MS-CRD-PTI-E

Rev 0 3-04-WEL

Industrial Pressure Transducers

User’s Manual

E Model

www.swagelok.com

■ General Information and Ratings . . . . . . . . . . . . . . 1

■Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . 1

■ Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . 1

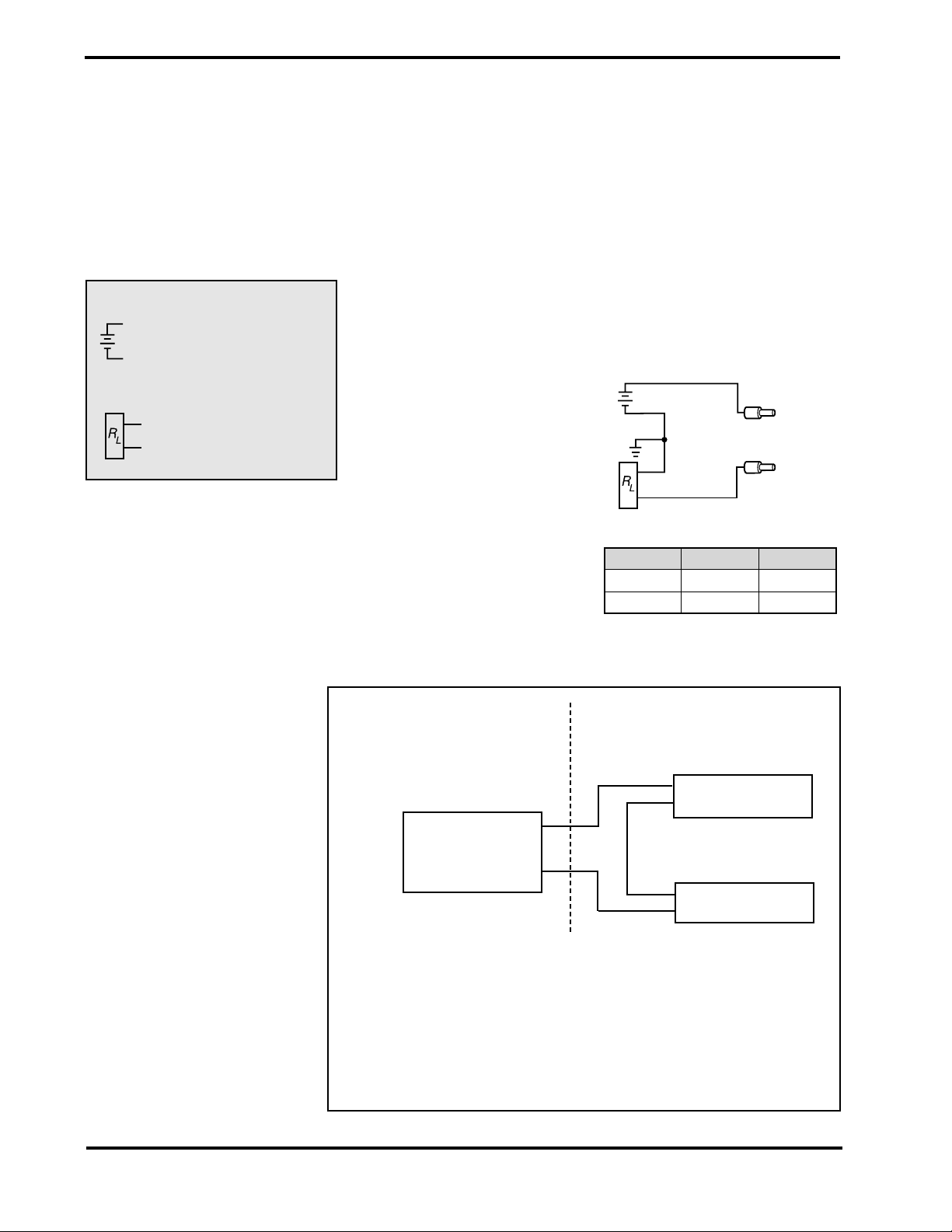

■Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . 2

■Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

■Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Contents

E Model

Use this hex only to

secure transducer while

installing electrical

conduit.

Mechanical Installation

Using the appropriate mating process connection, install the

transducer away from excessive heat and vibration whenev-

er possible. Be sure to install the system in accordance with

NEC requirements.

General information and Ratings

FM Approval Ratings

Explosion-proof

for Class I, Division 1, Groups A, B, C, D

Dust-ignition proof

for Class II and III, Division 1, Groups E, F, G

FM standards according to

FMRC 3600, 3615, and 3810

CSA Approval

CSA Standards according to CSA 25-1966, 30-M1986,

94-M91, and 142-M1987

Use this hex to install

the transducer process

connection

Safety Instructions

!For proper and safe operation, Swagelok E model

transducers must be installed, operated, and

serviced according to NEC, applicable local

regulations, and these instructions. Otherwise,

serious personal injuries, damage or both can

occur.

! Except for adjusting the length of the wires, the

electrical connection provided on the transducer

must be used as originally supplied and not

bypassed. Only qualified persons should work on

theses instruments.

! The shield / ground connection must be wired to

ground to protect the instrument from electromag-

netic disturbances.

! Do not exceed the overpressure rating.

Introduction

Swagelok®industrial pressure transducers allow for elec-

tronic monitoring of system pressures in a variety of indus-

trial applications. The E model transducer is specifically

designed to meet durability and performance demands of

industrial applications where explosion-proof ratings are

required.

50 N • m (36 ft • lb) max

®

Safe Product Use

Follow any enclosed instructions and refer to the product

catalog for detailed product information. When using a

transducer, the total system design must be considered to

ensure safe, trouble-free performance. Function, material

compatibility, adequate ratings, proper installation, oper-

ation, and maintenance are the responsibilities of the

system designer and user.