Surewerx JET JGP Series User manual

M18-MH111136 -8

Operator’s MANUAL

JGP SERIES GRIP PULLERS

Prod. No. 111136

111137

111138

M18-MH111136-38-Eng+Fre-FA.indd 1 2018-07-23 4:11 PM

2

Waranty Policy ..............................................................2, 3

Warnings............................................................................3

Introduction.......................................................................4

Specifications....................................................................4

Unpacking, Assembly and Setup....................................4

Inserting Wire Rope .........................................................5

Operation...........................................................................5

Maintenance......................................................................6

Troubleshooting................................................................6

Parts Breakdown and Parts List................................7 - 12

WARRANTY POLICY

JET EQUIPMENT AND TOOLS LTD.

(JET®) makes every effort to ensure

its products are manufactured to the

highest standards and are guaranteed

against defects in materials and

workmanship when the product is

used for the purpose for which it was

designed. This guarantee applies only

to JET products purchased new from a

JET authorized distributor.

JET product warranties are extended to

the original retail purchaser only. This

warranty does not apply to any product

showing signs of abuse, misuse,

alteration, or having been improperly

maintained or repaired.

This warranty does not cover damage

attributable to normal wear and tear.

Any JET product that fails during

normal use and is within the specified

warranty period for that product will be

repaired or replaced at JET’s discretion.

Repairs and/or replacements are

warranted as described for the specific

product only for the remainder of the

warranty period.

Repair or replacement is the exclusive

remedy for defective products under

this warranty.

Warranty is expressly in lieu of all

other warranties, including the implied

warranty or merchantability or any

implied warranty of fitness for a

particular application.

Any JET product for which there is

a warranty claim should be returned

PREPAID to an authorized JET

distributor or service centre. Authorized

Warranty Depots can be found at

surewerx.com

All warranty claims must be

accompanied by proof of purchase and

an explanation of the defect or failure.

It is the customer’s responsibility to

provide this information.

JET shall not be held liable for any

consequential or incidental damages

for breach of any expressed or implied

warranty on their products. No claim

for damages or any type will be

considered, and all products are sold

with this understanding.

Any costs incurred to obtain warranty

consideration or services are the

Customer’s responsibility including

shipping and handling, travel, lost time

or lost production.

SPECIFIED WARRANTY – MATERIAL HANDLING

1 Year Limited Warranty

Chain Hoists Hand Cable Pullers

Air Hoists Lever Chain Pullers

Electric Hoists

Grip Pullers

Electric Trolleys Manual Adjustable

Trolleys

Drum Clamps Beam Clamps

Plate Clamps Blocks and Sheaves

Pallet Trucks Mobile Lift Tables

Winches

GENERAL INFORMATION ON JET

CHAIN HOISTS AND PULLERS

Customs Lifts – Custom lift lengths are

available, however, custom lift hoists

and pullers are NOT returnable.

CAUTION: be sure that supporting

structures and load-attaching devices

used in conjunction with hoists,

provide an adequate safety factor to

handle the rated load plus the weight

of the equipment. If in doubt, consult a

qualified structural engineer.

This equipment is not to be used for

lifting, supporting, or transporting

people, or lifting, supporting, or

transporting loads over people.

IMPORTANT: Before installation

and operation, see maintenance and

operations manual for additional

warnings, precautions and operating

instructions.

NOTE: Batteries supplied with certain

products may have been subjected to

long shelf life, resulting in low energy

or a dead battery. Please source

replacement batteries locally. Please

follow instructions in the manuals for

products using rechargeable batteries.

Dead batteries do not constitute a

warranty claim.

TABLE OF CONTENTS

M18-MH111136-38-Eng+Fre-FA.indd 2 2018-07-23 4:11 PM

3

Any JET product that fails during

normal use and is within the

specified warranty period for that

product will be repaired or replaced

at JET’s discretion. Repairs and/

or replacements are warranted as

described for the specific product and

only for the remainder of the original

warranty period.

Repair or replacement is the exclusive

remedy for defective product under

this warranty. Warranty is expressly in

lieu of all other warranties, including

the implied warranty of merchantability

or any implied warranty of fitness

for a particular application. Any JET

product for which there is a warranty

claim should be returned PREPAID

to an authorized JET distributor or

service centre. Authorized Warranty

Depots are found at surewerx.com

ALL warranty claims must

be accompanied by proof of

purchase and an explanation of the

responsibility including shipping

and handling, travel, lost time, or lost

production.

