electronica EL 750 Quick start guide

EL 750

Operational Manual

Digital Readout System

For

Machine Tool

EL750

2 | P a g e

Table of Contents

1.

INTRODUCTION ................................................................................................................................................... 4

2.

DRO SPECIFICATIONS ........................................................................................................................................... 5

3.

READ BEFORE PROCEEDING ................................................................................................................................. 6

4.

GETTING STARTED ............................................................................................................................................... 7

4.1

F

RONT

V

IEW

.............................................................................................................................................................. 7

4.2

R

EAR

V

IEW

................................................................................................................................................................ 8

4.3

K

EYBOARD LAYOUT

...................................................................................................................................................... 9

4.4

S

OFT

K

EYS

................................................................................................................................................................ 10

4.5

P

OWER

S

UPPLY

......................................................................................................................................................... 12

4.6

E

NCODER

C

ONNECTIONS

............................................................................................................................................. 12

4.7

P

OWER

UP .............................................................................................................................................................. 13

4.8

S

CREEN

L

AYOUT

........................................................................................................................................................ 14

5.

SETUP ................................................................................................................................................................. 15

5.1

ENERAL

S

ETTIN S

: ................................................................................................................................................... 16

5.2

A

XIS

S

PECIFIC

S

ETTIN S

(L

INEAR

T

YPE

): ......................................................................................................................... 16

5.3

A

XIS

S

PECIFIC

S

ETTIN S

(A

N ULAR

T

YPE

): ..................................................................................................................... 18

5.4

E

RROR COMPENSATION

.............................................................................................................................................. 20

5.4.1

Error compensation for linear Axis .............................................................................................................. 20

5.5

M

ACHINE REFERENCE

................................................................................................................................................. 24

6.

PRIMARY FUNCTIONS ......................................................................................................................................... 25

6.1

A

BSOLUTE

/

I

NCREMENTAL MODE

(ABS

/

INC) ............................................................................................................... 25

6.2

I

NCH

M

ETRIC

D

ISPLAY

(I

N

/

MM

) ................................................................................................................................. 25

6.3

A

XIS

S

ET

/R

ESET

........................................................................................................................................................ 26

6.3.1

Axis Set: - ..................................................................................................................................................... 26

6.3.2

Axis Reset: - ................................................................................................................................................. 26

6.4

H

ALF

F

UNCTION

........................................................................................................................................................ 26

6.5

P

ROBE

M

EASUREMENT

............................................................................................................................................... 27

6.6

C

ALCULATOR

............................................................................................................................................................ 32

6.7

S

ETTIN

R

EFERENCE

.................................................................................................................................................. 33

6.7.1

Homin reference........................................................................................................................................ 33

6.7.2

Recallin machine reference ....................................................................................................................... 33

7.

SECONDARY FUNCTIONS .................................................................................................................................... 35

7.1

P

RESET

.................................................................................................................................................................... 35

7.2

S

UB

D

ATUM

M

EMORY

(SDM) .................................................................................................................................... 35

7.3 Soft Limit Settings….…………….………..…………………………………………………………………………………………………………..38

7.4 Vibration Filter (Digital Filter)…………………………………………………………………………………………………………………………..38

7.5 Feed rate display………………………………………………………………………………………………………………………………………………39

8.

MACHINE SPECIFIC FUNCTIONS .......................................................................................................................... 40

8.1

M

ILLIN

M

ACHINE

S

PECIFIC

F

UNCTIONS

:- ..................................................................................................................... 40

8.1.1

Circular Bolt Hole Function (PCD) ................................................................................................................ 40

8.1.2

Arc Bolt Hole Function ................................................................................................................................. 41

8.1.3

Custom Bolt Hole ......................................................................................................................................... 42

8.1.4

Line Hole ...................................................................................................................................................... 44

EL750

3 | P a g e

8.1.5

Grid ............................................................................................................................................................. 45

8.1.6

Frame: - ....................................................................................................................................................... 46

8.1.7

Arc Contourin : - ......................................................................................................................................... 47

