PH Series

Pressure Transducer – Wet Media

INSTALLATION INSTRUCTIONS

• Read instructions thoroughly prior to install

Applications shown are suggested means of installing sensors, but it is

the responsibility of the installer to ensure that the installation is in

compliance with all national and local codes and OSHA requirements.

Installation should be attempted only by individuals familiar with

proper installation techniques and with codes, standards, and proper

safety procedures for control installations. Warning: Do not use on

oxygen service, in an explosive/hazardous environment, or with

flammable/combustible media.

Install the PH Series in any stainless compatible media application.

Media must be compatible with 17-4 PH stainless steel.

A unique retainer bracket design eliminates the requirement for a

back-up wrench on the sensor fitting.

PH models can handle overload pressure of 2x’s maximum full scale

range. Burst pressure is 5x’s maximum full scale range.

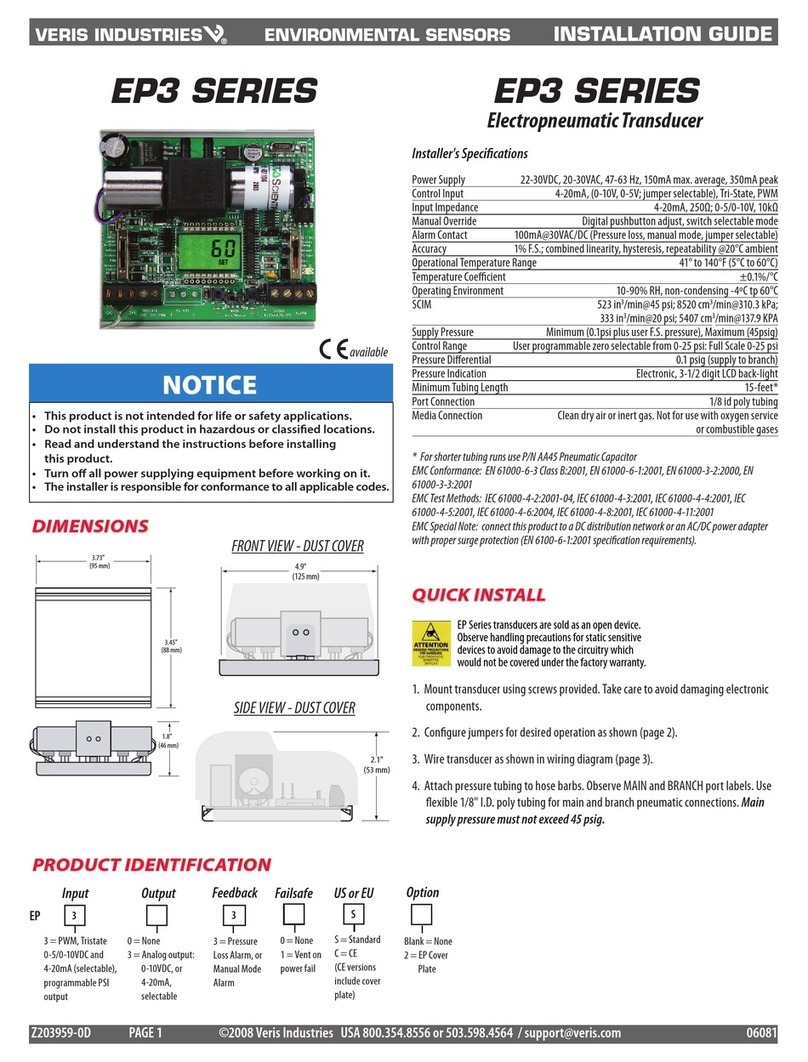

CONFIGURATION

#Z102149-0I

OPERATION

Test Mode: Test mode overrides output to full-scale. If product is

configured for current (mA) operation, output will be

20.0 mA in test mode. If product is configured for

voltage (VDC) operation, output will be 5.0 VDC or

10.0 VDC in test mode. (depending on position of JP2

output span jumper.)

Status LED: Status LED glows green to indicate normal operation.

Status LED glows red to indicate overpressure. Status

LED flashes red to indicate other fault condition.

TARE (Zero): Press and hold the “TARE” push-button for 2 seconds or

provide contact closure on auxiliary “REMOTE TARE”

terminal to automatically reset output to zero

pressure. To protect the unit from accidental tare, this

feature is enabled only when detected pressure is

within 5% of factory calibration.