These general instructions deal with

the normal installation, operation and

maintenance situations encountered

with the Grip Puller described herein.

The instructions should not be

interpreted to anticipate every possible

contingency or to anticipate the final

system or configuration that uses

these Grip Pullers.

These instructions include information

for a variety of hand chain hoists.

Therefore, all instructions and

information may not apply to one

specific Grip Puller. Disregard those

portions of the instructions that do

not apply.

WARNINGS

1. Read and understand owner’s manual before

operating grip puller. Familiarize yourself with the

content of the warning label on your puller.

2. Do not exceed rated capacity.

3. Supporting structure used with this device must

provide adequate support to handle all puller

operations plus the weight of the puller and attached

equipment. If in doubt, consult a registered structural

engineer.

4. Never use handle extensions (cheaters).

5. Do not use with twisted, kinked, frayed or otherwise

damaged wire rope.

6. Do not use if grip puller is damaged or malfunctioning.

7. Do not lift people or loads over people. Always keep

people clear from load path.

8. When using grip puller to lift vertically, make sure hook

is centered under the puller.

9. Do not use as a tow line.

10. Do not use with a hook that is open or twisted, or

without safety latch.

11. Never run wire rope over a sharp edge.

12. Never leave a suspended load unattended.

13. Do not swing a suspended load.

14. Always inspect the puller before each use. Replace if

any component is damaged or malfunctioning.

15. Always use gloves when handling wire rope. Do not

wear loose clothing which can become entangled in

moving parts.

16. Do not use this grip puller in an explosive

environment.

17. Give your work undivided attention. Looking around,

carrying on a conversation and “horse-play” are

careless acts that can result in serious injury.

18. Do not operate this tool while tired or under the

influence of drugs, alcohol or any medication.

19. Failure to comply with the above warnings may result

in personal injury and/or property damage.

M18-MH111136-38-Eng+Fre-FA.indd 3 2018-07-23 4:11 PM

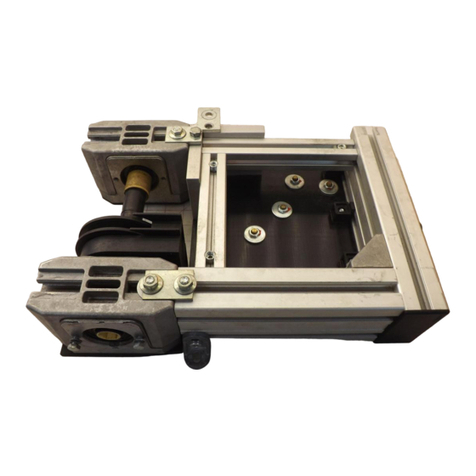

Telescoping Handle

Clamp

Lever

Forward

Lever

Reverse

Lever

Hand Grip

(Contains extra shear pins)

Fastening

Bolt

Puller Body

Swivel Hook Figure 1.

4

Product No. 111136 111137 111138

Model No. JGP-75A JGP-150A JGP-300A

Pulling Capacity (lb) 2,860 5,720 11,440

Lifting Capacity (lb) 1,760 3,520 7,040

Force Req. to raise load (lb) 64 93 99

Dimensions (L x W x H) 16-3/4" x 2-1/2" x 9" 21-1/2" x 3-3/4" x 10-1/4" 26" x 4-1/2" x 12-1/2"

Cable Diameter 5/16" 7/16" 5/8"

Net Weight (lb) 39.7 45.2 71.6

UNPACKING

Open carton and check for shipping damage. Report any

damage immediately to your distributor and shipping agent.

Do not discard any shipping material until the Grip Puller is

assembled and operating properly.

Compare the contents of your container with the following

parts list to make sure all parts are intact. Missing parts, if any,

should be reported to your distributor. Read the instruction

manual thoroughly for assembly, maintenance and safety

instructions.

ASSEMBLY AND SETUP

Pre-Lubrication

Before proceeding with assembly, lubricate the puller as

follows: Apply a lubricating oil to the puller mechanisms while

continuously operating the reverse lever. This will help spread

the oil to the internal parts. Use special care to oil pawls and

links well. A wear resistant oil is recommended.

CAUTION: Without proper lubrication, the pawls will fail to

engage the wire rope, and the wire rope will not move.

The above specifications were current at the time this manual was published, but because of our policy of continuous improvement,

JET reserves the right to change specifications at any time and without prior notice, without incurring obligations.