8.1.8

R- Function .................................................................................................................................................. 48

8.1.9

Pocket: - ...................................................................................................................................................... 50

8.1.10

Slot ......................................................................................................................................................... 50

8.1.11

Polar Coordinates ................................................................................................................................... 52

8.1.12

Axis Summin ......................................................................................................................................... 52

8.1.13

Zero Approach ........................................................................................................................................ 52

8.1.14

Shrinka e Factor .................................................................................................................................... 53

8.1.15

Tools ....................................................................................................................................................... 54

8.2

L

ATHE

M

ACHINE

S

PECIFIC

F

UNCTIONS

:-......................................................................................................................... 55

8.2.1

Summin ..................................................................................................................................................... 55

8.2.2

Vectorin ..................................................................................................................................................... 56

8.2.3

Taper ........................................................................................................................................................... 57

8.2.4

Tools ............................................................................................................................................................ 57

9.

AUXI IARY FUNCTIONS ....................................................................................................................................... 59

9.1

I

NPUT

...................................................................................................................................................................... 59

9.2

O

UTPUT

.................................................................................................................................................................. 59

9.3

S

ERIAL

C

OMMUNICATION

........................................................................................................................................... 60

10.

TROUB ESHOOTING ........................................................................................................................................... 62

10.1

S

ELF

D

IA NOSTICS

M

ODE

...................................................................................................................................... 62

11.

DRO MODE S...................................................................................................................................................... 63

EL750

4 | P a g e

1. Introduction

Congratulations on purchasing EL750 series Digital Readout System (DRO) from

Electronica Mechatronic Systems. Our DRO incorporates the latest state of the art

technology; giving you world class features which help in improving productivity, reducing

rejection and at the same time giving ease of operation to user with its ergonomic design.

Some of the key features of EL750 series DRO are:

Adaptability to various types of machines, old and new, simple and complex.

Ease of installation.

Soft touch keyboard for improved life and ease of operation.

4 axes version with provision of 4 axes display with option of internal summing of two

axes.

Display of dynamic tool position improving productivity and ease of operation.

Note: Please familiarize yourself with the contents of this Operators

manual to benefit from all features provided by EL750 DRO.

Electronica Mechatronic Systems (I) Pvt. Ltd. Reserves the right to

change specifications without prior notice.

EL750

5 | P a g e

2. DRO Specifications

Electrical:

Mains Supply: 90 VAC to 265 VAC (50 / 60 Hz)

Fuse Rating: 800mA Slow Blow 20mm

Power Consumption: 15W SMPS

Standard Compliance: EMC and Low Voltage Compliance BS

EN61326 RoHS

Environmental:

Storage Temperature: -20ºC to +70ºC

Operating Temperature: 0ºC to 50ºC

Relative Humidity: 20% To 85% Non-Condensing

Mechanical:

Dimensions (mm) 192 mm X 290 mm X 76 mm

Height X Width X Depth

Net Weight: Approx1.5 Kg

Display: 7” Colour TFT Display with LED backlight.

Connections

Encoder Input: RS422

Encoder Connector Type: 9-Pin D-Type Female

Encoder Resolution Supported: 0.1/0.2/0.5/1/2/5/10/20/50/100 Micron

Auxiliary Connectors: 15-Pin D-Type Female for Auxiliary Output

(Optional), Encoder Jack Plug connector for

Probe input. USB B type Connector

ISO 9001

COMPANY

EL750

6 | P a g e

3. Read Before Proceeding

The EL750 DRO is sophisticated electronic equipment and should be carefully

handled to avoid any damage.

The rated supply to DRO should be within specified limits and should not be

exceeded under any circumstances. Doing so may cause irreversible damage to

DRO.

DRO should be opened by authorized person only. Otherwise it will invalidate the

warranty of the unit.

Equipotential Point (Ground) should be provided to avoid erratic operations of DRO.

Cable routing of DRO and encoders should not be routed through or nearby high

capacity switching/inductive load or where it can cause danger.

