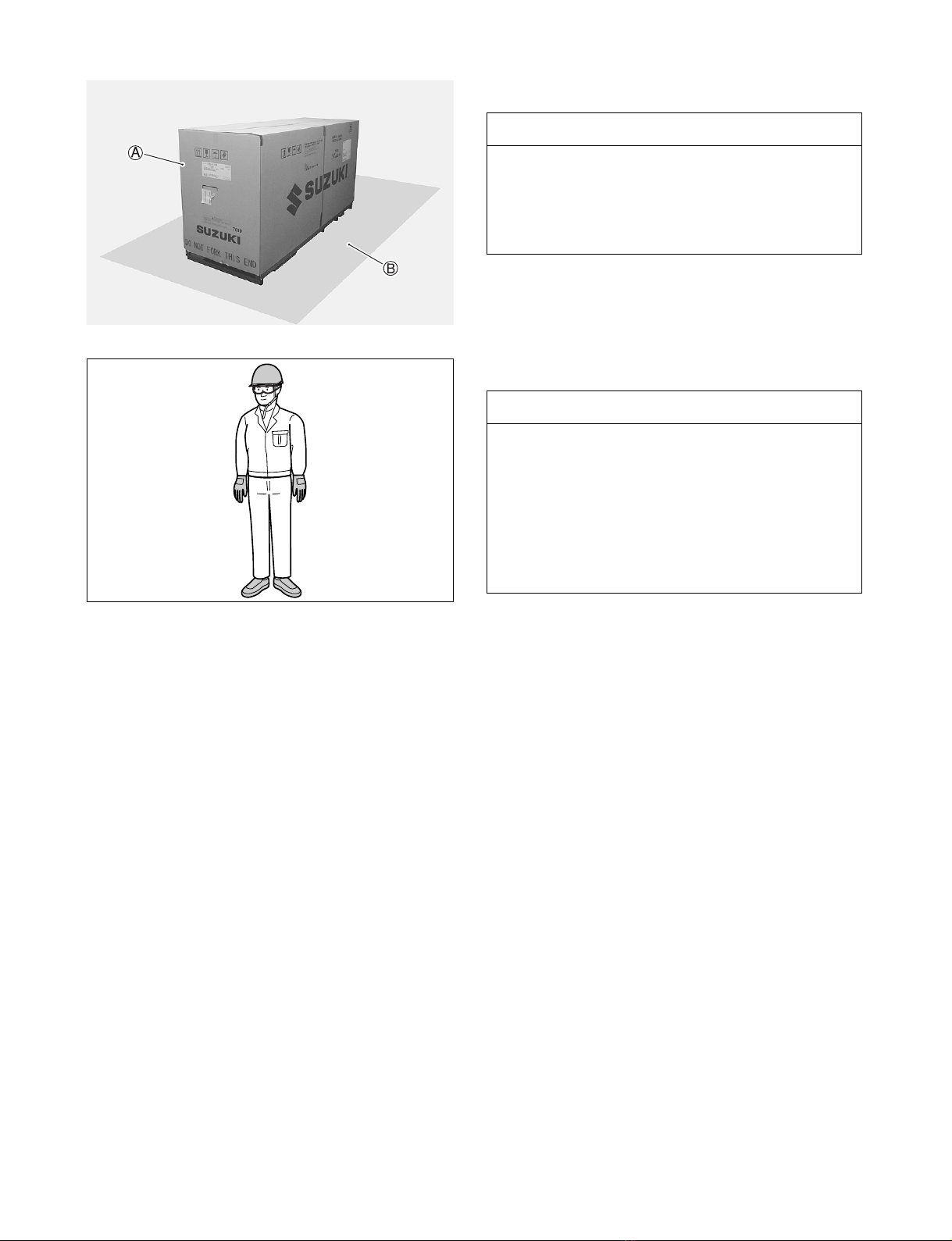

Suzuki RM-Z250L9 User guide

Other Suzuki Motorcycle manuals

Suzuki

Suzuki GSX1400 User manual

Suzuki

Suzuki SV650S User manual

Suzuki

Suzuki RM250 Application guide

Suzuki

Suzuki Intruder VS1400 User manual

Suzuki

Suzuki DR-Z400SY Configuration guide

Suzuki

Suzuki GSX-F 750 - User manual

Suzuki

Suzuki Intruder VL1500B User manual

Suzuki

Suzuki 1982 GS450GA User manual

Suzuki

Suzuki RG50 User manual

Suzuki

Suzuki 2001 GSX-R1000 User manual

Suzuki

Suzuki SFV650 User manual

Suzuki

Suzuki GSF 400 BANDIT User manual

Suzuki

Suzuki GSX-R250 User manual

Suzuki

Suzuki GSX 400F User manual

Suzuki

Suzuki Intruder VZR1800 User manual

Suzuki

Suzuki TL1000S User manual

Suzuki

Suzuki GSX-R1000 2007 User manual

Suzuki

Suzuki GS500/F User manual

Suzuki

Suzuki 1987 GSX-R150 User manual

Suzuki

Suzuki GV1400 User manual