Bringing the Benefits of Real-Time Data Collection to the World

Sutron Corporation, 22400 Davis Drive, Sterling, Virginia 20164-4444

1

Table of Contents

1. Introduction....................................................................................................................... 3

2. Quick Start ....................................................................................................................... 4

3. Cabling ............................................................................................................................. 5

Sutron-Supplied Cable.............................................................................................................. 5

Terminal Strip .......................................................................................................................... 5

SDI-12 Wiring .......................................................................................................................... 6

RS-232 Wiring ......................................................................................................................... 6

Analog Wiring .......................................................................................................................... 7

4. Setup and Operation ........................................................................................................ 8

Introduction .............................................................................................................................. 8

Nomenclature ........................................................................................................................... 8

Setting the Address ................................................................................................................... 8

Using Switches to Set the Address ............................................................................. 9

Using a command to Set the Address ......................................................................... 9

Verifying the Address and Operation ....................................................................................... 10

Commands (Overview) ............................................................................................................. 11

Making a Measurement ............................................................................................................ 12

Selecting a measurement command class ................................................................... 12

Always supported ......................................................................................... 12

Multiple long measurement time sensors ..................................................... 12

Improved data integrity checking ................................................................. 12

Making a non-concurrent Measurement (M command) ............................................. 12

Making a Concurrent Measurement (C command) .................................................... 14

Making a non-concurrent Measurement with CRC-16 (MC command)..................... 15

Making a Concurrent Measurement with CRC-16 (CC command) ............................ 16

Other Measurements .................................................................................................. 18