EL750 DRO is standard compliant with

•

EMC Directive EN61326 Standard 61326-4-2, 61326-4-4, 61326-4-11, 61326-

4-5, CISPR 16-1 and 16-2.

•

RoHS compliant.

Warranty will be considered void if and not limited to

•

Failing to meet manufacturers specified supply conditions.

•

Abusive handling.

•

Environmental conditions outside of Manufacturers specifications.

•

Manipulation, tampering of electronics.

•

Replacement of original parts with other parts than specified by manufacturer.

•

Used with encoders other than those supplied by the manufacturer.

Disposal

At the end of its life the EL750 DRO systems should be disposed of in a safe and

environmentally sympathetic manner as applicable to local legislation. The casework

and other components may be suitable for recycling. DO NOT BURN.

EL750

7 | P a g e

4. Getting Started

4.1 Front View

Axis

Keys

Numeric

Keypad

Basic

Operation

DRO

Display Soft Keys Arrow Keys

EL750

8 | P a g e

4.2 Rear View

Encoder

Inputs

Manufacturers

label with Serial

Number

Power Inlet

IEC Connector Equipotential

Point (Ground

terminal)

Power ON

Switch

Fuse (Spare included)

800mA Slow Blow

20mm

Probe

Connector

USB B type

connector

Auxiliary

Connector

Optional

EL750

9 | P a g e

4.3 Keyboard layout

Symbols Description

FUNCTION KEYS

ABS / INC

Inch / mm

Reference

Preset

SDM Function

---

Numeric Keys

NUMERIC

KEYBOARD

Toggle Sign

Decimal Entry

Enter

Cancel

Navigation Keys

Soft key Selection / Axis Selection COMMON

OPERATIONS

LCD standby Key

EL750

10 | P a g e

4.4 Soft Keys

Key Description

Machine reference

Homing

Set reference

Diameter

Mill/Lathe Tool set

Delete tool

Tool On

Tool Off

Vector Angle

SDM ON

Next SDM

Delete SDM

Select NO

OFF

ON

Output configuration Key

Input configuration Key

Linear encoder mode

Angular encoder mode

Probe

Key Description

Height Measurement

Corner Measurement

Angle measurement

Skew Measurement

Internal measurement

External Measurement

Datum

Calculator

Calculate

Diameter

Internal diameter

External diameter

Linear Measurement

Step Length

Measurement

Center

English

Open

Select

Exit

Function

Half

EL750

11 | P a g e

Key Description

New job

Job delete

Linear Compensation

Segmented

compensation

Save

Edit

Multimode

Single

Set

Reset

Setup

Select

Zero

Probe measurement

Key Description

Next arrow

Next hole

Apply the tool

Exit from tool

Plane selection

No

Yes

Plane Selection

Position

EL750

12 | P a g e

4.5 Power Supply

The EL750 DRO series uses a Switch mode power supply inside which covers the

universal power input range i.e. 90VAC to 265VAC / 50 to 60 Hz. Ensure the input power is

within the specifications before powering the unit.

The power supply to the DRO should not be given from the same source as that of any high

capacity switching / inductive loads to avoid interference. Ensure proper equipotential point

(Ground) connection is provided to the DRO to avoid any erratic operations.

4.6 Encoder Connections

Note:

*

1 – ABS is Reference Mark.

*2 – Ensure proper shielding of the encoder cables for proper functioning of the encoder

and the DRO.

Encoder Cable should be properly routed as per manufacturer’s guidelines. Cable

should not be routed near any inductive loads to avoid electrical noise interference.

It should be routed away from the machine moving parts to avoid any damage.

Pin

Number Output Signal

1 ABS

*1

2 /ABS

3 VCC (+5V)

4 Shield

*2

5 GND (0V)

6 Phase A

7 Phase /A

8 Phase /B

9 Phase B

EL750

13 | P a g e

4.7 Power UP

Switch ON the power switch located on the back of the DRO. The DRO will display the

power UP message momentarily as shown below

*Owing to continuous Research & Development software version may be different

than displayed.

