MKS 910-11000-0016 User manual

Other MKS Transducer manuals

MKS

MKS 902B Specification sheet

MKS

MKS 901P Specification sheet

MKS

MKS 910 DualTrans Series Specification sheet

MKS

MKS Baratron 722B User manual

MKS

MKS 905 MicroPirani Guide

MKS

MKS UniMag 971B Specification sheet

MKS

MKS 907 Series User manual

MKS

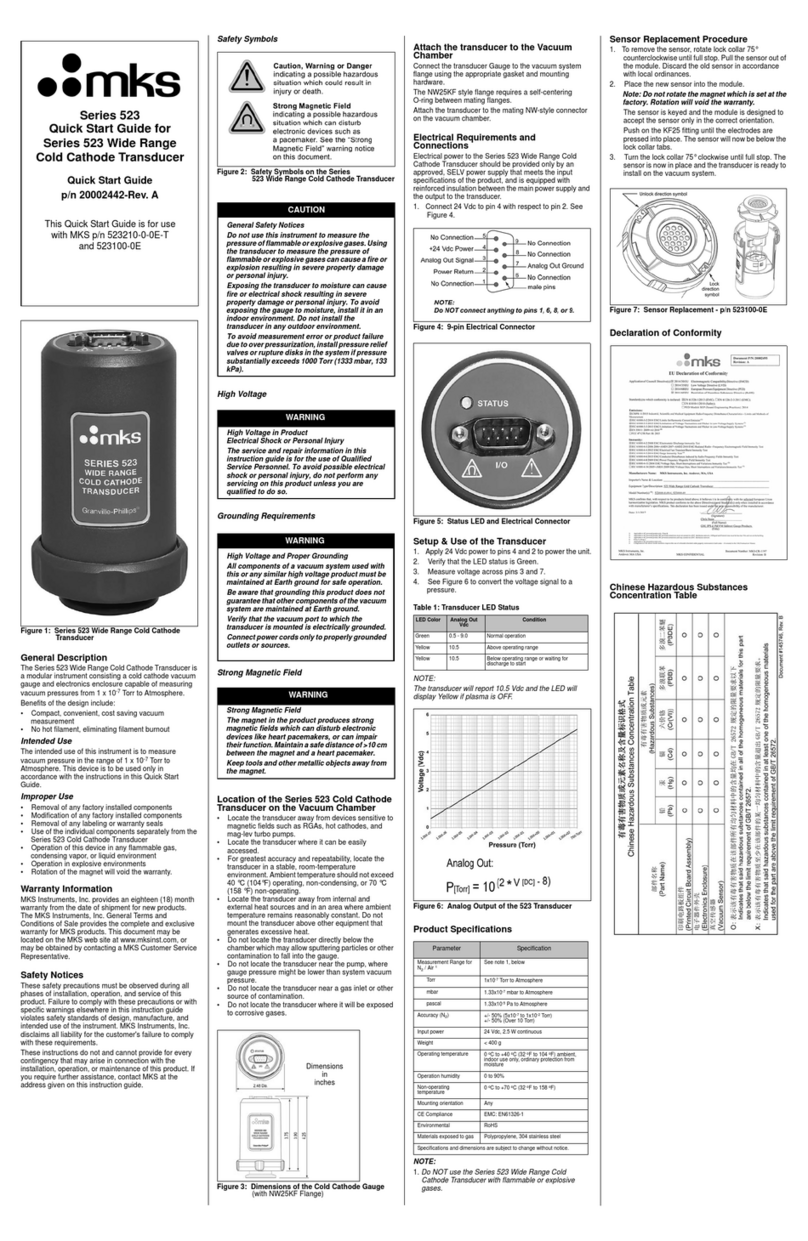

MKS 523210-0-0E-T User manual

MKS

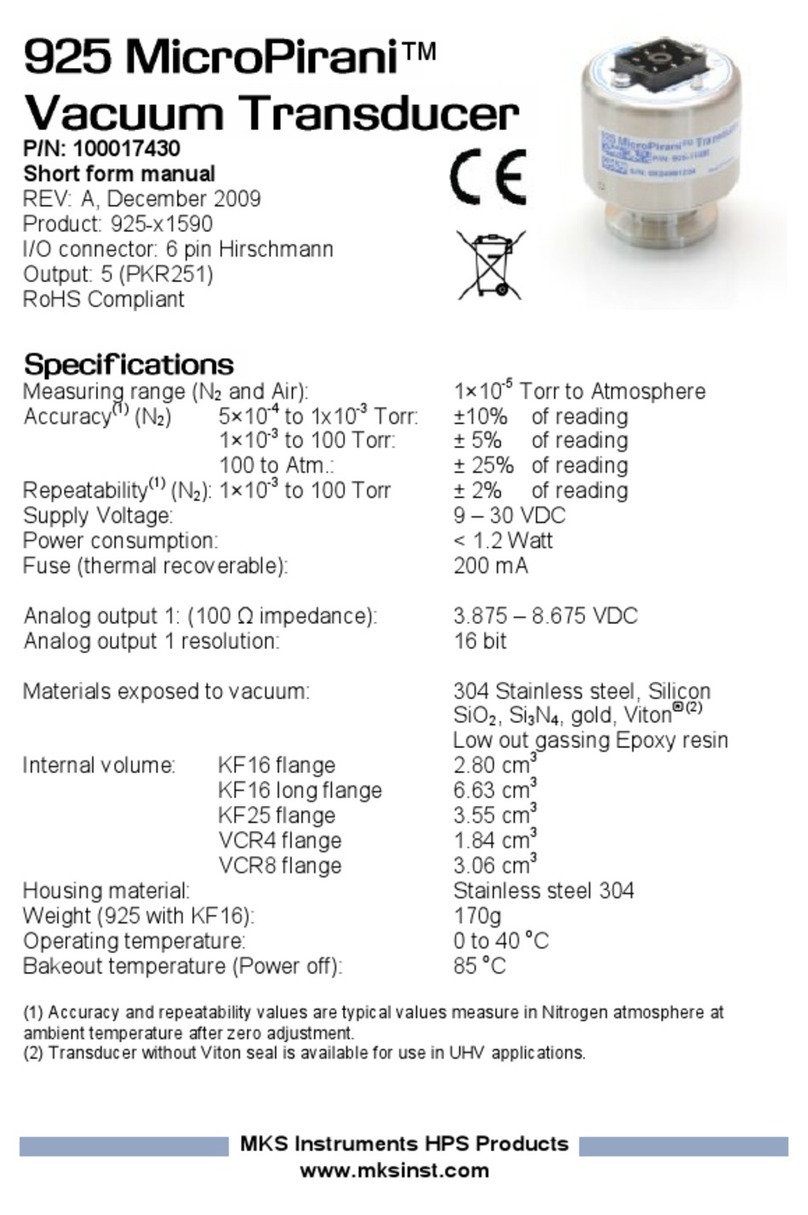

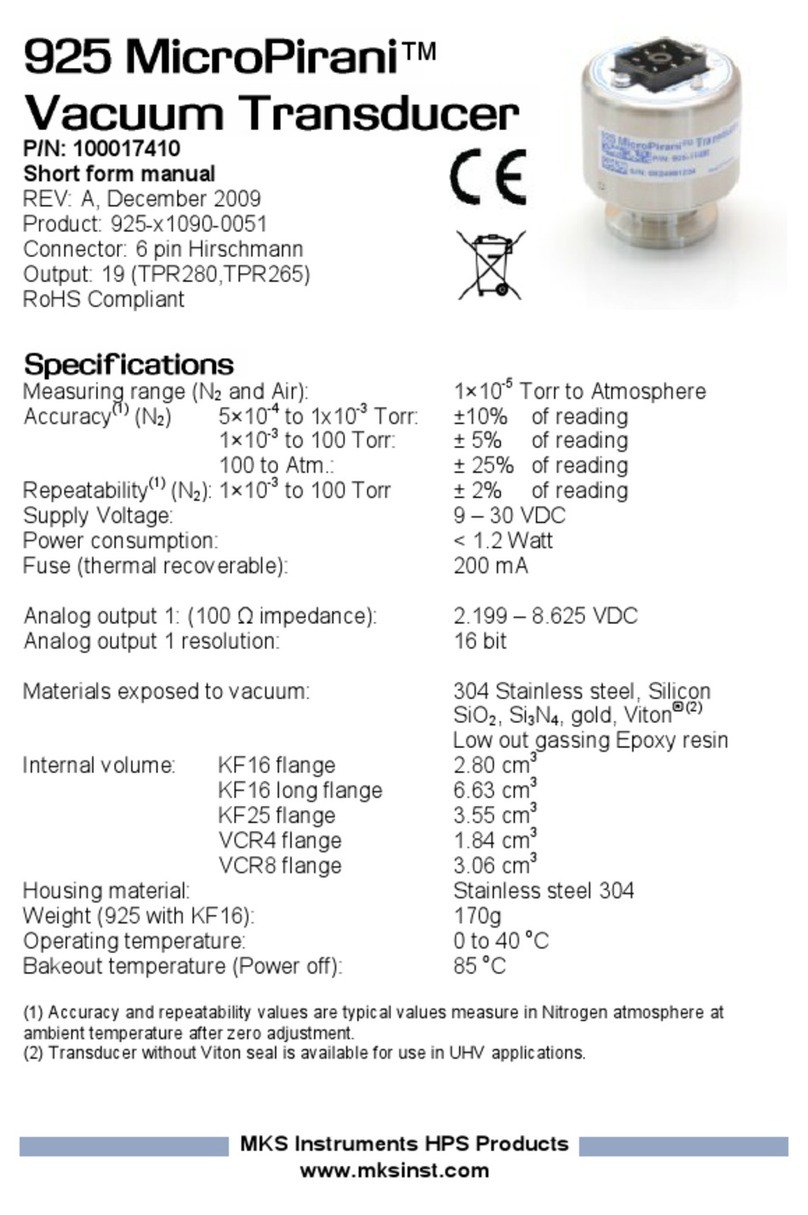

MKS MicroPirani 925 Series How to use

MKS

MKS MicroPirani 925 Series How to use

MKS

MKS Baratron 122A Series User manual

MKS

MKS Baratron 121A User manual

MKS

MKS Baratron 722C User manual

MKS

MKS HPS Products 999 Quattro Series User manual

MKS

MKS Baratron 127A User manual

MKS

MKS Baratron 722A User manual

MKS

MKS 910 DualTrans Series Installation guide

MKS

MKS Baratron 122B User manual

MKS

MKS Baratron 631D User manual

MKS

MKS Micro-Baratron 870B User manual

Popular Transducer manuals by other brands

Mianyang Weibo Electronic

Mianyang Weibo Electronic WB Series user manual

ProMinent

ProMinent Dulcometer DMT operating instructions

WIKA

WIKA WU-20 operating instructions

Alcatel Vacuum Technology

Alcatel Vacuum Technology BARATRON 622A instruction manual

Camille Bauer

Camille Bauer SIRAX CH-5610 operating instructions

WIKA

WIKA F2802 operating instructions