MS-CRD-PTI-S

Rev 5 12-10-WEL

Industrial Pressure Transducers

User’s Manual

S Model

www.swagelok.com

■ Safety Definitions...................... 1

■ Safety Instructions..................... 1

■ Mechanical Installation ................. 1

■Service and Maintenance ............... 2

■Electrical Installation .................. 2

■Wiring Diagrams ...................... 3

■ Troubleshooting Guide ................. 4

Contents

S Model

Introduction

Swagelok industrial pressure transducers allow for

electronic monitoring of system pressures in a

variety of industrial applications. The products

feature an accuracy of 0.5 % Limit point calibration

(0.25 % Best fit straight line), and temperature

compensation to ensure accuracy and long term

stability when exposed to temperature variations. The

transducers are zero and span adjustable, and are

available in a wide variety of pressure and electrical

connections, pressure ratings, pressure units, and

signal outputs to fulfill many application requirements.

The Swagelok®S model transducer is

ideal for general use in a wide variety

of industrial applications such as

machine control, process control,

laboratory and test equipment,

hydraulics, and pneumatics.

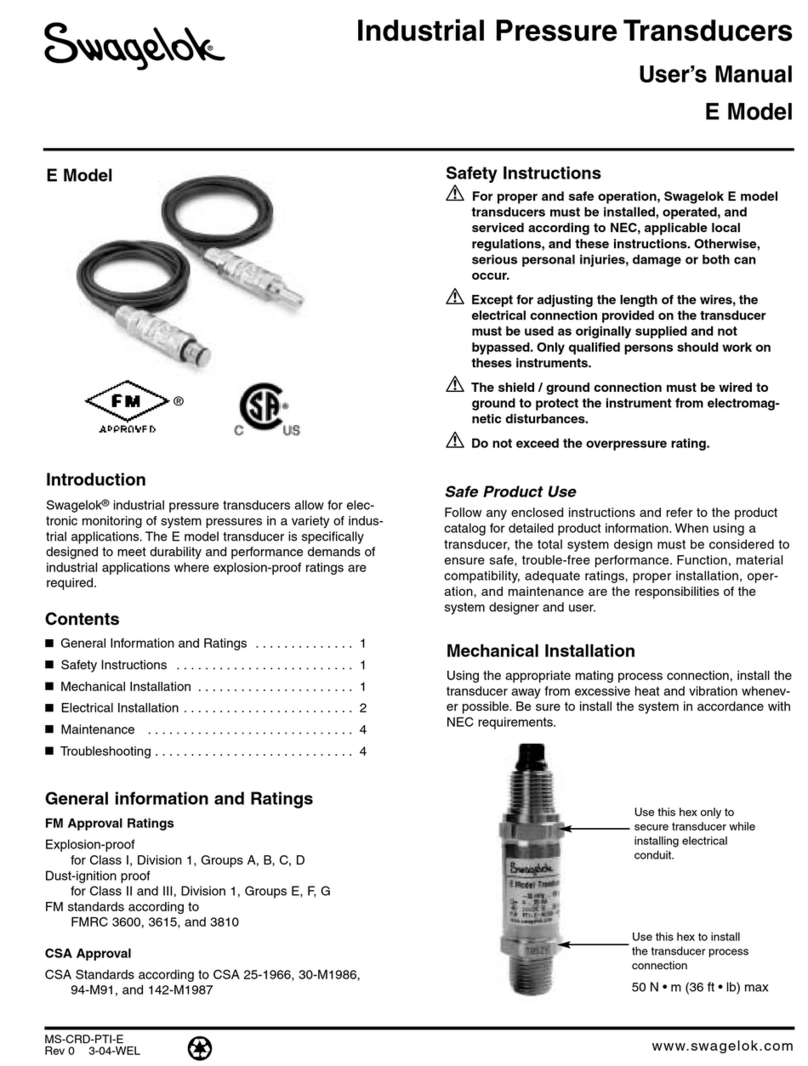

50 N·m (36 ft·lb) max.

Mechanical Installation

For proper and safe operation, Swagelok

S model transducers must be installed,

operated, and serviced according to NEC,

applicable local regulations, and these

instructions. Otherwise, serious personal

injuries, damage or both can occur.

Except for adjusting the length of the

wires, the electrical connection provided

on the transducer must be used as

originally supplied and not bypassed. Only

qualified persons should work on these

instruments.

Do not exceed the overpressure rating.

Before servicing any installed pressure

transducer you must

● depressurize system

●purge the transducer

Residual material may be left in the

transducer and system.

Safety Instructions

Safe Product Use

Follow any enclosed instructions and refer to the

product catalog for detailed product information. When

using a transducer, the total system design must be

considered to ensure safe, trouble-free performance.

Function, material compatibility, adequate ratings,

proper installation, operation, and maintenance

are the responsibilities of the system designer and

user. Improper selection or misuse of the product

may result in serious personal injury or property

damage.

Potential danger to life or of serious

injuries.

Potential danger to life or of serious injuries

due to catapulting parts.

Potential danger of burns due to hot

surfaces.

Notice, important information.

The product complies with the applicable

European directives.

The product was tested and certified by

CSA International. It complies with the

applicable Canadian standards on safety.

Certificate-No.: 1567213

Warning

Warning

Caution

Warning

Warning

Warning

Warning

Warning

Safety Definitions