IMPORTANT: IF A #2 PLENUM SHROUD OR A #12 DECORATIVE COVER ARE TO BE INSTALLED

WITH THE MINI 5 LIFT. PLEASE READ THEIR INSTALLATION INSTRUCTION BEFORE

PROCEEDING. THE SUPPORTING STRUCTURE SHOULD ALSO ALLOW ENOUGH SPACE TO

INSTALL THE MOUNTING HARDWARE OF THE DECORATIVE COVER AND THE PLENUM

SHROUD.

4. LIFT INSTALLATION:

a. Preparation:

1. The lift is shipped in a wood crate. Remove the Philips screws from the top lid.

2. Unbolt the lift from the bottom panel of the crate to remove the lift out of the crate.

3. The warranty information and the low voltage controller are located in the white box.

b. Installing the lift in the ceiling:

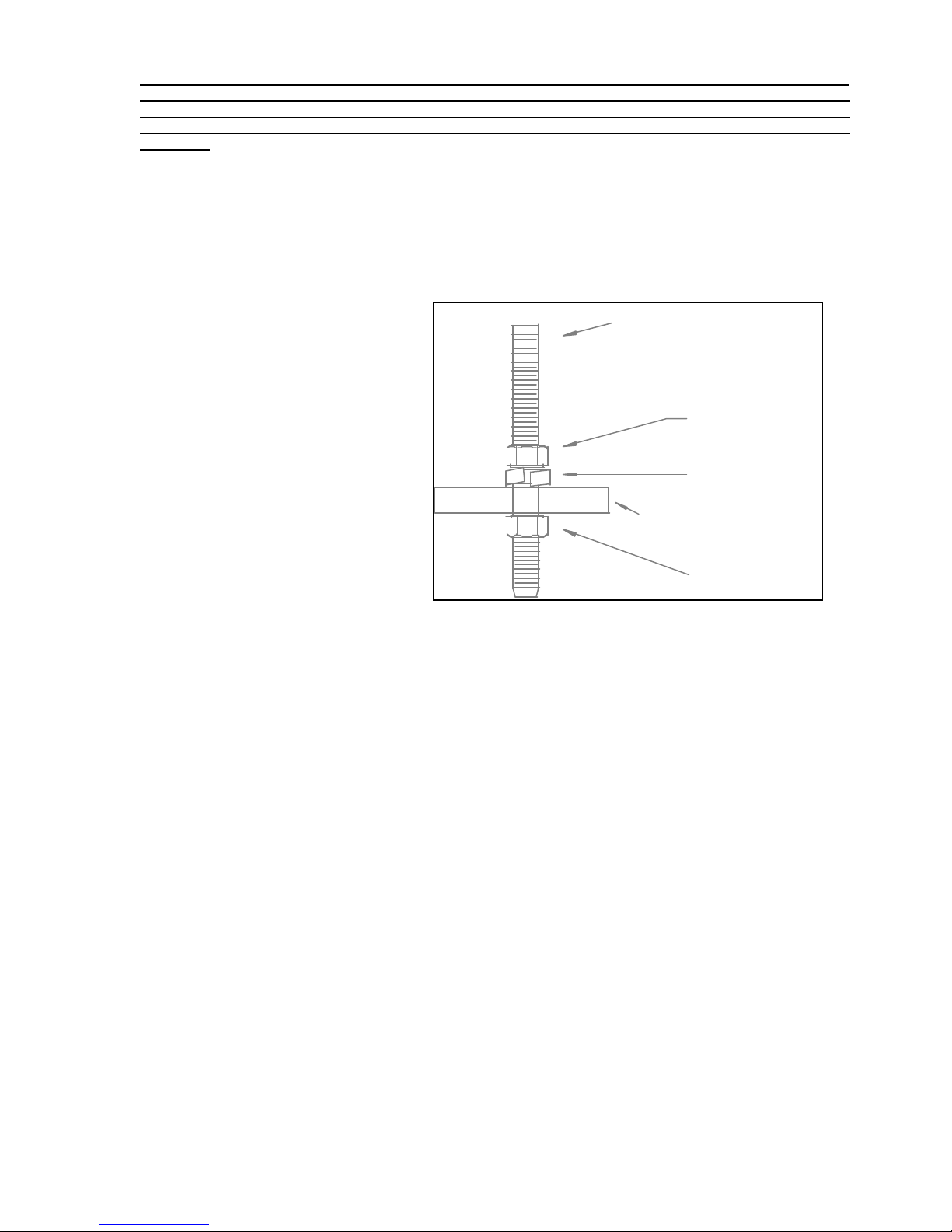

1. Raise the lift, insert it into the ceiling

and line up the four (4) mounting holes

of the top frame to the ½" threaded rods

of the supporting structure. Make sure

that there is atop nut and aflat washer

before the lift is mounted -see figure 6.

Once the lift's top frame has been

inserted, add a½" hexnut to each

threaded rod. Always leave top nut loose

to allow adjustments until the lift is

leveled.

2. Secure the lift to the threaded rods.

3. Check that the top frame of the lift is

leveled from front-to-back

and side-to-side. Figure 6.

4. Secure the top nuts. Do not over tighten the fasteners before the lift is leveled as it could distort the top

frame.

5. If Power Sensor is used, please refer to the power sensor instructions, otherwise, plug in the 12 pin

connector of the low voltage controller (the Key Switch Control Box) into the 12 pin receptor of the grey

electrical box, which is supplied with the lift and shipped in the white box located underneath the lid of the

shipping crate.

6. Remove the four (4) shipping Blocks from the lift. Never remove the blocks until the lift is properly

installed in the ceiling.

7. Make sure that cables are out of the way of operation.

8. Before lowering the lift, you should have some weight attached to the bottom of the lift in order to

keep the cables tight until the projector is mounted. Both cables are placed on the drum so that they start

unwinding from the inside to the outside of the drum. They are vertical to the eye bolts in the closed

position and slightly angled toward the outside of the drum to avoid friction/rubbing with the previous

cable loop.

To avoid cable spill:

- Do not push the bottom frame upward once the lift has been installed.

- Make sure that there is no obstructions in the lift's path. If the bottom frame lowers onto a chair,

table or any other object, this will cause the cables to slack and spill over the drum.

5. CEILING CLOSURE INSTALLATION –Please refer to installation instructions included with the

#1 Ceiling Closure. It is the self-aligning closure system installed underneath the projector and used to

conceal the ceiling hole when the lift and projector are raised in the ceiling. It is attached to the four (4)

mounting holes of the lift's bottom frame with threaded rods.

SVS MINI 5 LIFT INSTALLATION Page 8of 13

1/2" HEXNUT

LOCK WASHER

1/2" THREADED ROD

TOP FRAME OF LIFT

1/2" HEXNUT