*NOTE: The above product numbers do not include the wire rope.

SPECIFICATIONS

INTRODUCTION

This manual is provided by JET covering the safe operation

and maintenance procedures for a JET Grip Puller.

This manual contains instructions on installation, safety

precautions, general operating procedures, maintenance

instructions and parts breakdown. This tool has been

designed and constructed to provide consistent, long-term

operation if used in accordance with instructions set forth in

this manual. If there are any questions or comments, please

contact either your local supplier or SureWerx. JET can also

be reached at our web site: www.surewerx.com

M18-MH111136-38-Eng+Fre-FA.indd 4 2018-07-23 4:11 PM

Insert Wire Rope

Clamp Lever

Engaged

Attach

Telescopic

Handle

Safety Latch

Correct

Correct

Incorrect

Incorrect

Figure 5.

Figure 4.

Figure 3.

Figure 2.

5

INSERTING WIRE ROPE

1. Release the clamp by pushing the clamp lever securely into

the notch on the puller body.

2. Insert the end of the wire rope into the rope inlet at the

rear of the puller. Feed the wire rope through until it emerges

at the other end.

3. Pull the wire rope through by hand to take up the slack and

make sure the exit point is not obstructed.

4. While keeping the wire rope taut, push down on the clamp

lever and allow it to spring back to its natural position.

This will engage the wire rope within the puller.

5. Mount the telescopic handle to either the forward or reverse

lever, according to the action desired. Rotate the handle

until it is secure on the lever.

6. The puller is now ready to operate.

OPERATION

The grip puller uses standard ASA wire rope and may be used

in any position to lift, pull, lower or stretch heavy loads. Before

attempting operation of this product, you should become

thoroughly familiar with the warnings on page 3.

To operate the grip puller:

1. Place load cable(s) in the middle of the hook and inside the

safety latch. DO NOT attach any cables outside the safety latch

on either the puller hook or the wire rope hook.

2. Lay out the wire rope correctly without twisting. Twisting the

wire rope reduces its strength. See Figure 5.

3. To send the wire rope forward, set the telescopic handle on the

forward lever and move it back and forth.

4. To send the wire rope backward, set the telescopic handle on

the reverse lever and move it back and forth.

IMPORTANT: A shear pin is installed in the forward lever. If the

load being handled is too excessive for the puller’s capacity,

the shear pin is designed to break. If this occurs, decrease

the load or use other equipment of higher pulling capacity.

The broken shear pin is easily replaced using one of the spare

shear pins which are found within the hand grip of the pullers.

See Figure 1.

Before storing the grip puller:

1. After use, remove the wire rope from the main body by setting

the clamp lever into the notch (disengage clamp), then pulling

the wire rope from the inlet side at the rear of the puller.

2. After the wire rope is removed, push the clamp lever out of the

notch and let it snap back to its original position. If the clamp

lever is kept in the notch for an extended time period, its spring

may become stretched.

3. Wipe off any sand or water from the puller body, including

internal mechanisms, and the wire rope, then apply oil

liberally to both.

4. Store the grip puller away from rain, dew, high humidity areas

or around acidic chemicals, which will promote rusting.

M18-MH111136-38-Eng+Fre-FA.indd 5 2018-07-23 4:11 PM

6

MAINTENANCE

Make frequent and careful inspections of the puller. Make

sure puller and wire rope are sufficiently oiled, and that

they are free of any sand, dirt, dust or other obstruction or

abnormality.

Make sure hooks are not deformed and that the puller body

has not been warped or damaged.

Use care to prevent the wire rope from kinking. If the rope

is left shaped like a basket or is kinked many turns at a

single point, its strength is greatly diminished and may

result in failure.

Replace the wire rope immediately if:

• The thickness of the rope becomes less than

half of the original value due to abrasion.

• The rope exhibits basket-like shapes, kinks,

or any abnormal deformation.

• The rope is given an exceptionally heavy shock during

operation; this can fatigue the rope even if the load is

within puller capacity.

• The entire rope is napped due to many small cuts.

• The eye section (thimble) of the wire rope becomes

elliptical in shape.

• The clamp is deformed.

Trouble Probable Cause Remedy

Insufficient lubrication. Oil the puller and wire rope.

Wire rope will not move in

either direction.

Puller is dirty. Disassemble and clean out dust, dirt or other

foreign matter. Oil the puller after reassembly.

Clamp lever is not in proper

position.

