FOREWORD

This

outboard

motor

hasbeen

designedand

produced

utilizing

Suzuki's

mostmoderntechnology.

The

finest

product,however,cannot

perform

properly

unless

itis

correctly

assembled

andserviced.

This

set-up

manual

has

been

produced

toaid

you

inproperly

assembling

and

servicing

thisoutboard

motor.

. Thismanual

hasbeen

prepared

on

the

basis

ofthe

latest

specifications

atthetimeofpublication.

lf

modifications

have

beenmadesincethen,

differences

may

exist

between

thecontentofthis

manual

andthe

actualoutboard

motor.

. lllustrations

in

this

manual

areused

toshowthe

basic

principles

of

operation

andwork

procedures

andmay

notrepresent

theactualoutboard

motor

exactly

in

detail.

t This

manual

is

intended

forthosewhohaveenough

knowledge

and

skills

toservice

SUZUKIoutboard

motors.

Without

suchknowledge

andskills,

you

should

not

attempt

servicing

byrelying

onthis

manual

only.lnstead,please

contact

your

nearbyauthorized

SUZUKI

outboard

motor

dealer.

CONTENTS

SYMBOL. ........,.........

I

MATERIALS

REAURED ......,...

1

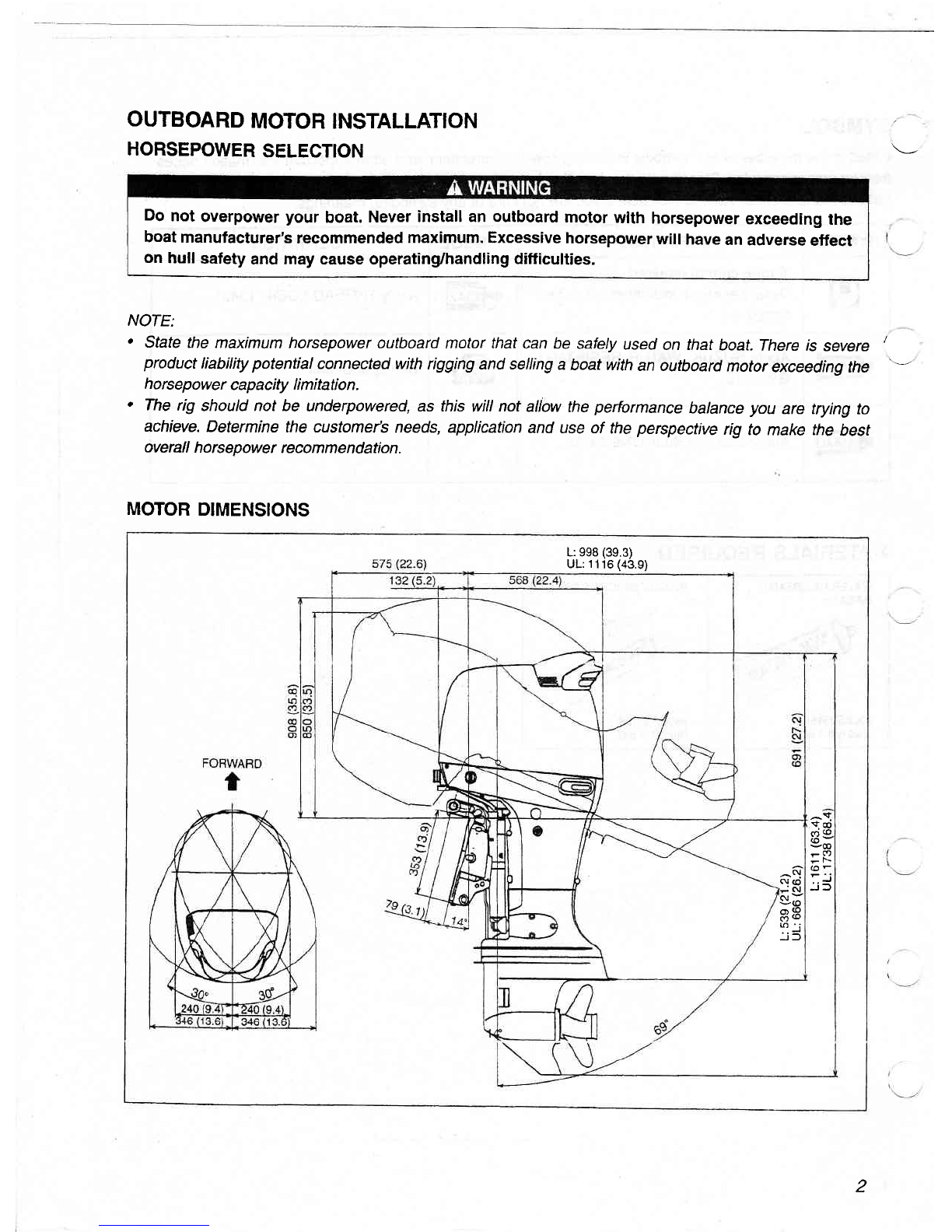

OUTBOARD

MOTOR

INSTALLATION ......2

HORSEqOWER

SELECTTON............. .......,.......

