulator.

1. Unscrew the empty gas bottle anti-clockwise out of the pressure regulator.

2. Remove the black rubber sealing cap from the valve of the new gas bottle and feed it

into the holder from below.

3. Screw it clockwise into the thread in the pressure regulator. Do not worry if a little gas

escapes when you do this, just continue to screw the bottle firmly into the thread until

the connection is audibly sealed.

Refillable gas containers come with higher pressures of up to 300 bar. They come with their

own stopcock. Close the stopcock before exchanging the bottle even when the bottle is

empty, and make sure there is no remaining pressure on the regulator.

The removable dispense heads of the By the Glass® Modular wine dispensers make

changing a bottle as well as cleaning and maintenance, very easy.

1. Take hold of the wine bottle neck and the

dispense head at the seal and pull them

together straight out of the appliance.

2. Pull the dispense head and the plug and

tube out of the bottle. To allow residual

wine to flow from the tube back into the

bottle, you can press the tensioning spring

when the tube is hanging freely in the

bottle.

3. Feed the tube into the new bottle and push

the dispense head firmly onto the bottle so

that the plug seals the bottle well.

Caution: for bottles with a high fill level and

especially for screw-thread bottles, you may

have to first pour out a small amount so the

bottle does not overflow.

4. Place the new bottle with the dispense head

into the appliance. To do this, take hold of

the seal and bottleneck again and place the

bottle and dispense head into position

straight until it engages.

11. Connecting wine bottles

5. Move the sliding bottle plate from below firmly onto the bottle so that the wine

bottle sits firmly on the dispense head at the top and level on the plate. Push the

spring below the bottle plate from the front to slide it up or down.

6. Then dispense a small quantity of the wine by pressing the Enter button or repeatedly

pressing a Dispense button (Start/Stop). The wine now reaches the top of the tap and

the bottle is protected against spoiling by the noble gas.

Fig. 3 By the Glass® Modular overview and details

Video 3