1) Disconnect the power supply cord from the outlet.

2) Remove the screws from the rear and along side

edges of the case.

The outer case must be moved backward to be

1) Remove the outer case.

2) Disconnect two terminals, and remove one screw of

the earth terminal.

MEASUREMENT OF MICROWAVE POWER OUTPUT

• Microwave power output measurement is made with

the microwave oven supplied at its rated voltage and

operated at its maximum microwave power setting with

a load of (1000±5) g of potable water.

• The water is contained in a cylindrical borosilicate glass

vessel having a maximum material thickness of 3 mm

and an outside diameter of approximately 190mm.

• The oven and the empty vessel are at ambient

temperature prior to the start of the test.

• The initial temperature (T1) of the water is (10±2)°C. It

is measured immediately before the water is added to

the vessel. After addition of the water to the vessel,

the load is immediately placed on the center of the

turntable which is in thd lowest position and the

microwave power switched on.

• The time T for the temperature of the water to rise by a

value ∆ T of (10±2)°K is measured, where T is the time

in seconds and ∆T is the temperature rise. The initial

and final water temperatures are selected so that the

maximum difference between the final water

temperature and the ambient temperature is 5°K.

4187 x (∆T) + 0.55 X (T2- T0) X M

T

• T

2

: Temperature after heating

• T

0

: Temperature of bowl

• M: Weight of bowl

is measured while the microwave generator is

operating at full power. Magnetron filament heat-up

time is not included. (about 3 sec)

• The water is stirred to equalize temperature throughout

the vessel, prior to measuring the final water

temperature.

• Stirring devices and measuring instruments are

selected in order to minimize addition or removal of

heat.

WATER LOAD

TURNTABLE

P =

• The microwave power output P in watts is calculated

from the following formula :

NOTES:

For simple tests of micromave power output,

it by heating one litre water for one minute,

minimum temperature rise should be 6 C

°

conduct

DISASSEMBLY AND ADJUSTMENT

CAUTION: DISCHARGE THE HIGH VOLTAGE

CAPACITOR BEFORE SERVICING

(refer to page 1)

lifted off.

5

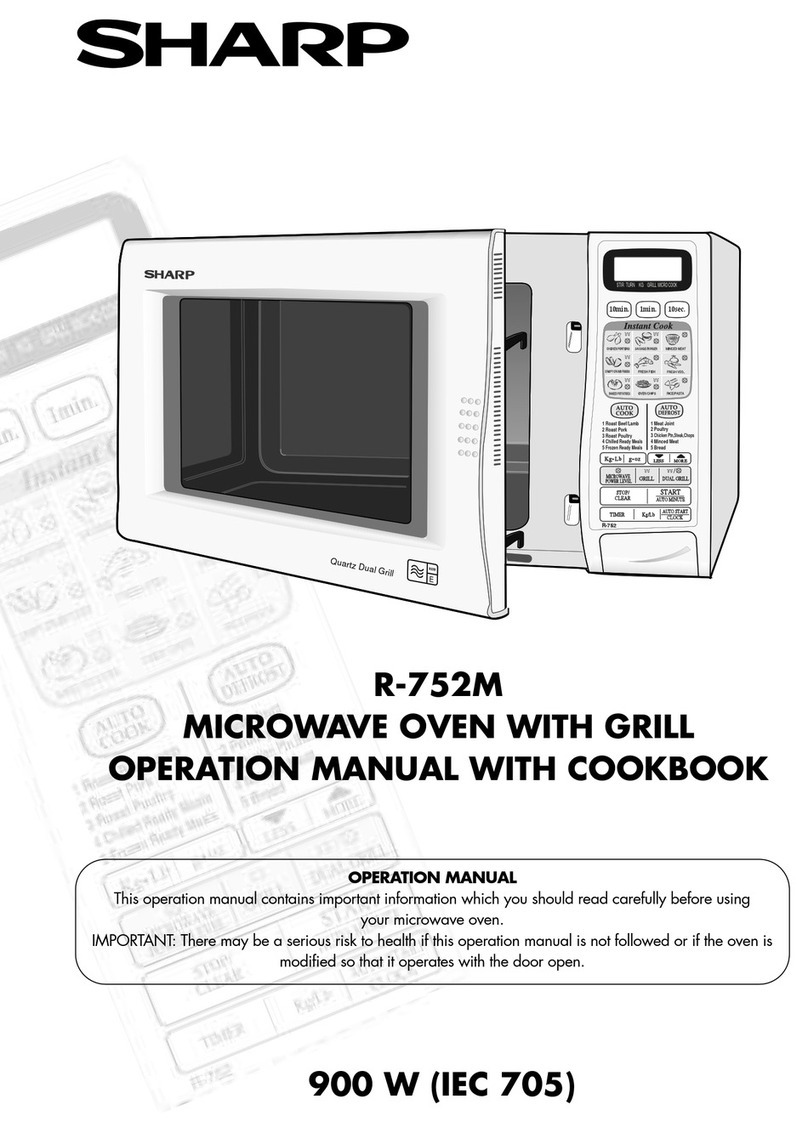

2. OUTER CASE REMOVAL

3. POWER SUPPLY CORD REMOVAL

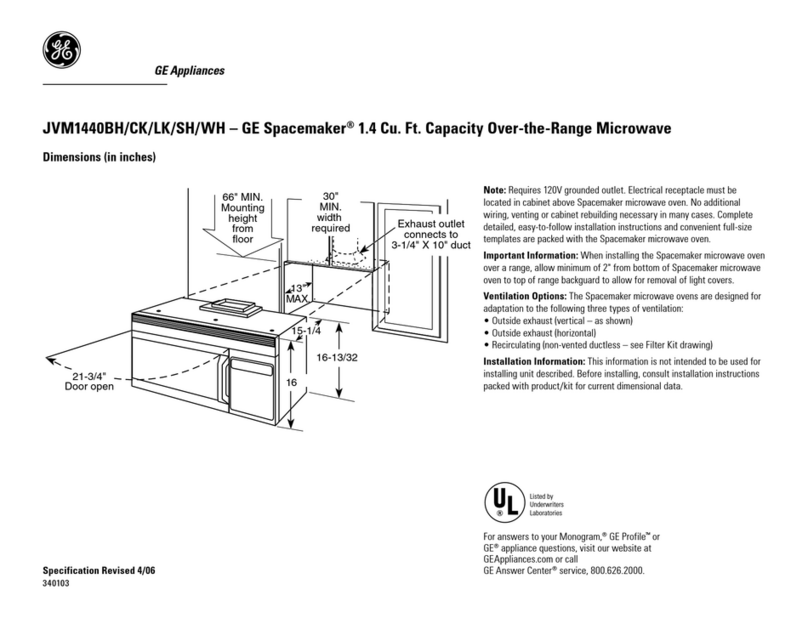

1) Open the door, remove the Screw B from the installa-

1. TRIM ASSEMBLY REMOVAL

Installation Hole

Screw B

tion hole.

3) Remove the screws on both side. Then remove the

2) Pull the Microwave oven out.

trim Assembly out of cavity.