2

MOTOR

DIMENSIONS ,,...2

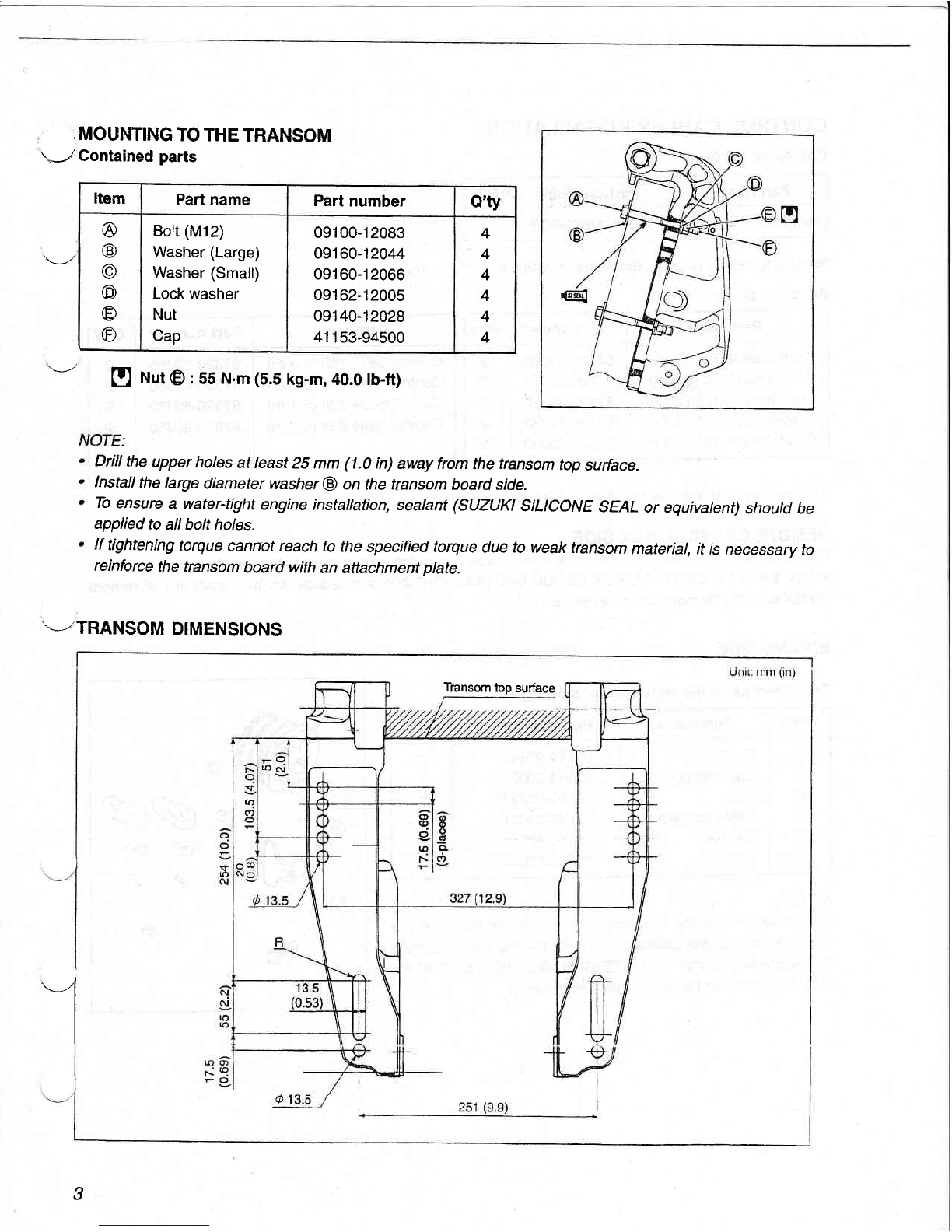

MOUNTING

TOTHETRANSOM .,.....

g

TRANSOM

DTMENSIIONS .................