Release clamp lever from notch,

and allow it to return to engaged position.

Clamp lever is not in proper

position.

Release clamp lever from notch,

and allow it to return to engaged position.

Wire rope will not advance

during normal operation, or

advances with great difficulty.

Pawls are not lubricated. Oil the pawl linkages properly;

the pawls must engage the wire rope.

Load is beyond puller capacity. Decrease load.

There is an obstruction within the

wire rope’s path.

Remove the wire rope; clean and oil the puller

and the wire rope.

The reverse lever is engaging the

wire rope.

Check the position of the reverse lever.

Correct as needed.

Clamp lever will not engage

the wire rope properly.

Spring on clamp lever has

become stretched.

Replace spring.

TROUBLESHOOTING

M18-MH111136-38-Eng+Fre-FA.indd 6 2018-07-23 4:11 PM

7

JGP75A | 3/4 T GRIP PULLER PARTS BREAKDOWN | PROD. NO. 111136

M18-MH111136-38-Eng+Fre-FA.indd 7 2018-07-23 4:11 PM

8

801 PWC-SGP75-801 SGP75 ANCHOR PIN 1

802 PWC-SGP75-802 SGP75 CASE LEFT/RIGHT ALUMINUM 2

804 PWC-SGP75-804 SGP75 CRANK AXLE 1

805 PWC-SGP75-805 SGP75 CONNECTING ROD 2

806 PWC-SGP75-806 SGP75 FRONT JAW BLOCK 1

807 PWC-SGP75-807 SGP75 REAR JAW BLOCK 1

808 PWC-SGP75-808 SGP75 ROPE GUIDE 1

809 PWC-SGP75-809 SGP75 CASE BOLT 6

810 PWC-SGP75-810 SGP75 RELEASE HANDLE 1

811 PWC-SGP75-811 SGP75 RELEASE CONNECTING

ROD AXLE

1

812 PWC-SGP75-812 SGP75 REVERSE LEVER 1

813 PWC-SGP75-813 SGP75 CONNECTING ROD LEFT SIDE 1

814 PWC-SGP75-814 SGP75 CONNECTING AXLE 1

815 PWC-SGP75-515 SGP75 RELEASE HANDLE PIN 1

816 PWC-SGP75-816 SGP75 SHAKE ROD W/819

OPERATING LEVER

1

818 PWC-SGP75-818 SGP75 SHEAR PIN 1

818 PWC-SGP75-18A SGP75 SHEAR PIN 7.5 MM 1

819 PWC-SGP75-819 SGP75 OPERATING LEVER W/816

SHAKE ROD

1

822 PWC-SGP75-822 SGP75 SPRING 1

823 PWC-SGP75-823 SGP75 CLAMP PLATE W/828

LONG CLAMP PLATE

2

824 PWC-SGP75-824 SGP75 CLAMP PLATE AXLE 1

825 PWC-SGP75-825 SGP75 SPRING HOUSING 1

827 PWC-SGP75-827 SGP75 LOWER JAW 2

828 PWC-SGP75-828 SGP75 LONG CLAMP PLATE 2

829 PWC-SGP75-829 SGP75 UPPER JAW 2

830 PWC-SGP75-830 SGP75 JAW AXLE 4

831 PWC-SGP75-831 SGP75 TELESCOPIC HANDLE 1

8101 PWC-SGP75-809 SGP75 CASE BOLT 6

8102 PWC-SGP75-8102 SGP75A NUT 6

8103 PWC-SGP75-801 SGP75 ANCHOR PIN 1

8104 PWC-SGP75A-8104 SGP75A CASE LEFT METAL 1

8105 PWC-SGP75-8105 SGP75A BUSHING FOR SHAKE ROD 2

8106 PWC-SGP75A-8106 SGP75A CASE RIGHT METAL 1

8107 PWC-SGP75-8107 SGP75 WASHER 1

8108 PWC-SGP75-8108 SGP75 SCREW BOLT 1

8109 PWC-SGP75-8109 SGP75A COVER 1

8110 PWC-SGP75-818 SGP75 SHEAR PIN 1

8111 PWC-SGP75-808 SGP75 ROPE GUIDE 1

8112 PWC-SGP75-8112 SPG75A UPPER DUST SHIELD 1

8113 PWC-SGP75-8113 SPG75A LOWER DUST SHIELD 1

8114 PWC-SGP75-8114 SGP75A NAME PLATE 1

8115 PWC-SGP75-8115 SGP75A RIVET 8

8116 PWC-SGP75-8116 SGP75A INSTRUCTION PLATE 1

8202 PWC-SGP75-804 SGP75 CRANK AXLE 2

8206 PWC-SGP75-816 SGP75 SHAKE ROD W/819

OPERATING LEVER

1

8206 PWC-SGP75-819 SGP75 OPERATING LEVER W/816

SHAKE ROD

1

8209 PWC-SGP75-818 SGP75 SHEAR PIN 1

8301 PWC-SGP75-831 SGP75 TELESCOPIC HANDLE 1

8401 PWC-SGP75-8401 SGP75A SNAP RING 2

8402 PWC-SGP75-815 SGP75 RELEASE HANDLE PIN 1

8403 PWC-SGP75-810 SGP75 RELEASE HANDLE 1

8501 PWC-SGP75-812 SGP75 REVERSE LEVER 1

8502 PWC-SGP75-814 SGP75 CONNECTING AXLE 1

8503 PWC-SGP75-813 SGP75 CONNECTING ROD LEFT SIDE 2

8504 PWC-SGP75-8504 SGP75A CONNECTING ROD

RIGHT SIDE

1

8505 PWC-SGP75-8505 SGP75A SNAP RING 2

8506 PWC-SGP75-811 SGP75 RELEASE CONNECTING

ROD AXLE

1

8600 PWC-SGP75-8600 SGP75A REAR JAW BLOCK

ASSY SET

1

8700 PWC-SGP75-8700 SGP75A FRONT JAW BLOCK ASSY 1

8103A PWC-SGP75-8103 SGP75A TOP HOOK 1

8103B PWC-SGP75A-SAF SGP75A SWIVEL HOOK SAFETY

LATCH KIT

1

8107A PWC-SGP75-8107A SGP75A SNAP RING 2

8301A PWC-SGP75-8301A SGP75 TELESCOPIC HANDLE

RUBBER GRIP

1

** PELJG75BCP JG75 WIRE ROPE LOWER HOOK 1

** PELJG75SAF JG75 WIRE ROPE LOWER HOOK

LATCH KIT

1

REF. PART NUMBER DESCRIPTION REQ. REF. PART NUMBER DESCRIPTION REQ.

JGP75A | 3/4 T GRIP PULLER PARTS LIST | PROD. NO. 111136

Note: To determine if the puller is old or new style, establish if the unit has a top hook (new) or a pin (old).

See reference numbers 8103 and 8103A located on parts breakdown, for further clarification.

