Instriniscally Safe PTX User’s Manual 5

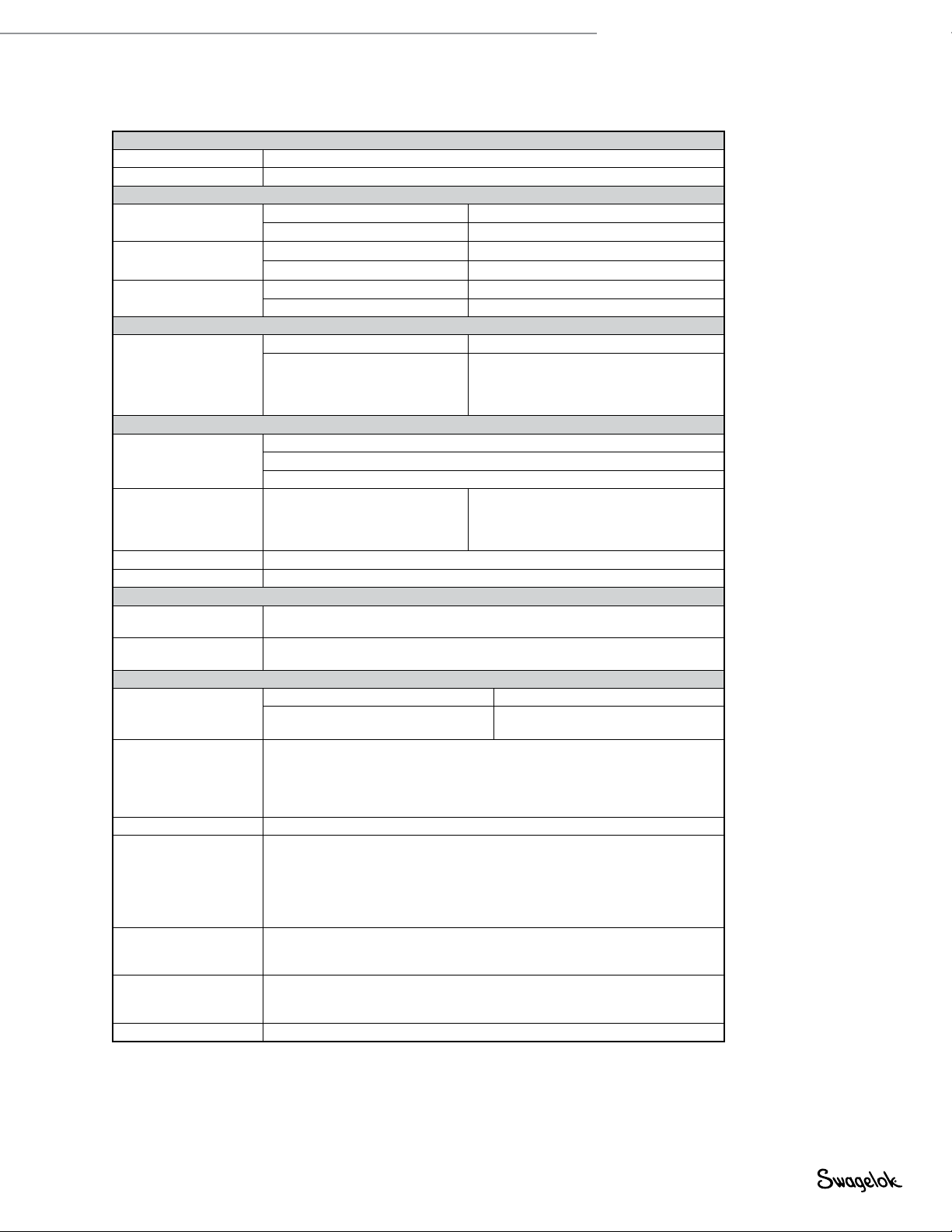

Specifications

Power

Voltage 9 to 28 V (dc), 24 V (dc), nominal

Current < 20 mA (dc) at 24 V (dc)

Temperature (environment)

Operating (Ambient) Minimum 23°F (–5°C)

Maximum 158°F (70°C)

Media Minimum 23°F (-5°C)

Maximum 158°F (70°C)

Storage Minimum -40°F (–40°C)

Maximum 158°F (70°C)

Temperature Measurement

Temperature

Measurement

Measurement Range 23 to 158°F (–5 to 70°C)

Accuracy, including:

Repeatability

Hysteresis

Nonlinearity

± 9°F (± 5°C absolute accuracy)

Pressure

Full-scale Range

0 to 50 psig (0 to 3.4 bar)

0 to 250 psig (0 to 17.2 bar)

0 to 500 psig (0 to 34.4 bar)

Pressure Measurement

Accuracy, including:

Repeatability

Hysteresis

Nonlinearity

± 2 % of full scale pressure of measurement

Overrange Pressure 2 × full scale

Burst Pressure 5 × full scale

Output Reading to Voltage Conversion

Temperature -40°F (-40°C) = 0.5 V (dc)

158°F (70°C) = 4.5 V (dc)

Pressure 0 psig = 0.5 V (dc)

full scale = 4.5 V (dc)