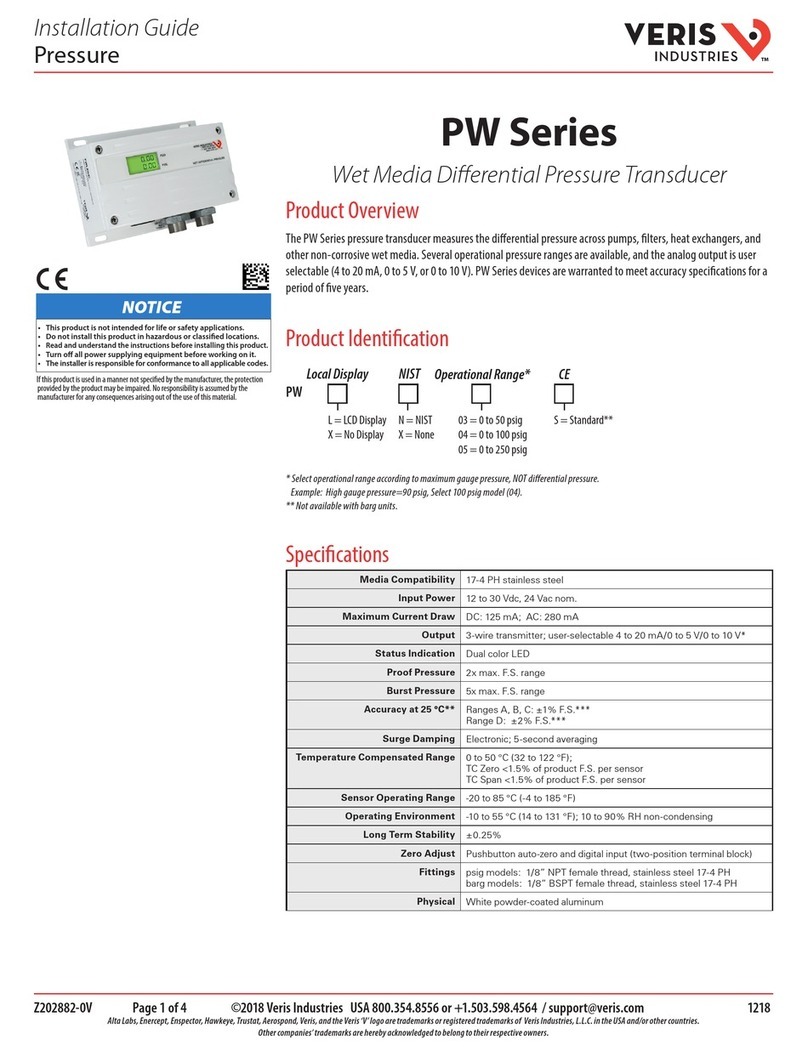

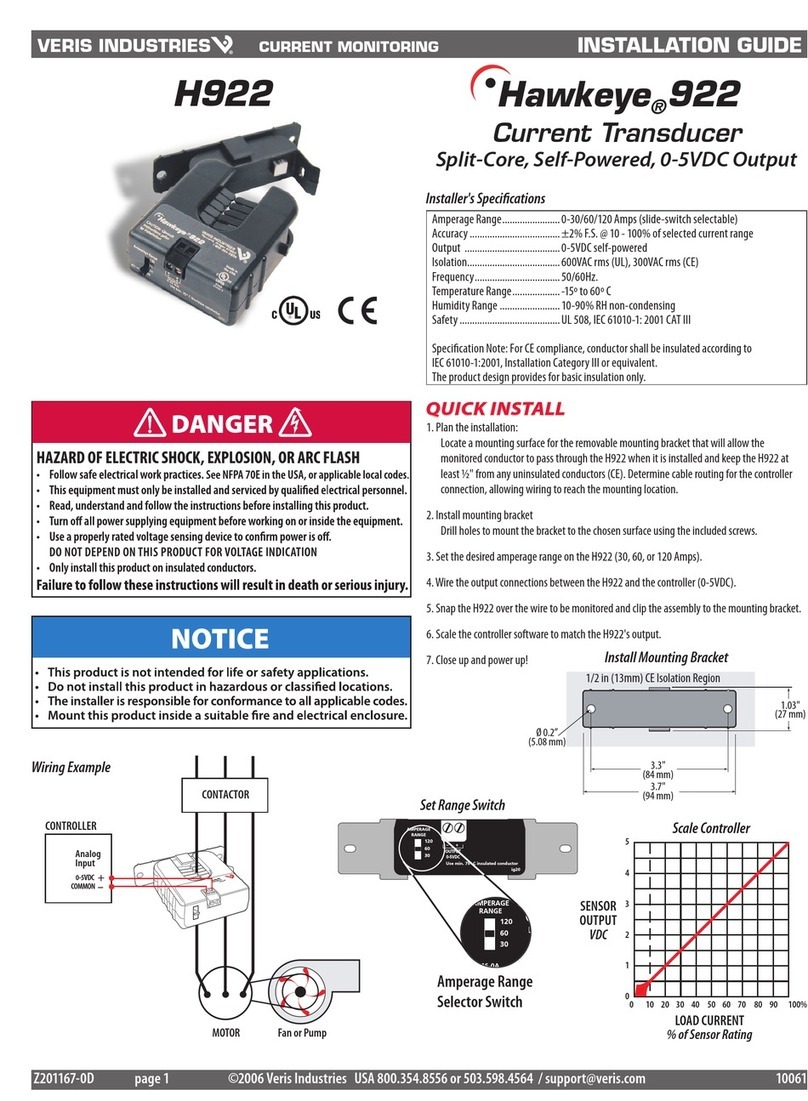

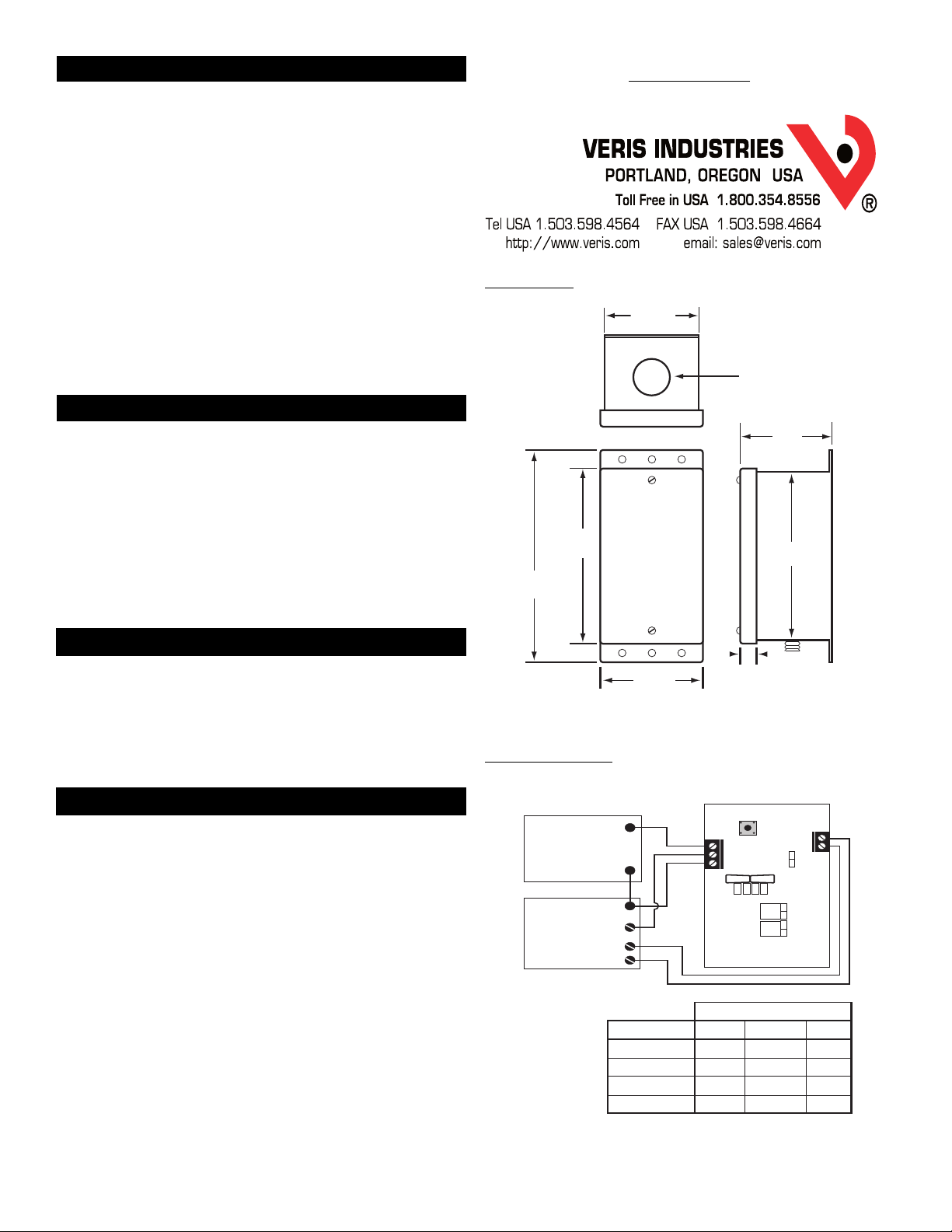

WIRING

Connect transmitter to control system and power supply as indicated.

Note: PH Series are 3-wire sourcing type transmitters.

CAUTION: This product utilizes a half-wave rectifier power supply. If a

transformer is to be used to power this product, the transformer must

not be used to power other devices utilizing non-isolated full-wave

power supplies.

OPTIONAL: Connect TARE (zero) terminals to digital output (contact

closure) of control system.

CAUTION: TARE input is for dry-contact. Do not apply voltage to TARE

(zero) terminals.

Use jumper JP1 to select voltage (V) or current (mA) mode.

Use jumper JP2 to select 0-10V or 0-5V output span. (Voltage mode only).