M18-MH111136-38-Eng+Fre-FA.indd 8 2018-07-23 4:11 PM

9

JGP150A | 1-1/2 T GRIP PULLER PARTS BREAKDOWN | PROD. NO. 111137

M18-MH111136-38-Eng+Fre-FA.indd 9 2018-07-23 4:11 PM

10

1601 PWC-SGP150-1601 SGP150 ANCHOR PIN 1

1602 PWC-SGP150-1602 SGP150 CASE LEFT/RIGHT

ALUMINUM

2

1604 PWC-SGP150-1604 SGP150 CRANK AXLE 1

1605 PWC-SGP150-1605 SGP150 CONNECTING ROD 2

1606 PWC-SGP150-1606 SGP150 FRONT JAW BLOCK 1

1607 PWC-SGP150-1607 SGP150 REAR JAW BLOCK 1

1608 PWC-SGP150-1608 SGP150 ROPE GUIDE 1

1609 PWC-SGP150-1609 SGP150 CASE BOLT 6

1610 PWC-SGP150-1610 SGP150 RELEASE HANDLE 1

1611 PWC-SGP150-1611 SGP150 RELEASE CONNECTING

ROD AXLE

1

1612 PWC-SGP150-1612 SGP150 REVERSE LEVER 1

1613 PWC-SGP150-1613 SGP150 CONNECTING ROD 2

1614 PWC-SGP150-1614 SGP150 CONNECTING AXLE 1

1615 PWC-SGP150-1615 SGP150 RELEASE HANDLE PIN 1

1616 PWC-SGP150-1616 SGP150 SHAKE ROD USE 1619 1

1618 PWC-SGP150-18 SGP150 SHEAR PIN 1

1619 PWC-SGP150-1619 SGP150 OPERATING LEVER

C/W 1616

1

1622 PWC-SGP150-1622 SGP150 SPRING 2

1623 PWC-SGP150-1623 SGP150 CLAMP PLATE 1

1624 PWC-SGP150-1624 SGP150 CLAMP PLATE AXLE 1

1625 PWC-SPC150-1625 SGP150 SPRING HOUSING 2

1626 PWC-SGP150-1626 SGP150 SUPPORT WHEEL 1

1627 PWC-SGP150-1627 SGP150 LOWER JAW 2

1628 PWC-SGP150-1628 SGP150 LONG CLAMP PLATE 2

1629 PWC-SGP150-1629 SGP150 UPPER JAW 2

1630 PWC-SGP150-1630 SGP150 JAW AXLE 4

1631 PWC-SGP150-1631 SGP150 TELESCOPIC HANDLE 1

16101 PWC-SGP150-1609 SGP150 CASE BOLT 6

16102 PWC-SGP15-16102 SGP150A CASE NUT 6

16103 PWC-SGP150-1601 SGP150 ANCHOR PIN 1

16104 PWC-SGP15-16104 SGP150A CASE LEFT METAL 1

16105 PWC-SGP15-16105 SGP150A BUSH FOR SHAKE ROD 2

16106 PWC-SGP15-16106 SGP150A CASE RIGHT METAL 1

16107 PWC-SGP15-16107 SGP150A WASHER 1

16109 PWC-SGP15-16109 SGP150A PLASTIC PLUG 1

16111 PWC-SGP150-1608 SGP150 ROPE GUIDE 1

16112 PWC-SGP15-16112 SPG150A UPPER DUST SHIELD 1

16113 PWC-SGP15-16113 SPG150A LOWER DUST SHIELD 1

16114 PWC-SGP15-16114 SGP150A NAME PLATE 1

16115 PWC-SGP15-16115 SGP150A RIVET 8

16116 PWC-SGP15-16116 SGP150A INSTRUCTION PLATE 1

16202 PWC-SGP150-1604 SGP150 CRANK AXLE 1