EL750

14 | P a g e

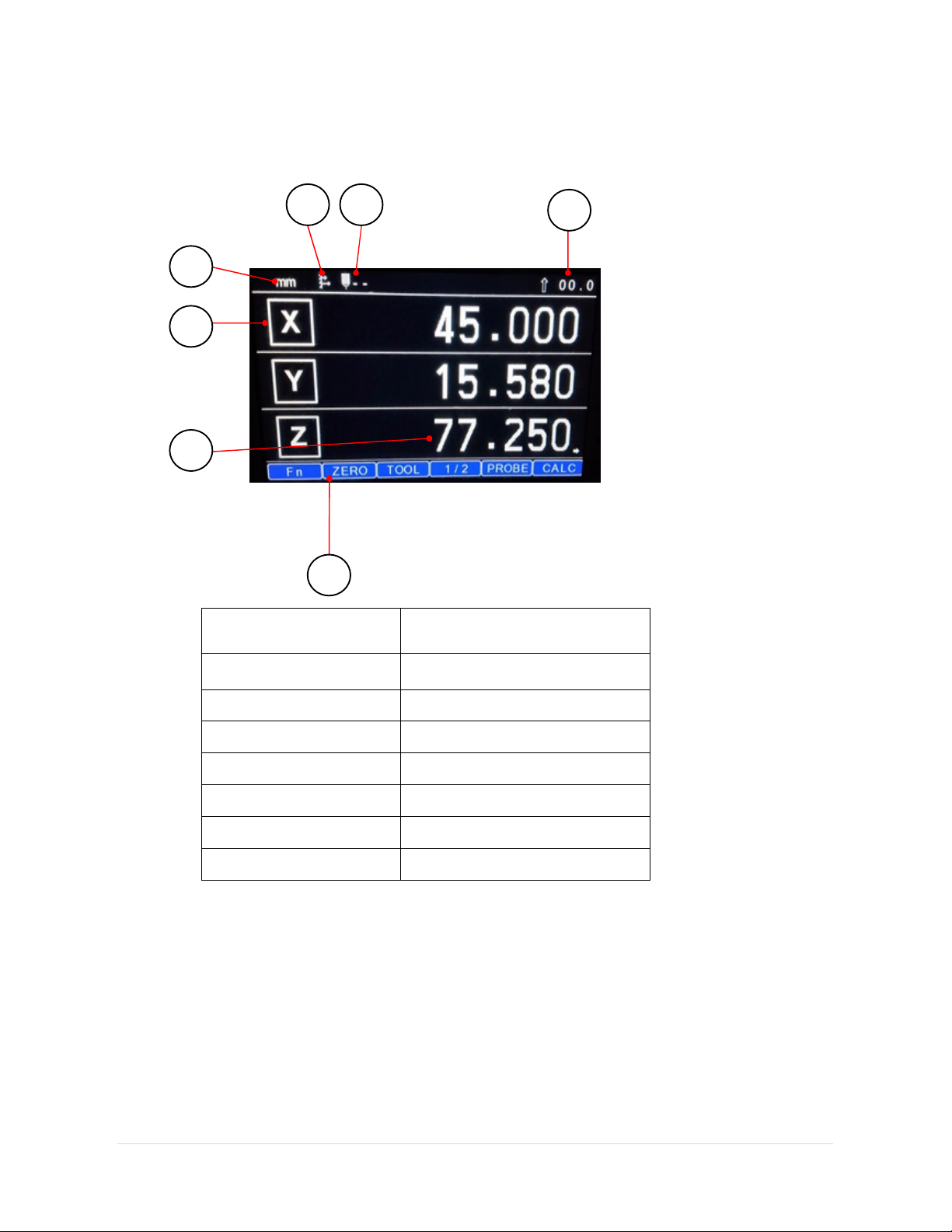

4.8 Screen Layout

Sample screen of EL750 DRO, Labels description is as below.