Use jumper JP3 to select slow or fast mode. Slow mode provides

5-second averaging for surge dampening.

Select appropriate full-scale range using the slide switch. WIRING DIAGRAM

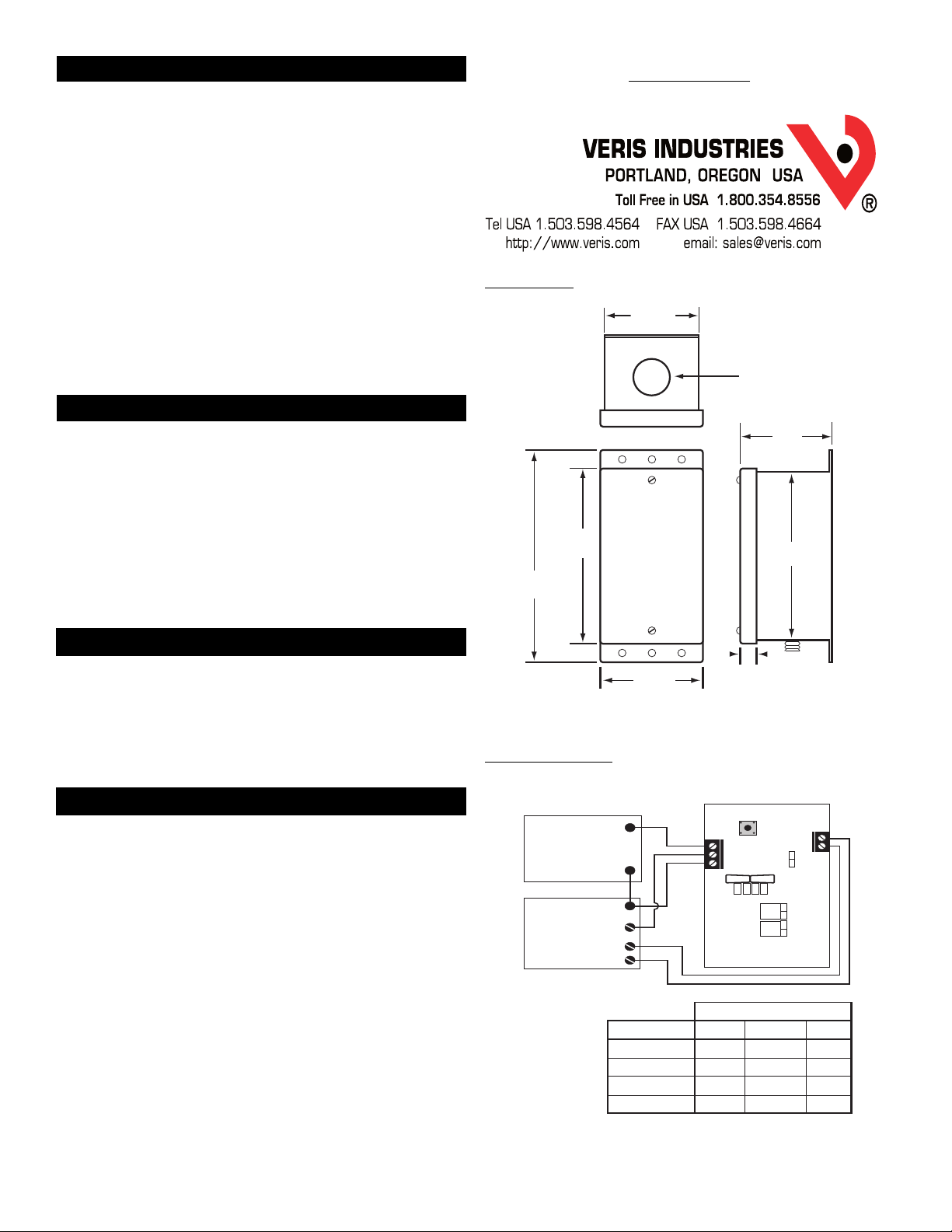

1/4” NPT male thread,

stainless 17-4 PH

2.189"

(56 mm)

2.249"

(57mm)

.871" dia.

(22 mm)

.391"

(10mm)

4.176"

(106 mm) 4.0"

(102 mm)

5.06"

(129 mm)

2.445"

(62 mm)

DIMENSIONS

MODEL

07

08

09

10

A

25

62.5

125

250

B

50

125

250

500

C

100

250

500

1000

RANGE

+

-

-

POWERSUPPLY

12to 24 VDC/24 VAC

DIGITALCONTROL

AnalogInput

0-5V/0-10V

or4-20mA

Optional

Digital Output

VIN

OUT

COMMON

ZeroRemote

Zero

Slow

Fast

VOLT

mA

0-5

0-10

Response

Output

Range

TEST

A

B

C

VerisPS-24 Series