16206 PWC-SGP150-1616 SGP150 SHAKE ROD USE 1619 1

16209 PWC-SGP150-18 SGP150A SHEAR PIN 1

16301 PWC-SGP150-1631 SGP150 TELESCOPIC HANDLE 1

16401 PWC-SGP15-16401 SGP150A SNAP RING 2

16402 PWC-SGP150-1615 SGP150 RELEASE HANDLE PIN 1

16403 PWC-SGP150-1610 SGP150 RELEASE HANDLE 1

16501 PWC-SGP150-1612 SGP150 REVERSE LEVER 1

16502 PWC-SGP150-1614 SGP150 CONNECTING AXLE 1

16503 PWC-SGP150-1613 SGP150 CONNECTING ROD 1

16504 PWC-SGP150-1613 SGP150 CONNECTING ROD 1

16505 PWC-SPC15-16505 SGP150A SNAP RING 2

16506 PWC-SGP150-1611 SGP150 RELEASE CONNECTING

ROD AXLE

1

16601 PWC-SGP15-16601 SGP150A LONG CLAMP PLATE 2

16602 PWC-SGP15-16602 SGP150A CLAMP PLATE PIN 1

16603 PWC-SGP15-16603 SGP150A UPPER JAW 1

16604 PWC-SGP15-16604 SGP150A LOWER JAW 1

16605 PWC-SGP15-16605 SGP150A CLAMP PLATE 2

16606 PWC-SGP15-16606 SGP150A JAW AXLE 4

16607 PWC-SGP150-1605 SGP150 CONNECTING ROD 2

16608 PWC-SGP15-16608 SGP150A SPRING 1

16609 PWC-SGP150-1607 SGP150 REAR JAW BLOCK 1

16610 PWC-SGP15-16610 SGP150A CLAMP PLATE AXLE 2

16611 PWC-SGP15-16611 SGP150A SNAP RING 4

16701 PWC-SGP150-1628 SGP150 LONG CLAMP PLATE 2

16702 PWC-SGP15-16702 SGP150A CLAMP PLATE PIN 1

16703 PWC-SGP150-1629 SGP150 UPPER JAW 2

16704 PWC-SGP150-1627 SGP150 LOWER JAW 2

16705 PWC-SGP150-1623 SGP150 CLAMP PLATE 1

16706 PWC-SGP150-1630 SGP150 JAW AXLE 4

16707 PWC-SPC150-1625 SGP150 SPRING HOUSING 2

16708 PWC-SGP150-1622 SGP150 SPRING 2

16709 PWC-SGP150-1606 SGP150 FRONT JAW BLOCK 1

16710 PWC-SGP15-16710 SGP150A CLAMP PLATE AXLE 2

16711 PWC-SGP15-16711 SGP150A SNAP RING 4

16103A PWC-SGP15-16103 SGP150 TOP HOOK 1

16103B PWC-SGP150A-SAF SGP150A SWIVEL HOOK SAFETY

LATCH KIT

1

16107A PWC-SGP15-16107A SGP150A SNAP RING 2

16301A PWC-SGP15-16301A SGP150A TELESCOPIC HANDLE

RUBBER GRIP

1

1634 PWC-SGP150-1634 TOP HOOK 1

REF. PART NUMBER DESCRIPTION REQ. REF. PART NUMBER DESCRIPTION REQ.

JGP150A | 1-1/2 T GRIP PULLER PARTS LIST | PROD. NO. 111137

Note: To determine if the puller is old or new style, establish if the unit has a top hook (new) or a pin (old).

See reference numbers 16103 and 16103A located on parts breakdown, for further clarification.