Labels Description

1

Feed rate

2 Tool No.

3 ABS/ Inc mode

4 Inch / MM

5 Axis Label

6 Display Area

7 Soft key notification

1

2

3

4

5

6

7

EL750

15 | P a g e

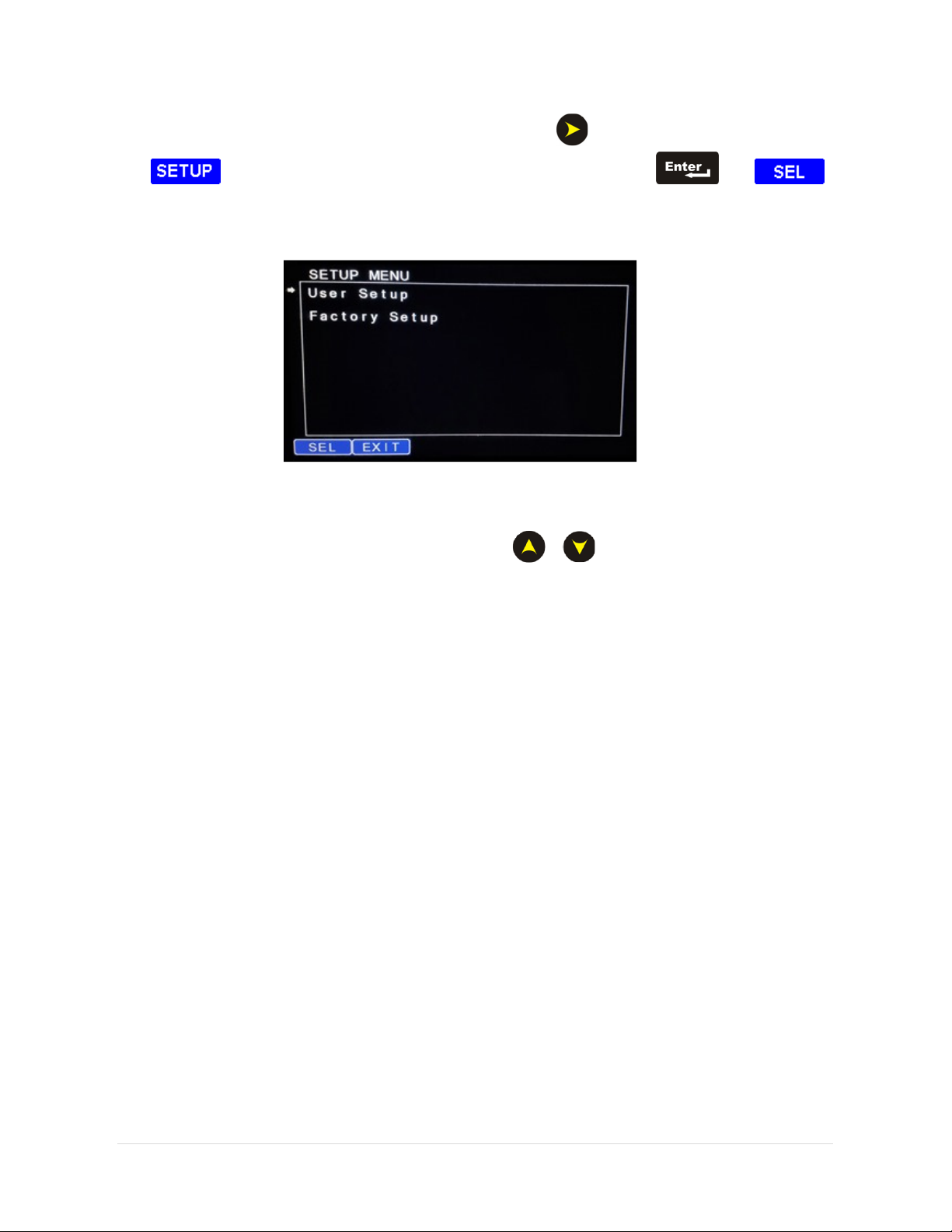

5. Setup

The EL750 setup can be accessed by pressing [ ] key followed by SOFT KEY

{ }. The SETUP mode screen is as shown below. Press [ ] or { }

key to access the setup.