Miscellaneous Data

Weight

with MPC process connections 0.83 lb (375 g)

with 1/4 in. and 6 mm Swagelok tube

fitting end connections

1.27 lb (576 g)

Certifications

■ANSI/NFPA Class I, Division 1, Groups A, B, C, D, Temperature Class T4

■UL 913 - Edition 8, UL 60079-0 - Edition 6, UL 60079-11 - Edition 6

■cUL®- CSA C22.2 NO. 157-92 - Edition 3

■ATEX Standards: EN 60079-0, EN 60079-11

■ IEC: IEC 60079-0 - Edition 6, IEC 60079-11 - Edition 6

Ingress Protection IP64

Electromagnetic

Compatibility

EN 61326-1:2006

■RF Emissions: EN 55011

■ESD Immunity: EN 61000-4-2

■RF Immunity: EN 61000-4-3

■EFT Immunity: EN61000-4-4

■Conducted Immunity: EN 61000-4-6

Vibration

Tested to IEC 60068-2-6:2007

■ 10 to 150 Hz, at 2.04 g

■ 10 sweeps at 0.5 Octave/min

Shock

Tested to IEC 6068-2-27:1987

■ 50 g, 11 msec

■ 3 positive and 3 negative pulses each axis

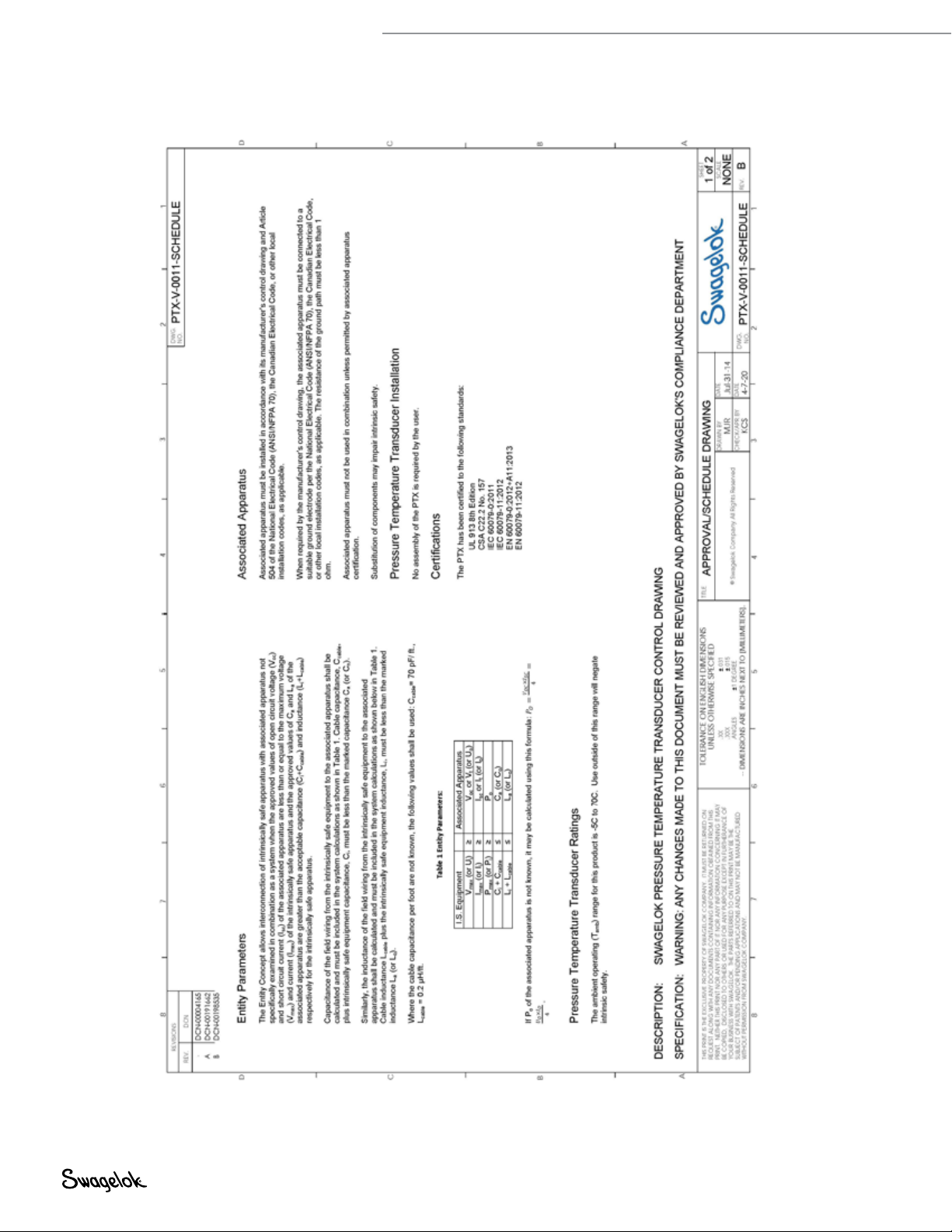

Entity Parameters See Control Drawing: PTX-V-0011-SCHEDULE

Note: Before installing the PTX in a hazardous location, review the control drawing on page 6.

This will help ensure all electrical connections to and from the PTX comply with safety requirements. For an

electronic copy of this manual, see www.swagelok.com.