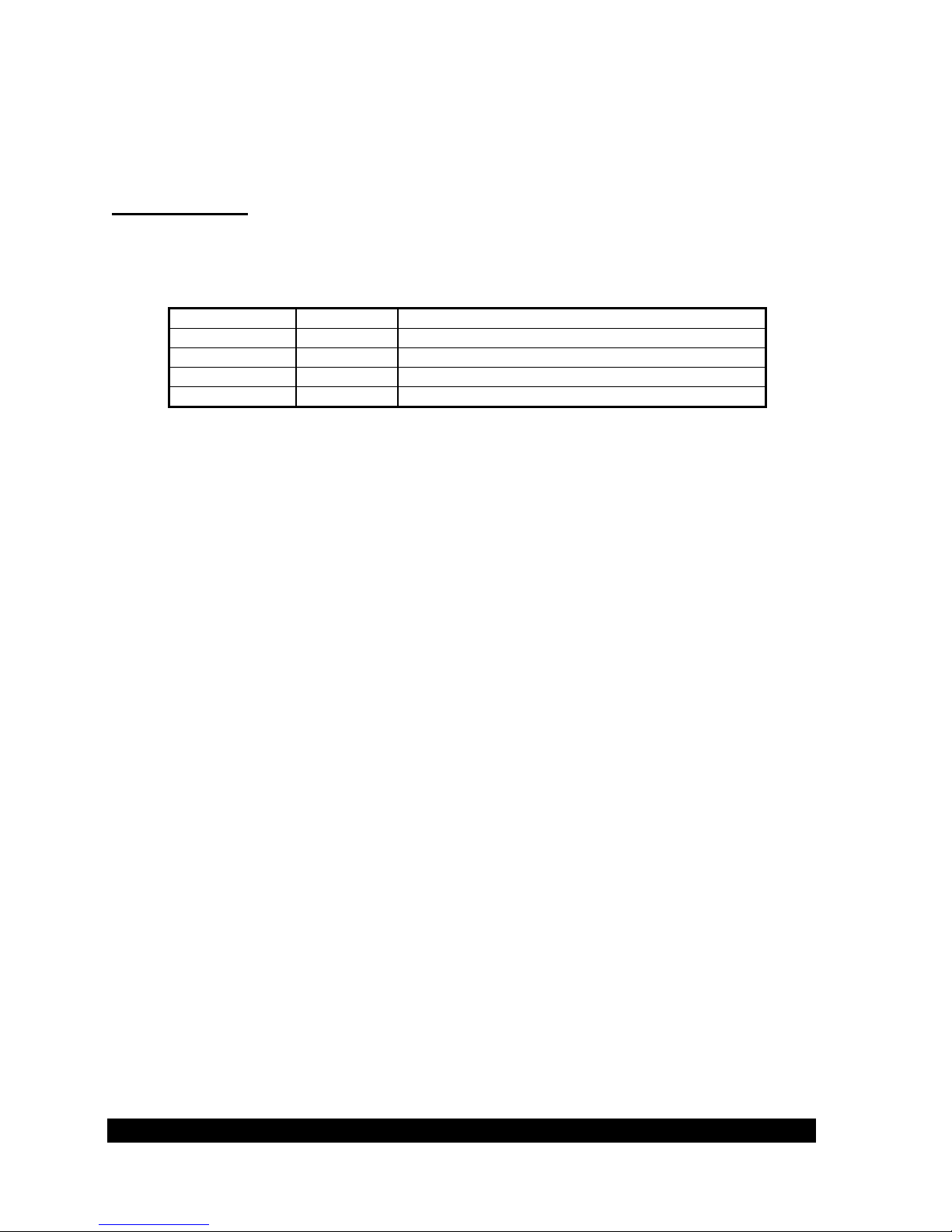

Changing the Units ..................................................................................................... 18

Setting User Units ...................................................................................................... 19

Setting Station Elevation ............................................................................................ 19

Analog Output Range ................................................................................................. 20

Converting Voltage to Pressure .................................................................................. 21

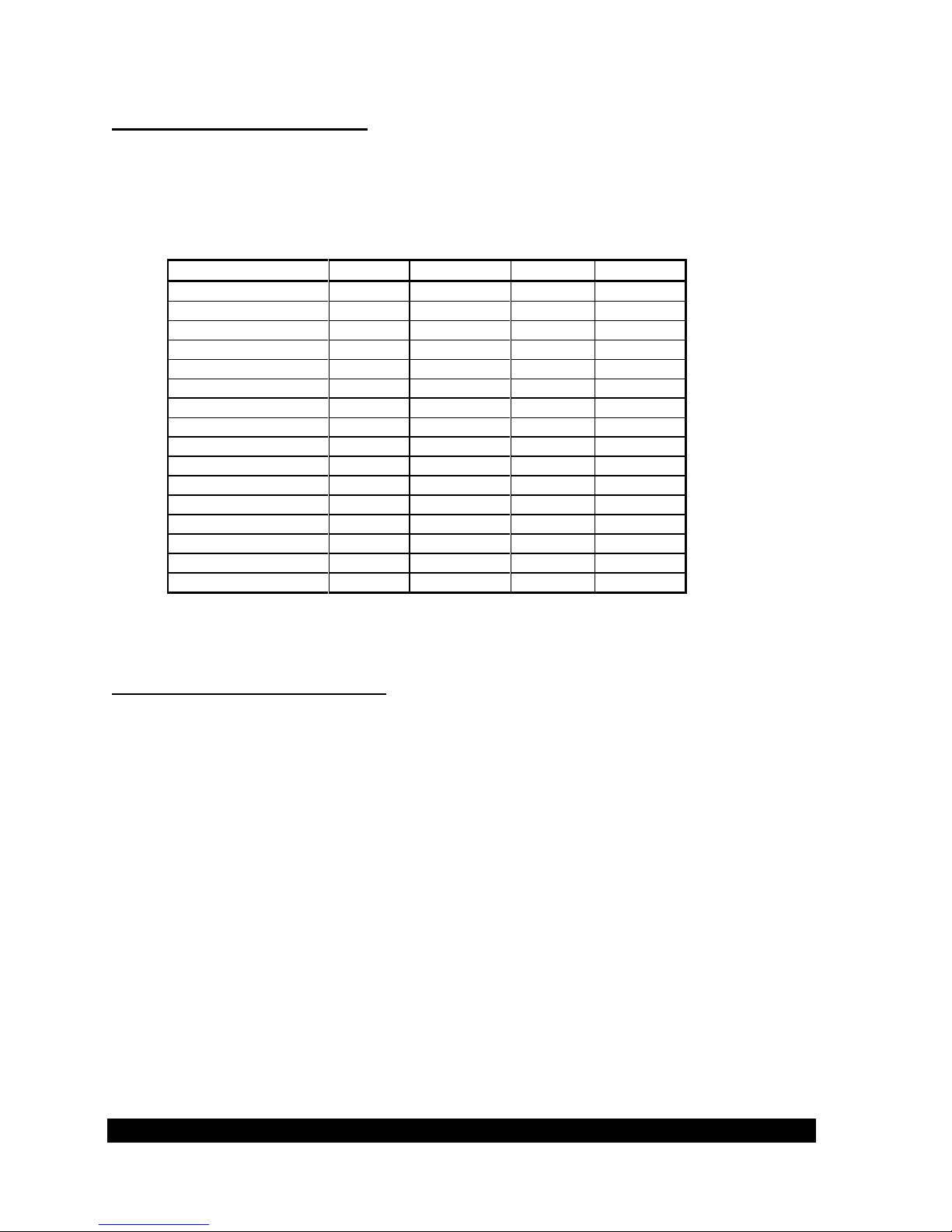

Configuring the Operating Mode and Averaging Time ............................................................ 22