•

Different menus can be navigated using [ ] [ ] keys.

•

Options for each field to be selected are displayed at the SOFT Key labels. A

particular option can be selected using the SOFT key.

Note

: In this manual, following notations will be used

[name] denotes a dedicated key name

{name} denotes a Soft key name

EL750

16 | P a g e

5.1 General Settings:

Sr.

no. User Setup

Parameters Description

1 Sleep Mode Time

(min)

Defines Sleep Time Interval in minutes (5 to 120).

2 Key Beep Enable

To enable or disable keyboard beep ON or OFF.

3 Zero App. Beep En

To enable or disable Zero Approach Beep ON or OFF.

4 Zero App. Tolerance

This sets a tolerance value for Zero Value in Zero approach

modes.

5 Diagnostics

This can be used checking the Keyboard, Encoder, Probe,

and Display as diagnostic tool.

6 Select Axis

This is used for setting axis specific parameters. (Axis

parameters are given below in 5.2 & 5.3)

7

Serial

communication

Enables the user to set the Serial communications

parameters.

8

Recall OEM setting

Recalling OEM settings will reset all the users settings

related to Axis and Auxiliary I/O to Standard OEM setting.

9

Auxiliary Setup

This options enables user to configure auxiliary Inputs &

Outputs

10

Machine Model

User can select Mill or Lathe machine functionality as per

application requirement.

11

Save & Exit

To save the changes and exit from setup.

12

Exit without saving

Exit from setup without saving changes.

5.2 Axis Specific Settings (Linear Type):

1. Scale Resolution:

This option is available for all axes if configured as linear type.

The options available are 0.1 µm, 0.2 µm, 0.5 µm, 1 µm, 2 µm, 5 µm, 10 µm, 20

µm, 50 µm and 100 µm. The default value is

5µm

.

2. Display Resolution:

Option available for all axis, resolution settings available

are 0.1 µm, 0.2 µm, 0.5 µm, 1 µm, 2 µm,

5µm

, 10 µm, 20 µm, 50 µm and 100 µm

if the axis is configured as linear type.

3. Axis Direction:

The counting direction can be set either Left or Right for each

individual axis. The default value is

left

direction.

4. Axis Mode:

The Axis mode can be set either Radius or Diametric for each

individual axis. This is valid only if the DRO is configured as Lathe model. In Mill

model, all axes are forced to RAD mode.

5. Machine Reference:

Keep the encoder position near to the desired reference on

the encoder.

EL750

17 | P a g e

Procedure:-

1) Press { } key in “Machine Ref.” in axis settings. “Homing” Message is

shown on the screen.

2) Pass the reference mark on the encoder. Here the DRO will reset the axis on

the reference mark.

3) Go to the machine reference position and press { }.

6. Zero App. Distance:

Zero Approach Distance is the distance band for zero

approach beep which is used to get operators attention when the axis count is

within the band. There is also a proportional bar graph display that is shown

below the axis display. The default value is “1.000 mm”.

7. Calibrate Axis:

Axis calibration is required to compensate for errors arising due

to wear and tear, encoder misalignment etc. Each axis can be calibrated for

Linear Errors or Segmented errors as applicable. The detailed procedure for

calibration is explained in section 5.4.

8. Apply Compensation:

The type of compensation applied to selected axis is

programmed here. Three options are possible NONE, LEC and SLEC. The

default compensation type is set “NONE”.

9. Soft Limit Settings

: It is used to indicate end point of machine slide. Soft limit

can be turn ON/OFF with desired positive and negative settings

.

The soft limit

working on pure absolute value.

10. Vibration Filter:

In some applications because of vibration or unstable scale the

values of the display could become unstable and unreadable. For example in

grinding application because of the grinding machine vibration the values of the

DRO display can become unstable. It disturbs the user. So this vibration filter

function will help the operator to read the position correctly.

EL750

18 | P a g e

5.3 Axis Specific Settings (Angular Type):

1. Counts per Revolution. (CPR):

This parameter defines the Encoder counts per

rotation. Either the operator can enter this value if this is known or there is an

automatic calibration process for finding the CPR value. In the automatic process,

the user is prompted to pass two reference marks in the same direction. The

DRO counts within them, and sets the CPR value. The default value is 4096.

