Pressure and Temperature Transducer User’s Manual 5

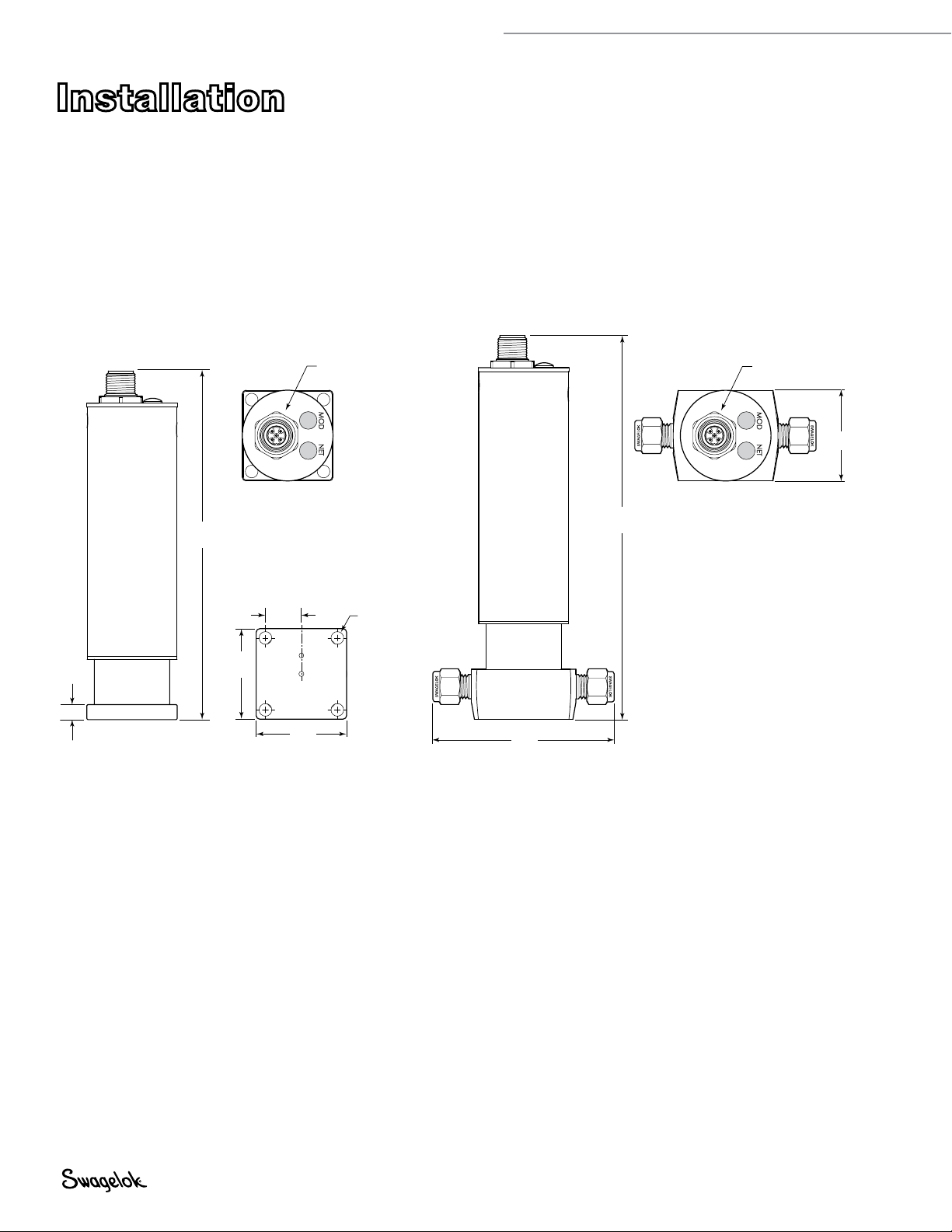

Control Drawing

OR

1

23

4

5

Notes:

(1) The Entity Concept allows interconnection of nonincendive apparatus with

associated apparatus not specifically examined in combination as a system when the

approved values of Voc and Isc of the associated apparatus are less than or equal to

Vmax and Imax of the nonincendive apparatus and the approved values of Ca and

La of the associated apparatus are greater than Ci+Ccable and Li+Lcable respectively

for the nonincendive apparatus.

(2) Capacitance and inductance of the field wiring from the nonincendive equipment

to the associated apparatus shall be calculated and must be included in the system

calculations as shown in Table 1. Cable capacitance, Ccable, plus nonincendive

equipment capacitance, Ci, must be less than the marked capacitance (Lcable, Li

and La or Lo, respectively). Where the cable capacitance per foot are not known, the

following values shall be used: Ccable = 60 pF/ft., Lcable = 0.2

µ

H/ft.