M18-MH111136-38-Eng+Fre-FA.indd 10 2018-07-23 4:11 PM

11

JGP300A | 3 T GRIP PULLER PARTS BREAKDOWN | PROD. NO. 111138

M18-MH111136-38-Eng+Fre-FA.indd 11 2018-07-23 4:11 PM

12

3201 PWC-SGP300-3201 ANCHOR PIN 1

3202 PWC-SGP300-3202 CASE LEFT/RIGHT SIDE 2

3203 PWC-SGP300-3203 LONG HEX HEAD CASE BOLT 1

3204 PWC-SGP300-3204 CRANK AXLE 1

3205 PWC-SGP300-3205 CONNECTING ROD 1

3206 PWC-SGP300-3206 FRONT JAW BLOCK 1

3207 PWC-SGP300-3207 REAR JAW BLOCK 1

3208 PWC-SGP300-3208 ROPE GUIDE 1

3209 PWC-SGP300-3209 HOUSING SCREW BOLT 6

3210 PWC-SGP300-3210 RELEASE HANDLE 1

3211 PWC-SGP300-3211 RELEASE CONNECTING ROD AXLE 1

3212 PWC-SGP300-3212 REVERSING LEVER 1

3213 PWC-SGP300-3213 CONNECTING ROD 2

3214 PWC-SGP300-3214 CONNECTING AXLE 1

3215 PWC-SGP300-3215 RELEASE HANDLE PIN 1

3216 PWC-SGP300-3216 SHAKE ROD 1

3217 PWC-SGP300-3217 CONNECTING ROD 1

3218 PWC-SGP150-18 SHEAR PIN 1

3219 PWC-SGP300-3219 OPERATING LEVER 1

3220 PWC-SGP300-3220 CONNECTING ROD AXLE 1

3221 PWC-SGP300-3221 OPERATING HANDLE AXLE 1

3222 PWC-SGP300-3222 SPRING 1

3223 PWC-SGP300-3223 CLAMP PLATE 2

3224 PWC-SGP300-3224 CLAMP PLATE AXLE 2

3225 PWC-SGP300-3225 SPRING HOUSNG 1

3226 PWC-SGP300-3226 SUPPORT WHEEL 1

3227 PWC-SGP300-3227 LOWER JAW 1

3228 PWC-SGP300-328 LONG CLAMP PLATE 2

3229 PWC-SGP300-3229 UPPER JAW 1

3230 PWC-SGP300-3230 JAW AXLE 4

3231 PWC-SGP300-3231 TELESCOPE HANDLE 1

32101 PWC-SGP300-3209 HOUSING SCREW BOLT 6

32102 PWC-SGP30-32102 NUT 1

32103 PWC-SGP300-3201 ANCHOR PIN 1

32104 PWC-SGP30-32104 HOUSING (LEFT SIDE) 1

32105 PWC-SGP30-32105 BUSH FOR SHAKE ROD

NO LONGER USED

32106 PWC-SGP30-32106 HOUSING (RIGHT SIDE) 1

32107 PWC-SGP75-8107 WASHER 1

32108 PWC-SGP75-8108 SCREW BOLT 1

32109 PWC-SGP30-32109 COVER 1

32110 PWC-SGP150-18 SPARE SHEAR PIN 2

32111 PWC-SGP300-3208 ROPE GUIDE 1

32112 PWC-SGP30-32112 UPPER DUST PROOF 1

32113 PWC-SGP30-32113 LOWER DUST PROOF 1

32114 PWC-SGP30-32114 NAMEPLATE 1

32115 PWC-SGP15-16115 RIVET 8

32116 PWC-SGP30-32116 INSTRUCTION PLATE 1

32201 PWC-SGP300-32201 BUSH FOR CRANK AXLE

NO LONGER USED

32202 PWC-SGP300-3204 CRANK AXLE 2

32203 PWC-SGP300-3220 CONNECTING ROD AXLE 2

32204 PWC-SGP30-32204 BUSH FOR OPERATING HANDLE AXLE 2

32205 PWC-SGP300-3221 OPERATING HANDLE AXLE 1