2. Resolution (Deg.):

This parameter defines the Display resolution in degrees.

The default value is

0.1

degrees. The different display resolutions are available

based on CPR value.

CPR Value Resolution available (degrees)

CPR < 3600 0.5

CPR < 7200 0.5, 0.1

CPR < 36000 0.5, 0.1, 0.05

CPR < 72000 0.5, 0.1, 0.05, 0.01

CPR >= 72000 0.5, 0.1, 0.05, 0.01, 0.005

3. Reference Mode

: This defines which reference mode to select, internal or

external. For internal mode, the DRO uses the encoder reference mark for

referencing. For external mode, the DRO senses an external input (Input 4) first

and then references the DRO on encoder internal reference mark. This mode can

be used where sometimes one machine rotation corresponds to more encoder

rotations due to gear coupling. The default is set to internal.

Note:- External Reference is available only for options DRO

4. Axis Direction

: This defines the counting direction of the encoder, clockwise

(CW) or counter-clockwise (CCW). The default is set to CW.

5. Count Mode

: Under this parameter there are two options:

Rollover: The angle rolls back to zero after 360

°

.

Continuous: The angle continues accumulating after 360

°

.

The default is set to Continuous mode.

6. Machine reference

: There are two types of reference mode, as described In

section 5.3.3

a. Internal reference: -This is similar to that in linear. Only thing the value

is set in degrees.

b. External mode: - The DRO senses an external input first and then

references the DRO on encoder internal reference mark.

7. Display Mode

: The angular axis is configurable for two possible options.

a. DDMMSS – Degrees: Minutes: Seconds (00.00.00).

b. DDDEC – Degrees Decimal (0.0000).

The default mode is DDMMSS.

EL750

19 | P a g e

8. Axis Lock

: Two options are possible for this parameter.

a. Axis Lock ON

b. Axis Lock OFF.

Axis Lock ON prevents the operator from axis setting in absolute mode. Only the

operator can perform referencing. The default value is Axis Lock OFF.

9. Zero App. Angle

: This is similar to the Zero Approach distance in linear mode.

Only the setting is in angular mode. The default value is 10.00.00.

10. Zero App. Tolerance

: This is similar to the Zero approach tolerance in linear

mode. Only the setting is in angular mode. The default value is 0.00.00.

11. Vibration Filter:

In some applications because of vibration or unstable scale the

values of the display could become unstable and unreadable. For example in

grinding application because of the grinding machine vibration the values of the DRO

display can become unstable. It disturbs the user. So this vibration filter function will

help the operator to read the position correctly.

Note

The changes made in the setup mode should be saved by using “Save and Exit”.

Note that the options for each Menu item are displayed on the Soft key label.

User has to press the correct soft key for required settings.

In 4 axis mode, use up key { } to toggle display of Z and U axis in normal

counting mode of DRO.

EL750

20 | P a g e

5.4 Error compensation

These deviations in job accuracies could be the errors in screw pitch of machine or result of

deflection / tilting of axes or encoder installation.

These can be linear or non-linear and can be determined with the help of Standard

measuring system or a high accuracy slip gauge / gauge block.

5.4.1 Error compensation for linear Axis

5.4.1.1 Linear Error Compensation (LEC)

Linear error compensation can be applied, if the results of the comparison with a reference

standard show a linear deviation over the whole measuring length. In this case the error

can be compensated by the calculation of a single correction factor.

Procedure:-

Scroll to “SELECT AXIS” in user setup mode, select the required axis to calibrate using ‘X’,

‘Y’, ‘Z’, ‘U’ soft keys. Following screen will be displayed in axis settings.

•

Error compensation should be done only in case job accuracies are

not as per expectations.

•

If job accuracies are acceptable, the error compensation should not

be performed.

This manual suits for next models

12

Table of contents

Other electronica Industrial Equipment manuals