Setting the Operating Mode ....................................................................................... 22

Setting the Averaging Time........................................................................................ 22

Resetting the unit to Factory Default Configuration ................................................................. 23

5. Command Reference ....................................................................................................... 24

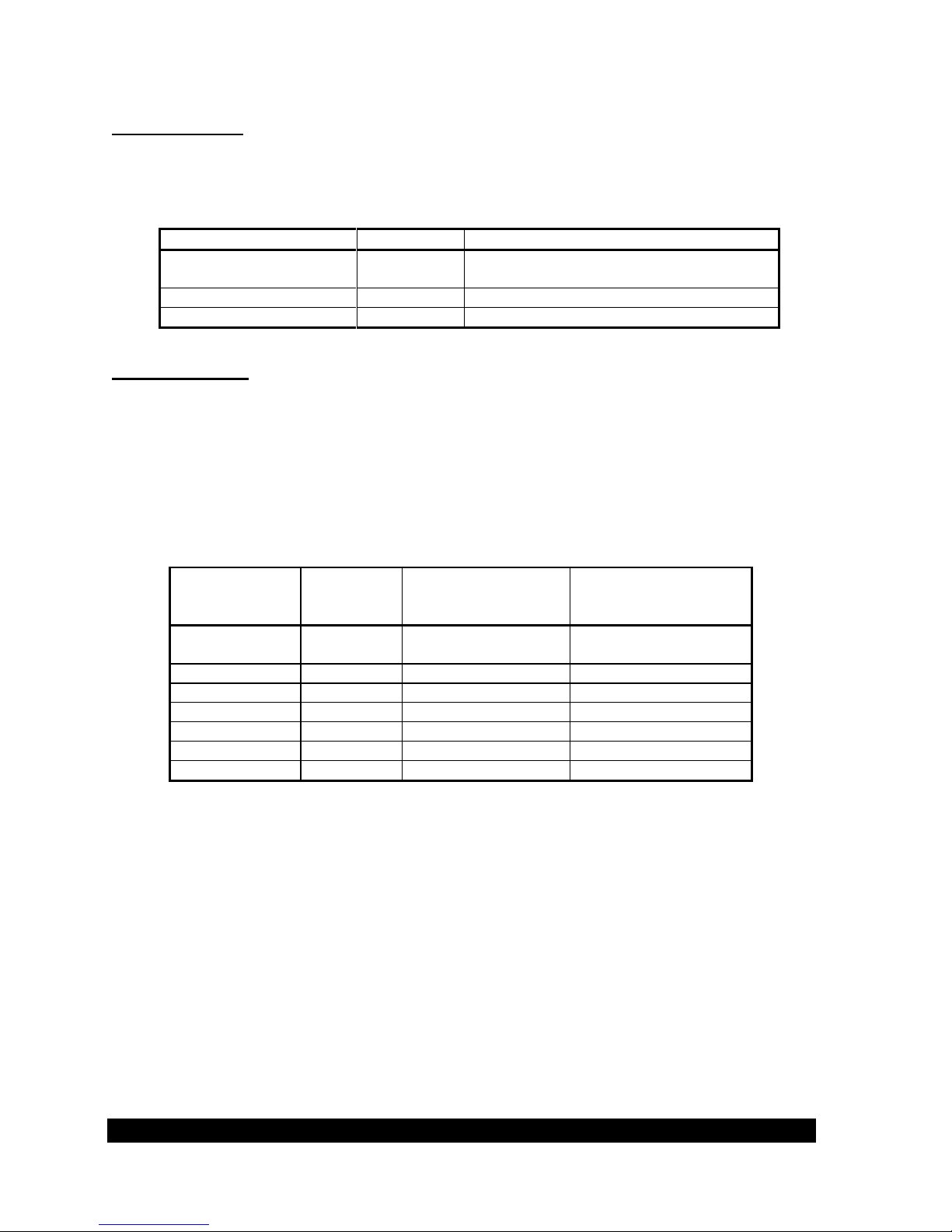

Accubar Basic SDI-12 Commands ........................................................................................... 24

Accubar Extended Commands ................................................................................................. 33

Additional commands for Analog output units (-2) .................................................................. 36

6. Installation ........................................................................................................................ 37

7. Calibration ........................................................................................................................ 38

Factory Calibration ................................................................................................................... 38

Metrology Lab Calibration ....................................................................................................... 38

8. Troubleshooting and Maintenance ................................................................................... 40