TABLE 1:

TABLE 2:

Nonincendive Equipment

Associated Apparatus

V max (or Ui)

≥

Voc (or Uo)

I max (or Ii)

≥

Isc (or lo)

P max (or Pi)

≥

Po

Ci

≤

Ca (or Co)

Li

≤

La (or Lo)

If Po of the associated apparatus is not known, it may be calculated using the formula:

Po = (Voc * Isc)/4 = (Uo * Io)/4.

(3) Associated apparatus must be installed in accordance with its manufacturer's

control drawing and Article 504 of the National Electrical Code (ANSI/NFPA 70), the

Canadian Electrical Code, or other local installation codes, as applicable. The

resistance of the ground path must be less than 1 ohm.

(4) When required by the manufacturer's control drawing, the associated apparatus

must be connected to a suitable ground electrode per the National Electrical Code

(ANSI/NFPA 70), the Canadian Electrical Code, or other local installation codes, as

applicable. The resistance of the ground path must be less than 1 ohm.

(5) The PTX is powered by two separate nonincendive circuits, designated Power and

Signal as indicated in Table 1. Cable and wiring for these two circuits must maintain

the separations for different nonincendive circuits required by Article 504 of the

National Electrical Code (ANSI/NFPA 70), ISA RP12.6 for installing nonincendive circuits,

or other local codes, as applicable.

(6) Associated apparatus must not be used in combination unless permitted by

associated apparatus certification.

(7) WARNING: Substitution of components may impair safety.

(8) The ambient operating (Tamb) range for this product is -5C to 70C.

(9)

Each unit must be connected to an IP64 or higher rated connector or IP rating will be void.

HAZARDOUS LOCATION

Class I, Div. 2, Groups A, B, C, D

Any associated apparatus power

supply with Entity Concept

Parameters (1) appropriate for

connection to an nonincendive

device with Entity concept

parameters listed in Table 1.

Any nonincendive or associated

apparatus communication

controller with Entity Concept

parameters (1) (Vmax, Imax, Ci,

Li) appropriate for connections to

nonincendive devices with Entity

Concept parameters listed in

Table 1.

NON-HAZARDOUS LOCATION

CONTROL

EQUIPMENT

NONINCENDIVE FIELD

WIRING - POWER CIRCUIT

(PINS 2,3)

NONINCENDIVE FIELD/

ASSOCIATED APPARATUS

WIRING - SIGNAL CIRCUIT

(PINS 4,5)

Field Wiring Diagram

1 - Drain bare

2 - V+ red

3 - V- black

4 - CAN_H white

5 - CAN_L blue

WARNING: ANY CHANGES MADE TO THIS DOCUMENT MUST BE REVIEWED AND APPROVED BY SWAGELOK COMPLIANCE DPT

MATERIAL: NA

DESCRIPTION: SWAGELOK DEVICENET PTX CONTROL DRAWING

Male

DWG.

NO.

PTX-DN-0006-SCHEDULE

TITLE

DRAWN BY

CHECK/APR BY

JEK

DWG.

NO.

PTX-DN-0006-SCHEDULE

THIS PRINT IS THE EXCLUSIVE PROPERTY OF SWAGELOK COMPANY. IT MUST BE RETURNED ON

REQUEST ALONG WITH ANY DOCUMENTS CONTAINING INFORMATION OBTAINED FROM THIS

PRINT. NEITHER THIS PRINT NOR ANY PART OF IT NOR ANY INFORMATION CONCERNING IT MAY

BE COPIED, DISCLOSED TO OTHERS OR USED FOR ANY PURPOSE EXCEPT IN FURTHERANCE OF

YOUR BUSINESS WITH SWAGELOK. THE PARTS REFERRED TO ON THIS PRINT MAY BE THE

SUBJECT OF PATENTS AND/OR PENDING APPLICATIONS AND MAY NOT BE MANUFACTURED

WITHOUT PERMISSION FROM SWAGELOK COMPANY.

SCALE

NONE

REV.

-

SHEET

1 of 1

REVISIONS

TOLERANCE ON ENGLISH DIMENSIONS

UNLESS OTHERWISE SPECIFIED

7

6

5

4

3

2

1

D

C

B

A

8

8

7

6

5

4

3

2

1

A

B

C

D

APPROVAL/SCHEDULE DRAWING

.XX

.031

.XXX

.015

ANGLES

1 DEGREE

DCN

REV.

Jul-5-11

DATE

DATE

BRM

Jul-29-11

-- DIMENSIONS ARE INCHES NEXT TO [MILLIMETERS].

© Swagelok Company All Rights Reserved

Fig. 3 PTX-DN-0006 SCHEDULE