1. Health and safety at work.

IT IS ABSOLUTELY FORBIDDEN:

-RUN THE DRYER WHEN PEOPLE ARE INSIDE

-RUN THE DRYER IF THE DOOR IS INCORRECTLY CLOSED

-TO OPERATE THE DRYER BY A PERSON OTHER THAN THE OPERATOR

TRAINED BY THE MANUFACTURER

-USE THE DRYER IN CASE OF ANY FAILURE

-MAKE ANY MODIFICATIONS TO THE DRYER

-USE THE DRYER FOR PURPOSES OTHER THAN DRYING RAW WOOD

NOT SOAKED IN AGENTS LOWERING ITS IGNITION TEMPERATURE,

-BRING FLAMMABLE MATERIALS INSIDE, SMOKE IN THE VICINITY,

-OPEN THE DRYER DOOR WHILE THE MOTOR IS RUNNING.

THERE MUST BE EASILY ACCESSIBLE IN THE VICINITY OF THE DRYER

APPROPRIATE EXTINGUISHING MEDIA IN SUFFICIENT QUANTITY!

The dryer operator should pay attention to the following:

-Before loading wood into the dryer, check that there are no people inside, and:

inflammable, dusty, toxic materials and wood residues: bark, sawdust, chips, knots, etc.

(it is necessary to keep the inside of the drying room clean),

-make sure there are no people inside the chamber before closing the door,

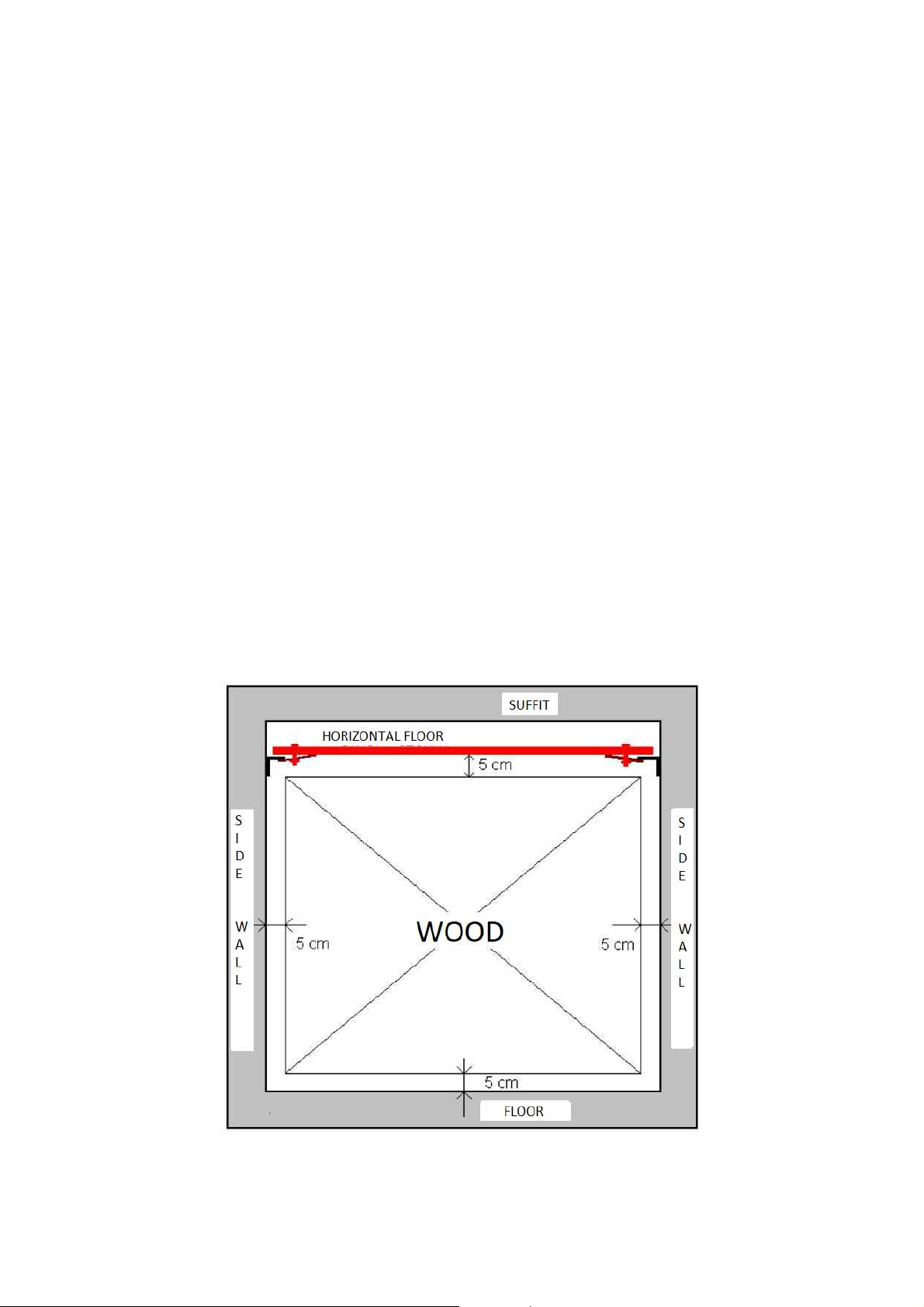

-when filling the drying room with wood, keep a distance of at least 25 cm from the

protective shutter of the turbine system,

-regularly check the condition of the rails, the suspension and the trolleys, as well as the

leveling of the suspension. The raid must be levelled both in length and width,

-Before starting the dryer, make sure that there are no people inside,

-Check the functionality of the residual current circuit breaker on a monthly basis using

the test button on the breaker,

-Check every 6 months whether the terminals of devices installed inside the electrical

switchboard have come loose,

-check protective installation and short circuit loop impedance annually,

-during drying it is necessary to follow the temperature parameters, to pay attention that

the temperature does not exceed 70

O

C. In case of exceeding the temperature threshold

one should immediately switch off the drying room,

-in case of any dryer malfunctions - knocks, vibrations, other non-standard

and unnatural symptoms, stop the drying process immediately and contact the dryer

manufacturer,

-in case of fire (smoke escaping through the vents fitted on the chamber door, or from

anywhere else), an extinguishing action should be taken as soon as possible. Before

taking the extinguishing action, disconnect the electrical supply. Use extinguishing

agents approved for extinguishing electrical installations,

-In winter, excess snow must be removed from the roof, and it is prohibited to walk on

the roof,

-when the dryer is not in use, set the main switch to the position 0 (off) and secure it

with a padlock in this position.