s

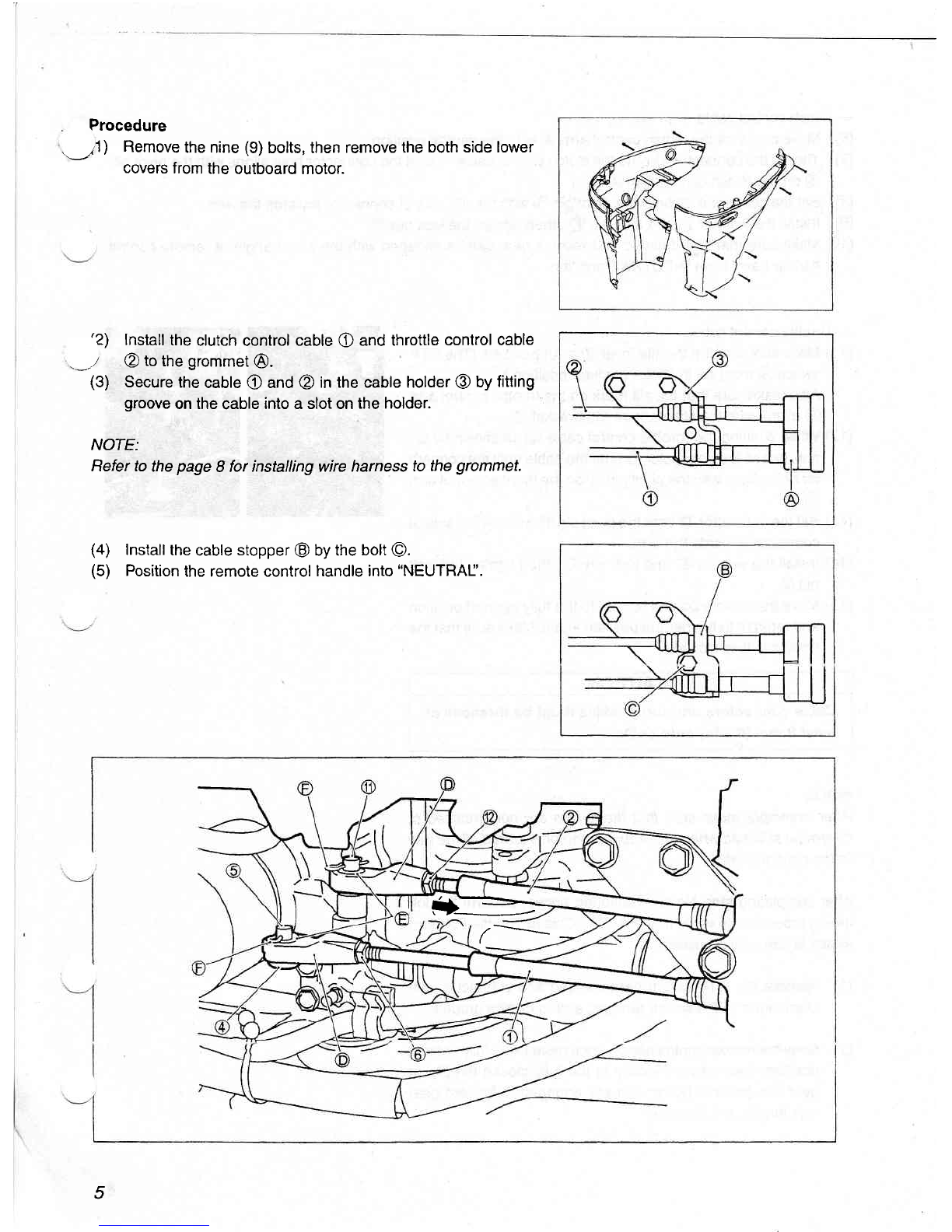

CONT4OL

CABLESINSTALLATTON .......4

REMOTE

CONTROLBOXSiDE .......4

ENGTNE

SIDE ......,............

4

WIRE

HARNESS

INSTALLATION ...........,.

8

DRAG

LINK

TNSTALLATTON .........,-..........

g

couNTERROTAnON

MODEL

ORDUALENGINE,

T\E-ROD

KtT(O?T\ONAL?ARTS)

iN9TALLATION........ ..................

11

INSTALLATION

WITH

THE

PRE-RIGGED

ITEMS

FOR

2 CYCLE

MODEL

............,..

14

wtRtNcDTAGRAM .....,...........

16

WIRING

DIAGRAM

FORDUALENGINE .................

17

SUZUKIMOTOR

CORPORATION

Marine

& Power

products

Division

Apprentice

mechanics

or do-it-yourselfmechanicsthatdon't have

the proper

toolsandequlp-

mentrnay

not beableto properlyperform

theservices

described

inthis manual.

lmproperas-

sembly

and/or

servicing

mayresultin injurytothemechanie

and

mayrender

theengineunsafe

fortheboat

operator

andpassengers.

OCOPYRIGHT

SUZUKI

MOTOB

CORPORATION

2OO1