32206 PWC-SGP300-3219 OPERATING LEVER 1

32207 PWC-SGP300-3217 CONNECTING ROD 1

32208 PWC-SGP300-3216 SHAKE ROD 1

32209 PWC-SGP150-18 SHEAR PIN 1

32301 PWC-SGP300-3231 TELESCOPE HANDLE 1

32401 PWC-SGP30-32401 SNAP RING 2

32402 PWC-SGP300-3215 RELEASE HANDLE PIN 1

32403 PWC-SGP300-3210 RELEASE HANDLE 1

32501 PWC-SGP300-3212 REVERSING LEVER 1

32502 PWC-SGP300-3214 CONNECTING AXLE 1

32503 PWC-SGP300-3213 CONNECTING ROD(LEFT SIDE) 1

32504 PWC-SGP300-3213 CONNECTING ROD(RIGHT SIDE) 1

32505 PWC-SGP30-32505 SNAP RING 2

32506 PWC-SGP300-3211 RELEASE CONNECTING ROD AXLE 1

32601 PWC-SGP30-32601 LONG CLAMP PLATE 2

32602 PWC-SGP30-32602 CLAMP PLATE PIN 1

32603 PWC-SGP30-32603 UPPER JAW 1

32604 PWC-SGP30-32604 LOWER JAW 1

32605 PWC-SGP30-32605 CLAMP PLATE 2

32606 PWC-SGP30-32606 JAW AXLE 4

32607 PWC-SGP300-3205 CONNECTING ROD 1

32608 PWC-SGP30-32608 SPRING 1

32609 PWC-SGP300-3207 REAR JAW BLOCK 1

32610 PWC-SGP30-32610 CLAMP PLATE AXLE 2

32611 PWC-SGP30-32611 SNAP RING 4

32701 PWC-SGP300-328 LONG CLAMP PLATE 2

32702 PWC-SGP30-32702 CLAMP PLATE PIN 1

32703 PWC-SGP300-3229 UPPER JAW 1

32704 PWC-SGP300-3227 LOWER JAW 1

32705 PWC-SGP300-3223 CLAMP PLATE 2

32706 PWC-SGP300-3230 JAW AXLE 4

32707 PWC-SGP300-3226 SUPPORT WHEEL 1

32708 PWC-SGP300-3222 SPRING 1

32709 PWC-SGP300-3206 FRONT JAW BLOCK 1

32710 PWC-SGP300-3224 CLAMP PLATE AXLE 2

32711 PWC-SGP30-32711 SNAP RING 4

32103A PWC-SGP3032103A SWIVEL HOOK(FOR A TYPE) 1

32103B PWC-SGP300A-SAF SAFTEY LATCH W HARDWARE 1

32107A PWC-SGP3032107A SNAP RING(FOR A TYPE) 2

PWC-SGP300-3234 SWIVEL HOOK 1

REF. PART NUMBER DESCRIPTION REQ. REF. PART NUMBER DESCRIPTION REQ.

JGP300A | 3 T GRIP PULLER PARTS LIST | PROD. NO. 111138

M18-MH111136-38-Eng+Fre-FA.indd 12 2018-07-23 4:11 PM

This manual suits for next models

3

Table of contents

Other Surewerx Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

electronica

electronica EL 750 Operational manual

EC POWER

EC POWER XRGI 6 Maintenance Instruction

LCM SYSTEMS

LCM SYSTEMS CPA Operator instructions

Luminator

Luminator RR-GPS 18 Series Installation and setup manual

IAI

IAI ELECYLINDER EC-RTC9 instruction manual

Wilo

Wilo Helix V 2 Installation and operating instructions